F14: Self Driving Undergrad Team

Contents

- 1 Grading Criteria

- 2 Chi Lam

- 3 Self-Driving Autonomous Car

- 4 Abstract

- 5 Objectives & Introduction

- 6 We are

- 6.1 Schedule

- 6.2 Parts List & Cost

- 6.3 Design & Implementation

- 6.3.1 Hardware Design

- 6.3.2 Sensor Controller Team Hardware Design

- 6.3.3 Motor Controller Team Hardware Design

- 6.3.4 I/O Team Hardware Design

- 6.3.5 Communication Bridge + Android Hardware Design

- 6.3.6 Geographical Controller Team Hardware Design

- 6.3.7 Master Controller Team Hardware Design

- 6.3.8 Hardware Interface

- 6.3.9 Software Design

- 6.3.9.1 Sensor Controller Team Software Design

- 6.3.9.2 Motor Controller Team Software Design

- 6.3.9.3 Motor Movement Commands

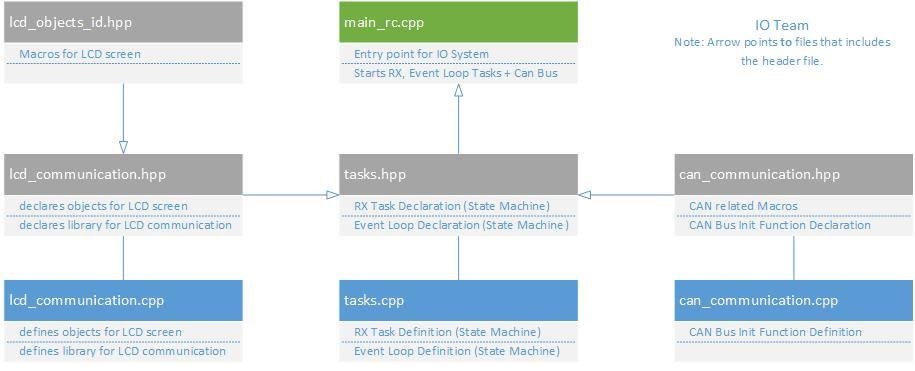

- 6.3.9.4 I/O Team Software Design

- 6.3.9.5 Communication Bridge + Android Software Design

- 6.3.9.6 Geographical Controller Team Software Design

- 6.3.9.7 Master Controller Team Software Design

- 6.3.10 Software Interface

- 6.3.10.1 Sensor Controller Team Software Interface

- 6.3.10.2 Motor Controller Team Software Interface

- 6.3.10.3 I/O Team Software Interface

- 6.3.10.4 Communication Bridge + Android Software Interface

- 6.3.10.5 Geographical Controller Team Software Interface

- 6.3.10.6 Master Controller Team Software Interface

- 6.3.10.7 CAN Communication Table

- 6.4 Testing

- 6.5 Technical Challenges

- 6.6 Conclusion

- 6.7 References

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

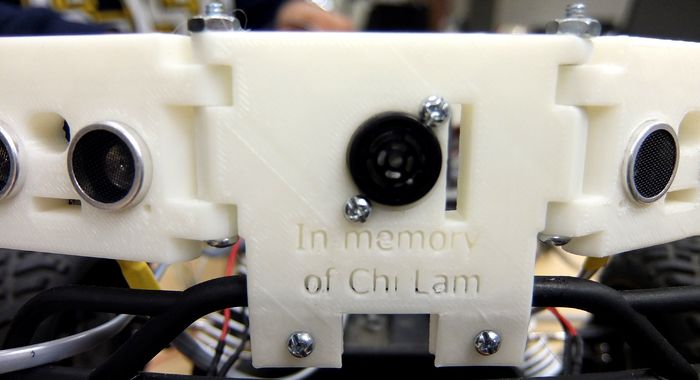

Chi Lam

In Memory of Chi Lam

June 7th, 1991 - October 27th, 2014

This project is dedicated to Chi Lam, a beloved friend, dedicated Computer Engineering student, and member of this team.

You will be missed, friend

Self-Driving Autonomous Car

Abstract

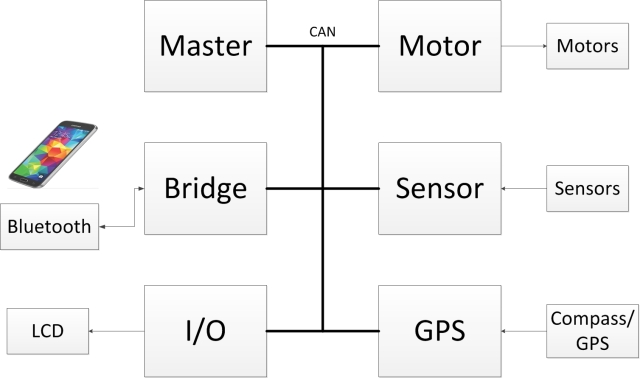

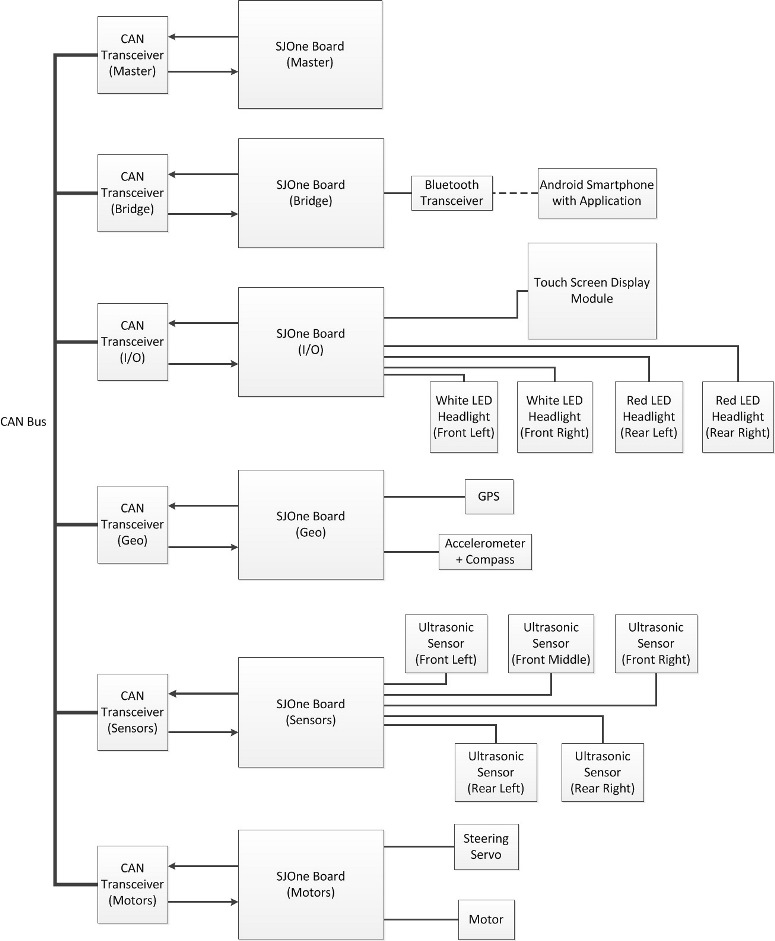

The objective of the project is to create a self-driving autonomous car in a 15 person team. The car utilizes several components and sensors in order to get from Point A to Point B. Implementation of the car involves multiple SJONE processor boards using FreeRTOS to communicate with each other via CAN bus.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

The team consisted of 15 undergraduate students taking a graduate level course, thus competing against the Master's level students.

