Difference between revisions of "F14: Self Driving Undergrad Team"

Proj user8 (talk | contribs) (→I/O Team Software Design) |

Proj user8 (talk | contribs) (→Motor Pin Connections) |

||

| Line 678: | Line 678: | ||

Discuss your hardware design of Sensor Controller | Discuss your hardware design of Sensor Controller | ||

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS | *INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

==== Motor Controller Team Hardware Design ==== | ==== Motor Controller Team Hardware Design ==== | ||

Revision as of 22:42, 30 November 2014

Contents

- 1 Grading Criteria

- 2 In Memory of Chi Lam

- 3 Self-Driving Autonomous Car

- 4 Abstract

- 5 Objectives & Introduction

- 6 Schedule

- 7 Parts List & Cost

- 8 Design & Implementation

- 8.1 Hardware Design

- 8.1.1 Sensor Controller Team Hardware Design

- 8.1.2 Motor Controller Team Hardware Design

- 8.1.3 Motor Pin Connections

- 8.1.4 I/O Team Hardware Design

- 8.1.5 I/O Pin Connections

- 8.1.6 Communication Bridge + Android Hardware Design

- 8.1.7 Communication Bridge Pin Connections

- 8.1.8 Geographical Controller Team Hardware Design

- 8.1.9 Master Controller Team Hardware Design

- 8.2 Hardware Interface

- 8.3 Software Design

- 8.4 Software Interface

- 8.4.1 Sensor Controller Team Software Interface

- 8.4.2 Motor Controller Team Software Interface

- 8.4.3 I/O Team Software Interface

- 8.4.4 Communication Bridge + Android Software Interface

- 8.4.5 Geographical Controller Team Software Interface

- 8.4.6 Master Controller Team Software Interface

- 8.4.7 CAN Communication Table

- 8.1 Hardware Design

- 9 Testing

- 10 Technical Challenges

- 11 Conclusion

- 12 References

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

In Memory of Chi Lam

June 7th, 1991 - October 27th, 2014

This project is dedicated to Chi Lam, a beloved friend, dedicated Computer Engineering student, and member of this team.

You will be missed, friend.

Self-Driving Autonomous Car

Abstract

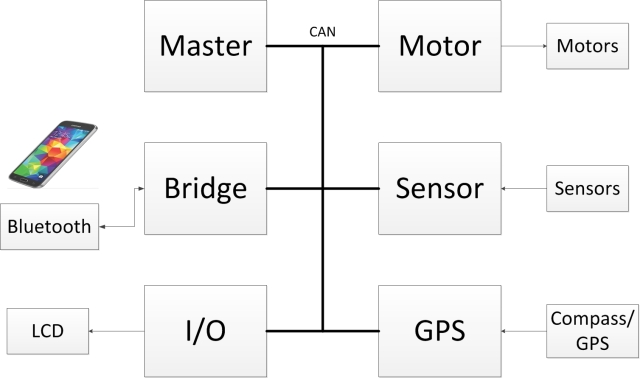

The objective of the project is to create a self-driving autonomous car in a 15 person team. The car utilizes several components and sensors in order to get from Point A to Point B. Implementation of the car involves multiple SJONE processor boards using FreeRTOS to communicate with each other via CAN bus.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

| Master Controller Team | ||

|---|---|---|

| Charles Pham | Joshua Ambion | Michael Schneider |

| - Overall vehicle logic - Overall software vehicle Integration - CAN TX/RX messages architecture |

- Vehicle hardware - Assistant to other teams - Module specific logic |

- Module specific logic - CAN RX processing |

| Motor Controller Team | |

|---|---|

| Nikko Esplana | Chi Lam |

| - Motor/steering control via PWM signals - interface/test/attach wheel encoder |

- Rest in peace Chi! |

| Sensor Controller Team | |

|---|---|

| Sanjay Maharaj | Wei-chieh "Andy" Lo |

| - | - |

| Geographical Controller Team | ||

|---|---|---|

| Carlos Fernandez-Martinez | Zach Baumgartner | Albert Chen |

| - Compass calibration/integration | - GPS testing/integration | - CAN communication |

| Bridge Controller Team | ||

|---|---|---|

| Robert Julius | Tim Martin | Joseph Bourne |

| - Android Application | - Bluetooth Message Interface | - Board to CAN Communication |

| IO Controller Team | |

|---|---|

| Devin Villarosa | George Sebastian |

| - | - |

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

Final Product Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/12 | CAN Network Benchtest | Complete |

| 2 | 10/15 | Basic CAN Communication | Complete |

| 3 | 10/31 | Secure devices to R/C car | Complete |

| 4 | 11/7 | Basic Vehicle Self-Driving Test | In progress |

| 5 | 11/14 | P2P testing and improved obstacle avoidance | In progress |

| 6 | 11/31 | Buffer time for previous tasks and increased vehicle speed | In progress |

