Difference between revisions of "S22: Firebolt"

(→Software Design) |

(→Software Design) |

||

| Line 761: | Line 761: | ||

<br/> | <br/> | ||

| − | [[File: Motor Software design.jpg|center| | + | [[File: Motor Software design.jpg|center|700px|thumb|Speed Control Flowchart]] |

=== Technical Challenges === | === Technical Challenges === | ||

Revision as of 07:50, 23 May 2022

Contents

FireBolt RC Car

Abstract

Firebolt is battery powered autonomous RC car. The car uses four microcontrollers for communication between the nodes- driver node, motor node, bridge & sensor node, and geological node over the CAN bus. It is interfaced to the mobile application which sends GPS coordinates for the destination location to the driver node and reaches the destination by avoiding any obstacles that comes in the path. For obstacle detection and avoidance it uses Ultrasonic Sensor and makes the decision of steering and maintaining speed after performing calculations based on the bridge and sensor node's data.

Objectives & Introduction

Objectives

The objective of this project is to get hands on experience of application of embedded systems in autonomous vehicles, have understanding of CAN bus communication, CAN database files, TDD and other related tools such as PCAN dongle and Busmaster.

Software side:-

- The car can communicate with an Android application

- Receive coordinates from gps to drive itself to the destination while avoiding obstacles

- Send diagnostic information to the LCD display

- Take care of elevation and make right speeding decisions

- DBC file for all the nodes

Hardware side:-

- Design PCB for four controllers and other necessary components

- Choose good options for mounting the ultrasonic sensors on the car

- Make a good GUI Android application for interfacing with the microcontroller

Introduction

Nodes of the RC Car are:

- Driver Node

- GEO Node

- Sensors and Bridge Node

- Motor Node

- Mobile Application

Team Members & Responsibilities

Priyanka Rai

- Geo Controller

- GPS and Compass Interfacing

- Motor Controller

- Integration Testing

- Wiki Page Update

Ritu Patil

- Motor Controller

- RPM sensor(Wheel encoder)