We are

| Master Controller Team | ||

|---|---|---|

| Charles Pham | Joshua Ambion | Michael Schneider |

| - Overall vehicle logic - Overall software vehicle Integration - CAN TX/RX messages architecture |

- Vehicle hardware interfacing - Assistant to other teams - Module specific logic |

- Module specific logic - CAN RX processing |

| Motor Controller Team | |

|---|---|

| Nikko Esplana | Chi Lam |

| - Motor/steering control via PWM signals - interface/test/attach wheel encoder |

- Rest in peace Chi! |

| Sensor Controller Team | |

|---|---|

| Sanjay Maharaj | Wei-chieh "Andy" Lo |

| - Vehicle hardware - Sensor implementation - CAN communication |

- Sensor implementation - Sensor values verification - CAN communication |

| Geographical Controller Team | ||

|---|---|---|

| Carlos Fernandez-Martinez | Zach Baumgartner | Albert Chen |

| - Compass calibration/integration | - GPS testing/integration | - CAN communication |

| Bridge Controller Team | ||

|---|---|---|

| Robert Julius | Tim Martin | Joseph Bourne |

| - Android Application | - Bluetooth Message Interface | - Board to CAN Communication |

| IO Controller Team | |

|---|---|

| Devin Villarosa | George Sebastian |

| - Receive Task - GUI Interface - Headlights Task - uLCD Library |

- Event Handle Task - GUI Interface - Headlights Task - uLCD Library |

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

Final Product Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/12 | CAN Network Benchtest | Complete |

| 2 | 10/15 | Basic CAN Communication | Complete |

| 3 | 10/31 | Secure devices to R/C car | Complete |

| 4 | 11/7 | Basic Vehicle Self-Driving Test | In progress |

| 5 | 11/14 | P2P testing and improved obstacle avoidance | In progress |

| 6 | 11/31 | Buffer time for previous tasks and increased vehicle speed | In progress |

Sensor Controller Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/13 | Sensor Input Distance Calibration | Incomplete: Sonar is mostly calibrated, IR still needs work. Need sensor value "filtering" logic. |

| 2 | 10/17 | Off car CAN network test (full team) | Completed. Able to send raw sensor value to master. |

| 3 | 10/20 | Interface Sensors with CAN | Completed. Updates to the formatting of data being sent is ongoing. |

| 4 | 10/27 | Mount Sensors and test coverage | Completed. Still need to mount with actual brackets. |

| 5 | 10/31 | Mount Sensors with 3d printed brackets | Completed. IR brackets to be printed based on offset. |

| 6 | 11/1 | Implement diagnostic LED patterns | Completed. |

| 7 | 11/3 | Send obstacle avoidance decisions to master | Completed. Raw values sent to master for processing. |

| 8 | 11/4 | Add RJ11 cabling to all sensors | Completed. Still need to make neat and tidy. |

| 9 | 11/10 | Eliminate outliers (software) | Completed. |

| 10 | 11/13 | Eliminate outliers by strengthening sensor wiring (hardware) | Completed. |

| 12 | 11/24 | Continue testing and tuning as necessary | In progress |

Motor Controller Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/12 | Open up servo and motor modules,

find a speed sensor |

Complete |

| 2 | 10/19 | Interface/test PWM bus to steering servo and DC motor | Complete |

| 3 | 10/26 | Allow self-driving capability with master/bridge/sensor teams | Incomplete, only partial self-driving achieved |

| 4 | 11/2 | Improve fine motor movements with master/sensor teams | Incomplete, still needs tweaking. |

| 5 | 11/9 | Once wheel encoder comes in, learn/test/implement onto car | Incomplete, wheel encoder cannot be implemented, scrapping. |

| 6 | 11/16 | Integrate wheel encoder with rest of car | Incomplete, scrapped wheel encoder. |

| 7 | 11/23 | Test for proper operation | Complete, added functionality for center steer and forward speed calibration. |

| 8 | 11/30 | Continue testing until proper operation | Complete, motor works as intended. |

I/O Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/4 | Create LCD Screen Library (create ability to set value, get value, and write string to LCD screen) | 10/4 (String function completed on ~10/18) |

| 2 | 10/4 | Create LCD Screen GUI (generate forms for debugging and general usage) | 10/4 |

| 3 | 10/11 | LCD Library Test (Do unit tests on individual functions for LCD library)

Ability to get value from gauge on screen. Ability to set value to gauge on screen. Ability to send a string value to screen. |

10/11 (Finished string function on ~10/18) |

| 4 | 10/11 | Interface LCD with CAN

Create task for LCD event loop. Create task for Receiving on CAN. |

Complete (Completed on 10/26/2014) |

| 5 | 10/18 | Test LCD with CAN

Process CAN Messages from system |

Complete (Completed on 10/25/2014) |

| 6 | 10/25 | Implement onto Final Product | Complete (Completed on 11/23/2014) |

| 7 | 11/2 | Headlights for car (hardware and software) + Aesthetics for GUI + Clean up code | Complete (Completed on 12/01/2014) *NOTE Headlights are lost in hardware land |

Communication Bridge and Android Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/13 | CAN Network Test | Complete |

| 2 | 10/20 | Interface Bluetooth Module with CAN | Complete |

| 3 | 10/27 | Mount PCB on car | In progress |

| 4 | 11/3 | Create basic Android application | Completed on 10/18 |

| 5 | 11/10 | Add map onto the Android application | In Progress |

| 6 | 11/17 | Send/receive CAN Messages via Android Application | Sending completed on 10/18, receiving in progress |

| 7 | 11/24 | Debug and Optimize Android Application | In progress |

| 8 | 12/1 | Continue Debugging and Optimizing as Necessary | In progress |

Geographical Controller Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/8 | Interface with GPS/Compass | Complete - receiving values |

| 2 | 10/15 | Finish core API | Complete |

| 3 | 10/22 | GPS get fix and receive raw data | Complete - raw data received, but need faster fix |

| 4 | 10/22 | Compass determine heading | Complete - heading may require additional calibration |

| 5 | 10/29 | Self calibration completed | Complete |

| 6 | 10/29 | GPS parse raw data to extract needed data | Complete - returns latitude, longitude, and calculated heading |

| 7 | 10/29 | Compass use heading from GPS to improve accuracy | In progress - may not provide tangible improvement |

| 8 | 11/5 | Improve GPS satellite procurement (antennae?) | Complete - attached antennae to GPS unit |

| 9 | 11/12 | Improve boot up time of GPS module via warm start | N/A - EZ start fast fix mode cannot coincide with 10 Hz update rate (defaults down to 1 Hz) |

| 10 | 11/12 | Fine tune compass calibration technique for accuracy | In progress |

| 11 | 12/3 | Buffer time for completion of previous tasks | In progress |

Master Controller Schedule

| Line Item # | Expected End Date | Task | Status |

|---|---|---|---|

| 1 | 10/15/14 | Decide on raw CAN struct architecture | Early completion |

| 2 | 10/18/14 | Develop and layout general common CAN messages | On-time completion |

| 3 | 10/20/14 | Design vehicle initialization procedure | Early completion |

| 4 | 10/23/14 | Develop and layout Inter-Controller Communication - Each Module's CAN messages | Early completion |

| 5 | 10/25/14 | Design vehicle initial running freed drive mode procedure - Controlled via Phone, no object detection and avoidance, no GPS, no Heading | Early completion |

| 6 | 10/28/14 | Complete design on vehicle running free drive mode procedure | On-time completion |

| 7 | 10/30/14 | Design vehicle initial running indoor drive mode procedure - Timed autonomous drive , object detection and avoidance, (possibly heading), and no GPS | In progress |

| 8 | 11/01/14 | All CAN message definitions complete | Early Completion |

| 9 | 11/02/14 | Design vehicle initial running gps drive mode procedure - Full autonomous drive , object detection and avoidance, heading and GPS | In progress |

| 10 | 11/05/14 | All CAN message receive processing complete | On-time completion |

| 11 | 11/14/14 | All basic vehicle functionality state machines implemented and verified | On-time completion |

| 12 | 11/15/14 | Complete design on vehicle running indoor drive mode procedure | In progress |

| 13 | 11/20/14 | Complete design on vehicle running gps drive mode procedure | In progress |

| 14 | 11/30/14 | Any additional advanced functionality implemented and verified | In progress |

Parts List & Cost

| Line Item# | Part Desciption | Vendor | Part Number | Qty | Cost ($) |

|---|---|---|---|---|---|

| 1 | CAN Board | Waveshare International Limited | SN65HVD230 | 15 | 92.00 |

| 2 | Traxxas Slash Pro 2WD Short-Course R/C Truck | Traxxas | 58034 Slash | 1 | 337.00 |