Sensor Controller Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/13 | Sensor Input Distance Calibration | Incomplete: Sonar is mostly calibrated, IR still needs work. Need sensor value "filtering" logic. |

| 2 | 10/17 | Off car CAN network test (full team) | Completed. Able to send raw sensor value to master. |

| 3 | 10/20 | Interface Sensors with CAN | Completed. Updates to the formatting of data being sent is ongoing. |

| 4 | 10/27 | Mount Sensors and test coverage | Completed. Still need to mount with actual brackets. |

| 5 | 10/31 | Mount Sensors with 3d printed brackets | Completed. IR brackets to be printed based on offset. |

| 6 | 11/1 | Implement diagnostic LED patterns | In progress. |

| 7 | 11/3 | Send obstacle avoidance decisions to master | Completed. Raw values sent to master for processing. |

| 8 | 11/4 | Add RJ11 cabling to all sensors | Completed. Still need to make neat and tidy. |

| 9 | 11/10 | Implement speed sensitivity | In progress |

| 10 | 11/13 | Test sensors during outdoor runs | In progress |

| 11 | 11/17 | Check wiring and label parts | In progress |

| 12 | 11/24 | Continue testing and tuning as necessary | In progress |

Motor Controller Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/12 | Open up servo and motor modules,

find a speed sensor |

Complete |

| 2 | 10/19 | Interface/test PWM bus to steering servo and DC motor | Complete |

| 3 | 10/26 | Allow self-driving capability with master/bridge/sensor teams | Incomplete, only partial self-driving achieved |

| 4 | 11/2 | Improve fine motor movements with master/sensor teams | In progress |

| 5 | 11/9 | Once wheel encoder comes in, learn/test/implement onto car | In progress |

| 6 | 11/16 | Integrate wheel encoder with rest of car | In progress |

| 7 | 11/23 | Test for proper operation | In progress |

| 8 | 11/30 | Continue testing until proper operation | In progress |

I/O Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/4 | Create LCD Screen Library (create ability to set value, get value, and write string to LCD screen) | 10/4 (String function completed on ~10/18) |

| 2 | 10/4 | Create LCD Screen GUI (generate forms for debugging and general usage) | 10/4 |

| 3 | 10/11 | LCD Library Test (Do unit tests on individual functions for LCD library)

Ability to get value from gauge on screen. Ability to set value to gauge on screen. Ability to send a string value to screen. |

10/11 (Finished string function on ~10/18) |

| 4 | 10/11 | Interface LCD with CAN

Create task for LCD event loop. Create task for Receiving on CAN. |

Complete (Completed on 10/26/2014) |

| 5 | 10/18 | Test LCD with CAN

Process CAN Messages from system |

Complete (Completed on 10/25/2014) |

| 6 | 10/25 | Implement onto Final Product | Incomplete (ready for implementation) |

| 7 | 11/2 | Headlights for car (hardware and software) + Aesthetics for GUI + Clean up code |

Communication Bridge and Android Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/13 | CAN Network Test | Complete |

| 2 | 10/20 | Interface Bluetooth Module with CAN | Complete |

| 3 | 10/27 | Mount PCB on car | In progress |

| 4 | 11/3 | Create basic Android application | Completed on 10/18 |

| 5 | 11/10 | Add map onto the Android application | In Progress |

| 6 | 11/17 | Send/receive CAN Messages via Android Application | Sending completed on 10/18, receiving in progress |

| 7 | 11/24 | Debug and Optimize Android Application | In progress |

| 8 | 12/1 | Continue Debugging and Optimizing as Necessary | In progress |

Geographical Controller Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/8 | Interface with GPS/Compass | Completed no issues encountered |