- Geo Controller and GPS interfacing

- Integration Testing

- Wiki Page Update

Ritika Beniwal

- Driver Node

- LCD interfacing

- Motor Controller

- Integration Testing

- Wiki Page Update

Utsav Savaliya

- Sensor Controller

- Integration Testing

- Wiki Page Update

Dhanush Babu

- Bluetooth module interfacing

- Motor Controller

- Android App

- Integration Testing

Noel Smith

- PCB Designing

Schedule

| Week# | Start Date | Target Date | Task | Completion Date | Status |

|---|---|---|---|---|---|

| Week 1 |

|

|

|

|

|

| Week 2 |

|

|

|

|

|

| Week 3 |

|

|

|

|

|

| Week 4 |

|

|

|

|

|

| Week 5 |

|

|

|

|

|

| Week 6 |

|

|

|

|

|

| Week 7 |

|

|

|

|

|

| Week 8 |

|

|

|

|

|

| Week 9 |

|

|

|

|

|

| Week 10 |

|

|

|

|

|

| Week 11 |

|

|

|

|

|

| Week 12 |

|

|

|

|

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Price($) |

|---|---|---|---|---|

| 1 | RC Car | Traxxas [1] | 1 | 280 |

| 2 | CAN Transceivers MCP2551-I/P | Comimark [2] | 5 | 8.99 |

| 3 | Ultrasonic Sensors | Max Botix[3] | 4 | 24.95 |

| 4 | GPS Breakout Board | Adafruit[4] | 1 | 29.95 |

| 5 | GPS Antenna | Adafruit[5] | 1 | 19.95 |

| 6 | RPSMA female to mhf4 | Superbat[6] | 1 | 7.99 |

| 7 | HC05 bluetooth RF Transceiver | HiLetgo[7] | 1 | 15.99 |

| 8 | Triple-axis Accelerometer | Adafruit[8] | 1 | 14.95 |

| 9 | Traxxas RPM Sensor | Traxxas[9] | 1 | 13.76 |

| 10 | Traxxas Battery and Charger | Traxxas[10] | 1 | 62.95 |

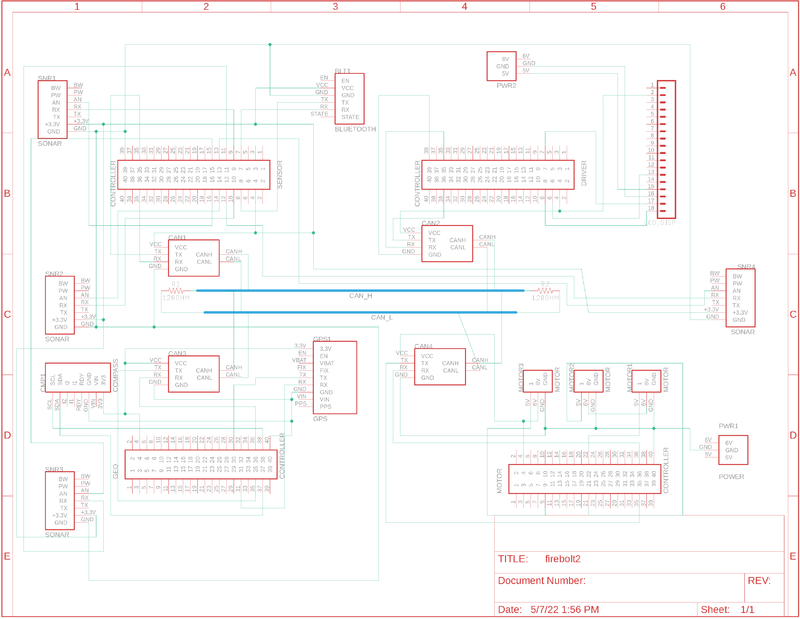

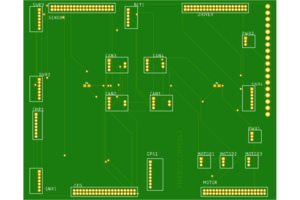

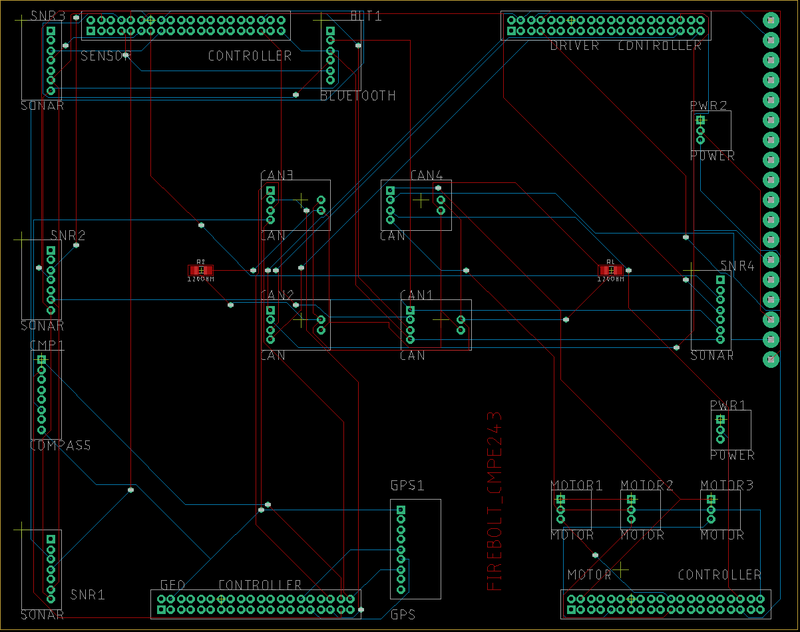

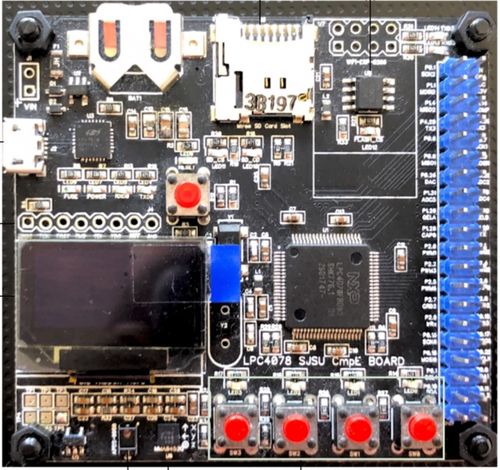

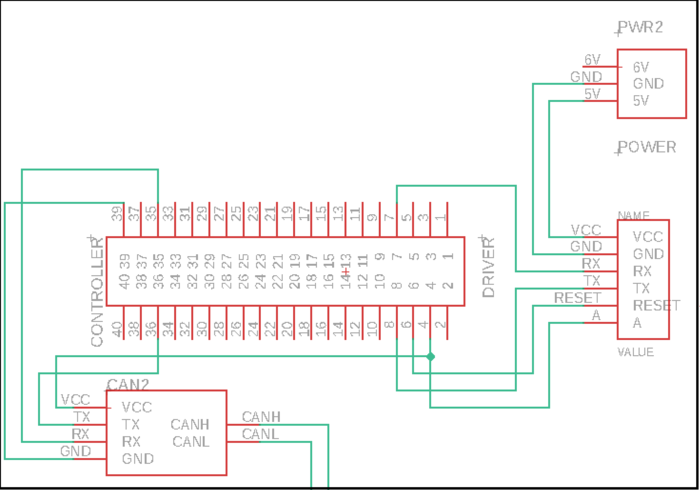

Printed Circuit Board

PCB Schematic

PCB Design

CAN Communication

We use controller area network to broadcast data between the 4 nodes. All nodes are connected to each other through a physically conventional two wire bus. The wires are a twisted pair with 120 Ω resistors at each ends of the bus. 1s and 0s are transmitted as CAN High(0V difference) and Can Low(2v difference). A CAN frame has the following contents:

- Data Length Code (4bits)

- Remote Transmission Request.