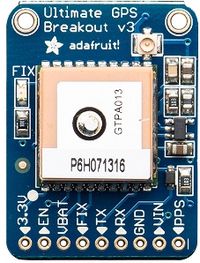

| 3 | Adafruit Ultimate GPS Breakout | Adafruit | MTK3339 | 1 | 39.95 + (4.685 Shipping) |

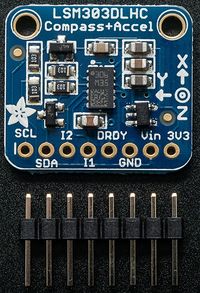

| 4 | Triple-axis Accelerometer+Magnetometer (Compass) Board | Adafruit | LSM303 | 1 | 14.95 + (4.685 Shipping) |

| 5 | GPS Antenna - External Active Antenna - 3-5V 28dB 5 Meter SMA | Adafruit | 960 | 1 | 12.95 + (4.735 Shipping) |

| 6 | SMA to uFL/u.FL/IPX/IPEX RF Adapter Cable | Adafruit | 851 | 1 | 3.95 + (4.735 Shipping) |

| 7 | 3.5" Intelligent module w/ Touch | 4D Systems | uLCD 35DT | 1 | 89.00 |

| 8 | 2GB microSD Card | ||||

| 9 | uUSB-PA5 Programming Adaptor | ||||

| 10 | 150mm 5 way Female-Female jumper cable | ||||

| 11 | 5 way Male-Male adaptor | ||||

| 12 | Sharp Infrared Range Finder | 4D Systems | GP2Y0A21 | 2 | 9.95 + 3.32 Shipping |

| 13 | SainSmart Sonar Ranging Detector | Amazon | HC-SR04 | 3 | 5.59 |

| 14 | RC LED Headlights | Amazon Prime | 2 | 5.99 | |

| 15 | XBee Bluetooth | Amazon Prime | WLS04051P | 1 | 27.50 |

| 16 | SJONE Board | Preet Industries | 6 | 480.00 | |

| 17 | Traxxas XL5 ESC unit | dollarhobbyz.com | 2WDS ESC | 2 | 54.00 + (4.67 Shipping) |

| Additional Shipping | $$$.$$ | ||||

| Total Cost | $$$.$$ |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Overall Hardware Design Components

|

58034 Traxxas Slash RC Truck:

|

|

|

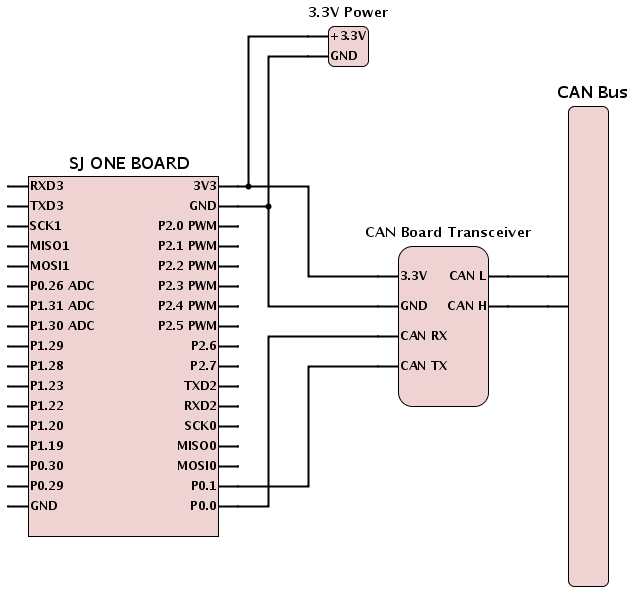

SN65HVD230 CAN Board Transceiver:

The SN65HVD230 CAN board transceiver is used to interface the microcontrollers logical signals to CAN electrical specifications. The SN65HVD230 CAN board transceiver was chosen specifically because not only did it work perfectly for CAN interfacing, but it came pre-built with the in-line resistors. Because there were fifteen people in our team, this was desired because a lot of work would be needed if we built each CAN board transceiver individually. The transceivers were purchased on eBay for $8.99 each. However, the item's location was in China, so ordering early would be best for future students. |

|

|

3D Printed Materials:

|

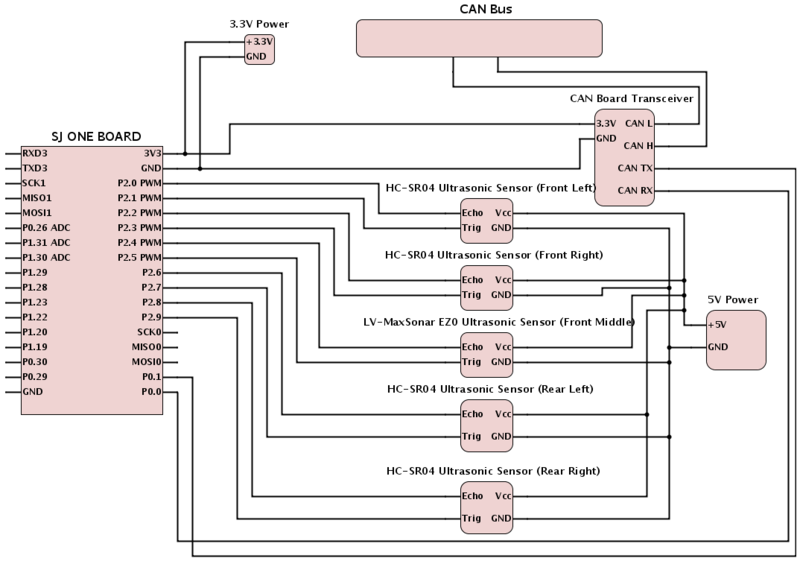

Sensor Controller Team Hardware Design

Sensor Pin Connections

| Line Item# | Node A Source | Node A Pin | Node B Source | Node B Pin | Description |

|---|---|---|---|---|---|

| 1 | 3.3V Power Supply | 3.3V | SJOne Board | 3V3 | SJOne Power |

| 2 | 3.3V Power Supply | GND | SJOne Board | GND | SJOne Ground |

| 3 | CAN Transceiver | Tx | SJOne Board | P0.1 (Tx) | SJOne - CAN Tx |

| 4 | CAN Transceiver | Rx | SJOne Board | P0.0 (Rx) | SJOne - CAN Rx |

| 5 | CAN Transceiver | 3.3V | 3.3V Power Supply | 3.3V | SJOne - CAN Power |

| 6 | CAN Transceiver | Ground | 3.3V Power Supply | GND | SJOne - CAN Ground |

| 7 | HC-SR04 Ultrasonic Sensor (Front Left) | Vcc | 5V Power Supply | +5V | Front Left Sensor Power |

| 8 | HC-SR04 Ultrasonic Sensor (Front Left) | GND | 5V Power Supply | GND | Front Left Sensor GND |

| 9 | HC-SR04 Ultrasonic Sensor (Front Left) | Echo | SJOne Board | P2.0 | Front Left Sensor Echo |

| 10 | HC-SR04 Ultrasonic Sensor (Front Left) | Trig | SJOne Board | P2.1 | Front Left Sensor Trig |

| 11 | HC-SR04 Ultrasonic Sensor (Front Right) | Vcc | 5V Power Supply | +5V | Front Right Sensor Power |

| 12 | HC-SR04 Ultrasonic Sensor (Front Right) | GND | 5V Power Supply | GND | Front Right Sensor GND |

| 13 | HC-SR04 Ultrasonic Sensor (Front Right) | Echo | SJOne Board | P2.2 | Front Right Sensor Echo |

| 14 | HC-SR04 Ultrasonic Sensor (Front Right) | Trig | SJOne Board | P2.3 | Front Right Sensor Trig |

| 15 | LV-MaxSonar-EZ-0 Ultrasonic Range Sensor (Front Middle) | Vcc | 5V Power Supply | +5V | Front Middle Sensor Power |

| 16 | LV-MaxSonar-EZ-0 Ultrasonic Range Sensor (Front Middle) | GND | 5V Power Supply | GND | Front Middle Sensor GND |