| 2 | 10/15 | Finish core API | In progress |

| 3 | 10/22 | GPS get fix and receive raw data | In progress |

| 4 | 10/22 | Compass determine heading | In progress |

| 5 | 10/29 | Self calibration completed | In progress |

| 6 | 10/29 | GPS parse raw data to extract needed data | In progress |

| 7 | 10/29 | Compass use heading from GPS to improve accuracy | In progress |

| 8 | 11/5 | Improve GPS satellite procurement (antennae?) | In progress |

| 9 | 11/12 | Improve boot up time of GPS module via warm start | In progress |

| 10 | 11/12 | Fine tune compass calibration technique for accuracy | In progress |

| 10 | 12/3 | Buffer time for completion of previous tasks | In progress |

Master Controller Schedule

| Line Item # | Expected End Date | Task | Status |

|---|---|---|---|

| 1 | 10/15/14 | Decide on raw CAN struct architecture | Early completion |

| 2 | 10/18/14 | Develop and layout general common CAN messages | On-time completion |

| 3 | 10/20/14 | Design vehicle initialization procedure | Early completion |

| 4 | 10/23/14 | Develop and layout Inter-Controller Communication - Each Module's CAN messages | Early completion |

| 5 | 10/25/14 | Design vehicle initial running freed drive mode procedure - Controlled via Phone, no object detection and avoidance, no GPS, no Heading | Early completion |

| 6 | 10/28/14 | Complete design on vehicle running free drive mode procedure | On-time completion |

| 7 | 10/30/14 | Design vehicle initial running indoor drive mode procedure - Timed autonomous drive , object detection and avoidance, (possibly heading), and no GPS | In progress |

| 8 | 11/01/14 | All CAN message definitions complete | Early Completion |

| 9 | 11/02/14 | Design vehicle initial running gps drive mode procedure - Full autonomous drive , object detection and avoidance, heading and GPS | In progress |

| 10 | 11/05/14 | All CAN message receive processing complete | In progress |

| 11 | 11/14/14 | All basic vehicle functionality state machines implemented and verified | In progress |

| 12 | 11/15/14 | Complete design on vehicle running indoor drive mode procedure | In progress |

| 13 | 11/20/14 | Complete design on vehicle running gps drive mode procedure | In progress |

| 14 | 11/30/14 | Any additional advanced functionality implemented and verified | In progress |

Parts List & Cost

| Line Item# | Part Desciption | Vendor | Part Number | Qty | Cost ($) |

|---|---|---|---|---|---|

| 1 | CAN Board | Waveshare International Limited | SN65HVD230 | 15 | 92.00 |

| 2 | Traxxas Slash Pro 2WD Short-Course R/C Truck | Traxxas | 58034 Slash | 1 | 337.00 |

| 3 | Adafruit Ultimate GPS Breakout | Adafruit | MTK3339 | 1 | 39.95 + (4.685 Shipping) |

| 4 | Triple-axis Accelerometer+Magnetometer (Compass) Board | Adafruit | LSM303 | 1 | 14.95 + (4.685 Shipping) |

| 5 | 3.5" Intelligent module w/ Touch | 4D Systems | uLCD 35DT | 1 | 89.00 |

| 6 | 2GB microSD Card | ||||

| 7 | uUSB-PA5 Programming Adaptor | ||||

| 8 | 150mm 5 way Female-Female jumper cable | ||||

| 9 | 5 way Male-Male adaptor | ||||

| 10 | Sharp Infrared Range Finder | 4D Systems | GP2Y0A21 | 2 | 9.95 + 3.32 Shipping |

| 12 | SainSmart Sonar Ranging Detector | Amazon | HC-SR04 | 3 | 5.59 |

| 13 | RC LED Headlights | Amazon Prime | 2 | 5.99 | |

| 14 | XBee Bluetooth | ||||

| 15 | |||||

| Additional Shipping | $$$.$$ | ||||

| Total Cost | $$$.$$ |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss System Level Hardware Design

