Difference between revisions of "S19: Mystery Machine"

Proj user18 (talk | contribs) (→Hardware Design) |

Proj user18 (talk | contribs) (→Hardware Design) |

||

| Line 449: | Line 449: | ||

<Show your CAN bus hardware design> | <Show your CAN bus hardware design> | ||

| − | [[File:CMPE243 S19 RCcar SystemArchitecture.jpg| 800px |Team Logo|Center| System Architecture]] | + | [[File:CMPE243 S19 RCcar SystemArchitecture.jpg| 800px |Team Logo|Center|System Architecture]] |

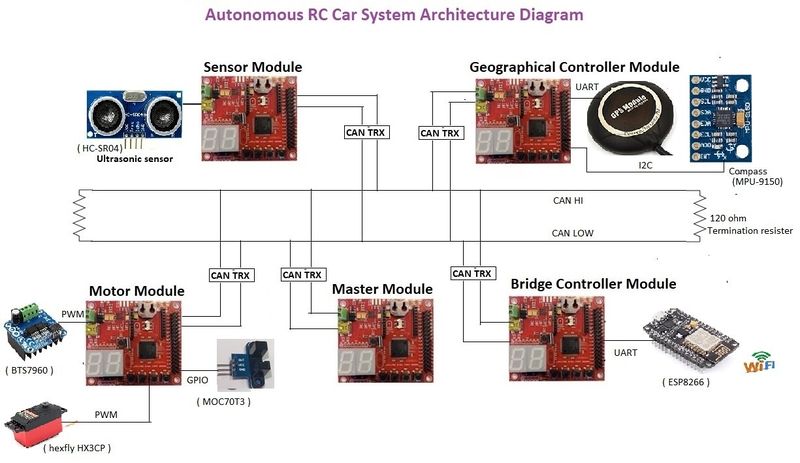

System Nodes: SENSOR, MOTOR, GEO CONTROLLER, BRIDGE, MASTER | System Nodes: SENSOR, MOTOR, GEO CONTROLLER, BRIDGE, MASTER | ||

Revision as of 23:34, 7 May 2019

Contents

Abstract

This project demonstrates the learning involved in Embedded Systems class to design a self-driving car capable of navigating through terrain and avoiding obstacles to reach a destination. The car receives destination GPS coordinates from a custom Android Application and relays back statistics and progress in reaching the target.

Introduction

The objective of this project was to create an autonomous self-driving car which was able to reach the target destination while avoiding obstacles through the terrain. In order to accomplish this, five SJ One boards were used that handled separate functionality of the car:

- Master Controller

- Sensor Controller

- Geo Controller

- Bridge Controller

- Android Application

- Motor and Steering Controller

Team Members & Responsibilities

<Team Picture>

Gitlab Project Link

- Master Controller

- Neeraj Dhavale [Point of Contact]

- Sudarshan Aithal

- Chithambaram Singaravelu Poonkodi

- Tarun Chawla

- Sensor Controller

- Adithya Baskaran [Point of Contact]

- Sudarshan Aithal

- Geo Controller

- Neeraj Dhavale [Point of Contact]

- Sai Kiran

- Bridge Controller

- Sanket Patil [Point of Contact]

- Sai Kiran

- Android Application

- Chithambaram Singaravelu Poonkodi [Point of Contact]

- Neeraj Dhavale

- Motor and Steering Controller

- Tarun Chawla [Point of Contact]

- Rachit Mathur

- Unit Testing

- Chithambaram Singaravelu Poonkodi [Point of Contact]

- Hardware and PCB

- Sanket Patil [Point of Contact]

- Adithya Baskaran

- Documentation

- Rachit Mathur [Point of Contact]