| 17 | LV-MaxSonar-EZ-0 Ultrasonic Range Sensor (Front Middle) | Echo | SJOne Board | P2.4 | Front Middle Sensor Echo |

| 18 | LV-MaxSonar-EZ-0 Ultrasonic Range Sensor (Front Middle) | Trig | SJOne Board | P2.5 | Front Middle Sensor Trig |

| 19 | HC-SR04 Ultrasonic Sensor (Rear Left) | Vcc | 5V Power Supply | +5V | Rear Left Sensor Power |

| 20 | HC-SR04 Ultrasonic Sensor (Rear Left) | GND | 5V Power Supply | GND | Rear Left Sensor GND |

| 21 | HC-SR04 Ultrasonic Sensor (Rear Left) | Echo | SJOne Board | P2.6 | Rear Left Sensor Echo |

| 22 | HC-SR04 Ultrasonic Sensor (Rear Left) | Trig | SJOne Board | P2.7 | Rear Left Sensor Trig |

| 23 | HC-SR04 Ultrasonic Sensor (Rear Right) | Vcc | 5V Power Supply | +5V | Rear Right Sensor Power |

| 24 | HC-SR04 Ultrasonic Sensor (Rear Right) | GND | 5V Power Supply | GND | Rear Right Sensor GND |

| 25 | HC-SR04 Ultrasonic Sensor (Rear Right) | Echo | SJOne Board | P2.8 | Rear Right Sensor Echo |

| 26 | HC-SR04 Ultrasonic Sensor (Rear Right) | Trig | SJOne Board | P2.9 | Rear Right Sensor Trig |

| 27 | CAN Transceiver | CANL | CAN BUS | CANL | CANL to CAN BUS |

| 28 | CAN Transceiver | CANR | CAN BUS | CANR | CANR to CAN BUS |

Sensor Controller Hardware Design Components

Motor Controller Team Hardware Design

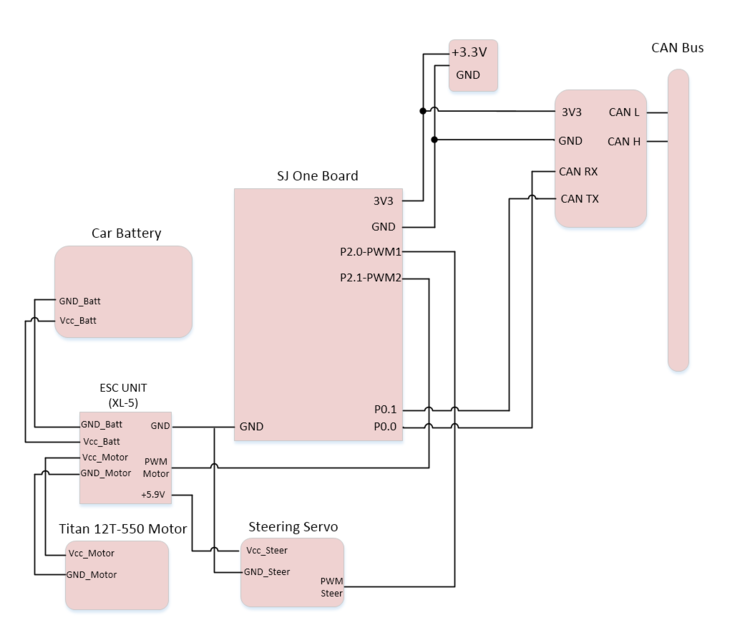

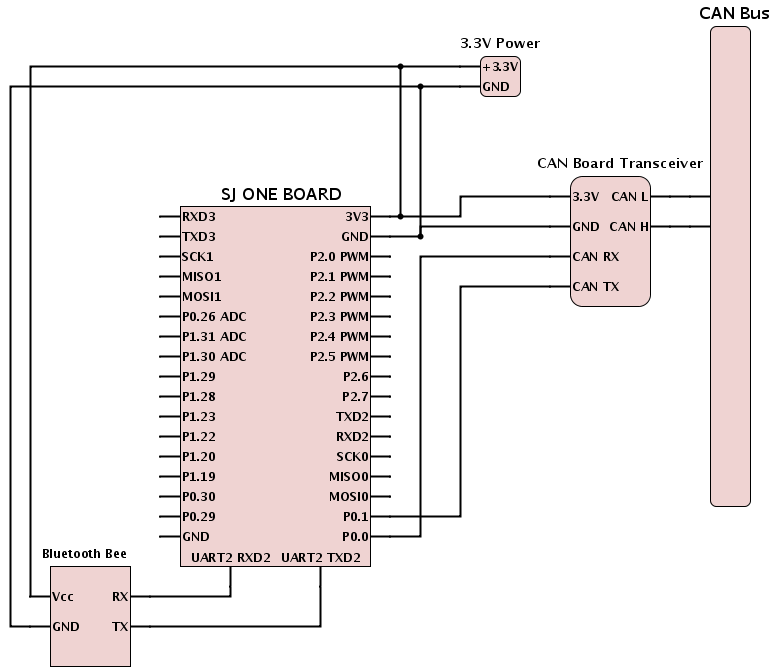

As seen above, the car battery(accepts compatible Ni-MH, Li-Po, and Ni-Cad batteries) powers the ESC unit (XL-5), which in turn drives the Titan 12T-550 motor and also powers the steering servo. It is necessary for the ESC unit, steering servo and SJ One board to share a common ground in order for the PWM signals to have the same reference voltage.

The CAN transceiver requires the use of the SJ One Board's +3.3V and GND, as well as P0.0 (CAN RX) and P0.1 (CAN TX).

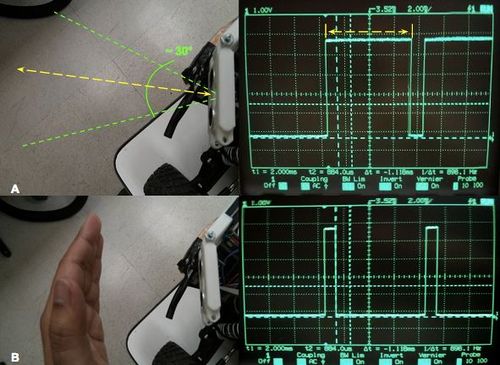

P2.0/P2.1 (PWM1/PWM2) controls the steering/motor via the SJ One board by sending out PWM signals that change the width of a 20ms period waveform. 1ms width represents a 0% duty cycle, 1.5ms width represents a 50% duty cycle, and 2ms width represents a 100% duty cycle.

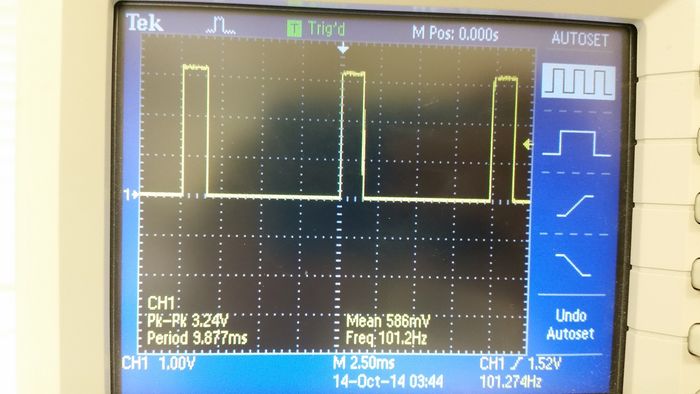

Controlling motor and steering

In the photo above, a digital oscilloscope probes a PWM pin on the SJ One board and detects a signal with a 3.3 peak-to-peak voltage, a 100hz PWM frequency, and a width of 1.5ms (50% duty cycle). In terms of steering control, a width between 1ms to 1.499ms equates to left steering (1ms = max left angle) and a width between 1.501ms to 2ms equates to right steering (2ms = max right angle). The motor is similar, such that a width between 1ms to 1.499ms equates to a reverse throttle and a width between 1.501ms to 2ms equates to a forward throttle. For both steering and motor control, 1.5ms (50% duty cycle) represents a center steer or non-throttle.

