S14: Virtual Dog

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Contents

Project Title : Virtual Dog - An Object Following Robot

Abstract

This section should be a couple lines to describe what your project does.

In this project, we plan to build a device which would be able to track and follow a particular object. So if suppose that object is you, that device will follow you just like your dog. This tracking and following will be done in two dimensions, i.e. not just forward-backward movement, but left-right also. This can be achieved with the help of two devices, one will be used as reference and other device will continuously keep on monitoring the reference device. If position of reference device changes other device rearranges its position so as to maintain the desired relationship between them.

Objectives & Introduction

The main objective is to build an object following robot, which will follow a particular object in 2-Dimension. To make the robot follow at the same speed as of object we used four DC motor for the four wheels of robot so that it can accelerate the robot to desired speed. To keep track of object movement we used three proximity sensors (20cm-150cm) so that the robot can easily track the object. To power up the robot we used two batteries, one of 5V and other of 12V. 5V battery is used to power up the SJOne Board and 12V battery is required to run the DC motors. We have also implemented an Android App to start/stop robot and read the realtime statistics of sensors and our algorithm. To display the value of sensor as well as decision taken by robot on Android App we used Bluetooth module.

Team Members & Responsibilities

- Hari

- Implemented sensor driver and algorithm to normalize sensor values, Android Application.

- Manish

- Implemented central control logic and FSM.

- Viral

- Implemented motor driver and Motor State Machine, bluetooth driver.

Schedule

| Week# | Task | Estimated Completion Date |

Status | Notes |

|---|---|---|---|---|

| 1 | Order Parts | 3/16 | Partially Completed | Not finalized with sensor for distance measurement. Ordered other parts. |

| 2 | Sensor Study | 3/23 | Completed (3/30) | Research on sensors took more time than expected due speed constrains of sensors conflicting with our requirement. Finally decided to move with IR proximity sensor. Sensors ordered. |

| 3 | Sensor Controller Implementation | 3/30 | Completed (4/6) | Three sensors interfaced with on board ADC pins. Controller implemented to determine direction of movement based on those three sensors |

| 4 | Servo and Stepper Motor Controller Implementation | 4/6 | Completed (4/6) | Initially planned to use stepper motor for steering and servo to move robot. But due to power constraints, decided to use DC motors to make a 4WD robot. Controller implemented to move and turn robot based on differential wheel speeds. |

| 5 | Central Controller Logic Implementation | 4/13 | Completed (4/13) | Integrated both controllers and developed basic logic to control wheels based on sensor input. |

| 6 | Assembly and Building Final Chassis | 4/20 | Completed (4/20) | Mounted all hardware parts on chassis to make a standalone robot. Central controller logic is still tuning. |

| 7 | Unit Testing and Bug Fixing | 4/27 | Completed (5/4) | Tested various combinations of object movement and tuned our algorithm accordingly. Tuning of algorithm took more time than expected because of many corner cases. |

| 8 | Testing and Finishing Touch | 5/4 | Completed (5/11) | Faced strange problem at final stages. Earlier sensors were giving linear output for distance v/s ADC value. Over the period we realized that our robot is not following the way it used to follow earlier. So we need to calibrate distance v/s ADC value again, and based on that we required to change our algorithm. |

| 9 | Android Application using Bluetooth | N/A | Completed (5/22) | Developed an Android Application through which we can start and stop our robot and able to collect realtime data for sensor values as well as decisions taken by robot. |

Parts List & Cost

| # | Part Description | Quantity | Manufacturer | Part No | Cost |

|---|---|---|---|---|---|

| 1 | SJOne Board | 1 | Preet | $80.00 | |

| 2 | IR Distance Sensor (20cm - 150cm) | 3 | Adafruit | GP2Y0A02YK | $47.85 |

| 3 | DC Motor (12V) | 4 | HSC Electronics | $6.00 | |

| 4 | Wheels | 4 | Polulu | $8.00 | |

| 5 | Battery 5V/1A 10000mAh | 1 | Amazon | $40 | |

| 6 | Battery 12V/1A 3800mAh | 1 | Amazon | $25 | |

| 7 | LM2938D (Motor Driver IC) | 2 | HSC Electronic | $5.40 | |

| 8 | Chassis | 2 | Walmart | $12.00 | |

| 9 | Accessories (jumper wires, nut-bolts, prototype board, USB socket) | $20.00 | |||

| 10 | RN42-XV Bluetooth Module | 1 | Sparkfun | WRL-11601 | $20.95 |

| Total (Excluding Shipping and Taxes) | $265.20 |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