- ID extend bit.

- Message ID (11 bit or 29 bit)

- Data bytes( depends on DLC)

- CRC

Arbitration: No two nodes will transmit at the same time because of arbitration. A lower Message-ID has a Higher priority on the CAN bus since 0 is the dominant bit.

Bit Stuffing: CAN bus stuffs extra bits when a long chain of multiple 1's or 0's occur to improve CAN integrity.

DBC File

The DBC file is a simple text file that consists of information for decoding raw CAN bus data to physical values or in human readable form.

| Sr. No | Message ID | Message function | Receivers |

|---|---|---|---|

| Driver command | |||

| 1 | 300 | speed and steering direction for the motor. | Motor |

| 2 | 100 | Driver running | Motor, Sensor, Geo |

| Sensor Controller | |||

| 3 | 200 | Sensor sonars from front, back, left ,right sensor | Driver |

| Motor Controller | |||

| 4 | 600 | motor speed, motor direction | Driver |

| Geo and Bridge Controller | |||

| 5 | 250 | Bearing, Heading and Distance | Driver |

| Debug messages | |||

| 6 | Driver Debug | SENSOR,MOTOR,GEO_AND_BRIDGE | |

| 7 | Motor Debug | SENSOR,MOTOR,GEO_AND_BRIDGE | |

| 8 | Sensor Debug | SENSOR,MOTOR,GEO_AND_BRIDGE | |

The ECUs

In this section we will explain the hardware design, logic and challenges faced during development of every node invloved.

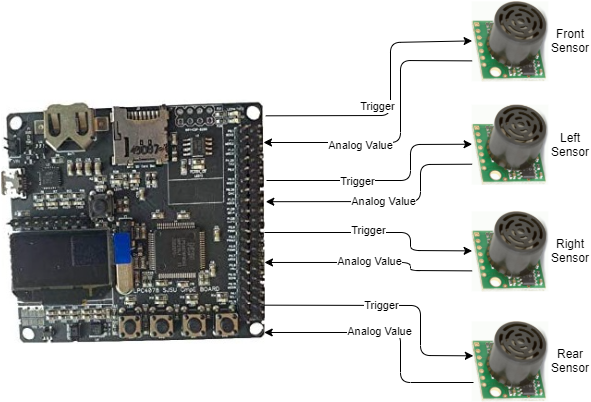

Sensor and Bluetooth ECU

Software Design

Technical Challenges

Neighboring Sensor Interference:

Frequent noisy measurements:

Motor ECU

The Motor ECU acts as an encoder for the DC motor (used for propulsion) and Servo motor (used for turning the axle and changing direction of the car). The car is a two wheel drive with DC motor connected to the rear wheels and the servo motor is connected to the front wheels. The DC motor is controlled by Electronic Speed Control. The ECU supplies PWM signal to the ESC and the ESC powers the DC motor. The Servo motor is powered by the car battery as well and gets its PWM signal from the ECU.

Hardware Design

ESC & DC Motor

The ESC(Electronic Speed Control, Traxxas ESC XL-05) and DC Motor we used were provided with the RC car. The DC motor is controlled by ESC using PWM signals provided by the motor controller for forward and reverse movements. We used the 7.4v LiPo battery to power up the ESC. The DC motor is powered by the ESC which has a dc-to-dc converter which converts 7.4v to 6v. ESC can provide high current to the power-hungry DC motor running at faster speeds. ESC has an LED and a button which is used for calibration and setting different modes for the car.

| Wires on ESC | Description | Wire Color |

|---|---|---|

| PWM(P2.1) | Takes PWM input from SJ2-Board | WHITE |

| VDD(6V) | Power Output | RED |

| GND | Ground | BLACK |

The car can be operated in the following 3 modes:

Sport mode(100% Forward, 100% Brakes, 100% Reverse)

Racing mode(100% Forward, 100% Brakes, No Reverse)

Training mode(50% Forward, 100% Brakes, 50% Reverse)

As we needed more than 50% speed for steep ramps, we used Sport mode. The frequency of the PWM signal fed to the servo motor is 100Hz. Based on the duty cycle set by the user, the car will go forward, reverse, or neutral. 10% - 20% duty cycle for reverse. 15% duty cycle for neutral. 15%-20% duty cycle for the forward motion.