Motor Controller Hardware Design Components

|

58034 Traxxas Slash RC Truck:

|

|

|

Traxxas XL-5 Electronic Speed Control (ESC) Unit:

|

|

|

Steering Servo:

|

Motor Pin Connections

| Line Item# | Node A Source | Node A Pin | Node B Source | Node B Pin | Description |

|---|---|---|---|---|---|

| 1 | 3.3V Power Supply | 3.3V | SJOne Board | 3V3 | SJOne Power |

| 2 | 3.3V Power Supply | GND | SJOne Board | GND | SJOne Ground |

| 3 | CAN Transceiver | CAN Tx | SJOne Board | P0.1 (Tx) | SJOne - CAN Tx |

| 4 | CAN Transceiver | CAN Rx | SJOne Board | P0.0 (Rx) | SJOne - CAN Rx |

| 5 | CAN Transceiver | 3.3V | 3.3V Power Supply | 3.3V | SJOne - CAN Power |

| 6 | CAN Transceiver | Ground | 3.3V Power Supply | GND | SJOne - CAN Ground |

| 7 | CAN Transceiver | CANL | CAN BUS | CANL | CANL to CAN BUS |

| 8 | CAN Transceiver | CANR | CAN BUS | CANR | CANR to CAN BUS |

| 9 | Steering Servo | PWM Port | SJOne Board | P2.0 PWM | Steering Control |

| 10 | Steering Servo | Ground | SJOne Board | GND | Common ground for reference voltage |

| 11 | ESC/Motor | PWM Port | SJOne Board | P2.1 PWM | Motor Control |

| 12 | ESC/Motor | Ground | SJOne Board | GND | Common ground for reference voltage |

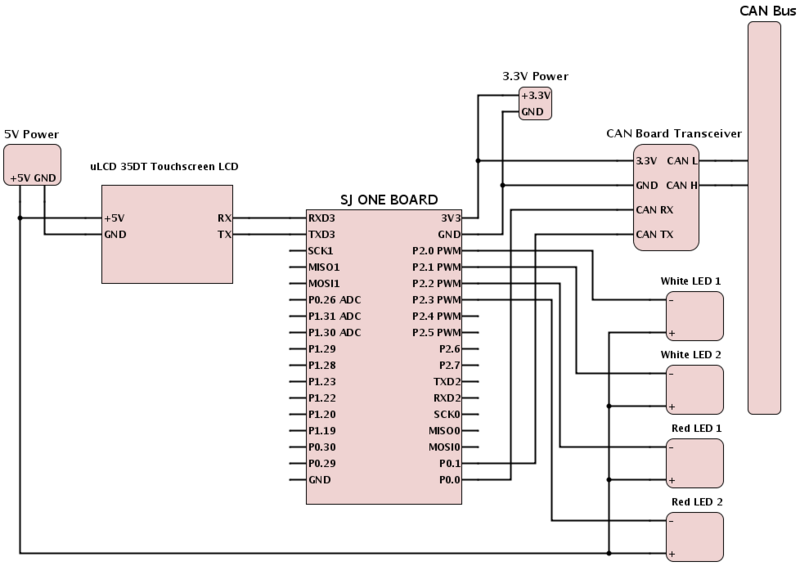

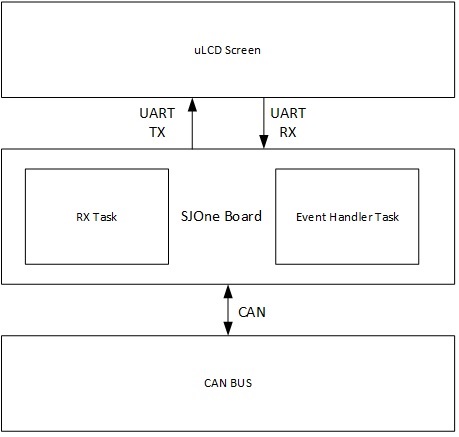

I/O Team Hardware Design

I/O Design Components

|

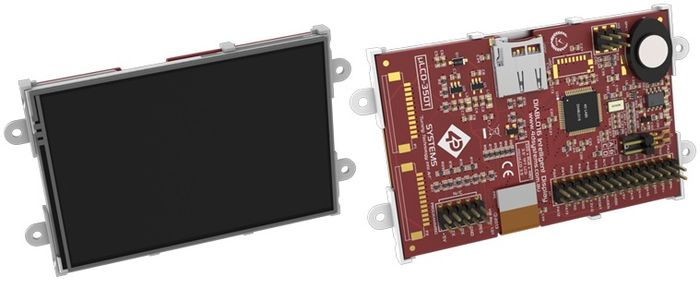

uLCD-35DT Intelligent Display Module:

The uLCD-35DT is an intelligent display module used to display information of the system, such as viewing the GPS destination, and a controller for the system, such as setting the car to indoor mode which tests for sensor only navigation. The uLCD-35DT system was chosen specifically because of its touch screen capabilities. The display is driven by A DIABLO16 processor. The processor allows stand-alone functionality for the screen. In order to program the screen with an interactive GUI, the 4D Systems Workshop 4 IDE Software was used. |

I/O Pin Connections

| Line Item# | Node A Source | Node A Pin | Node B Source | Node B Pin | Description |

|---|---|---|---|---|---|

| 1 | LCD | 1 (LCD +5V) | 5V Power Supply | 5V | uLCD 35DT LCD Power |

| 2 | LCD | 7 (LCD GND) | 5V Power Supply | GND | uLCD 35DT LCD Ground |

| 3 | LCD | 5 (LCD RX) | SJOne Board | RX3 | uLCD 35DT LCD Receive Pin |

| 4 | LCD | 3 (LCD TX) | SJOne Board | TX3 | uLCD 35DT LCD Transmit Pin |

| 5 | 3.3V Power Supply | +3.3V | SJOne Board | 3V3 | SJOne Power |

| 6 | 3.3V Power Supply | GND | SJOne Board | GND | SJOne Ground |

| 7 | UART2 RX | P2.9 | SJOne RX | ||

| 8 | UART2 TX | P2.8 | SJOne TX | ||

| 9 | +5V | +5V Power | SJOne Board | GPIO P2.0 | Active Low |

| 10 | +5V | +5V Power | SJOne Board | GPIO P2.1 | Active Low |

| 11 | +5V | +5V Power | SJOne Board | GPIO P2.2 | Active Low |

| 12 | +5V | +5V Power | SJOne Board | GPIO P2.3 | Active Low |

| 13 | CAN Transceiver | CAN Tx | SJOne Board | P0.1 (Tx) | SJOne - CAN Tx |

| 14 | CAN Transceiver | CAN Rx | SJOne Board | P0.0 (Rx) | SJOne - CAN Rx |

| 15 | CAN Transceiver | CAN 3.3V | 3.3V Power Supply | 3.3V | SJOne - CAN Power |

| 16 | CAN Transceiver | CAN Ground | 3.3V Power Supply | GND | SJOne - CAN Ground |

| 17 | CAN Transceiver | CANL | CAN BUS | CANL | CANL to CAN BUS |

| 18 | CAN Transceiver | CANR | CAN BUS | CANR | CANR to CAN BUS |

Communication Bridge + Android Hardware Design

The Bluetooth module is connected to the SJOne board through the XBee socket, with only the RX/TX data connections into the board.

