Difference between revisions of "S22: Firebolt"

(→Team Members & Responsibilities) |

(→Team Members & Responsibilities) |

||

| (593 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

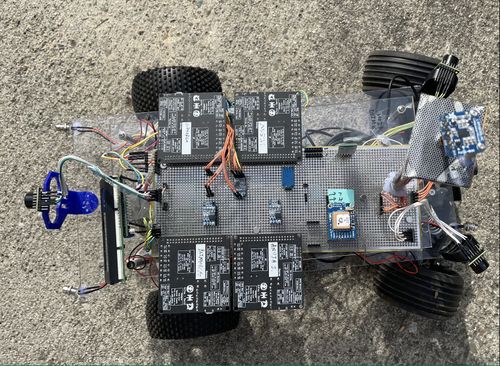

| − | + | [[File:Firebolt2.jpeg|500px|thumb|right| The RC Car]] | |

== Abstract == | == Abstract == | ||

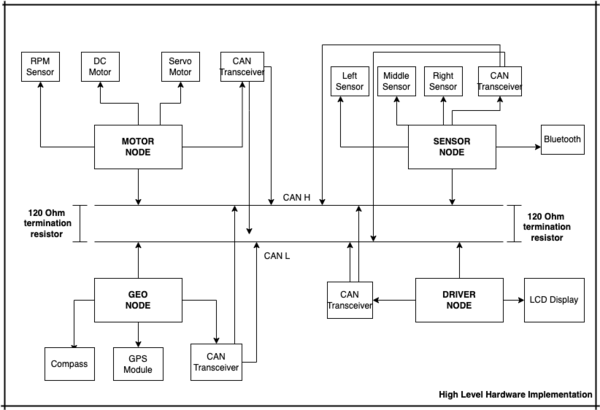

| − | + | Firebolt is battery powered autonomous RC car. The car uses four microcontrollers for communication between the nodes- driver node, motor node, bridge & sensor node, and geological node over the CAN bus. It is interfaced to the mobile application which sends GPS coordinates for the destination location to the driver node and reaches the destination by avoiding any obstacles that comes in the path. For obstacle detection and avoidance it uses Ultrasonic Sensor and makes the decision of steering and maintaining speed after performing calculations based on the bridge and sensor node's data. | |

== Objectives & Introduction == | == Objectives & Introduction == | ||

| − | + | === Objectives === | |

| − | + | The objective of this project is to get hands on experience of application of embedded systems in autonomous vehicles, have understanding of CAN bus communication, CAN database files, TDD and other related tools such as PCAN dongle and Busmaster. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | ==== | + | ====Software side ==== |

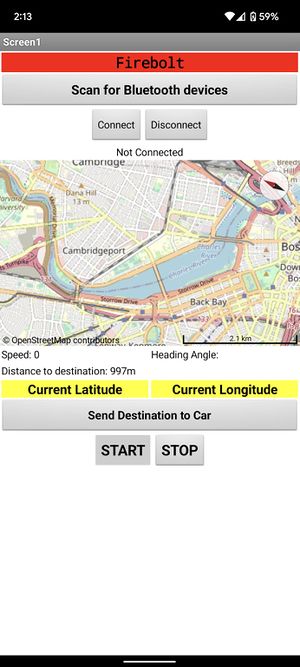

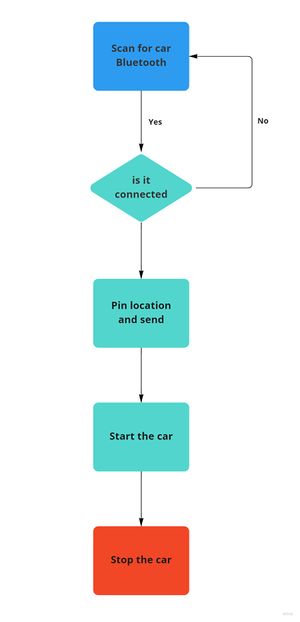

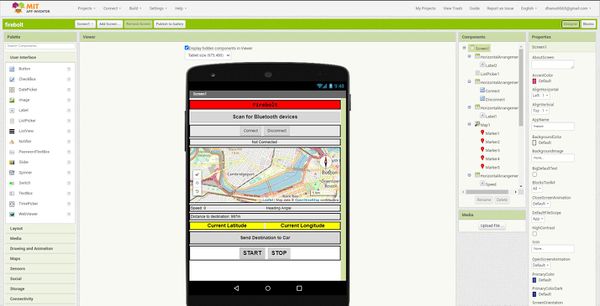

| − | The | + | * The car communicates with an Android application |

| − | + | * Receive coordinates from gps to drive itself to the destination while avoiding obstacles | |

| − | + | * Display useful information on the LCD | |

| − | + | * Take care of elevation and make correct speed decisions | |

| − | + | * DBC file for all the nodes | |

| − | === | + | ====Hardware side ==== |

| + | * Design PCB for four controllers and other necessary components | ||

| + | * Choose good options for mounting the ultrasonic sensors on the car | ||

| + | * Make a good GUI Android application for interfacing with the microcontroller | ||

| − | [[File: | + | <div><ul> |

| − | + | <li style="display: inline-block;">[[File:High_Level_Implementation2.png|600px|thumb|Center|High Level Hardware]] </li> | |

| − | + | </ul></div> | |

| − | |||

| + | ==== Introduction ==== | ||

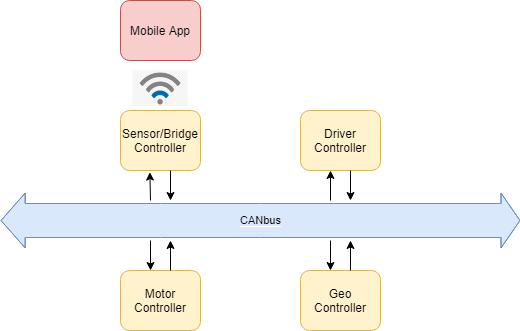

| + | The controllers for the project are divided in 5 parts. Each controller has different tasks and communicate with each other over CAN bus. | ||

| + | # Driver Node | ||

| + | # GEO Node | ||

| + | # Sensors and Bridge Node | ||

| + | # Motor Node | ||

| + | # Mobile Application | ||

| − | [[File: | + | === Team Members & Responsibilities === |

| − | + | <div><ul> | |

| − | ** | + | <li style="display: inline-block;">[[File:Team_Photo_2.jpg|600px|thumb|Right|Team FireBolt]] </li> |

| − | ** | + | <li style="display: inline-block;">[[File:Team_Photo_Final.jpeg|500px|thumb|Left|Team FireBolt]]</li> |

| + | </ul></div> | ||

| + | <font color="black"> '''Priyanka Rai [https://www.linkedin.com/in/priyanka-rai-009ba975/ LinkedIn]'''''' | ||

| + | * Geo Controller | ||

| + | * GPS and Compass Interfacing | ||

| + | * Integration Testing | ||

| + | * Wiki Page Update | ||

| − | + | <font color="black"> '''Ritu Patil [https://www.linkedin.com/in/ritu-patil/ LinkedIn]'''''' | |

| − | + | * Motor Controller | |

| − | ** | + | * RPM Sensor |

| + | * Integration Testing | ||

| + | * Wiki Page Update | ||

| − | + | <font color="black"> '''Ritika Beniwal [https://www.linkedin.com/in/ritikabeniwal03/ LinkedIn]'''''' | |

| − | + | * Driver Node | |

| − | ** | + | * LCD interfacing |

| + | * Integration Testing | ||

| + | * Wiki Page Update | ||

| − | + | <font color="black"> '''Utsav Savaliya [https://www.linkedin.com/in/utsav-savaliya-7383ab15b/ LinkedIn]'''''' | |

| − | + | * Sensor Controller | |

| − | * | + | * Integration Testing |

| − | * | + | * Wiki Page Update |

| − | ** | + | * Bluetooth integration with Sensor |

| − | * | + | <font color="black"> '''Dhanush Babu [https://www.linkedin.com/in/dhanushsbabu/ LinkedIn]'''''' |

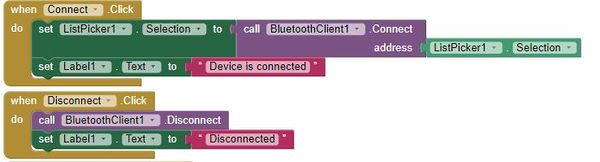

| − | * | + | * Bluetooth module interfacing |

| + | * Motor Controller | ||

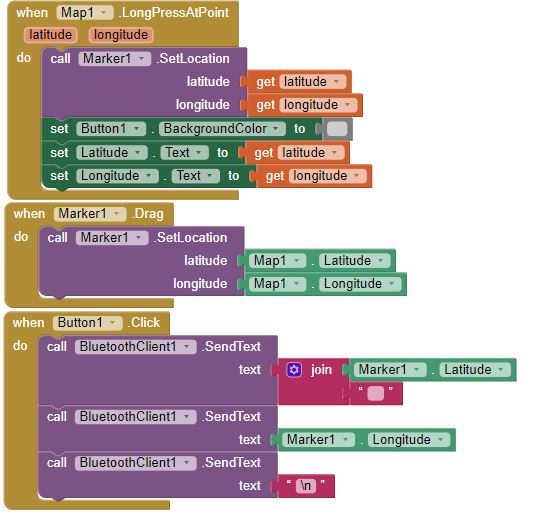

| + | * Android App | ||

| + | * Integration Testing | ||

== Schedule == | == Schedule == | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{| class="wikitable" | {| class="wikitable" | ||

| Line 79: | Line 73: | ||

! scope="col"| Week# | ! scope="col"| Week# | ||

! scope="col"| Start Date | ! scope="col"| Start Date | ||

| − | ! scope="col"| | + | ! scope="col"| Target Date |

! scope="col"| Task | ! scope="col"| Task | ||

| + | ! scope=:col"| Completion Date | ||

! scope="col"| Status | ! scope="col"| Status | ||

|- | |- | ||

| − | ! scope="row"| 1 | + | ! scope="row"| Week 1 |

| − | | | + | | |

| − | + | * 03/06 | |

| + | * 03/08 | ||

| + | * 03/12 | ||

| + | | | ||

| + | * 03/10 | ||

| + | * 03/10 | ||

| + | * 03/12 | ||

| | | | ||

| − | + | * Study and discuss previous project reports | |

| + | * Brainstorm on the requirements for the project | ||

| + | * Identify and order/purchase the required components | ||

| | | | ||

| − | * | + | * 03/10 |

| + | * 03/10 | ||

| + | * 03/12 | ||

| | | | ||

| − | * < | + | *<font color = "green">Completed |

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

|- | |- | ||

| − | ! scope="row"| 2 | + | ! scope="row"| Week 2 |

| − | | | + | | |

| − | + | * 03/13 | |

| − | | | + | * 03/13 |

| − | + | * 03/14 | |

| + | | | ||

| + | * 03/14 | ||

| + | * 03/18 | ||

| + | * 03/18 | ||

| | | | ||

| − | * | + | * Distribute initial roles among the team members |

| − | * | + | * Study the datasheets and manual of acquired components |

| + | * Create and setup Gitlab Repository | ||

| | | | ||

| − | * < | + | * 03/14 |

| − | * < | + | * 03/18 |

| + | * 03/18 | ||

| + | | | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

|- | |- | ||

| − | ! scope="row"| 3 | + | ! scope="row"| Week 3 |

| | | | ||

| − | + | * 03/20 | |

| + | * 03/22 | ||

| + | * 03/20 | ||

| | | | ||

| − | + | * 03/25 | |

| + | * 03/26 | ||

| + | * 03/24 | ||

| | | | ||

| − | * | + | * Write basic driver for ultrasonic sensor |

| − | * | + | * Analyze and decide the hardware placement of the RC Car |

| − | + | * Create SENSOR and DRIVER nodes to transmit and receive data | |

| − | |||

| − | |||

| − | * | ||

| − | |||

| | | | ||

| − | * | + | * 03/26 |

| − | * | + | * 03/23 |

| − | * | + | * 03/25 |

| − | * < | + | | |

| − | * < | + | *<font color = "green"> Completed |

| − | * < | + | *<font color = "green"> Completed |

| − | + | *<font color = "green"> Completed | |

| − | |||

|- | |- | ||

| − | ! scope="row"| 4 | + | ! scope="row"| Week 4 |

| | | | ||

| − | + | * 03/27 | |

| + | * 03/27 | ||

| + | * 03/27 | ||

| | | | ||

| − | + | * 04/04 | |

| + | * 04/01 | ||

| + | * 03/28 | ||

| | | | ||

| − | * | + | * Create the GEO node to get coordinates and cardinal directions from GPS and Compass |