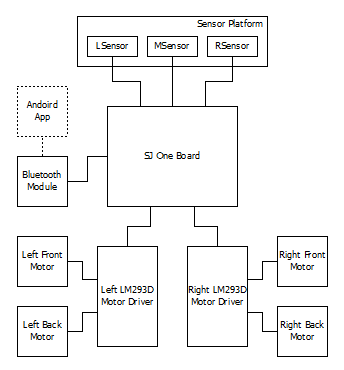

Hardware Design

All the three proximity sensor will measure their respective value analog and send it to the ADC pin of the SJOne board which will convert it to the digital value,the convert digital value will be utilized to determine the distance between the robot and the object. Based on the calculated distance the PWM value is determine for each DC motor, these PWM value is given as input to the DC motor via LM293D IC. The Bluetooth device will read the value of the sensor from the SJOne board through UART and send it to the Android App which will display the value of sensor as well as decision taken by robot.

DC Motor

We are using four DC motor for our project, the DC motor we are using has following rating 5-12V, 0.16Amp, 2000RPM. We are using DC motor so that we can provide 360 degree rotation to our robot wheel as well as it can help to drive the robot at a very high speed.

We are using four DC motor for our project, the DC motor we are using has following rating 5-12V, 0.16Amp, 2000RPM. We are using DC motor so that we can provide 360 degree rotation to our robot wheel as well as it can help to drive the robot at a very high speed.

Proximity Sensor

This SHARP distance sensor bounces IR off objects to determine how far away they are. It returns an analog voltage that can be used to determine how close the nearest object is. These sensors are good for detection between 20cm-150cm.

This SHARP distance sensor bounces IR off objects to determine how far away they are. It returns an analog voltage that can be used to determine how close the nearest object is. These sensors are good for detection between 20cm-150cm.

LM293D IC

L293D is a typical Motor driver or Motor Driver IC which allows DC motor to drive on either direction. L293D is a 16-pin IC which can control a set of two DC motors simultaneously in any direction. It means that you can control two DC motors with a single L293D IC.

L293D is a typical Motor driver or Motor Driver IC which allows DC motor to drive on either direction. L293D is a 16-pin IC which can control a set of two DC motors simultaneously in any direction. It means that you can control two DC motors with a single L293D IC.

Bluetooth Module

The RN-42 is compatible with the Bluetooth versions 2 and below. The advantage of using this module is it's low power and at the same time can provide a good data rate. This provides a high performance on chip antenna where data rates upto 3Mbps are transferred. The disadvantage is that, it has a very less distance which is approximately 20 meters. There is a pull up circuit of 1k to the Vcc. This is provided so that if the input power supply has instability or tends to bounce which causes the that device to be damaged. There is separate pin allocated for the Factory Reset such that this comes into the picture when the module is misconfigured. The toggle of the specific GPIO pins indicate the status of the module. When toggled at 1Hz, the module is discoverable and is waiting for a connection. When at 10Hz, it made to change to the command mode. If it is very low, then module is already connected to another device over the bluetooth.

The RN-42 is compatible with the Bluetooth versions 2 and below. The advantage of using this module is it's low power and at the same time can provide a good data rate. This provides a high performance on chip antenna where data rates upto 3Mbps are transferred. The disadvantage is that, it has a very less distance which is approximately 20 meters. There is a pull up circuit of 1k to the Vcc. This is provided so that if the input power supply has instability or tends to bounce which causes the that device to be damaged. There is separate pin allocated for the Factory Reset such that this comes into the picture when the module is misconfigured. The toggle of the specific GPIO pins indicate the status of the module. When toggled at 1Hz, the module is discoverable and is waiting for a connection. When at 10Hz, it made to change to the command mode. If it is very low, then module is already connected to another device over the bluetooth.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

Send me your zipped source code and I will upload this to SourceForge and link it for you.

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.