S17: MyAutoHealth

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

MyAutoHealth

Abstract

Wear and tear or ageing of parts of an automobile may cause it to malfunction and this may lead to accidents and loss of life and property. Therefore, it is important to monitor a vehicle's internal systems continuously and report any spurious activity to the driver. Most modern vehicles, just like a computer, have a central processing unit called the Engine Control Unit (ECU). This microcontroller oversees all operations. The project uses an OBD 2 module to communicate with the ECU and display the status of all critical vehicle parameters to the driver. This will enable the driver to monitor the engine’s internal functioning. The module will suggest measures to improve driving efficiency and avoid accidents and damage. It will keep an eye on the engine to see if the instantaneous load on it is more than it can handle and warn the driver if so. This will provide real-time feedback to the driver and ensure that appropriate steps can be taken preemptively to avert any major accidents. The module also track the driver's habits. A bump detection algorithm has been developed using deterministic signal processing that the user can turn on to monitor himself or herself.

Objectives & Introduction

The main objectives of this project are as follows:-

- Develop a standalone system to communicate with the ECU

- Monitor critical engine parameters

- Measure road inclination against the vehicles torque-speed characteristics

- Detect careless driving behaviour using signal processing

- Display vehicle parameters and provide real-time updates about the same on a LCD screen

Team Members & Responsibilities

- Manan Mehta

- BOM, PCB design, and assembly

- Code testing and integration

- Interface accelerometer to obtain inclination and declination of vehicle.

- Pushpender Singh

- Interface OBD-II sensor to the SJOne Board over UART

- Acquire and translate ODB-II data to acquire engine load, vehicle speed, engine RPM and torque

- Integrating OBD2 code with and accelerometer code- worked with Shashank Iyer

- Sameer Saran

- Interfacing LCD Display

- LCD GUI design

- Integrating Display code to OBD2 and accelerometer code

- Sanman Pradhan

- PCB Design

- Edit the Wiki Report

- Shashank Iyer

- Bump detection using an accelerometer

- Using Signal Processing- FFT and PSD analysis to assess if the detected bump is valid

- Ensure critical section access is provided to all tasks created by team members.

Schedule

| Week# | Date | Task | Action |

|---|---|---|---|

| 1 | 03/21 | Research Project design and Finalize concept | Completed |

| 2 | 03/28 | Purchasing BOM and Assign Tasks | Completed |

| 3 | 04/04 | Developing C code to read Accelerometer readings | Completed |

| 4 | 04/11 | Interfacing OBD II sensor with SJ one board, LCD Communication Protocol setup | Completed |

| 5 | 04/18 | Developing C code to retrieve data from Vehicle and PCB design, LCD GUI Design | Completed |

| 6 | 04/25 | Integrating OBD and Sensor code into tasks and PCB design, LCD hex Codes Integration | Completed |

| 7 | 05/02 | Testing, troubleshooting, debugging and optimization | Completed |

| 8 | 05/09 | PCB Assembly and Testing | Assembly- Completed, testing - In progress |

| 9 | 05/16 | Ready for Demo |

Parts List & Cost

A list of the cost of our project broken down by components.