- Sai Kiran

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 |

|

|

|

|

| 2 |

|

|

|

|

| 3 |

|

|

|

|

| 4 |

|

|

|

|

| 5 |

|

|

|

|

| 6 |

|

|

|

|

| 7 |

|

|

|

|

| 8 |

|

|

|

|

| 9 |

|

|

|

|

| 10 |

|

|

|

|

| 11 |

|

|

|

|

| 12 |

|

|

|

|

| 13 |

05/10/2019 |

|

Design and implementation of exterior body |

|

| 14 |

05/17/2019 |

|

Resolve any issues before Final Demo |

|

| 15 |

05/22/2019 |

|

FINAL DEMO |

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Amazon | 1 | $90.00 |

| 2 | CAN Transceivers MCP2551-I/P | AliExpress | 8 | $1.13/piece |

Printed Circuit Board

<Picture and information, including links to your PCB>

CAN Communication

Hardware Design

<Show your CAN bus hardware design>

System Nodes: SENSOR, MOTOR, GEO CONTROLLER, BRIDGE, MASTER

CAN(Controlled Area Network) is a Broadcast Bus which is heavily used in automotive industry. It defines protocol and hardware interface. It operates in standard baudrates like 100k, 125k, 250k, 500k or 1M bps. CAN uses half duplex communication over differential pair. The number of nodes affect the cable length because more CAN transeives add more capacitance to the bus.

An MCU can be interfaced to CAN bus using CAN transceiver and terminated on each end with 120 ohm resistors. Resisters are used to avoid signal reflexion. CAN is frame based communication where each frame contains ID, length(DLC), and up to 8 data bytes.Message ID field can be 11-bit or 29-bit. Only one transmitter can transmit at a time which has highest priority will go ahead first. Low priority message ID's will back-off.Lower message ID wins i.e zero is dominant.

Each node asserts an ACK if it receives a good frame. Software may or may not accept the frames. If no one ACKS, then the message is retransmitted. Depending on the CAN specifications retransmission error can be send and can eventually lead to "Bus off" state.