Communication Bridge Pin Connections

| Line Item# | Node A Source | Node A Pin | Node B Source | Node B Pin | Description |

|---|---|---|---|---|---|

| 1 | 3.3V Power Supply | 3.3V | SJOne Board | 3V3 | SJOne Power |

| 2 | 3.3V Power Supply | GND | SJOne Board | GND | SJOne Ground |

| 3 | CAN Transceiver | CAN Tx | SJOne Board | P0.1 (Tx) | SJOne - CAN Tx |

| 4 | CAN Transceiver | CAN Rx | SJOne Board | P0.0 (Rx) | SJOne - CAN Rx |

| 5 | CAN Transceiver | CAN 3.3V | 3.3V Power Supply | 3.3V | SJOne - CAN Power |

| 6 | CAN Transceiver | CAN Ground | 3.3V Power Supply | GND | SJOne - CAN Ground |

| 7 | Bluetooth Bee | VCC | 3.3V Power Supply | 3V3 | Bluetooth Bee Power |

| 8 | Bluetooth Bee | GND | 3.3V Power Supply | GND | Bluetooth Bee GND |

| 9 | Bluetooth Bee | RX | SJOne Board | P2.9 (RXD2) | Bluetooth Bee RX |

| 10 | Bluetooth Bee | TX | SJOne Board | P2.8 (TXD2) | Bluetooth Bee TX |

| 11 | CAN Transceiver | CANL | CAN BUS | CANL | CANL to CAN BUS |

| 12 | CAN Transceiver | CANR | CAN BUS | CANR | CANR to CAN BUS |

Communication Bridge + Android Hardware Design Components

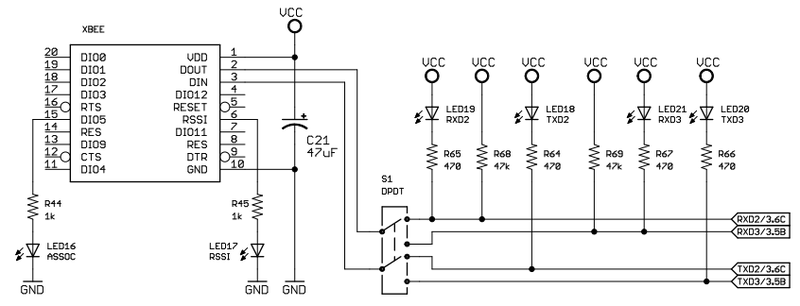

|

Bluetooth Bee Standalone:

The Bluetooth Bee Standalone Module by Seeed Studio Works allows for the connection of a bluetooth module onto the XBee Socket of the SJOne Board. This module contains an ATMEGA168 for reprogramming. Only the SJOne Board's UART2/3 pins are capable of transferring data to the module, depending on which UART the XBee Socket is connected to with a switch configuration. |

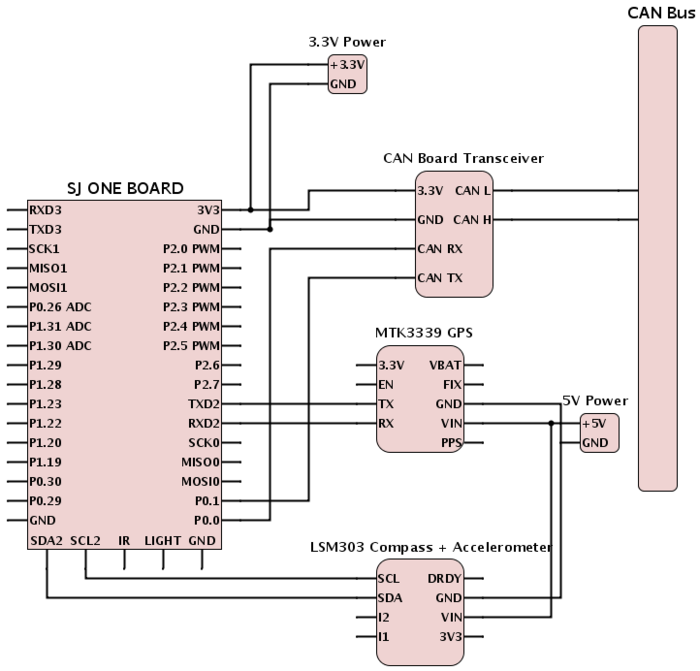

Geographical Controller Team Hardware Design

Geographical Pin Connections

| Line Item# | Node A Source | Node A Pin | Node B Source | Node B Pin | Description |

|---|---|---|---|---|---|

| 1 | 3.3V Power Supply | 3.3V | SJOne Board | 3V3 | SJOne Power |

| 2 | 3.3V Power Supply | GND | SJOne Board | GND | SJOne Ground |

| 3 | CAN Transceiver | Tx | SJOne Board | P0.1 (Tx) | SJOne - CAN Tx |

| 4 | CAN Transceiver | Rx | SJOne Board | P0.0 (Rx) | SJOne - CAN Rx |

| 5 | CAN Transceiver | 3.3V | 3.3V Power Supply | 3.3V | SJOne - CAN Power |

| 6 | CAN Transceiver | Ground | 3.3V Power Supply | GND | SJOne - CAN Ground |

| 7 | MTK3339 GPS | VCC | 5V Power Supply | +5V | MTK3339 GPS Power |

| 8 | MTK3339 GPS | GND | 5V Power Supply | GND | MTK3339 GPS GND |

| 9 | MTK3339 GPS | RX | SJOne Board | RXD2 | MTK3339 GPS RX |

| 10 | MTK3339 GPS | TX | SJOne Board | TXD2 | MTK3339 GPS TX |

| 7 | LSM303 Compass + Accelerometer | VIN | 5V Power Supply | +5V | Compass + Accelerometer Power |

| 8 | LSM303 Compass + Accelerometer | GND | 5V Power Supply | GND | Compass + Accelerometer GND |

| 9 | LSM303 Compass + Accelerometer | RX | SJOne Board | RXD2 | Compass + Accelerometer SCL |

| 10 | LSM303 Compass + Accelerometer | TX | SJOne Board | TXD2 | Compass + Accelerometer SDA |

| 11 | CAN Transceiver | CANL | CAN BUS | CANL | CANL to CAN BUS |

| 12 | CAN Transceiver | CANR | CAN BUS | CANR | CANR to CAN BUS |

Geographical Controller Hardware Design Components

|

Adafruit MTK3339 GPS:

|

|||||

|

Adafruit LSM303 Compass:

|

| Line Item# | Node A Source | Node A Pin | Node B Source | Node B Pin | Description |

|---|---|---|---|---|---|

| 1 | 3.3V Power Supply | 3.3V | SJOne Board | 3V3 | SJOne Power |

| 2 | 3.3V Power Supply | GND | SJOne Board | GND | SJOne Ground |

| 3 | CAN Transceiver | CAN Tx | SJOne Board | P0.1 (Tx) | SJOne - CAN Tx |

| 4 | CAN Transceiver | CAN Rx | SJOne Board | P0.0 (Rx) | SJOne - CAN Rx |

| 5 | CAN Transceiver | CAN 3.3V | 3.3V Power Supply | 3.3V | SJOne - CAN Power |

| 6 | CAN Transceiver | CAN Ground | 3.3V Power Supply | GND | SJOne - CAN Ground |

| 7 | CAN Transceiver | CANL | CAN BUS | CANL | CANL to CAN BUS |

| 8 | CAN Transceiver | CANR | CAN BUS | CANR | CANR to CAN BUS |

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

SYSTEM LEVEL HARDWARE INTERFACE INTERFACE GOES HERE

Sensor Controller Team Hardware Interface

Sensor team uses CAN bus as a communication bus to communicate with master. The specific message ID used is 0x330. There are 5 sensor values (Front Left, Front, Front Right, Rear Left, Rear Right). 8 bits of integer is the size of our data for each sensor. frontLeftDistance:uint8_t:bytes[0] frontDistance:uint8_t:bytes[1] frontRightDistance:uint8_t:bytes[2] rearLeftDistance:uint8_t:bytes[3] rearDistance:uint8_t:bytes[4] rearRightDistance:uint8_t:bytes[5] After microcontroller obtained all the values, a tasks that is designated to send data to master will run. Every sensor value is updated periodically.

Motor Controller Team Hardware Interface

The motor team only uses the CAN bus for simple communication. Only 2 messages are being listened for: 0x100 and 0x124.

-0x100 is the master heartbeat message and motor replies back with message 0x200 for acknowledgement.

-0x124 is the master movement command message. Master sends a uint8_t byte, with unique numbers that represent specific movement commands such as forward, reverse, left forward, right reverse, etc.

During each heartbeat, a second message is sent: 0x221

-0x221 contains 2 dwords, as it sends two float values (reinterpreted to uint32_t) to I/O. dword[0] is a float type containing the forward speed value and dword[1] is also a float type containing the neutral steer value.