| − | * | + | * Create the MOTOR node to drive the RC Car |

| − | * | + | * Design DBC file and create CAN signals for every node |

| | | | ||

| − | * < | + | * 04/02 |

| − | * < | + | * 04/04 |

| − | * < | + | * 04/01 |

| + | | | ||

| + | *<font color = "Green"> Completed | ||

| + | *<font color = "Green"> Completed | ||

| + | *<font color = "Green"> Completed | ||

|- | |- | ||

| − | ! scope="row"| 5 | + | ! scope="row"| Week 5 |

| | | | ||

| − | + | * 04/02 | |

| + | * 04/02 | ||

| + | * 04/02 | ||

| + | * 04/02 | ||

| | | | ||

| − | + | * 04/08 | |

| + | * 04/08 | ||

| + | * 04/08 | ||

| + | * 04/08 | ||

| | | | ||

| − | * | + | * Finalize the DBC file |

| − | * | + | * Design obstacle avoidance and steering logic on the DRIVER node |

| − | * | + | * Design motor driving logic on the MOTOR node with the encoder |

| − | * | + | * Start and design the Bluetooth app xml for destination. |

| − | + | ||

| − | |||

| | | | ||

| − | * | + | * 04/09 |

| − | * | + | * 04/09 |

| − | * < | + | * 04/09 |

| − | * < | + | * 04/09 |

| − | * < | + | | |

| − | * < | + | *<font color = "green"> Completed |

| + | *<font color = "green"> Completed | ||

| + | *<font color = "green"> Completed | ||

| + | *<font color = "green"> Completed | ||

|- | |- | ||

| − | ! scope="row"| 6 | + | ! scope="row"| Week 6 |

| | | | ||

| − | + | * 04/09 | |

| + | * 04/09 | ||

| + | * 04/09 | ||

| + | * 04/09 | ||

| + | * 04/09 | ||

| | | | ||

| − | + | * 04/15 | |

| + | * 04/15 | ||

| + | * 04/15 | ||

| + | * 04/15 | ||

| + | * 04/15 | ||

| | | | ||

| − | * | + | * Integrate GPS module with compass to get the current location. |

| − | * | + | * Write UART interface for Bluetooth integration on sensor node. |

| − | + | * Get raw sensor data from the ultrasonic sensor. | |

| − | + | * Integrate GEO node to DRIVER node for navigation. Check whether the DRIVER node is receiving the coordinates. | |

| − | * | + | * Backend development for android app. Should be able to scan BT devices and connect. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | * | ||

| − | * | ||

| − | |||

| | | | ||

| − | * | + | * 04/15 |

| − | * | + | * 04/15 |

| − | * | + | * 04/15 |

| − | * < | + | * 04/15 |

| − | * < | + | * 04/15 |

| − | * < | + | | |

| − | * < | + | *<font color = "green">Completed |

| − | * < | + | *<font color = "green">Completed |

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

|- | |- | ||

| − | ! scope="row"| 7 | + | ! scope="row"| Week 7 |

| − | | | + | | |

| − | + | * 04/16 | |

| + | * 04/16 | ||

| + | * 04/16 | ||

| + | * 04/16 | ||

| + | * 04/16 | ||

| + | * 04/16 | ||

| | | | ||

| − | + | * 04/23 | |

| + | * 04/23 | ||

| + | * 04/23 | ||

| + | * 04/23 | ||

| + | * 04/23 | ||

| + | * 04/23 | ||

| | | | ||

| − | * | + | * Communicate to the GEO node over Bluetooth via Android app |

| − | + | * Complete Driver obstacle logic | |

| − | * | + | * Design driving decision logic based on the navigation data |

| − | * | + | * Lay out basic PCB Board design for mounting the ECUs |

| − | * | + | * Filtering ultrasonic sensor data and sending processed data to Driver |

| + | * RPM Sensor logic and testing. | ||

| | | | ||

| − | * < | + | * 04/26 |

| − | * < | + | * 04/26 |

| − | * < | + | * 04/26 |

| − | * < | + | * 04/26 |

| − | * < | + | * 04/26 |

| + | * 04/26 | ||

| + | | | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

|- | |- | ||

| − | ! scope="row"| 8 | + | ! scope="row"| Week 8 |

| − | | | + | | |

| − | + | * 04/25 | |

| + | * 04/25 | ||

| + | * 04/25 | ||

| + | * 04/25 | ||

| + | * 04/25 | ||

| + | * 04/25 | ||

| | | | ||

| − | + | * 04/30 | |

| + | * 04/30 | ||

| + | * 04/30 | ||

| + | * 04/30 | ||

| + | * 04/30 | ||

| + | * 04/30 | ||

| | | | ||

| − | * | + | * Design a dashboard on the LCD to display the values |

| − | * | + | * Driver logic for sensor data and geo data on busmaster. |

| − | * | + | * Add functionality for pinning location on maps and extracting latitude and longitude |

| − | *< | + | * Improve obstacle avoidance logic |

| + | * Break and ramp logic for the motor. | ||

| + | * '''Collective Test 1''':<font color = "DarkGreen">''' Drive the car to a hardcoded GPS destination'''</font color> | ||

| | | | ||

| − | * < | + | * 04/29 |

| − | * < | + | * 04/27 |

| − | * < | + | * 04/30 |

| − | * < | + | * 04/30 |

| + | * 04/30 | ||

| + | * 05/06 | ||

| + | | | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

|- | |- | ||

| − | ! scope="row"| 9 | + | ! scope="row"| Week 9 |

| − | |||

| − | |||

| | | | ||

| − | + | * 05/01 | |

| + | * 05/01 | ||

| + | * 05/01 | ||

| + | * 05/01 | ||

| + | * 05/01 | ||

| | | | ||

| − | * | + | * 05/07 |

| − | * | + | * 05/07 |

| − | * | + | * 05/07 |

| − | * | + | * 05/07 |

| − | * | + | * 05/07 |

| − | |||

| | | | ||

| − | * | + | * Design individual architecture diagrams and algorithms for documentation |

| − | * | + | * Make any necessary improvements based on previous test results |

| − | * | + | * Complete the final version of the Android app |

| − | * | + | * Get the PCB printed |

| − | * < | + | * '''Collective Test 2''':<font color = "DarkGreen">''' Test the car driving with navigation data from the Android app'''</font color> |

| − | |||

| + | | | ||

| + | * 05/10 | ||

| + | * 05/07 | ||

| + | * 05/01 | ||

| + | * 05/07 | ||

| + | * 05/11 | ||

| + | | | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "Green">Completed | ||

| + | *<font color = "green">Completed | ||

|- | |- | ||

| − | ! scope="row"| 10 | + | ! scope="row"| Week 10 |

| − | |||

| − | |||

| | | | ||

| − | + | * 05/09 | |

| + | * 05/09 | ||

| + | * 05/09 | ||

| + | * 05/09 | ||

| | | | ||

| − | * | + | * 05/14 |

| − | * | + | * 05/14 |

| − | * | + | * 05/14 |

| − | * | + | * 05/14 |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | | | ||

| − | + | * Replace the circuits with their corresponding PCBs and assemble | |

| + | * Complete the RC Car structure and assembly with the 3D printed parts - Prototype 1 | ||

| + | * Refactor the code modules with necessary improvements | ||

| + | * '''Collective Test 3:'''<font color = "DarkGreen">''' Test car on various terrains and slopes'''</font color> | ||

| | | | ||

| − | * | + | * 05/20 |

| − | * | + | * 05/20 |

| − | * | + | * 05/20 |

| + | * 05/20 | ||

| | | | ||

| − | * < | + | *<font color = "green">Completed |

| − | * < | + | *<font color = "green">Completed |

| − | * < | + | *<font color = "green">Completed |

| + | *<font color = "green">Completed | ||

|- | |- | ||

| − | ! scope="row"| | + | ! scope="row"| Week 11 |

| − | |||

| − | |||

| | | | ||

| − | + | * 05/16 | |

| + | * 05/16 | ||

| + | * 05/16 | ||

| + | * 05/16 | ||

| | | | ||

| − | * | + | * 05/21 |

| − | * | + | * 05/21 |

| − | * | + | * 05/21 |

| − | * | + | * 05/21 |

| − | |||

| | | | ||

| − | * | + | * Revise and improve the wiki report to cover all the aspects of design and implementation |

| − | * | + | * Fix all the errors and make improvements |

| − | * | + | * Final testing of all the modules and car |

| − | * | + | * '''Collective Test 4:'''<font color = "DarkGreen">''' Have the final version of the project tested with all the functionalities'''</font color> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | | | ||

| − | + | * 05/22 | |

| + | * 05/22 | ||

| + | * 05/22 | ||

| + | * 05/22 | ||

| | | | ||

| − | *< | + | *<font color = "green">Completed |

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | *<font color = "green">Completed | ||

| + | |- | ||

| + | ! scope="row"| Week 12 | ||

| | | | ||

| − | * | + | * 05/25 |

| − | + | * 05/25 | |

| − | |||

| − | |||

| − | |||

| | | | ||

| − | + | * 05/27 | |

| + | * 05/27 | ||

| | | | ||

| − | * | + | * Demo |

| − | * | + | * Final Wiki Page Update with addition of all the problems faced during the development |

| − | |||

| − | |||

| | | | ||

| − | * | + | * 05/25 |

| − | * | + | * 05/26 |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| | | | ||