Servo Motor

The servo motor we used is Traxxas 2075 which was provided with the car and it is responsible for steering the car. It takes the 6V power directly from ESC. The servo motor is controlled directly from the SJ2 micro-controller board. The PWM signal fed to the servo motor is of frequency 100Hz. Based on the duty cycle of the signal sent to the servo, it rotates in the left / right direction. 10% - 20% duty cycle for left. 15% duty cycle for straight. 15%-20% duty cycle for right.

| Wires on ESC | Description | Wire Color |

|---|---|---|

| PWM(P2.0) | Takes PWM input from SJ2-Board | WHITE |

| VDD(6V) | Power Input | RED |

| GND | Ground | BLACK |

| Wires on ESC | Description | Wire Color |

|---|---|---|

| GPIO(P0.6) | Provides pulses to Motor SJ2-Board | WHITE |

| VDD(6V) | Power Input | RED |

| GND | Ground | BLACK |

DC Motor

The motor node(SJ-2) interfaces primarily interfaces with:

- Traxass Motor ESC over PWM

- Traxass RPM Sensor over GPIO Interrupt

- Traxass Servo Motor over PWM

All these three components have 3 pins each. The functionalities of these pins are mentioned in the table below.

| Module | Black | Red | White |

|---|---|---|---|

| ESC | Ground | Vout : 6 V | PWM Input |

| Servo | Ground | Vin : 6 V | PWM Input |

| RPM Sensor | Ground | Vin : 6 V | Pulse Output |

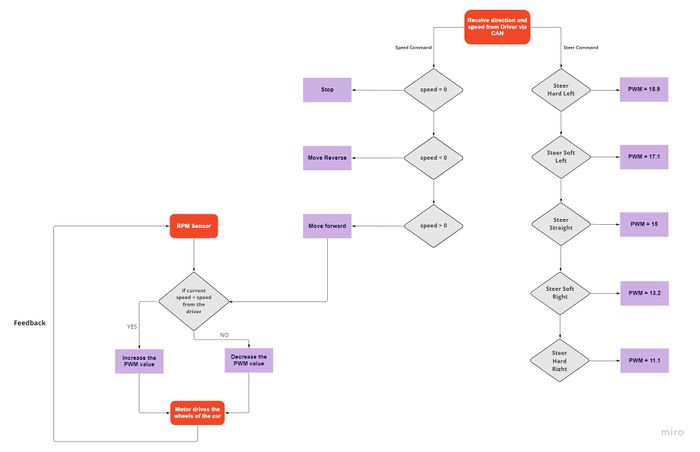

Software Design

The motor node acts based on the speed and direction received over CAN bus from the Driver Node. The positive speed values are treated as forward motion and the negative speed values are considered to be the reverse motion of the RC car.

The steering angles are divided into 5-degree segments and the motor node sends the pre-defined pwm duty cycle of the particular segment to the servo motor depending on the angle value received from the driver node.

Technical Challenges

Geographical And Bridge Controller

Hardware Design

Software Design

The GEO controller consisted of 4 main parts which are: 1. GPS Module 2. Compass 3.Waypoints Algorithm 4. Geo Logic

The Geo logic takes data from GPS module processes it to get current coordinates, takes data from compass for raw heading. After acquiring data from compass and GPS, it calculates heading , bearing and distance and sends it on CAN bus.

1. GPS Processing

The GPS module uses UART1 to communicate with our SJ2 board. The API call for the GPS driver requires setting up the gps registers to only allow GPGGA data to improve processing. The main API function is called gps__run_once() which digests data from the physical GPS hardware. Inside gps__run_once(), we call two functions that help with parsing the gps coordinates. The first is taking using a line buffer for the UART characters that are digested during operation and checking if they are in fact a full GPGGA string. The second function parses those coordinates from the line buffer and converts them from GPGGA minutes data to polar coordinates. Once the function is called, global static variables located in geo_gps.c are used while a gps__get_coorindate() function is called whenever the API's data wants to be used outside of the gps.c file. In order to check if there is a gps fix, we created a function that checks if certain GPGGA bits are set or not.

2.

Technical Challenges

Driver Node

Driver Node is the master controller. It receives input from sensor and bridge node, processes it to make right decision for controlling the speed and steering direction of the car and finally commands the motor node to drive accordingly. This node is also interfaced to an LCD, which acts as dashboard of the car and displays information such as car speed and distance to destination on the screen.

Hardware Design

Software Design

Technical Challenges

Mobile Application

User Interface

Software Design

Maps Activity

Bluetooth/WIFI

Technical Challenges

Conclusion

Project Video

Project Source Code

Advise for Future Students

Acknowledgement

References

http://socialledge.com/sjsu/index.php/Industrial_Application_using_CAN_Bus