PWM signals are sent from the SJ One board towards the ESC unit and steering servo. Depending on the width of the signals sent (ranging between 1ms to 2ms), the motor and steering can be manipulated.

I/O Team Hardware Interface

Communication Bridge + Android Hardware Interface

Discuss your hardware design of Communication Bridge and Android

*SHOW HOW FRAMES ARE SENT

123

Geographical Controller Team Hardware Interface

Discuss your hardware design of Geographical Controller

*SHOW HOW FRAMES ARE SENT

Master Controller Team Hardware Interface

Discuss your hardware design of Master Controller

*SHOW HOW FRAMES ARE SENT

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

SYSTEM LEVEL SOFTWARE DESIGN GOES HERE

Sensor Controller Team Software Design

Describe how your hardware communicates. WHAT BUSes were used

*SHOW SOFTWARE FLOWCHART DIAGRAM

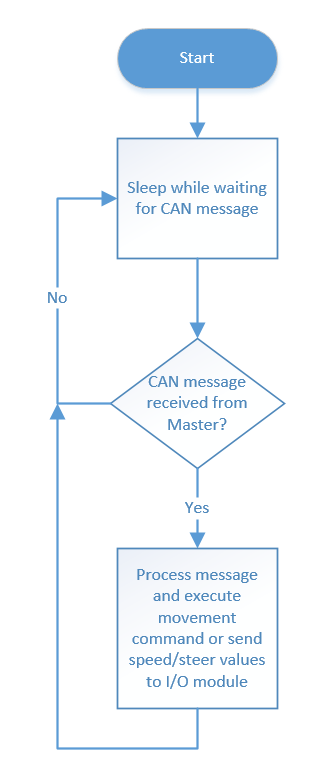

Motor Controller Team Software Design

The Motor module only has one running task. That is to listen to two CAN messages from the Master module (0x100 and 0x124). During each heartbeat (0x100), Motor will send back an acknowledgement CAN message (0x200) and send the current forward speed value and neutral steer value with a CAN message (0x221) for the I/O module. When Motor receives (0x124) from Master, it will unpack that CAN message and execute the given movement command, which can be seen in the table below.

Motor Movement Commands

| Master CAN Payload Value | Movement Command |

|---|---|

| 0 | No command |

| 1 | Slow forward |

| 2 | Fast forward |

| 3 | Slow reverse |

| 4 | Fast reverse |

| 5 | Slow right forward |

| 6 | Slow left forward |

| 7 | Slow right reverse |

| 8 | Slow left reverse |

| 9 | Stop |

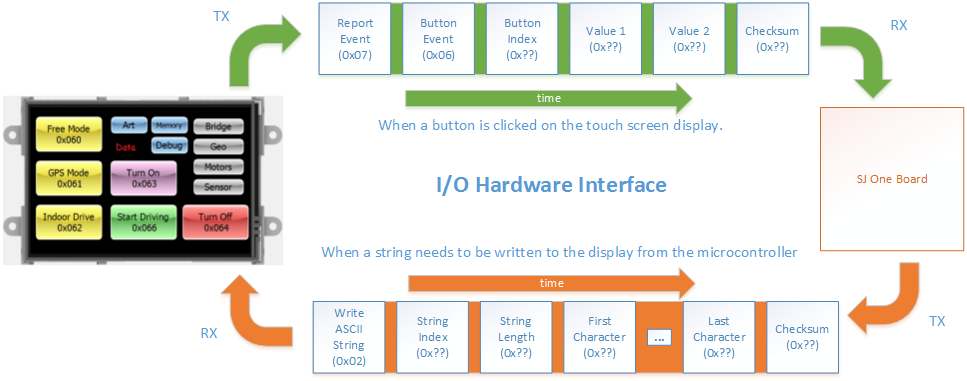

I/O Team Software Design

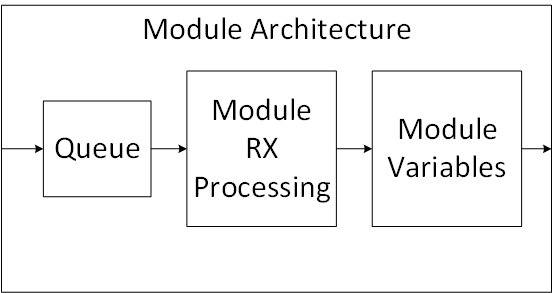

The I/O Software is based off of two tasks: The Event Handler Task and the RX Task.

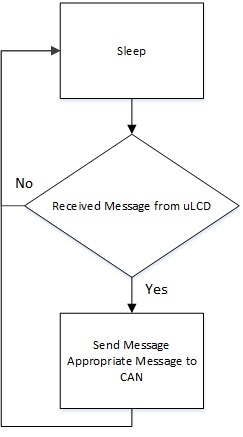

Event Handler Task (High Priority):

This Task receives any immediate messages sent from the uLCD, processes the message, and sends the message to the CAN BUS.

This task enables the system to: Turn On/Off the Vehicle and Change Vehicle Modes.

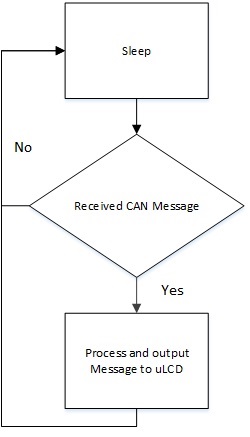

RX Task (Low Priority):

This task receives all messages from the CAN BUS, and outputs message data onto the uLCD

High Level IO Software Logic

Event Handler Task Logic

RX Task Logic

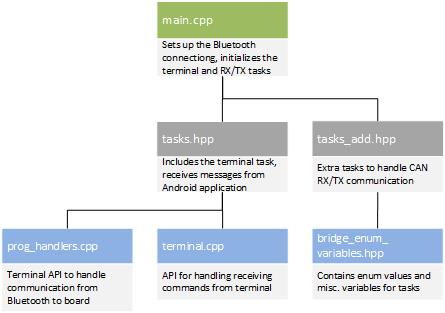

Communication Bridge + Android Software Design

Discuss your hardware design of Communication Bridge and Android

*SHOW SOFTWARE FLOWCHART DIAGRAM

Geographical Controller Team Software Design

Discuss your hardware design of Geographical Controller

*SHOW SOFTWARE FLOWCHART DIAGRAM

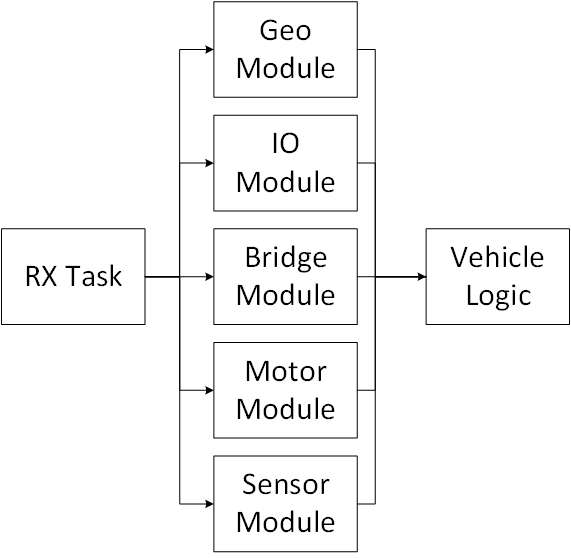

Master Controller Team Software Design

The master controller has a single receive task that fans out the messages into individual "modules". The modules then either store the data from the incoming messages into the module's variables, or call the vehicle logic API functions to alter the state of the vehicle.

Each module includes a queue that stores messages until the module has the opportunity to process it. The module code then processes the received message, which can include updating the module's variables. Module variables include data such as the current GPS location. All modules are friends of the vehicle logic class, so the vehicle logic can access these variables to get their data.

Software Interface

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

SYSTEM LEVEL SOFTWARE IMPLEMENTATION GOES HERE

Sensor Controller Team Software Interface

Describe steps to communicate hardware

Motor Controller Team Software Interface

The main function initializes the CAN bus and proceeds to call the only task called CAN_rx_tx.