| − | + | *<font color = "green"> Completed | |

| − | + | *<font color = "green"> Completed | |

| − | |||

| − | |||

| − | |||

| − | *< | ||

| − | |||

| − | |||

| − | * < | ||

| − | |||

|} | |} | ||

| Line 353: | Line 412: | ||

|- | |- | ||

! scope="col"| Item# | ! scope="col"| Item# | ||

| − | ! scope="col"| Part | + | ! scope="col"| Part Desciption |

! scope="col"| Vendor | ! scope="col"| Vendor | ||

! scope="col"| Qty | ! scope="col"| Qty | ||

| − | ! scope="col"| | + | ! scope="col"| Price($) |

|- | |- | ||

! scope="row"| 1 | ! scope="row"| 1 | ||

| − | | | + | | RC Car |

| − | | Traxxas [https:// | + | | Traxxas [https://www.amazon.com/gp/product/B07DFXN118/ref=ppx_yo_dt_b_asin_title_o06_s00?ie=UTF8&psc=1] |

| 1 | | 1 | ||

| − | | | + | |280 |

|- | |- | ||

! scope="row"| 2 | ! scope="row"| 2 | ||

| − | | | + | | CAN Transceivers MCP2551-I/P |

| − | | | + | | Comimark [https://www.amazon.com/Comimark-Transceiver-TJA1050-Controller-Schnittstelle/dp/B07W4VZ2F2/ref=sr_1_4?crid=L6PXVWD9BFTN&dchild=1&keywords=can+transceiver&qid=1621786818&sprefix=can+trans%2Caps%2C566&sr=8-4] |

| − | | | + | | 5 |

| − | | | + | | 8.99 |

|- | |- | ||

! scope="row"| 3 | ! scope="row"| 3 | ||

| − | | | + | | Ultrasonic Sensors |

| − | | | + | | Max Botix[https://www.amazon.com/gp/product/B07Q588SBP/ref=ppx_yo_dt_b_asin_title_o04_s00?ie=UTF8&psc=1] |

| − | | | + | | 4 |

| − | | | + | | 24.95 |

|- | |- | ||

! scope="row"| 4 | ! scope="row"| 4 | ||

| − | | | + | | GPS Breakout Board |

| − | | | + | | Adafruit[https://www.adafruit.com/product/746] |

| 1 | | 1 | ||

| − | | | + | | 29.95 |

|- | |- | ||

! scope="row"| 5 | ! scope="row"| 5 | ||

| − | | | + | | GPS Antenna |

| − | | Adafruit [https://www.adafruit.com/product/ | + | | Adafruit[https://www.adafruit.com/product/960] |

| 1 | | 1 | ||

| − | | | + | | 19.95 |

|- | |- | ||

! scope="row"| 6 | ! scope="row"| 6 | ||

| − | | | + | | RPSMA female to mhf4 |

| − | | | + | | Superbat[https://www.amazon.com/dp/B08N6C7XGD/ref=cm_sw_r_cp_api_i_THK732JGSBBCCZFEPF58?_encoding=UTF8&psc=1] |

| 1 | | 1 | ||

| − | | | + | | 7.99 |

|- | |- | ||

| − | ! scope="row"|7 | + | ! scope="row"| 7 |

| − | | | + | | HC05 bluetooth RF Transceiver |

| − | | | + | | HiLetgo[https://www.amazon.com/HiLetgo-Bluetooth-Transceiver-Integrated-Communication/dp/B07VL725T8/] |

| 1 | | 1 | ||

| − | | | + | | 15.99 |

|- | |- | ||

| − | ! scope="row"|8 | + | ! scope="row"| 8 |

| − | | | + | | Triple-axis Accelerometer |

| − | | | + | | Adafruit[https://www.adafruit.com/product/1120] |

| 1 | | 1 | ||

| − | | | + | | 14.95 |

|- | |- | ||

| − | ! scope="row"|9 | + | ! scope="row"| 9 |

| − | | | + | | Traxxas RPM Sensor |

| − | | | + | | Traxxas[https://www.amazon.com/Traxxas-6520-RPM-Sensor-long/dp/B006IRXEZM] |

| 1 | | 1 | ||

| − | | | + | | 13.76 |

|- | |- | ||

| − | ! scope="row"|10 | + | ! scope="row"| 10 |

| − | | | + | | Traxxas Battery and Charger |

| − | | | + | |Traxxas[https://www.amazon.com/Traxxas-Battery-Charger-Completer-2-amp/dp/B074FXXP5J/ref=asc_df_B074FXXP5J/?tag=hyprod-20&linkCode=df0&hvadid=312136795426&hvpos=&hvnetw=g&hvrand=9135382788468531733&hvpone=&hvptwo=&hvqmt=&hvdev=c&hvdvcmdl=&hvlocint=&hvlocphy=9032144&hvtargid=pla-493010666784&psc=1] |

| − | | | + | |1 |

| − | | | + | |62.95 |

| + | |- | ||

| + | ! scope="row"| 11 | ||

| + | | Voltage Regulator | ||

| + | |Valefod[https://www.amazon.com/dp/B076H3XHXP?ref_=cm_sw_r_cp_ud_dp_5HTAVWPZJ2QS6AMXTM93] | ||

| + | |6 | ||

| + | |10.99 | ||

| + | |- | ||

| + | ! scope="row"| 12 | ||

| + | | Headlights | ||

| + | |Hobbypark[https://www.amazon.com/dp/B01GY8VFIM?ref_=cm_sw_r_cp_ud_dp_PK32ZA2HM4DRWMGV55YC] | ||

| + | |1 | ||

| + | |7.96 | ||

|- | |- | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| Line 430: | Line 496: | ||

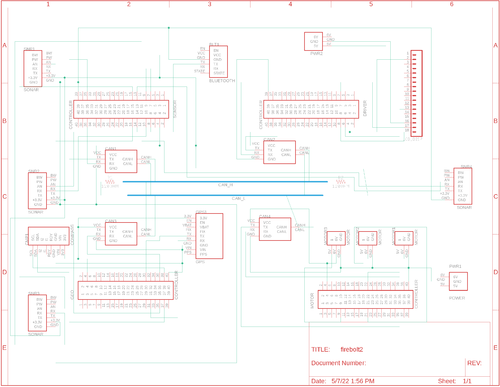

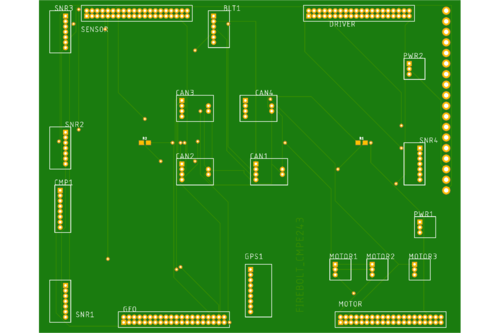

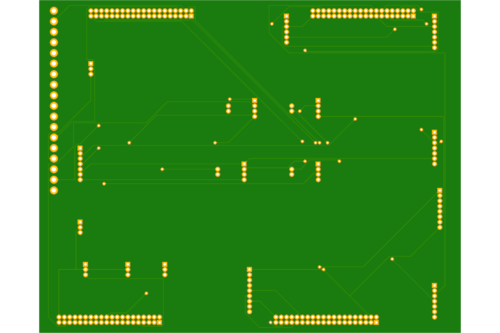

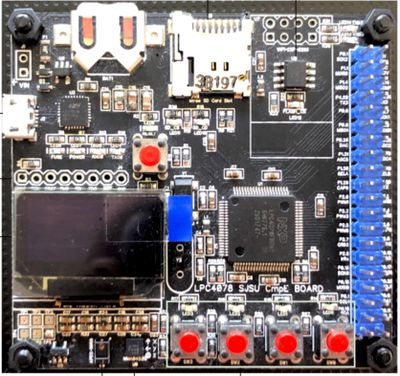

== Printed Circuit Board == | == Printed Circuit Board == | ||

| − | + | Initially we started our testing with mounting all our hardware on the breadboard (yes, it was messy and unstable!). | |

| − | + | <div><ul> | |

| + | <li style="display: inline-block;">[[File:Initial_Car.jpeg|400px|thumb|Centre|Initial_Hardware]] </li> | ||

| + | </ul></div> | ||

| − | |||

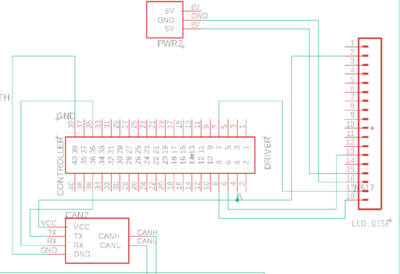

| + | <h4>PCB Schematic</h4> | ||

| − | == | + | <div><ul> |

| − | + | <li style="display: inline-block;">[[File:Final_Sch.png|500px|thumb|Left|Schematic]] </li> | |

| + | <li style="display: inline-block;">[[File:Final_PCB.png|500px|thumb|Right|Final_Board]] </li> | ||

| + | </ul></div> | ||

| − | |||

| − | |||

| + | <h4>PCB Board</h4> | ||

| − | + | <div><ul> | |

| + | <li style="display: inline-block;">[[File:Final_Top_Side.png|500px|thumb|Left|Top_Side]]</li> | ||

| + | <li style="display: inline-block;">[[File:Final_Bottom_Side.png|500px|thumb|Right|Bottom_Side]] </li> | ||

| + | </ul></div> | ||

| + | <h4>Challenges </h4> | ||

| + | * Since there are four controllers and a significant number of components (gps, sensors, can transceivers, volt regulator etc.) it was difficult for us to keep our hardware stable because every time we go for field testing some will get disconnected and we were kind of stuck up in the hardware setup. | ||

| + | * We decided to get the PCB printed but there were some issues and resolving them and getting a new PCB would take time. | ||

| − | + | <h4>Solution </h4> | |

| − | + | * Finally we decided to use the prototype board for mounting all the components and stabilizing our hardware. | |

| − | + | <div><ul> | |

| − | + | <li style="display: inline-block;">[[File:Final_Hardware_Physical.jpeg|500px|thumb|Left|Protoype_Board]]</li> | |

| − | + | </ul></div> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[File: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | < | ||