| Item# | Part Desciption | Vendor | Part Number | Qty | Cost |

|---|---|---|---|---|---|

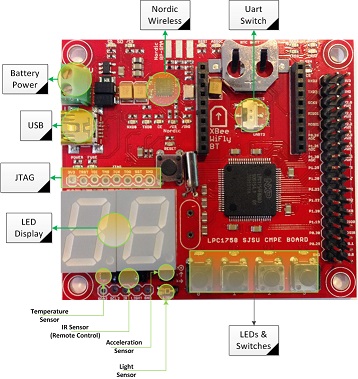

| 1 | SJOne Board | SCE | 1 | $80.00 | |

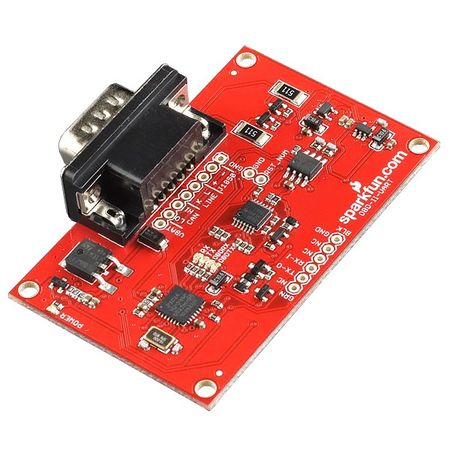

| 2 | OBD-II | SparkFun | WIG-09555 ROHS | 1 | $49.95 |

| 3 | OBD-II to DB9 Cable | SparkFun | CAB-10087 ROHS | 1 | $9.95 |

| 4 | uLCD Display | 4D Systems | uLCD-32PTU | 1 | $79.00 |

| 5 | SD card and Adapter for LCD | Amazon | SDSDQM-016G-B35A | 1 | $6.95 |

| 6 | FTDI Cable | SparkFun | DEV-09718 ROHS | 1 | $17.50 |

| 7 | PCB | PCBWay | N/A | 1 | $11.50 |

| 8 | SPDT Toggle Switches | Amazon | a14072300ux0371 | 10 | $8.83 |

| 9 | Li-po battery 3.7V 2000mAh | Adafruit | 2011 | 1 | $12.50 |

| 10 | Li-po battery charger | Adafruit | 2465 | 1 | $19.95 |

| Total | $296.13 |

Hardware Design

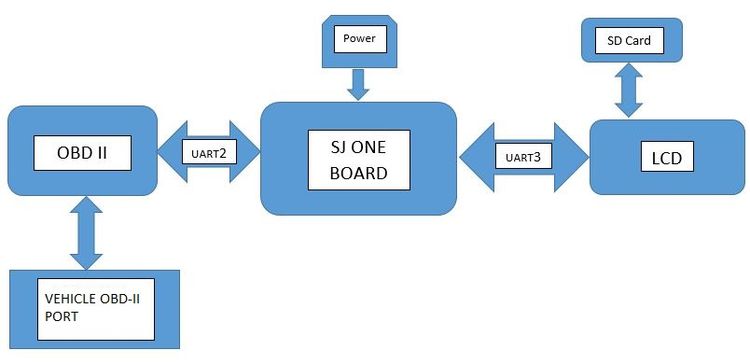

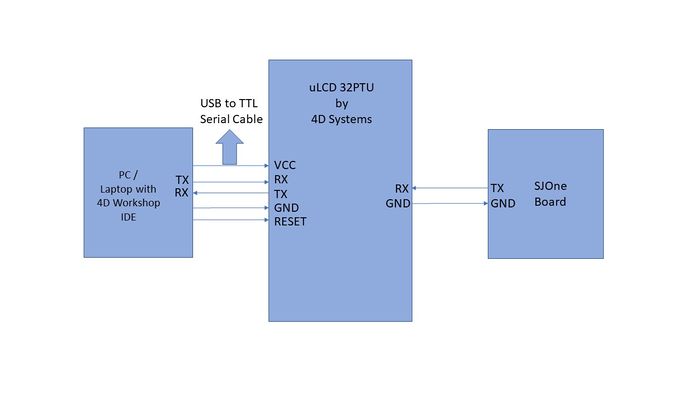

The SJOne microcontroller unit communicated with:

- The OBD II terminal over UART

- The LCD screen over UART

- It's onboard accelerometer using I2C.

A circuit was designed to supply power to the hardware. This was done to make the setup standalone.

The following block diagram highlights the architecture of the project.