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS

Sensor Controller Team Hardware Design

Discuss your hardware design of Sensor Controller

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS

Motor Controller Team Hardware Design

Discuss your hardware design of Motor Controller

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS

Motor Pin Connections

| Line Item# | Pin | SJONE Board Pin | Description |

|---|---|---|---|

| 1 | +3.3V | 3V3 | SJOne Power |

| 2 | GND | GND | SJOne Ground |

| 3 | CAN Tx | P0.1 (Tx) | SJOne - CAN Tx |

| 4 | CAN Rx | P0.0 (Rx) | SJOne - CAN Rx |

| 5 | P2.0 PWM | Steering | |

| 6 | P2.1 PWM | Motor | |

| 7 | ESC Ground | GND | SJONE - ESC Ground |

I/O Team Hardware Design

Discuss your hardware design of I/O

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS

I/O Pin Connections

| Line Item# | Pin | SJONE Board Pin | Description |

|---|---|---|---|

| 1 | 1 (LCD +5V) | 5.5V | uLCD 35DT LCD Power |

| 2 | 7 (LCD GND) | GND | uLCD 35DT LCD Ground |

| 3 | 5 (LCD RX) | RX3 | uLCD 35DT LCD Receive Pin |

| 4 | 3 (LCD TX) | TX3 | uLCD 35DT LCD Transmit Pin |

| 5 | +3.3V | 3V3 | SJOne Power |

| 6 | GND | GND | SJOne Ground |

| 7 | UART2 RX | P2.9 | SJOne RX |

| 8 | UART2 TX | P2.8 | SJOne TX |

| 9 | +5V | GPIO P2.0 | White LED1 |

| 10 | +5V | GPIO P2.1 | White LED2 |

| 11 | +5V | GPIO P2.2 | Red LED1 |

| 12 | +5V | GPIO P2.3 | Red LED2 |

| 13 | CAN Tx | P0.1 (Tx) | SJOne - CAN Tx |

| 14 | CAN Rx | P0.0 (Rx) | SJOne - CAN Rx |

| 15 | CAN Power | 3.3V | SJOne - CAN Power |

| 16 | CAN Ground | GND | SJOne - CAN Ground |

Communication Bridge + Android Hardware Design

Discuss your hardware design of Communication Bridge and Android

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS

Communication Bridge Pin Connections

| Line Item# | Pin | SJONE Board Pin | Description |

|---|---|---|---|

| 1 | Tx (Bluetooth) | P0.10 (TXD2) | Bluetooth Transmit |

| 2 | Rx (Bluetooth) | P0.11 (RXD2) | Bluetooth Receive |

| 3 | CAN Tx | P0.1 (Tx) | SJOne - CAN Tx |

| 4 | CAN Rx | P0.0 (Rx) | SJOne - CAN Rx |

| 5 | CAN Power | 3.3V | SJOne - CAN Power |

| 6 | CAN Ground | GND | SJOne - CAN Ground |

Geographical Controller Team Hardware Design

Discuss your hardware design of Geographical Controller

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS

Master Controller Team Hardware Design

Discuss your hardware design of Master Controller

*INCLUDE BLOCK DIAGRAM and PIN CONNECTIONS

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

SYSTEM LEVEL HARDWARE INTERFACE INTERFACE GOES HERE

Sensor Controller Team Hardware Interface

Describe how your hardware communicates. WHAT BUSes were used

*SHOW HOW FRAMES ARE SENT

Motor Controller Team Hardware Interface

Discuss your hardware design of Motor Controller

*SHOW HOW FRAMES ARE SENT

I/O Team Hardware Interface

Discuss your hardware design of I/O

*SHOW HOW FRAMES ARE SENT

Communication Bridge + Android Hardware Interface

Discuss your hardware design of Communication Bridge and Android

*SHOW HOW FRAMES ARE SENT

123

Geographical Controller Team Hardware Interface

Discuss your hardware design of Geographical Controller

*SHOW HOW FRAMES ARE SENT

Master Controller Team Hardware Interface

Discuss your hardware design of Master Controller

*SHOW HOW FRAMES ARE SENT

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

SYSTEM LEVEL SOFTWARE DESIGN GOES HERE

Sensor Controller Team Software Design

Describe how your hardware communicates. WHAT BUSes were used

*SHOW SOFTWARE FLOWCHART DIAGRAM

Motor Controller Team Software Design

Discuss your hardware design of Motor Controller

*SHOW SOFTWARE FLOWCHART DIAGRAM

Insert non-formatted text here==== I/O Team Software Design====

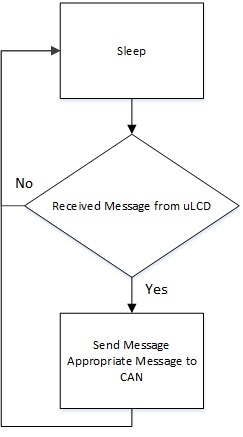

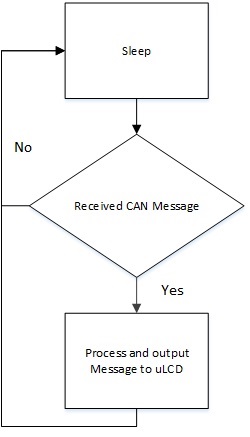

The I/O Software is based off of two tasks: The Event Handler Task and the RX Task.