DBC File

<Gitlab link to your DBC file>

<You can optionally use an inline image>

BU_: DBG DRIVER MASTER IO MOTOR SENSOR LIGHT BRIDGE GEO GATEWAY BO_ 600 SONAR_SENSOR_VALUES: 4 SENSOR SG_ SONAR_SENSOR_VALUES_Left_Sensor : 0|9@1+ (1,0) [0|300] "cm" BRIDGE,MASTER SG_ SONAR_SENSOR_VALUES_Right_Sensor : 9|9@1+ (1,0) [0|300] "cm" BRIDGE,MASTER SG_ SONAR_SENSOR_VALUES_Front_Sensor : 18|9@1+ (1,0) [0|300] "cm" BRIDGE,MASTER BO_ 601 DEMO_IR_SENSOR: 6 SENSOR SG_ LEFT_SENSOR : 0|16@1+ (1,0) [0|0] "LEFT_VALUES" MASTER SG_ RIGHT_SENSOR : 16|16@1+ (1,0) [0|0] "RIGHT_VALUES" MASTER SG_ FRONT_SENSOR : 32|16@1+ (1,0) [0|0] "FRONT_VALUES" MASTER BO_ 602 SONAR_SENSOR_THRESHOLD: 3 BRIDGE SG_ UPDATE_THRESHOLD_VALUE_Left : 0|8@1+ (1,0) [0|0] "cm" MASTER SG_ UPDATE_THRESHOLD_VALUE_Right : 8|8@1+ (1,0) [0|0] "cm" MASTER SG_ UPDATE_THRESHOLD_VALUE_Front : 16|8@1+ (1,0) [0|0] "cm" MASTER BO_ 603 STEER_CMD: 1 SENSOR SG_ SENSOR_STEER_DIRECTION : 0|8@1+ (1,0) [0|0] "DIRECTION" MASTER,BRIDGE BO_ 604 SONAR_REVERSE_SENSOR: 2 SENSOR SG_ SONAR_REVERSE_SENSOR_value : 0|9@1+ (1,0) [0|300] "cm" BRIDGE,MASTER BO_ 700 MOTOR_SPEED: 1 MASTER SG_ MOTOR_SPEED_speed_in_mps : 0|8@1+ (0.01,0) [0|2] "mps" MOTOR,BRIDGE BO_ 701 STEER_DIRECTION: 2 MASTER SG_ STEER_DIRECTION_ANGLE : 0|16@1- (1,0) [0|0] "ANGLE" MOTOR,BRIDGE BO_ 702 DEMO_STEER_DIRECTION: 2 MASTER SG_ STEER_DUTY_CYCLE_VAL : 0|8@1+ (0.01,0) [0|0] "DUTY_CYCLE" MOTOR,BRIDGE BO_ 703 DEMO_MOTOR_SPEED: 2 MASTER SG_ MOTOR_SPEED_DUTY_CYCLE : 0|8@1- (1,0) [-127|127] "DUTY_CYCLE" MOTOR,BRIDGE BO_ 704 MOTOR_FLAG: 1 MOTOR SG_ REVERSE_FLAG : 0|8@1+ (1,0) [0|0] "MOTOR_FLAG" MASTER,BRIDGE BO_ 740 COMPASS_DATA: 2 GEO SG_ COMPASS_HEADING_ANGLE : 0|9@1+ (1,0) [0|0] "DEGREES" MASTER,BRIDGE BO_ 750 GPS_DATA: 8 GEO SG_ GPS_LOCK : 0|1@1- (1,0) [0|0] "" MASTER,BRIDGE SG_ CURRENT_GPS_COORDINATES_X : 8|28@1- (0.000001,0) [36.000000|38.000000] "" MASTER,BRIDGE SG_ CURRENT_GPS_COORDINATES_Y : 36|28@1- (0.000001,0) [-122.000000|-120.000000] "" MASTER,BRIDGE BO_ 751 TELEMETRY: 8 GEO SG_ DISTANCE_TO_DEST : 0|8@1+ (1,0) [0|0] "" MASTER,BRIDGE BO_ 790 MASTER_HEARTBEAT: 1 MASTER SG_ HEART_BEAT : 0|8@1+ (1,0) [0|0] "MASTER_HEARTBEAT" BRIDGE BO_ 800 APP_CMD: 2 BRIDGE SG_ START_COMMAND : 0|8@1+ (1,0) [0|0] "" MASTER SG_ ABORT_COMMAND : 8|8@1+ (1,0) [0|0] "" MASTER BO_ 805 WHEEL_ENCODER: 1 MOTOR SG_ WHEEL_ENCODER_data : 0|7@1+ (1,0) [0|0] "" MASTER,BRIDGE BO_ 810 APP_DESTINATION_GPS: 8 BRIDGE SG_ DEST_GPS_COORDINATES_X : 0|28@1+ (0.000001,0) [0|0] "" GEO SG_ DEST_GPS_COORDINATES_Y : 28|28@1+ (0.000001,0) [0|0] "" GEO BO_ 909 SENSOR_TRIGGER: 1 SENSOR SG_ SENSOR_TRIGGER_Trigger_status : 0|1@1+ (1,0) [0|1] "" BRIDGE BO_ 908 SENSOR_INIT: 1 SENSOR SG_ SENSOR_INIT_init_Status : 0|1@1+ (1,0) [0|1] "" BRIDGE BO_ 910 SENSOR_TIMEOUT: 1 SENSOR SG_ SENSOR_TIMEOUT_left : 0|1@1+ (1,0) [0|1] "" BRIDGE SG_ SENSOR_TIMEOUT_center : 2|1@1+ (1,0) [0|1] "" BRIDGE SG_ SENSOR_TIMEOUT_right : 3|1@1+ (1,0) [0|1] "" BRIDGE SG_ SENSOR_TIMEOUT_reverse : 4|1@1+ (1,0) [0|1] "" BRIDGE BO_ 911 LEFT_SENSOR_ECHO_TIME: 2 SENSOR SG_ LEFT_SENSOR_ECHO_TIME_left_calculation_time : 0|16@1+ (1,0) [0|0] "us" BRIDGE BO_ 912 RIGHT_SENSOR_ECHO_TIME: 2 SENSOR SG_ RIGHT_SENSOR_ECHO_TIME_right_calculation_time : 0|16@1+ (1,0) [0|0] "us" BRIDGE BO_ 913 CENTER_SENSOR_ECHO_TIME: 2 SENSOR SG_ CENTER_SENSOR_ECHO_TIME_center_calculation_time : 0|16@1+ (1,0) [0|0] "us" BRIDGE BO_ 917 REVERSE_SENSOR_ECHO_TIME: 2 SENSOR SG_ REVERSE_SENSOR_ECHO_TIME_reverse_calculation_time : 0|16@1+ (1,0) [0|0] "us" BRIDGE BO_ 914 TOTAL_SENSOR_CALCULATION_TIME: 4 SENSOR SG_ TOTAL_SENSOR_CALCULATION_TIME_total_time : 0|32@1+ (1,0) [0|0] "us" BRIDGE BO_ 915 PERIODIC_SCHEDULER_INIT: 1 SENSOR SG_ PERIODIC_SCHEDULER_INIT_scheduler_init_status : 0|1@1+ (1,0) [0|1] "" BRIDGE BO_ 916 DBG_SENSOR_THRESHOLD: 4 MASTER SG_ THRESHOLD_VALUE_Left : 0|8@1+ (1,0) [0|0] "SONAR_DBG" BRIDGE SG_ THRESHOLD_VALUE_Right : 8|8@1+ (1,0) [0|0] "SONAR_DBG" BRIDGE SG_ THRESHOLD_VALUE_Front : 16|8@1+ (1,0) [0|0] "SONAR_DBG" BRIDGE SG_ THRESHOLD_VALUE_Reverse : 24|8@1+ (1,0) [0|0] "SONAR_DBG" BRIDGE BO_ 921 SPEED_CMPS: 1 MOTOR SG_ SPEED_CMPS_car : 0|7@1+ (1,0) [0|0] "CAR SPEED IN CM/S" MASTER,BRIDGE BO_ 926 MOTOR_DUTY: 1 MOTOR SG_ MOTOR_DUTY_CYCLE : 0|7@1+ (1,0) [0|1] "" MASTER,BRIDGE BO_ 922 ROTATIONS_PER_SECOND: 1 MOTOR SG_ ROTATIONS_PER_SECOND_WHEELS : 0|7@1+ (1,0) [0|0] "CAR SPEED IN ROTATIONS/SECOND" MASTER,BRIDGE BO_ 923 STEER_DUTY_LEFT: 1 MOTOR SG_ DUTY_CYCLE_LEFT : 0|7@1+ (1,0) [0|1] "" MASTER,BRIDGE BO_ 924 STEER_DUTY_RIGHT: 1 MOTOR SG_ DUTY_CYCLE_RIGHT : 0|7@1+ (1,0) [0|1] "" MASTER,BRIDGE BO_ 925 STEER_DUTY_CENTRE: 1 MOTOR SG_ DUTY_CYCLE_CENTRE : 0|7@1+ (1,0) [0|1] "" MASTER,BRIDGE