== CAN Communication == | == CAN Communication == | ||

| + | We used controller area network to communicate data between four nodes. All nodes are connected to each other through a physically conventional two wire bus CANH and CANL. The wires are a twisted pair with 120 Ω termination resistors at each end of the bus. 1s and 0s are transmitted as CAN High(0V difference) and Can Low(2v difference). | ||

| + | A CAN frame has the following contents: | ||

| + | * Data Length Code (4bits) | ||

| + | * Remote Transmission Request. | ||

| + | * ID extend bit. | ||

| + | * Message ID (11 bit or 29 bit) | ||

| + | * Data bytes( depends on DLC) | ||

| + | * CRC | ||

| − | |||

| − | + | '''Arbitration''': No two nodes will transmit at the same time because of arbitration. A lower Message-ID has a Higher priority on the CAN bus since 0 is the dominant bit. | |

| − | + | '''Bit Stuffing''': CAN bus stuffs extra bits when a long chain of multiple 1's or 0's occur to improve CAN integrity. | |

| + | [[File:High level diagram.png|thumb|600px|middle|center|Project Can Bus Diagram]] | ||

| − | |||

| − | |||

| − | |||

=== DBC File === | === DBC File === | ||

| + | The DBC file is a simple text file that consists of information for decoding raw CAN bus data to physical values or in human readable form. | ||

| − | + | {| class="wikitable" | |

| + | |- | ||

| + | ! scope="col"| Sr. No | ||

| + | ! scope="col"| Message ID | ||

| + | ! scope="col"| Message function | ||

| + | ! scope="col"| Receivers | ||

| + | |- | ||

| + | |- | ||

| + | |- | ||

| + | |- | ||

| + | ! colspan="4"| Driver Heartbeat | ||

| + | |- | ||

| + | |- | ||

| + | |1 | ||

| + | |100 | ||

| + | |Driver Heartbeat | ||

| + | |Motor, Sensor, Geo | ||

| + | |- | ||

| + | ! colspan="4"| Start Stop signal from Android app to Driver | ||

| + | |- | ||

| + | |- | ||

| + | |1 | ||

| + | |101 | ||

| + | |Bridge Sensor | ||

| + | |Driver | ||

| + | |- | ||

| + | ! colspan="4"| Ultrasonic sensors data transmit | ||

| + | |- | ||

| + | |- | ||

| + | |2 | ||

| + | |200 | ||

| + | |Sensor sonars from front, back, left ,right sensor | ||

| + | |Driver | ||

| + | |- | ||

| + | ! colspan="4"| Destination Location | ||

| + | |- | ||

| + | |- | ||

| + | |4 | ||

| + | |250 | ||

| + | |Bridge Sensor | ||

| + | |Geo | ||

| + | |- | ||

| + | |- | ||

| + | ! colspan="4"| Driver to Motor Command | ||

| + | |- | ||

| + | |- | ||

| + | |5 | ||

| + | |300 | ||

| + | |Speed and steering direction for the motor | ||

| + | |Motor | ||

| + | |- | ||

| + | |- | ||

| + | ! colspan="4"| Geo Controller | ||

| + | |- | ||

| + | |- | ||

| + | |6 | ||

| + | |400 | ||

| + | |Bearing, Heading and Distance | ||

| + | |Driver | ||

| + | |- | ||

| + | |- | ||

| + | ! colspan="4"| Motor Controller | ||

| + | |- | ||

| + | |- | ||

| + | |7 | ||

| + | |600 | ||

| + | |Motor speed | ||

| + | |Driver | ||

| + | |- | ||

| + | |- | ||

| + | ! colspan="4"| Debug messages | ||

| + | |- | ||

| + | |- | ||

| + | |8 | ||

| + | |700 | ||

| + | |Driver Debug | ||

| + | |BRIDGE_SENSOR,MOTOR,GEO | ||

| + | |- | ||

| + | |- | ||

| + | |9 | ||

| + | |750 | ||

| + | |Geo Debug | ||

| + | |BRIDGE_SENSOR,MOTOR,DRIVER | ||

| + | |- | ||

| + | |- | ||

| + | |} | ||

| + | |||

<pre> | <pre> | ||

VERSION "" | VERSION "" | ||

| − | |||

NS_ : | NS_ : | ||

| − | + | BA_ | |

| − | + | BA_DEF_ | |

| − | + | BA_DEF_DEF_ | |

| − | + | BA_DEF_DEF_REL_ | |

| − | + | BA_DEF_REL_ | |

| − | + | BA_DEF_SGTYPE_ | |

| − | + | BA_REL_ | |

| − | + | BA_SGTYPE_ | |

| − | + | BO_TX_BU_ | |

| − | + | BU_BO_REL_ | |

| − | + | BU_EV_REL_ | |

| − | + | BU_SG_REL_ | |

| − | + | CAT_ | |

| − | + | CAT_DEF_ | |

| − | + | CM_ | |

| − | + | ENVVAR_DATA_ | |

| − | + | EV_DATA_ | |

| − | + | FILTER | |

| − | + | NS_DESC_ | |

| − | + | SGTYPE_ | |

| − | + | SGTYPE_VAL_ | |

| − | + | SG_MUL_VAL_ | |

| − | + | SIGTYPE_VALTYPE_ | |

| − | + | SIG_GROUP_ | |

| − | + | SIG_TYPE_REF_ | |

| − | + | SIG_VALTYPE_ | |

| − | + | VAL_ | |

| − | + | VAL_TABLE_ | |

| − | |||

BS_: | BS_: | ||

| − | BU_: | + | BU_: DRIVER MOTOR BRIDGE_SENSOR GEO DEBUG |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | BO_ | + | BO_ 100 DRIVER_HEARTBEAT: 1 DRIVER |

| − | + | SG_ DRIVER_HEARTBEAT_cmd : 0|8@1+ (1,0) [0|0] "" BRIDGE_SENSOR,MOTOR,GEO | |

| − | |||

| − | BO_ | + | BO_ 101 DRIVE_STATUS: 1 BRIDGE_SENSOR |

| − | + | SG_ DRIVE_START_STOP : 0|8@1+ (1,0) [0|0] "" DRIVER | |

| − | |||

| − | BO_ | + | BO_ 200 SENSOR_SONARS: 5 BRIDGE_SENSOR |

| − | SG_ | + | SG_ SENSOR_SONARS_left : 0|10@1+ (1,0) [0|0] "cm" DRIVER |

| − | SG_ | + | SG_ SENSOR_SONARS_right : 10|10@1+ (1,0) [0|0] "cm" DRIVER |

| + | SG_ SENSOR_SONARS_middle : 20|10@1+ (1,0) [0|0] "cm" DRIVER | ||

| + | SG_ SENSOR_SONARS_rear : 30|10@1+ (1,0) [0|0] "cm" DRIVER | ||

| − | BO_ | + | BO_ 250 DESTINATION_LOCATION: 8 BRIDGE_SENSOR |

| − | SG_ | + | SG_ DEST_LATITUDE : 0|28@1+ (0.000001,-90.000000) [-90|90] "degrees" GEO |

| − | SG_ | + | SG_ DEST_LONGITUDE : 28|28@1+ (0.000001,-180.000000) [-180|180] "degrees" GEO |

| − | BO_ | + | BO_ 300 DRIVER_TO_MOTOR: 2 DRIVER |

| − | + | SG_ DRIVER_TO_MOTOR_speed : 0|8@1+ (1,0) [-30|30] "kmph" MOTOR | |

| − | SG_ | + | SG_ DRIVER_TO_MOTOR_direction : 8|8@1- (1,-2) [-2|2] "degrees" MOTOR |

| − | BO_ | + | BO_ 400 GEO_CONTROLLER_COMPASS: 8 GEO |

| − | + | SG_ HEADING : 0|12@1+ (0.1,0) [0|359.9] "degrees" DRIVER, BRIDGE_SENSOR | |

| − | + | SG_ BEARING : 12|12@1+ (0.1,0) [0|359.9] "degrees" DRIVER,BRIDGE_SENSOR | |

| + | SG_ DISTANCE_TO_DESTINATION: 24|32@1+ (0.01,0) [0|359.9] "meters" DRIVER,BRIDGE_SENSOR | ||

| − | BO_ | + | BO_ 600 MOTOR_SPEED: 2 MOTOR |

| − | + | SG_ MOTOR_SPEED_info : 0|8@1+ (0.1,-10) [-10|10] "kmph" DRIVER, BRIDGE_SENSOR | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | BO_ | + | BO_ 700 DRIVER_DEBUG: 2 DEBUG |

| − | + | SG_ car_driving_status: 0|8@1+ (1,0) [0|0] "" DEBUG | |

| + | SG_ car_steering_status: 8|8@1+ (1,0) [0|0] "" DEBUG | ||

| − | BO_ | + | BO_ 750 GEO_CONTROLLER_DEBUG_MESG: 10 DEBUG |

| − | SG_ | + | SG_ CURR_LATITUDE : 0|28@1+ (0.000001,-90.000000) [-90|90] "degrees" DEBUG |

| − | + | SG_ CURR_LONGITUDE : 28|28@1+ (0.000001,-180.000000) [-180|180] "degrees" DEBUG | |

| − | + | SG_ RAW_HEADING : 56|12@1+ (0.1,0) [0|359.9] "degrees" DEBUG | |

| − | |||

CM_ BU_ DRIVER "The driver controller driving the car"; | CM_ BU_ DRIVER "The driver controller driving the car"; | ||

| Line 631: | Line 712: | ||

CM_ BU_ SENSOR "The sensor controller of the car"; | CM_ BU_ SENSOR "The sensor controller of the car"; | ||

CM_ BO_ 100 "Sync message used to synchronize the controllers"; | CM_ BO_ 100 "Sync message used to synchronize the controllers"; | ||

| + | CM_ BU_ GEO "To provide raw GPS and compass heading"; | ||

CM_ SG_ 100 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver"; | CM_ SG_ 100 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver"; | ||

| − | + | VAL_ 300 DRIVER_TO_MOTOR_direction -2 "MOTOR_direction_HARD_LEFT" -1 "MOTOR_direction_SOFT_LEFT" 0 "MOTOR_direction_STRAIGHT" 1 "MOTOR_direction_SOFT_RIGHT" 2 "MOTOR_direction_HARD_RIGHT" ; | |

| − | + | VAL_ 700 car_steering_status 2 "RIGHT" 1 "LEFT" 0 "STRAIGHT"; | |

| − | + | VAL_ 700 car_driving_status 2 "BACKWARD" 1 "FORWARD" 0 "STOPPED"; | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | VAL_ | ||

</pre> | </pre> | ||

| − | |||

| − | |||

| − | == | + | === Technical Challenges === |

| − | + | * The CAN transceivers that we bought had inbuilt 120 ohm resistor each, which we didn't notice. And every time we interfaced all the four nodes the data won't show up in the busmaster software. We found this very late and until then we thought it's hardware/dbc file issue and wasted potential amount of time in debugging.So we de-soldered those termination resistors and we were able to see our data smoothly on busmaster. | |

| + | * As an advice, make sure at the end of all four nodes after adding termination resistors of 120 ohm on both sides, the resultant resistance is 60 ohms. Only then all four nodes can communicate over CAN bus. | ||

| + | == Sensor and Bluetooth ECU == | ||

=== Hardware Design === | === Hardware Design === | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