PCB Design

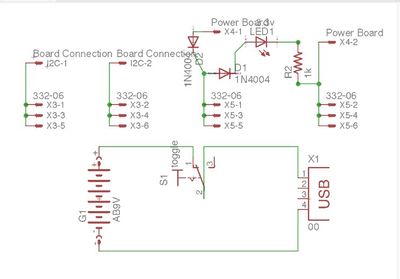

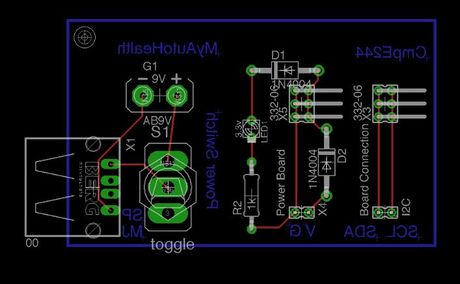

Autodesk EAGLE 8.1.1 was used to design the PCB's layout. The designed PCB provided a connection from the external portal power supply to the SJOne board and additional I2C and power pins to interface with additional devices.

Designing PCB in EAGLE is a two step process:

- Schematic Designing: Necessary connections and component connections were performed. Eagle Library was used for obtaining a basic footprint. We had to download specific libraries(.lbr) from adafruit and sparkfun which provided the appropriate component and board footprint. Using the wire function the necessary components were assembled.

- Board Designing: After completion of schematic design, the board view offered a black grid with the components clustered at one end. Efficient use of space and arranging the components so as to avoid any electrical shorts is a key factor. Once routing is done, check for errors using ERC (Electrical Rule Check) and DRC (Design Rule Check) checks. If there are no errors then the check should return "ERC: No Error" and "DRC: No Error". We added solder mask for protection.

The power supply required was designed to be housed on a PCB. The following are the schematics of the board. EaglePCB was used for design and development of the PCB.

.

Hardware Interface

UART Bus

1. Rx and Tx communication lines are used along with UART 2 connection which communicates between the SJOne board to UART. We used a UART to OBD board for interfacing the board with the vehicle.

2. The "TXD2"(P0.10) and "RXD2" (P0.11) of the SJOne Board interface with the OBD to UART board's RX-1 and TX-0.

I2C Bus

1. Alternative, I2C 2 connection between the SJ One Board and the LCD Display SJ One Board pins P0.10 "SDA2" and P0.11 "SCL2" to LCD Display J2 pin4 "I2C data" and J2 pin4 "I2C clock".

2. Observe that the pins interfere with the UART 2 connection so adaptation to a different UART port is necessary.

SOFTWARE DESIGN

BUMP DETECTION

This feature was added to enable monitoring a driver’s behavior. This could be used widely by schools to keep an eye on their drivers. An accelerometer is used to detect bumps in the vehicle path. Depending on the unevenness of the travel path, the LCD will display "No Bumps" or "Bump Detected". The accelerometer's z-axis value is read every 100 ms by creating a task.

The bump detection algorithm operates in the following manner:

1. Threshold value recognition to identify a preset value beyond which a bump will be detected

2. Acquiring values from the accelerometer.

3. Using signal processing to obtain its Power Spectrum Density.

4. Analyzing the power spectrum of the signal.

ACCELEROMETER READING

The onboard accelerometer was used for gathering readings. The algorithm was designed such that if z-axis values were greater than a preset threshold then a bump event is triggered whereas if the readings were lesser in value than the threshold then no bump event is triggered.

The readings from the z-axis were normalized, this helped in easing the computations. The readings were stored according to the following steps

--> An array a[8] initialized to '0' used to store the normalized readings.

--> New readings are appended to the array while performing a simultaneous left shift operation.

--> If a bump is detected, the array will then have a value of a={0,0,0,0,0,0,0,1} whereas if no bump is detected, the array will have a new value of a={0,0,0,0,0,0,1,0}.

--> Depending upon the movement of the vehicle there could be multiple '1's in the array, indicating multiple bumps.

SLOPE AND BUMP DETECTION

If the road on which the car was moving was inclined, then it was observed that the z-axis readings would cross the threshold. But these events were not to be considered as bumps. The algorithm was to be designed to ensure that it didn’t consider the occurrence of such an event a bump. Some examples of cases that needed differential treatment are as follows:

--> The array a in case the vehicle in ascending a slope will have values like a={0,1,1,1,0,0,0,0}.