Event Handler Task (High Priority):

This Task receives any immediate messages sent from the uLCD, processes the message, and sends the message to the CAN BUS.

This task enables the system to: Turn On/Off the Vehicle and Change Vehicle Modes.

RX Task (Low Priority):

This task receives all messages from the CAN BUS, and outputs message data onto the uLCD

Event Handler Task Logic

Event Handler Task Logic

Communication Bridge + Android Software Design

Discuss your hardware design of Communication Bridge and Android

*SHOW SOFTWARE FLOWCHART DIAGRAM

Geographical Controller Team Software Design

Discuss your hardware design of Geographical Controller

*SHOW SOFTWARE FLOWCHART DIAGRAM

Master Controller Team Software Design

Discuss your hardware design of Master Controller

*SHOW SOFTWARE FLOWCHART DIAGRAM

Software Interface

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

SYSTEM LEVEL SOFTWARE IMPLEMENTATION GOES HERE

Sensor Controller Team Software Interface

Describe steps to communicate hardware

Motor Controller Team Software Interface

Describe steps to communicate hardware

I/O Team Software Interface

Describe steps to communicate hardware

Communication Bridge + Android Software Interface

Describe steps to communicate hardware

Geographical Controller Team Software Interface

Describe steps to communicate hardware

Master Controller Team Software Interface

Describe steps to communicate hardware

CAN Communication Table

Master CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| 0x100 | 1hz Periodic | Request Heartbeat (Module state and Timestamp) | 0x200, 0x300, 0x400, 0x500, 0x600 (Respectively) | Motor, Sensor, Geo, Bridge, IO (Respectively) |

| 0x101 | 1hz Periodic | Send Vehicle State | N/A | Motor, Sensor, Geo, Bridge, IO |

| 0x124 | Spontaneous | Set Torque and Steering | N/A | Motor |

| 0x140 | Spontaneous | Send Destination GPS | N/A | Geo |

| 0x14A | Spontaneous | Request Calibrate Compass | N/A | Geo |

| 0x14B | Spontaneous | Request Compass Heading | N/A | Geo |

| 0x14C | Spontaneous | Request Current GPS | N/A | Geo |

| 0x14D | Spontaneous | Request Current Time | N/A | Geo |

Motor CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| N/A | N/A | N/A | N/A | N/A |

Sensor CAN Communication Table

| Module(s) listening | Module msgNum | Module(s) msgRate | Module(s) Msg Description | Module(s) data payload |

|---|---|---|---|---|

| 0x330 to master, io | 0x330 | 10hz | Distances (in cm) of front left, front, front right, rear left, rear, rear right | frontLeftDistance:uint8_t:bytes[0], frontDistance:uint8_t:bytes[1], frontRightDistance:uint8_t:bytes[2], rearLeftDistance:uint8_t:bytes[3], rearDistance:uint8_t:bytes[4], rearRightDistance:uint8_t:bytes[5] |

GEO/ GPS CAN Communication Table

| Master msgNum | MasterMsgRate | Master Msg Description | Master data payload | Module(s) listening | Module msgNum | Module(s) msgRate | Module(s) Msg Description | Module(s) data payload |

|---|---|---|---|---|---|---|---|---|

| 0x441 to master, io | 0x441 | 10hz | Current GPS Coordinates | latitude:float(32bits):dwords[0], longitude:float(32bits):dwords[1] | ||||

| 0x445 to master, io | 0x445 | 10hz | Heading and Bearing | heading:float(32bits):dwords[0], bearing:float(32bits):dwords[1] | ||||

| N/A | Send Destination GPS | heading:float(32bits):dwords[0], bearing:float(32bits):dwords[1] | 0x140 to geo | |||||