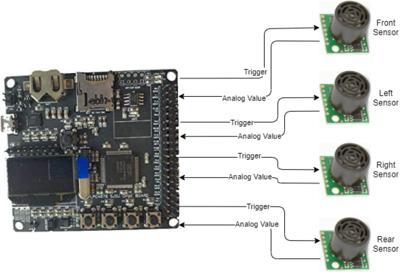

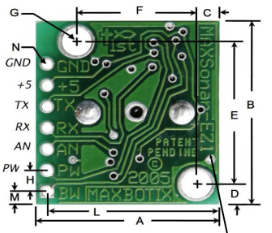

| − | + | The obstacle detection sensors used here are Ultrasonic sensors. The HRLV-MaxSonar-EZ1 sensors from MaxBotix are used here. In these sensors there is membrane which needs to be triggered in order to generate and send ultrasonic waves every few seconds. When ultrasonic waves collide and come back and strikes with this membrane a pulse is generated which is used for sensing. | |

| − | |||

| − | |||

| − | + | [[File:Sensor_Node.png|left|400px|thumb|Sensor Controller Diagram]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:Ultrasonic99.png|center|400px|thumb|Sensor Pins]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | {| class="wikitable" width="auto" style="text-align: center; margin-left: auto; margin-right: auto; border: none;" | |

| − | {| style="margin-left: auto; margin-right: auto; border: none;" | + | |+Pin connections between board and sensor: |

| − | | | + | |- |

| − | | | + | ! scope="col"| Sl No. |

| + | ! scope="col"| SJ2 board Pin No. | ||

| + | ! scope="col"| Ultrasonic sensor Pin No. | ||

| + | ! scope="col"| Function | ||

| + | |- | ||

| + | ! scope="row"| 1. | ||

| + | | ADC Pin 1.30 | ||

| + | | AN(Front left sensor) | ||

| + | | Input to ADC channel 4 | ||

| + | |- | ||

| + | ! scope="row"| 2. | ||

| + | | ADC Pin 1.31 | ||

| + | | AN(Front right sensor) | ||

| + | | Input to ADC channel 5 | ||

| + | |- | ||

| + | ! scope="row"| 3. | ||

| + | | ADC Pin 1.26 | ||

| + | | AN(Front sensor) | ||

| + | | Input to ADC channel 3 | ||

| + | |- | ||

| + | ! scope="row"| 4. | ||

| + | | ADC Pin 1.25 | ||

| + | | AN(Rear sensor) | ||

| + | | Input to ADC channel 3 | ||

| + | |- | ||

| + | ! scope="row"| 5. | ||

| + | | GPIO Pin 0.6 | ||

| + | | Rx(Front left sensor) | ||

| + | | Triggering pulse for left sensor | ||

| + | |- | ||

| + | ! scope="row"| 6. | ||

| + | | GPIO Pin 0.8 | ||

| + | | Rx(Front right sensor) | ||

| + | | Triggering pulse for right sensor | ||

| + | |- | ||

| + | ! scope="row"| 7. | ||

| + | | GPIO Pin 0.9 | ||

| + | | Rx(Front sensor) | ||

| + | | Triggering pulse for front sensor | ||

| + | |- | ||

| + | ! scope="row"| 8. | ||

| + | | GPIO Pin 0.7 | ||

| + | | Rx(Rear sensor) | ||

| + | | Triggering pulse for rear sensor | ||

| + | |- | ||

|} | |} | ||

| − | |||

| − | |||

| − | + | Apart from the pin connections for the Sensor node the important thing is to mount the sensors at particular angles. The angle placement is critical for left and right sensor as we faced lot of problems while detecting the walls. We chose the angle by error and trial method by simply placing the sensors at different angles. We tried keeping the angle above the 45 degrees so that to provide wider angle for the obstacles to detect. | |

| − | |||

| − | |||

| − | |||

| − | |||

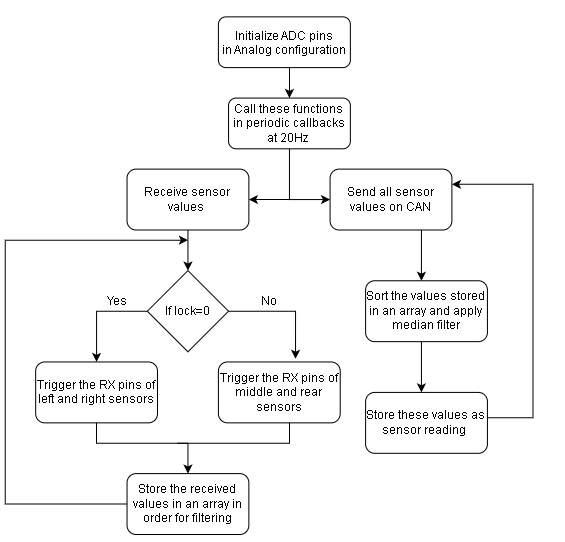

| + | === Software Design === | ||

| − | + | The sensor node has to receive values from all the sensors and send the distance values on the CAN bus for the driver to run the obstacle avoidance logic. | |

| − | The sensor | ||

| − | + | ====== Receive sensor values ====== | |

| − | The | + | Four sensors are used here. Three in the front and one at the rear side. We need four ADC channels to address the receiving from all sensors. In order to use four pins on the SJ2 board we need to set the pins to analog mode. In the adc.h file and adc.c file there are only three channels initialized, so one needs to add ADC channel 3 in these files. On how to use these sensors, the datasheet of helped a lot. It addresses every aspect of how to use this particular sensor and the solution to most of the problem that can arise. All the sensor raw values are digitally converted in the range of 0 to 1024( 10 bit ADC). These value is in inches as mentioned in the datasheet. So, one needs to convert it into centimeter by applying some formula. The formula can be different based on the configuration used to setup the ADC channel even if same sensor is used. |

| − | + | ====== Sending sensor values in terms of distance to CAN ====== | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The raw values coming from the sensor needs to be filtered before sending on the CAN bus. The more information about filtering is mentioned in the techical challenges section. The below diagram shows the detailed flowchart of software design implemented for the sensor node. | |

| − | The | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:f8.png|center|6600px|thumb|Sensor Controller Diagram]] | |

| − | |||

| − | |||

| − | + | === Technical Challenges === | |

| − | * | + | *The main challenge while using ultrasonic sensor with this particular project is of crosstalk. While detecting objects in the front all the front sensors waves are interfering with each other giving false values in the left or right sensor while the object is in the front only. The datasheet addresses this issues and what to do when multiple sensors are used in a system. It says that trigger each sensor are different time period in order to avoid crosstalk. So we triggered the front and rear at one particular time and left and right at one particular time. One sequence is triggered at particular 10Hz and other sequence is triggered at another 10Hz. There is a division of callbacks counts in 100Hz and a lock mechanism is used in order to used different 20Hz period out of 100Hz. |

| + | *For frequency noise measurements like when the values suddenly change or vary between certain range sometimes, a filter is implemented. The most common filter for this type of use is median filter where a series of values are stored in a array and median is taken of all the values stored in that array. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<HR> | <HR> | ||

| Line 753: | Line 815: | ||

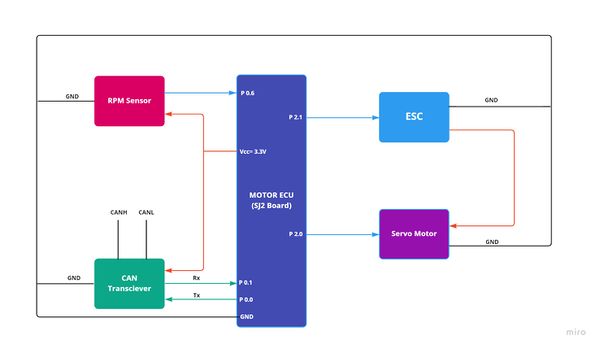

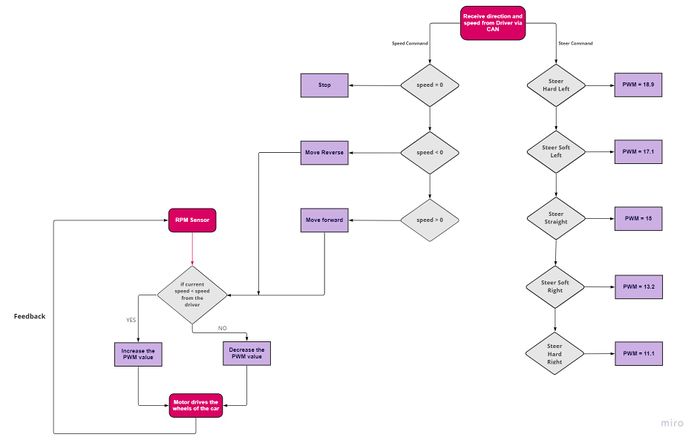

== Motor ECU == | == Motor ECU == | ||

| − | + | The Motor ECU acts as an encoder for the DC motor (used for propulsion) and Servo motor (used for turning the axle and changing direction of the car). The car is a two wheel drive with DC motor connected to the rear wheels and the servo motor is connected to the front wheels. The DC motor is controlled by Electronic Speed Control. The ECU supplies PWM signal to the ESC and the ESC powers the DC motor. The Servo motor is powered by the car battery as well and gets its PWM signal from the ECU. | |

| − | + | The RPM sensor sends its output to motor ECU by which the actual speed of the wheels is calculated. | |

| − | |||

=== Hardware Design === | === Hardware Design === | ||

| + | {| style="margin-left: auto; margin-right: auto; border: none;" | ||

| + | |[[File: Motor_HW_design.jpg|center|600px|thumb|Hardware Schematic Diagram]] | ||

| + | ==== ESC & DC Motor ==== | ||

| + | The DC motor is controlled by ESC using PWM signals provided by the motor controller for forward and reverse movements. We used the 9v NiMH battery to power up the ESC. The DC motor is powered by the ESC which has a dc-to-dc converter which converts 9v to 6v. The output from the ESC is used to power the Servo motor. ESC has an ease set button which is used for calibration and setting different modes for the car. | ||

| − | + | '''The car can be operated in the following 3 modes:''' | |

| + | <br/> | ||

| + | Sport mode(100% Forward, 100% Brakes, 100% Reverse) | ||

| + | <br/> | ||

| + | Racing mode(100% Forward, 100% Brakes, No Reverse) | ||

| + | <br/> | ||

| + | Training mode(50% Forward, 100% Brakes, 50% Reverse) | ||

| + | As we desire to run the car at full throttle, Sport mode is being used. The frequency of the PWM signal fed to the servo motor is 100Hz. Based on the duty cycle set by the user, the car will go forward, reverse, or neutral. | ||

| + | <br/> | ||

| + | PWM 10 to 14.9 for reverse. | ||

| + | <br/> | ||

| + | PWM 15 for neutral. | ||

| + | <br/> | ||

| + | PWM 15.1 to 20 for the forward. | ||

| − | + | {| class="wikitable" width="auto" style="text-align: center; margin-left: auto; margin-right: auto; border: none;" | |

| − | + | |+ESC Pinout | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | {| class="wikitable" style="margin- | ||

| − | |+ | ||

|- | |- | ||

| − | ! | + | ! scope="col"| Wires on ESC |

| + | ! scope="col"| Description | ||

| + | ! scope="col"| Wire Color | ||

|- | |- | ||

| − | | | + | ! scope="row"| PWM(P2.1) |

| − | + | | Takes PWM input from SJ2-Board | |

| − | + | | WHITE | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |- | ||

| − | | | ||

| − | |||

| − | |||

|- | |- | ||

| − | + | ! scope="row"| VDD(6V) | |

| − | + | | Power Output | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | ! scope="row"| | ||

| − | | Output | ||

| RED | | RED | ||

|- | |- | ||

| Line 815: | Line 858: | ||

| Ground | | Ground | ||

| BLACK | | BLACK | ||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

|} | |} | ||

| − | + | ||

| + | |||

<br/> | <br/> | ||

| − | + | {| style="margin-left: auto; margin-right: auto; border: none;" | |

| − | + | |[[File:ESC.jpg|center|300px|thumb|Traxxas ESC]] | |

| − | + | | | |

| − | + | |[[File:DCMotor.jpg|center|300px|thumb|Traxxas Brushless DC Motor]] | |