--> If the vehicle has climbed a slope and after this, due to negligent driving passes over a bump, then the array’s value could be a={0,1,1,1,1,0,1,0}.

To be able to distinguish between the two cases and make a decision that there is no bump in the first case and a clear bump in the second, signal processing was used. The array a needed to possess certain characteristics so that the signal processing techniques could produce a meaningful output.

WIDE SENSE STATIONERY SIGNAL

To analyse the power spectrum density of an array, it must be WSS or Wide Sense Stationery. The array a:

- Has a constant mean from which instantaneous values may deviate but will eventually return to:

m(n)=m

If the mean deviates from the constant value, then the equation indicates that at some time n the mean m(n) will return to its constant value m.

- The autocorrelation depends only on the difference (k-l) and is given as:

r(k,l)

- The normalised values from the z-axis have a value of either ‘1’ or ‘0’. Thus the variance of any new reading from the accelerometer from the previous value can be utmost ‘1’. The variance is given by c(n) and its value must be:

c(n)<∞

Since all three conditions are satisfied, the array a is WSS. To obtain the PSD of a wide sense stationery array, the following procedures are followed:

--> The autocorrelation sequence of the array is calculated.

--> It is transformed to its frequency domain equivalent using Fast Fourier Transform which has a running time of O(nlogn).

--> The Fourier Transform of the autocorrelation sequence is the Power Spectrum Density of the Signal.

AUTOCORRELATION

The autocorrelation sequence of the sequence is obtained using matrix multiplication and then summing up the lower triangular elements. This process reduces the time complexity by a fourth as compared to the traditional approach. The autocorrelation matrix R is computed by multiplying the array with it’s transpose. The elements of the matrix are as follows:

r= (1,1) (1,2) ⋯ (1,8)

(2,1) (2,2) ⋯ (2,8)

⋮ ⋮ ⋱ ⋮

(8,1) (8,2) ⋯ (8,8)

Each element of the autocorrelation matrix is obtained by:

--> Summing up all the elements along the right diagonal upto the left diagonal.

--> This summation is multiplied by two.

--> The element on the left diagonal is added to the summation.

An example of this operation is as follows:

--> For an even index, the value of the autocorrelation is

r(2)=r(2,1)*2.

--> For an odd index, the value of the autocorrelation is

r(3)=(r(3,1)*2)+r(2,2)

OBD Algorithm

Graphics LCD Design

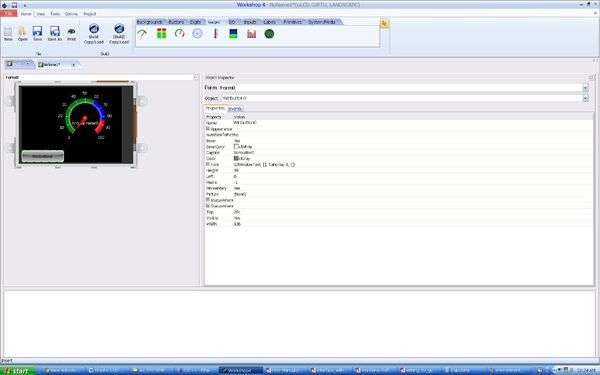

The following diagram highlights communication between LCD and LPC17xx. the pinout diagram shows the interfacing between the board and the peripheral device. This is an example of Master-slave communication between the LCD and the microcontroller

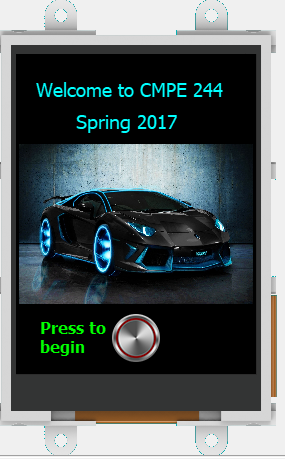

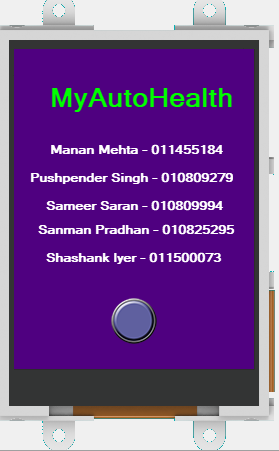

An uLCD-32PTU from 4D Systems was used. It’s a graphic LCD with a resolution of 240x320.