| N/A | Calibrate compass | N/A | 0x14A to geo | |||||

| N/A | Get Compass Heading | N/A | 0x14B to geo | |||||

| N/A | Get GPS | N/A | 0x14C to geo | |||||

| N/A | Get Time | N/A | 0x14D to geo |

GEO/ GPS CAN Communication Table

| Module msgNum | Module(s) msgRate | Module(s) Msg Description | Module(s) data payload | |

|---|---|---|---|---|

| 0x050 to master | 0x050 | N/A | Switch to Free Drive Mode | N/A |

| 0x051 to master | 0x051 | N/A | Switch to GPS Drive Mode | N/A |

| 0x052 to master | 0x052 | N/A | Switch to Indoor Drive Mode | N/A |

| 0x053 to master | 0x053 | N/A | Set Destintation GPS Coordinates | latitude:float(32bits):dwords[0], longitude:float(32bits):dwords[1] |

| 0x055 to master | 0x055 | N/A | Start Driving Command | N/A |

| 0x056 to master | 0x056 | N/A | Vehicle Turn Off | N/A |

| 0x057 to master | 0x057 | N/A | Vehicle Turn On | N/A |

| 0x058 to master | 0x058 | N/A | Free Mode Turn Left | OMIT |

| 0x058 to master | 0x058 | N/A | Free Mode Turn Left | OMIT |

| 0x059 to master | 0x059 | N/A | Free Mode Go Straight | OMIT |

| 0x05A to master | 0x05A | N/A | Free Mode Turn Right | OMIT |

| 0x05B to master | 0x05B | N/A | Free Mode Stop | OMIT |

| 0x05C to master | 0x05C | N/A | Free Mode Reverse Left | OMIT |

| 0x05D to master | 0x05D | N/A | Free Mode Reverse Straight | OMIT |

| 0x05E to master | 0x05E | N/A | Free Mode Reverse Right | OMIT |

GEO/ GPS CAN Communication Table

| Module(s) listening | Module msgNum | Module(s) msgRate | Module(s) Msg Description | Module(s) data payload |

|---|---|---|---|---|

| 0x060 to master | 0x060 | N/A | Switch to Free Drive Mode | N/A |

| 0x061 to master | 0x061 | N/A | Switch to GPS Drive Mode | N/A |

| 0x062 to master | 0x062 | N/A | Switch to Indoor Drive Mode | N/A |

| 0x063 to master | 0x063 | N/A | Vehicle Turn On | N/A |

| 0x064 to master | 0x064 | N/A | Vehicle Turn Off | N/A |

| 0x065 to master | 0x065 | N/A | latitude:float(32bits):dwords[0], longitude:float(32bits):dwords[1] | N/A |

| 0x066 to master | 0x066 | N/A | Start Driving Command | N/A |

Master TX Format (refer to ID structure for module's TX format)

| Modules | IDs |

|---|---|

| Everyone | 0x100 - 0x11F |

| Motor | 0x120 - 0x12F |

| Sensor | 0x130 - 0x13F |

| Geo/ GPS | 0x140 - 0x14F |

| Bridge | 0x150 - 0x15F |

| IO | 0x160 - 0x16F |

Testing

Sensor Controller Testing

Sensor Controller Testing #1

Describe how you tested the Sensors

Motor Controller Testing

Motor Controller Testing #1

Describe how you tested the motors

I/O Testing

I/O Testing #1

Describe how you tested the I/O Device

Communication Bridge + Android Testing

Communication Bridge + Android Testing #1

Describe how you tested the Communication Bridge + Android

Geographical Controller

Geographical Controller

Describe how you tested the Geographical Controller

Master Controller

Master Controller Testing #1

Describe how you tested the Master Controller

Technical Challenges

Sensor Controller Team Issues

MY ISSUE #1 TITLE

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

MY ISSUE #2 TITLE

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Motor Controller Team Issues

Motor Controller Issue #1

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Motor Controller Issue #2

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

I/O Team Issues

I/O Team Issue #1

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

I/O Team Issue #2

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Communication Bridge + Android Team Issues

Communication Bridge + Android Issue #1

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Communication Bridge + Android #2

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Geographical Controller Issues

Geographical Controller #1

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Geographical Controller #2

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Master Controller Team Issues

Master Controller Issue #1

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Master Controller#2

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.