| − | + | | | |

| − | + | |} | |

| − | |||

| − | |||

==== Servo Motor ==== | ==== Servo Motor ==== | ||

| − | + | We are using Traxxas 2075 for this project which came with the car and it is responsible for steering the car. It takes the 6V power directly from ESC. The servo motor is controlled directly from the SJ2 micro-controller board. The PWM signal is supplied at a frequency of 100 Hz. Based on the duty cycle of the signal sent to the servo, the direction of servo motor can be changed: | |

| + | PWM 10 to 14.9 for turning left. | ||

| + | <br/> | ||

| + | PWM 15 for straight. | ||

| + | <br/> | ||

| + | PWM 15.1 to 20 for turning right. | ||

| − | {| class="wikitable" style="text-align: center;" | + | {| class="wikitable" width="auto" style="text-align: center; margin-left: auto; margin-right: auto; border: none;" |

| + | |+Servo Pinout | ||

|- | |- | ||

| − | ! scope="col"| | + | ! scope="col"| Wires on ESC |

! scope="col"| Description | ! scope="col"| Description | ||

! scope="col"| Wire Color | ! scope="col"| Wire Color | ||

|- | |- | ||

| − | ! scope="row"| | + | ! scope="row"| PWM(P2.0) |

| − | | | + | | Takes PWM input from SJ2-Board |

| + | | WHITE | ||

| + | |- | ||

| + | ! scope="row"| VDD(6V) | ||

| + | | Power Input | ||

| RED | | RED | ||

|- | |- | ||

| Line 851: | Line 899: | ||

| Ground | | Ground | ||

| BLACK | | BLACK | ||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

|} | |} | ||

| − | + | {| style="margin-left: auto; margin-right: auto; border: none;" | |

| − | + | [[File:Servotrx.jpg|300px|centre|thumb|Traxass Servo Motor(2075)]] | |

| − | ==== | + | ==== RPM Sensor ==== |

| + | The RPM sensor is used as an input to maintain a constant speed of the vehicle. The sensor we are using is Traxxas RPM sensor which using hall effect to detect the movement of the DC motor. | ||

| + | <br/> | ||

| + | '''Mounting the sensor:''' | ||

| + | <br/> | ||

| + | There are two parts to the RPM sensor - one is the trigger magnet and the other is the sensor. The sensor mounts on the inside of the gear cover, the trigger magnet mounts on the DC motor shaft. The gear cover and motor shaft need to be removed using the toolkit provided along with the RC car. The mounting process can be found on youtube. | ||

| + | <br/> | ||

| + | '''How the sensor works:''' | ||

| + | <br/> | ||

| + | The trigger magnet attaches to the spur gear. The sensor uses the DC voltage of the motor to trigger a pulse on the sensor for every rotation of the spur gear. These pulses are sent as hardware interrupt to the SJ2 board. The number of pulses are counted for every half second and that is converted into RPM and KMPH. The RPM sensor has 3 wires, the white wire is the output wire that provides the pulses to the SJ2 Board, and the other wires are Supply(3.3V) and GND. | ||

| − | + | {| class="wikitable" width="auto" style="text-align: center; margin-left: auto; margin-right: auto; border: none;" | |

| − | + | |+RPM Pinout | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | {| class="wikitable" style="text-align: center;" | ||

|- | |- | ||

| − | ! scope="col"| | + | ! scope="col"| Wires on ESC |

! scope="col"| Description | ! scope="col"| Description | ||

! scope="col"| Wire Color | ! scope="col"| Wire Color | ||

|- | |- | ||

| − | ! scope="row"| | + | ! scope="row"| GPIO(P0.6) |

| − | | | + | | Provides pulses to Motor SJ2-Board |

| + | | WHITE | ||

| + | |- | ||

| + | ! scope="row"| VDD(3.3V) | ||

| + | | Power Input | ||

| RED | | RED | ||

|- | |- | ||

| Line 883: | Line 935: | ||

| BLACK | | BLACK | ||

|- | |- | ||

| − | + | |} | |

| − | | | + | |

| − | | | + | <br/> |

| − | | | + | {| style="margin-left: auto; margin-right: auto; border: none;" |

| + | |[[File:Rpm_sensor.jpg|center|300px|thumb|Traxxas RPM Sensor]] | ||

| + | | | ||

| + | |[[File:Trigger_magnet.jpg|center|300px|thumb|Trigger Magnet]] | ||

| + | | | ||

|} | |} | ||

=== Software Design === | === Software Design === | ||

| − | + | At startup the motor is initialized by giving a neutral PWM signal for 3s and the interrupt for the rpm sensor input is setup as well. | |

| − | + | The motor receives angle for steering and speed in a single CAN message from the driver ECU. After receiving the command the speed value is converted into corresponding value of PWM by increasing or decreasing neutral PWM value in steps of 0.01. The physical value of the motor speed is compared to the speed received from the driver and it is reduced or increased to match with the desired speed. For reverse a PWM of 14.5 is given to smoothly reverse the car. | |

| − | |||

| − | + | The direction of the car is set according to the value of ENUM received from the driver ECU. For navigation the car takes soft turns and when and obstacle is detected it takes hard turns to avoid collisions. | |

| − | + | '''The period_callbacks__initialize() function calls the following functions:''' | |

| + | * can_bus_initializer: Initializes CAN buffers and sets baud rate | ||

| + | * initialize_speed_sensor_interrupts: sets up GPIO pin as hardware interrupt | ||

| + | * motor_init_pwm: initializes pwm pin. | ||

| − | + | '''The period_callbacks__1Hz() function calls the following function:''' | |

| − | + | * can_handler__handle_all_incoming_messages_1hz: handles the incoming messages based on mesg ID. | |

| + | * can_handler__transmit_messages_1hz: sends the motor speed to Driver controller. | ||

| − | + | '''The period_callbacks__10Hz() function calls the following functions:''' | |

| − | + | * pwm1__set_duty_cycle: to calibrate the ESC by sending neutral signal for few seconds. | |

| + | * clear_rotations: clears interrupt counter every 0.5 seconds | ||

| + | * can_handler__handle_all_incoming_messages: receives any message frame sent on the CAN bus. | ||

| + | |||

| − | + | <br/> | |

| + | [[File: Motor_SW_design.jpg|center|700px|thumb|Speed Control Flowchart]] | ||

| + | === Technical Challenges === | ||

| − | + | * ESC calibration: The ESC controlling the DC motor goes out of calibration again and again. We had to connect it to the receiver of the RC car and re-calibrate it again. Finally I added a neutral signal in for the first 3 seconds in the initialization sequence of the motor so that the ESC can be calibrated every time the controller is reset or powered on. | |

| + | * Changing PWM: PWM value of the motor will change sometimes and depends on the weight of the car and also a faster speed might not give enough time for the sensor to detect an obstacle. Hence keeping a slow and steady speed and relying on the RPM sensor is necessary to ensure the car keeps moving and doesn't stop on any inclines. | ||

| + | * Receiving steer commands at a higher frequency helped in reducing the response time in obstacle avoidance compared to previously when it was being received at 10Hz. | ||

| + | <br/> | ||

| + | <HR> | ||

| + | <BR/> | ||

| − | + | == Geographical And Bridge Controller == | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

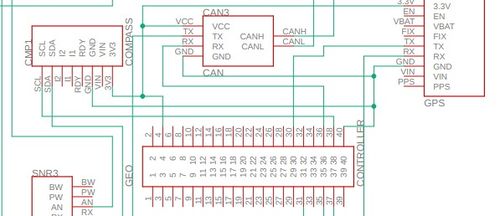

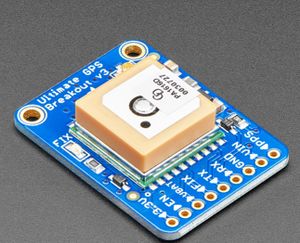

| + | === Hardware Design === | ||

| − | + | The Geographical controller does the processing for compass data and GPS data. After processing the data for heading ,bearing and distance to destination , the controller sends these data over can bus to the Driver node. The GPS module is interfaced with SJ2 board using UART. SJ2 board gets the data (NMEA string) for GPS coordinates processing. The controller sends the command to GPS module to filter the string and only send GPGGA string. The Compass module is interfaced over I2C to find the heading for car navigation. The CAN transceiver uses port 0 (can1) of the SJ2 board. | |

| − | |||

| − | |||

| − | |||

| − | |||

| + | <li style="display: inline-block;"> [[File:Geo_Node_Schematic.jpg|500px|thumb|centre|]] </li> | ||

| + | <li style="display: inline-block;">[[File:compass_Firebolt.jpg|300px|thumb|center|3 Axis Magnetometer (eCompass)]] </li> | ||

| − | < | + | <li style="display: inline-block;"> [[File:GPS_Firebolt.jpg|300px|thumb|centre|GPS Module]] </li> |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{| class="wikitable" width="auto" style="text-align: center; margin-left: auto; margin-right: auto; border: none;" | {| class="wikitable" width="auto" style="text-align: center; margin-left: auto; margin-right: auto; border: none;" | ||

| − | |+ | + | |+Geographical Node Pinout |

|- | |- | ||

! scope="col"| SJTwo Board | ! scope="col"| SJTwo Board | ||

! scope="col"| GPS/Compass Module | ! scope="col"| GPS/Compass Module | ||

! scope="col"| Description | ! scope="col"| Description | ||

| − | |||

|- | |- | ||

| − | | | + | | P0.15 (TX3) |

| RX | | RX | ||

| Adafruit GPS Breakout | | Adafruit GPS Breakout | ||

| − | |||

|- | |- | ||

| − | | | + | | P0.16 (RX3) |

| TX | | TX | ||

| Adafruit GPS Breakout | | Adafruit GPS Breakout | ||

| − | |||

|- | |- | ||

| − | | P0.10 ( | + | | P0.10 (SDA) |

| SDA | | SDA | ||

| Adafruit Magnetometer | | Adafruit Magnetometer | ||

| − | |||

|- | |- | ||

| − | | P0. | + | | P0.11 (SCL) |

| SCL | | SCL | ||

| Adafruit Magnetometer | | Adafruit Magnetometer | ||

| − | |||

|- | |- | ||

| − | | P0.1 | + | | P0.1 |

| CAN transceiver (Tx) | | CAN transceiver (Tx) | ||

| CAN transmit | | CAN transmit | ||

| − | |||

|- | |- | ||

| − | | P0.0 | + | | P0.0 |

| CAN transceiver (Rx) | | CAN transceiver (Rx) | ||

| CAN receive | | CAN receive | ||

| − | |||

|- | |- | ||

| Vcc 3.3V | | Vcc 3.3V | ||

| Vcc | | Vcc | ||

| Vcc | | Vcc | ||

| − | |||

|- | |- | ||

| GND | | GND | ||

| GND | | GND | ||

| Ground | | Ground | ||

| − | |||

|- | |- | ||

|} | |} | ||

| + | |||

| + | <BR/> | ||

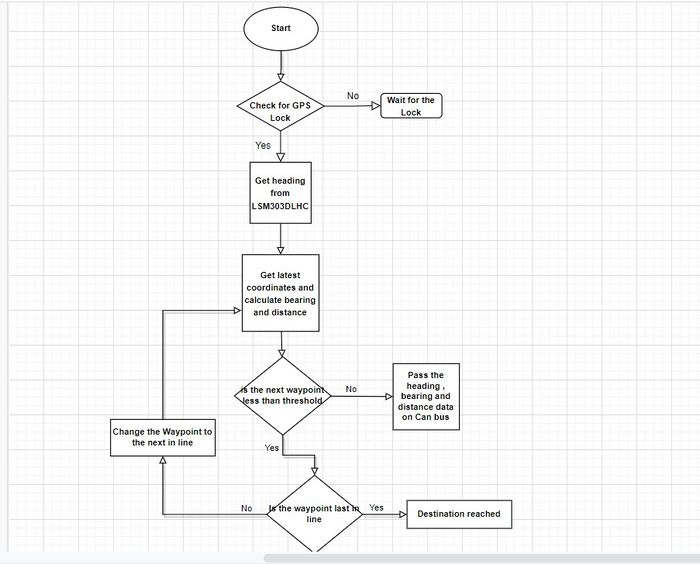

=== Software Design === | === Software Design === | ||

| − | The GEO controller consisted of 4 main parts which are: 1. GPS | + | The GEO controller consisted of 4 main parts which are: |