LCD Graphical User Interface Design

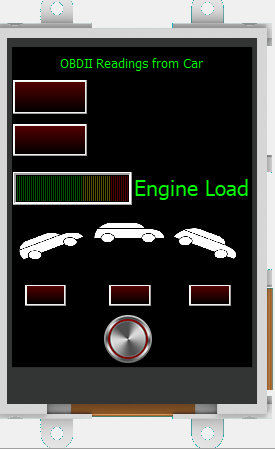

Below are the snaps of the different LCD screen GUI:

LCD Home Screen: This is the first screen that comes up once you start the LCD.

LCD Screen 2: This screen displays the title of our project and the team members names that contributed towards the development of the same.

LCD Main Screen: This screen gives the necessary vehicle parameters for health diagnostics including Engine Load, bump detection warning, slow down warning, incline, decline and straight movement of the vehicle. To make it visually appealing, Red LED's light up every time any signal is received.

LCD Programming

The LCD was used for making quick GUI’s.

The LCD was programmed as follows:

1) ViSi Genie: This is a drag and drop mode. Objects available in the menu were drag and dropped onto the screen. These objects included switches, text boxes, gauges, thermometers, angular meters, etc. This mode didn't require any programming. IDE automatically generated the code required for the object needed.

2) ViSi: This mode is a combination of the 4DGL programming language assisted with drag and drop of objects.

3) Designer: This mode is a pure 4DGL programming language. Each object needs to be added using a programming language. The only benefit of using this code is the feature to use the peripherals and busses available on the Touchscreen. The uLCD-32PTU has onboard I2C and UART ports and also has buzzer and ADC. These functionalities were used with 4DGL programming language. These peripherals can also be used in the ViSi mode. A thorough documentation of 4D systems can be found on this link: http:/www.4dsystems.com.au/appnotes/ Refer the app notes in the ViSi-Genie category.

UART protocol was used to communicate between the LPC1758 and LCD screen. The screen displayed the information sent to it.The communication between the LPC node and the LCD device then works as follows.

--> The LCD sends in acknowledgment to the LPC node once it receives the device ID

--> The LCD acknowledges that the register address has been sent and communication to begin writing data starts.

The following flowchart depicts communication between master and slave -

Testing & Technical Challenges

My Issue #1

We had created multiple producers and consumers to share information between tasks. A specific task was created to read values from the accelerometer, another to normalize the data and a third to perform signal analysis. We noticed that there was an issue with context switching and that the tasks weren't running synchronously. It was noticed that at least one task was getting blocked forever although they were all of the equal priority.

This problem was solved by forcing a producer to sleep for a fixed duration.

We had another set of tasks that needed to access the LCD screen to display data. We noticed that there was bus contention when multiple tasks tried to access the UART2 ports.

We overcame this issue by integrating all LCD write calls into a separate task and gave it a semaphore. It would thus print on the LCD screen after all other tasks had finished updating the variables to be printed.

Conclusion

The whole setup was placed inside a Honda Civic for an acquiring relevant data. The readings from the accelerometer were documented and the values observed were passed as input for FFT calculation and PSD calculation, these values were further . We recorded accurate values and observed a steady pattern while driving

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

We would like to acknowledge Professor Preet Kang for simplifying the concepts of FreeRTOS, clearing our doubts and guiding us with our coursework and project.

References Used

[1] Adafruit website: https://learn.adafruit.com/pir-passive-infrared-proximity-motion-sensor/overview

[2] SocialEdge Website: http://www.socialledge.com/sjsu/index.php?title=Main_Page

[3] Hayes, M. (2002). Statistical Digital Signal Processing and Modelling. Singapore: John Wiley & Sons (Asia) Pte. Ltd.

Appendix

You can list the references you used.