Sensor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Unreliable sonor sensors

<Problem Summary> <Problem Resolution>

Motor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Unreliable Servo Motors

<Problem Summary> <Problem Resolution>

Geographical Controller

<Picture and link to Gitlab>

The Geographical controller is responisable for navigating the car in the direction of destination selected in the android app. It uses GPS module which gives the current location of the car and compass module for getting the heading angle of the car. After a destination location is selected in the android app, using the shortest path algorithm, the app generates a pirticular number of check points. These check points are then send to bridge controller. Now Bridge controller sends one check point at a time to the Geographical controller. Geo controller uses its current location and the destination location(check point) to calculate the bearing angle and the distance to the destination. Subsequently, heading angle and bearing angle are used to determine the angle that the car should turn, and sent to the master module. On reaching destination, the car will stop.

Hardware Design

Two modules are used in Geograpgical controller: GPS and Compass

GPS

Ublox NEO-7M GPS Module is used for detecting the location of the car. This module returns NMEA string which need to be parsed to get lock, latitude and longitude values from the module. To use the GPS string first we need to get lock. Values read are valid only if we get GPS lock.

COMPASS

The MPU-9150 is first integrated 9-axis MotionTracking device that combines a 3-axis MEMS gyroscope, a 3-axis MEMS accelerometer, a 3-axis MEMS magnetometer and a Digital Motion Processor hardware accelerator engine. The MPU9150’s 9-axis MotionFusion combines acceleration and rotational motion plus heading information into a single data stream for the application.

The MPU-9150 features three 16-bit analog-to-digital converters (ADCs) for digitizing the gyroscope outputs, three 16-bit ADCs for digitizing the accelerometer outputs and three 13-bit ADCs for digitizing the magnetometer outputs. For precision tracking of both fast and slow motions, the parts feature a userprogrammable gyroscope full-scale range of ±250, ±500, ±1000, and ±2000°/sec (dps), a user programmable accelerometer full-scale range of ±2g, ±4g, ±8g, and ±16g, and a magnetometer full-scale range of ±1200µT.

Communication with all registers of the device is performed using I2C at 400 kHz.

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Unreliable GPS lock

<Problem Summary> <Problem Resolution>

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Insane Bug

<Problem Summary> <Problem Resolution>

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Improper Unit Testing

<Problem Summary> <Problem Resolution>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Wifi Link Reliability

<Problem Summary> <Problem Resolution>

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

Advise for Future Students

<Bullet points and discussion>