| + | |||

| + | *1. GPS | ||

| + | *2. Compass | ||

| + | *3. Waypoints | ||

| + | *4. Geo Logic | ||

| + | |||

| + | ====Overview==== | ||

| − | + | These code modules, calculate compass heading degree, bearing, parse GPS coordinates, calculate the checkpoints the RC car has to go through when navigating to a destination, send distance to destination to driver node, and handle messages received on the CAN bus. | |

| − | |||

| − | + | '''The period_callbacks__initialize() function calls the following functions:''' | |

| − | The | ||

| − | + | *can_bus_initializer__init(): initializes the CAN bus to handle MIA and messages(CAN). | |

| − | + | *gps__init(): initializes the GPS interface(UART). | |

| − | + | *geo_compass__setup_magnetometer(): initializes the compass interface(I2C). | |

| − | |||

| − | + | '''The period_callbacks__1Hz() function calls the following function:''' | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | * can_handler__handle_all_incoming_messages_1hz(): handles the incoming messages based on mesg ID. | |

| − | + | * gps__setup_command_registers(): sends command to GPS module to receive only GPGGA string. | |

| − | + | * can_handler__transmit_messages_10hz(): sends the heading ,bearing and distance to Driver controller. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''The period_callbacks__10Hz() function calls the following functions:''' | |

| − | |||

| − | |||

| − | + | *gps_run_once(): parses the NMEA string to get current coordinates | |

| − | + | [[File:FlowChart_Geo_Logic.jpg|center|700px|thumb|Geo Logic Flowchart]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ====GPS==== | |

| + | *In the initialization process of the GPS, the line buffer module is configured to parse the GPS messages, the GPIOs P0.15(Tx) and P0.16(Rx) are configured, UART interrupt queues enabled, and the UART is configured at a baudrate of 9600(GPS standard). | ||

| + | |||

| + | *Configuration | ||

| + | In the gps__run_once_10Hz() the GPS is initially configured once to disable all NMEA messages except GPGGA which is message chosen to parse the coordinates and GPS lock. | ||

| + | |||

| + | *Parsing NMEA GPGGA messages | ||

| + | The GPS module constantly transmits NMEA GPGGA messages over UART to the SJ2 MCU. These messages which come in the form of a string are stored character by character in the line | ||

| + | buffer until a new line character which indicates the end of string. The stored string is then extracted from the line buffer. The extracted line is then tokenized to parse the | ||

| + | latitude, latitude direction, longitude, longitude direction, and fix quality. South and West directions are also properly handled to make the latitude and longitude negative | ||

| + | values. | ||

| + | |||

| + | *GPS lock | ||

| + | Although the GPS module has fix indication , but GPGGA string has field for FIX status also. Getting the Fix/Lock status using the string is much easier than using GPIO pins to get | ||

| + | the Lock status using FIX led of the GPS module. The Lock status/flag was used as a condition to calculate the bearing and checkpoints only when the GPS had a lock meaning that the | ||

| + | current coordinates were valid. | ||

| + | |||

| + | ====Compass==== | ||

| + | |||

| + | *Initialization | ||

| + | The compass initialization configures the LSM303DLHC magnetometer and accelerometer registers over I2C bus to default settings using default gain and single mode. | ||

| + | |||

| + | *Heading degree computation | ||

| + | The compass heading degree is computed by using the tilt compensation algorithm and the pitch and roll values of LSM303DLHC accelerometer. The tilt compensation algorithm ensures | ||

| + | that the values of the compass heading are precise. The formulae used to calibrate the compass are mentioned below: | ||

| + | |||

| + | *Pitch and Roll:<br/> | ||

| + | |||

| + | pitch = asin(-acc_x / sqrt(acc_y * acc_y + acc_z * acc_z + acc_x * acc_x)) <br/> | ||

| + | roll = asin((acc_y / sqrt(acc_y * acc_y + acc_z * acc_z + acc_x * acc_x)) / cos(pitch)) | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Tilt compensated magnetic sensor values:<br/> | |

| − | + | mag_x = mag_x * cos(pitch) + mag_z * sin(pitch) | |

| − | + | mag_y = mag_y * cos(roll) + mag_x * sin(roll) * sin(pitch) - mag_z * sin(roll) * cos(pitch) | |

| + | mag_z = -mag_x * cos(roll) * sin(pitch) + mag_y * sin(roll) + mag_z * cos(roll) * cos(pitch) | ||

| − | |||

| − | |||

| − | + | Luckily our module had no offset but it might need to be compensated for the offset if there is any. | |

| − | + | ||

| − | + | *Heading angle | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | heading = atan2(mag_y, mag_x) * r2d | |

| + | r2d is radian to degree conversion function | ||

| − | + | This heading is calculated in radians since atan2 returns a value between -π and +π. Therefore, before converting the heading into degrees the value needs to be normalized to put | |

| − | + | it in the range from 0 to 360 degrees. | |

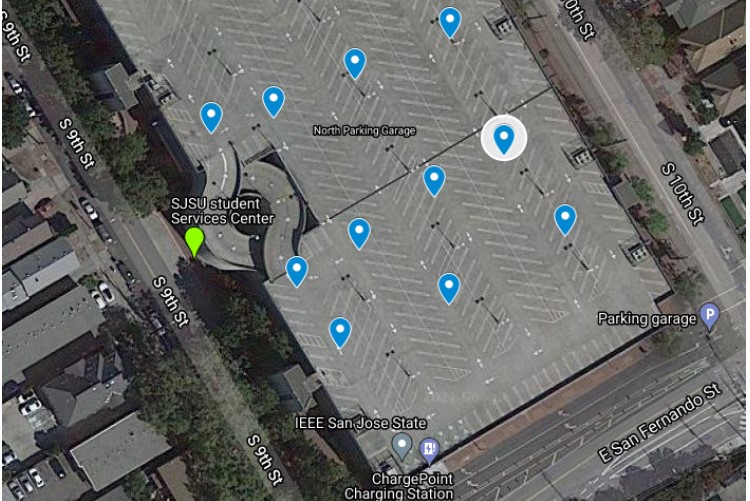

| − | + | ====Checkpoints==== | |

| − | + | In real world, the source and destination are not on a straight line. The car has to find the best possible and smallest route to its final destination. In this project keeping that in mind we have used checkpoint algorithm. These waypoints are known coordinates which are given according to the destination and source path. The car needs to follow the route determined by the waypoints from source to destination. | |

| − | + | We choose 10 points over a known location and hardcoded these coordinates in GEO node logic. Once our car gets the destination coordinates from Bridge and Sensor controller, it starts giving Heading , Bearing and Distance values to Driver Node. This waypoint must satisfy the below conditions: | |

| − | + | * It is the closest waypoint to the current location of the car. | |

| − | + | * Waypoint to destination distance is less than the current coordinate to the final coordinate distance. | |

| − | * | + | [[File:Checkpoint.jpg]] |

| − | * | ||

| − | |||

| − | |||

| − | + | So when the algorithm finds the destination coordinates, then bearing is calculated with that particular coordinate, so that car can be further instructions to move towards that particular point. As shown in the figure below, our algorithm keeps finding new coordinates with time (orange ones) and at last go to the final destination coordinates. The algorithm is mentioned below in the form of flowchart and code: | |

| − | |||

| − | |||

| − | |||

| − | + | The way point calculation determines the nearest way point continuously by computing the distance using Haversine formula and current location using GPS. | |

| − | + | The heading and bearing is also computed using the Haversine formula and is sent over the CAN bus for heading correction.* | |

| − | + | Alternatively, once the car is within the threshold distance, next way point is selected and the car heads to the next way point. | |

| − | |||

| − | |||

| − | + | To calculate the geographical distance between the two points the haversine formula was used which is called periodically from the waypoints.c module. Below is the formula used: | |

| − | === | + | a = sin²(ΔlatDifference/2) + cos(lat1) * cos(lt2) * sin²(ΔlonDifference/2) |

| + | c = 2 * atan2(sqrt(a), sqrt(1−a)) | ||

| + | d = R * c | ||

| − | * | + | *where: |

| − | ** | + | **ΔlatDifference = latitude 2 - latitude 1 (difference of latitude) |

| − | ** | + | **ΔlonDifference = longitude 2 - longitude 1 (difference of longitude) |

| − | ** | + | **R = 6371000.0 meters = radius of earth |

| − | ** | + | **d = distance computed between two points |

| + | **a and c are intermediate steps | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | *Bearing Angle computation | |

| − | |||

| − | + | The bearing which is the angle towards our desired destination is computed using the formulas below referenced at this [https://www.igismap.com/formula-to-find-bearing-or-heading-angle-between-two-points-latitude-longitude/ link]. | |

| − | The | ||

| − | + | X = cos θb * sin ∆L | |

| + | Y = cos θa * sin θb – sin θa * cos θb * cos ∆L | ||

| − | + | β = atan2(X,Y) | |

| − | === | + | *where: |

| + | **θa = current latitude | ||

| + | **θb = destination latitude | ||

| + | **∆L = destination longitude - current longitude | ||

| + | **β = heading degree in radians | ||

| − | + | The bearing is also calculated in radians since atan2 returns a value between -π and +π. Therefore, before converting the heading into degrees the value needs to be normalized to put it in the range from 0 to 360 degrees. The calculated bearing is then sent to the driver node which use the compass heading degree and the bearing to align the car toward the target destination. | |

| − | |||

| − | |||

| − | |||

=== Technical Challenges === | === Technical Challenges === | ||

| − | + | <HR> | |

| + | * Adafruit GPS | ||

| + | ** Problem: The data from the GPS was being refreshed every second which was causing issues for the controller. | ||

| + | *** Solution: Send the command to the GPS module only send the SJ2 board GPGGA data. | ||

| + | ** Problem: It would take way too long for the GPS to have a fix causing a 3-5 minute way when indoors and over 45 seconds when outside | ||

| + | *** Solution: Utilize the external antenna. It was able to get a fix inside in under a minute while outside within 25 seconds. Using separate battery can reduce the fix time. | ||

| + | |||

| + | * Compass | ||

| + | ** Problem: Standalone testing of the controller gave correct data but when integrated with all modules the data was inaccurate (not 0 to 360 degrees). | ||

| + | *** Solution: When mounting the compass module on RC car, mount it away from Motor controller and mount it on some height to avoid any interference with other nodes. | ||

| − | The | + | *General |

| + | ** Problem: The Geo node needs extensive testing with other nodes, if not unit tested and integration tested, it is not going to work properly. | ||

| − | + | == Driver Node == | |

| + | Driver Node is the master controller. It receives input from sensor and bridge node, processes it to make right decision for controlling the speed and steering direction of the car and then commands the motor node to drive accordingly. This node is also interfaced to the LCD, which acts as dashboard of the car and displays information such as car speed and distance to destination on the screen. | ||

| − | < | + | === Hardware === |

| − | < | + | LCD is interfaced with the SJ2 board and it communicates over UART. P4.28 and P4.29 which is UART3 on board is used. |

| + | Headlights and Tailights are also connected to the driver node using four GPIOs. | ||

| + | |||

| + | <li style="display: inline-block;">[[File:SJTWO.jpg|400px|thumb|Left|Sjtwo-board]] </li> | ||

| + | <li style="display: inline-block;">[[File:LCD_DIS.jpg|400px|thumb|Right|LCD Display]] </li> | ||

| + | <li style="display: inline-block;">[[File:Final_Sch2.png|400px|thumb|Right|Pinouts]] </li> | ||

| + | |||

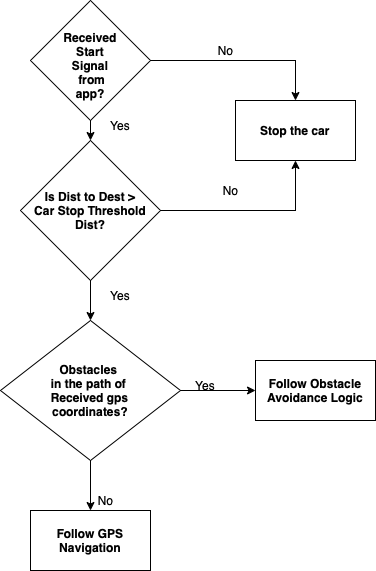

| + | === Software Architecture Driver Logic=== | ||

| + | |||

| + | <div><ul> | ||

| + | <li style="display: inline-block;">[[File:Driver_logic.png|600px|thumb|Left|Basic_Logic]] </li> | ||

| + | <li style="display: inline-block;">[[File:OAL.png|600px|thumb|Center|Obstacle Avoidance Logic]] </li> | ||

| + | <li style="display: inline-block;">[[File:Reverse_func.png|600px|thumb|Right|Reverse Functionality]] </li> | ||

| + | </ul></div> | ||

| − | |||

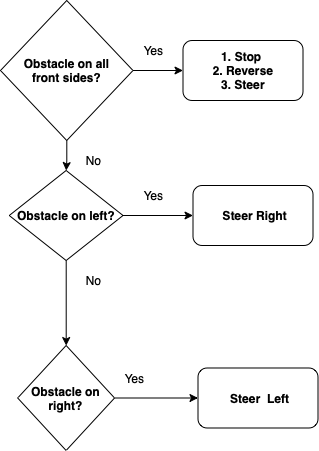

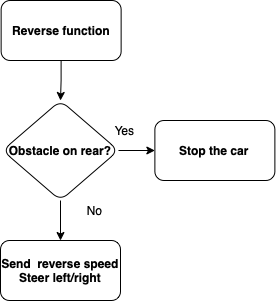

| − | + | === Obstacle Avoidance Logic === | |

| − | == | + | <pre> |

| − | + | if (obstacle_on_all_front_sides()) { | |

| + | stop_the_car(); | ||

| + | reverse_car_and_steer(); | ||

| + | } else if (obstacle_on_left() && obstacle_in_right() && (!obstacle_on_front())) { | ||

| + | drive_forward(); | ||

| + | } else if (obstacle_on_left() && (!obstacle_in_right())) { | ||

| + | obstacle_on_right = false; | ||

| + | get_steering_range(obstacle_on_right); // right steer | ||

| + | } else if (obstacle_in_right() && (!obstacle_on_left())) { | ||

| + | obstacle_on_right = true; | ||

| + | get_steering_range(obstacle_on_right); // left steer | ||

| + | } else if (obstacle_on_front() && (!obstacle_on_left() && !obstacle_in_right())) { | ||

| + | stop_the_car(); | ||

| + | reverse_car_and_steer(); | ||

| + | obstacle_on_right = | ||

| + | (internal_sensor_data.SENSOR_SONARS_right < internal_sensor_data.SENSOR_SONARS_left) ? true : false; | ||

| + | get_steering_range(obstacle_on_right); | ||

| − | + | } else if (obstacle_on_rear() && (!obstacle_on_all_front_sides())) { | |

| + | obstacle_on_right = | ||

| + | (internal_sensor_data.SENSOR_SONARS_right < internal_sensor_data.SENSOR_SONARS_left) ? true : false; | ||

| + | get_steering_range(obstacle_on_right); | ||

| + | debug_values.car_driving_status = FORWARD; | ||

| + | debug_values.car_steering_status = STRAIGHT; | ||

| + | } else { | ||

| + | stop_the_car(); | ||

| − | + | debug_values.car_driving_status = STOPPED; | |

| − | + | debug_values.car_steering_status = STRAIGHT; | |

| − | + | } | |

| − | + | </pre> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''''Steer Left and Right''''' | |

| + | <pre> | ||

| + | if (obstactle_on_right == true) { | ||

| + | motor_signal.DRIVER_TO_MOTOR_direction = MOTOR_direction_HARD_LEFT; | ||

| + | motor_signal.DRIVER_TO_MOTOR_speed = ideal_speed; | ||

| + | if (obstacle_in_right_far()) { | ||

| + | motor_signal.DRIVER_TO_MOTOR_direction = MOTOR_direction_SOFT_LEFT; | ||

| + | motor_signal.DRIVER_TO_MOTOR_speed = ideal_speed; | ||

| + | } else if (obstacle_in_right_near()) { | ||

| + | motor_signal.DRIVER_TO_MOTOR_direction = MOTOR_direction_HARD_LEFT; | ||

| + | motor_signal.DRIVER_TO_MOTOR_speed = reduced_speed; | ||

| + | } | ||

| − | + | } else { | |

| − | + | motor_signal.DRIVER_TO_MOTOR_direction = MOTOR_direction_HARD_RIGHT; | |

| − | + | motor_signal.DRIVER_TO_MOTOR_speed = ideal_speed; | |

| − | + | if (obstacle_on_left_far()) { | |

| − | + | motor_signal.DRIVER_TO_MOTOR_direction = MOTOR_direction_SOFT_RIGHT; | |

| + | motor_signal.DRIVER_TO_MOTOR_speed = ideal_speed; | ||

| + | } else if (obstacle_on_left_near()) { | ||

| + | motor_signal.DRIVER_TO_MOTOR_direction = MOTOR_direction_HARD_RIGHT; | ||

| + | motor_signal.DRIVER_TO_MOTOR_speed = reduced_speed; | ||

| + | } | ||

} | } | ||

| − | + | motor_signal.DRIVER_TO_MOTOR_speed = ideal_speed; | |

| − | + | // motor_signal.DRIVER_TO_MOTOR_speed = ideal_speed; | |

| − | + | } | |

| − | + | ||

| − | + | </pre> | |

| − | + | ||

| − | + | '''''Reverse and Steer''''' | |

| − | + | <pre> | |

| − | + | if (!obstacle_on_rear()) { | |

| − | + | motor_signal.DRIVER_TO_MOTOR_direction = 0; | |

| − | + | motor_signal.DRIVER_TO_MOTOR_speed = reverse_speed; | |

| − | + | update_lights(10, taillight_left); | |

| − | + | update_lights(10, taillight_right); | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

} else { | } else { | ||

| − | + | stop_the_car(); | |

| − | |||

| − | |||

} | } | ||

| − | + | </pre> | |

| − | + | ||

| + | === Navigation to Destination === | ||

| + | Driver receives raw heading and bearing from the Geo node and in order to calculate the turning direction, it first computes the difference between | ||

| + | heading and bearing. Then based on which quadrant the difference lies and where the destination lies, take navigation decisions to steer left, right or straight. | ||

| − | + | <pre> | |

| + | if (heading_difference >= 350 && heading_difference <= 10) { | ||

| + | gps_navigation_direction = straight; | ||

| + | heading_difference = fabs(heading_difference); | ||

| − | + | debug_values.car_driving_status = FORWARD; | |

| − | + | debug_values.car_steering_status = STRAIGHT; | |

| − | + | } else if (heading_difference > 180) { | |

| − | + | gps_navigation_direction = left; | |

| − | if (heading_difference > 180) { | ||

| − | |||

heading_difference = 360 - heading_difference; | heading_difference = 360 - heading_difference; | ||

| + | |||

| + | debug_values.car_driving_status = FORWARD; | ||

| + | debug_values.car_steering_status = LEFT; | ||

| + | |||

} else if (heading_difference < 0 && heading_difference > -180) { | } else if (heading_difference < 0 && heading_difference > -180) { | ||

| − | + | gps_navigation_direction = left; | |

heading_difference = fabs(heading_difference); | heading_difference = fabs(heading_difference); | ||

| − | } else if (heading_difference < -180) { | + | |

| − | + | debug_values.car_driving_status = FORWARD; | |

| − | heading_difference = fabs(360 | + | debug_values.car_steering_status = LEFT; |

| + | } | ||

| + | |||

| + | else if (heading_difference < -180) { | ||

| + | gps_navigation_direction = right; | ||

| + | heading_difference = fabs(heading_difference + 360); | ||

| + | |||

| + | debug_values.car_driving_status = FORWARD; | ||

| + | debug_values.car_steering_status = RIGHT; | ||

} else if (heading_difference > 0 && heading_difference <= 180) { | } else if (heading_difference > 0 && heading_difference <= 180) { | ||

| − | + | gps_navigation_direction = right; | |

| + | |||

| + | debug_values.car_driving_status = FORWARD; | ||

| + | debug_values.car_steering_status = RIGHT; | ||

} | } | ||

| − | + | </pre> | |

| − | + | ||

| − | + | ||

| + | === Periodic Callbacks === | ||

| + | |||

| + | The period_callbacks__initialize() function calls the following functions: | ||

| + | <pre> | ||

| + | can__bus_initializer(can1); | ||

| + | lcd__init(); | ||

| + | head_tail_lights_init(); | ||

| + | debug_led_init(); | ||

| + | </pre> | ||

| − | + | The period_callbacks__1Hz() function calls the following function: | |

| − | + | <pre> | |

| − | + | can_bus_handler_tx_debug_messsages(can1); | |

| − | + | static uint8_t count = 0; | |

| − | + | if (count == 0) { | |

| − | + | lcd__communication_init(); | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

} | } | ||

| − | + | count = 1; | |

| − | + | print_info_on_lcd(); | |

| − | + | </pre> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The period_callbacks__10Hz() function calls the following functions: | |

| + | <pre> | ||

| + | can_bus_handler__process_all_received_messages(can1); | ||

| + | can_bus_handler__manage_mia(); | ||

| + | can_bus_handler_tx_messages(can1); | ||

| + | </pre> | ||