-CAN_rx_tx.hpp contains an object declaration for a task that receives and sends out CAN messages. -CAN_rx_tx.cpp contains instructions on what CAN message IDs to listen for and what to execute when those messages are received. -motor_typedef.h contains nomenclature for values used within the program.

I/O Team Software Interface

Describe steps to communicate hardware

Communication Bridge + Android Software Interface

Describe steps to communicate hardware

Geographical Controller Team Software Interface

Describe steps to communicate hardware

Master Controller Team Software Interface

The primarily interaction between software level and hardware level was done over the CAN interface.

CAN Communication Table

Master CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| 0x100 | 1hz Periodic | Request Heartbeat (Module state and Timestamp) | 0x200, 0x300, 0x400, 0x500, 0x600 (Respectively) | Motor, Sensor, Geo, Bridge, IO (Respectively) |

| 0x101 | 1hz Periodic | Send Vehicle State | N/A | Motor, Sensor, Geo, Bridge, IO |

| 0x124 | Spontaneous | Set Torque and Steering | N/A | Motor |

| 0x140 | Spontaneous | Send Destination GPS | N/A | Geo |

| 0x14A | Spontaneous | Request Calibrate Compass | N/A | Geo |

| 0x14B | Spontaneous | Request Compass Heading | N/A | Geo |

| 0x14C | Spontaneous | Request Current GPS | N/A | Geo |

| 0x14D | Spontaneous | Request Current Time | N/A | Geo |

Motor CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| 0x221 | 1z Periodic | Transmits forward speed and neutral steer values. | N/A | I/O |

Sensor CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| 0x330 | 10hz Periodic | Transmit all sensor's distances | N/A | Master, IO |

Geo CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| 0x441 | 10hz Periodic | Transmit Current GPS Coordinates | N/A | Master, IO |

| 0x445 | 10hz Periodic | Transmit Current Heading and Bearing | N/A | Master, IO |

| 0x449 | 10hz Periodic | Transmit Current GPS Heading | N/A | Master, IO |

| 0x465 | Spontaneous | Signal User that Calibration is complete | N/A | I/O |

Bridge CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| 0x050 | Spontaneous | Request Drive Mode change to Free Drive | N/A | Master |

| 0x051 | Spontaneous | Request Drive Mode change to GPS Drive | N/A | Master |

| 0x052 | Spontaneous | Request Drive Mode change to Indoor Drive | N/A | Master |

| 0x053 | Spontaneous | Transmit Destination GPS Coordinates | N/A | Master |

| 0x055 | Spontaneous | Request Vehicle Start Driving Command | N/A | Master |

| 0x056 | Spontaneous | Request Vehicle Turn Off | N/A | Master |

| 0x057 | Spontaneous | Request Vehicle Turn On | N/A | Master |

| 0x058 | Spontaneous | Send Free Drive Turn Left | N/A | Master |

| 0x059 | Spontaneous | Send Free Drive Straight | N/A | Master |

| 0x05A | Spontaneous | Send Free Drive Turn Right | N/A | Master |

| 0x05B | Spontaneous | Send Free Drive Stop | N/A | Master |

| 0x05C | Spontaneous | Send Free Drive Reverse Left | N/A | Master |

| 0x05D | Spontaneous | Send Free Drive Reverse Straight | N/A | Master |

| 0x05E | Spontaneous | Send Free Drive Reverse Right | N/A | Master |

IO CAN Communication Table

| TX Message ID | TX Message Transmit Rate | TX Message Description | RX Response Message ID | RX Listening Module |

|---|---|---|---|---|

| 0x060 | Spontaneous | Request Drive Mode change to Free Drive | N/A | Master |

| 0x061 | Spontaneous | Request Drive Mode change to GPS Drive | N/A | Master |

| 0x062 | Spontaneous | Request Drive Mode change to Indoor Drive | N/A | Master |

| 0x063 | Spontaneous | Request Vehicle Turn On | N/A | Master |

| 0x064 | Spontaneous | Request Vehicle Turn Off | N/A | Master |

| 0x065 | Spontaneous | Transmit Destination GPS Coordinates | N/A | Master |

| 0x066 | Spontaneous | Request Vehicle Start Driving Command | N/A | Master |

| 0x067 | Spontaneous | Start Geo Calibration | N/A | Geo |

Testing

Sensor Controller Testing

Sensor Controller Testing #1

Describe how you tested the Sensors Sensors are calibrated prior to any testings. 1. For individual sensors: Set a obstacle(36" x 48" poster board) in front of a sensor and sensor team verifies the sensor values with a ruler. Repeat this process with different distances (20cm, 40cm,and 60cm). 2. Detect any outlier: Set a obstacle and allow sensor to detect for period of time and sensor team verifies values within the period. If there were outliers, sensor team would verify the wiring or write a filtering algorithm. 3. Integrated test: After all sensors are tested individually, sensor team tested collaboratively with master. Sensor team would sent CAN message (5 sensor values) to master team and check if master team can perform certain operations according to different sensor values.

Motor Controller Testing

Motor Controller Testing #1

Testing for the motor was done using a digital oscilloscope to probe for PWM signals. Through the usage of Preet's PWM API, various values were tested to find the range of usable values in order to attain a PWM signal width of 1ms to 2ms. It was found that using a PWM frequency of 100hz, a range between 10 and 20 were representative of a PWM duty cycle of 0% to 100%. 0%~49% equated to a left steer or a reverse throttle, while 51%~100% equated to a right steer or forward throttle. To get neutral steer or zero throttle, a 50% duty cycle was used.

However, a lot of trial and error testing were done to find suitable speeds and steering ratios. This had to be done manually by testing value ranges and physically running the car to hand pick PWM values that allowed the car to move in a slow, but steady pace.

I/O Testing

I/O Testing #1: uLCD UART Communication

Testing the following API calls:

-Write String

-Write int to String

-Write float to String

-uLCD TX events

I/O Testing #2: CAN COMMUNICATION

Tested if messages are sending and receiving tasks are operating correctly

I/O Testing #3: Data Processing

Tested if all tasks are processing the CAN frames appropriately

Communication Bridge + Android Testing

Communication Bridge + Android Testing #1

Since commands can come from terminal the communication bridge was first tested this way. When sending the commands through terminal the SJone board should be able to print them back onto the terminal showing that the SJone board is accepting the commands and storing them into variables. Since the board is taking values and storing them successfully the next step was to test if sending commands from the android app would be successful. One problem that occurred when testing the android to SJone board bridge communication is that when sending commands the board would not print out the latitude and longitude values. The communication bridge changed the code to log in the values instead of printing them out, with these changes the group confirmed that the android application is sending correct values and the SJone board is storing them correctly. This was verified by viewing the log on the SJone board. The next and final process was to see if the master board is receiving the commands that is sent out from the bridge controller, and also if the sent latitude and longitude values will be printed onto the IO screen. Connecting the bridge controller to the car network and viewing the master terminal it verified that master is receiving the latitude and longitude values, and they are showing onto the IO screen. All the values were confirmed on the needed controllers and communication bridge works successfully.

Geographical Controller

Geographical Controller

There are two devices interfaced with the Geographical Controller, the GPS and compass. The GPS is responsible for retrieving the coordinates of the device's location and the compass is responsible for producing magnetometer and accelerometer data. Therefore there are three things that must be tested: GPS, magnetometer, and accelerometer data. There are simple test cases that could be made to verify that the values produced by these modules are correct. Take the GPS module for example, by comparing the latitude and longitude from the module to the true values of it's location (from Google maps), one can verify the robustness of the device.

Master Controller

Master Controller Testing

We tested master controller by working directly with each individual module team. We would test communication over CAN with each module then test functionality with each module. We tested master controller by doing integration test with sub module teams into the overall vehicle.

Technical Challenges

Sensor Controller Team Issues

MY ISSUE #1 TITLE

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

MY ISSUE #2 TITLE

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Motor Controller Team Issues

Motor Controller Issue #1

PROBLEM: Going reverse during forward movement.

RESOLUTION: It was found out that a neutral-reverse-neutral-reverse signal had to be sent out with small amounts of vTaskDelay in order to do a reverse

FUTURE RECOMMENDATIONS: Find out how ESC unit controls reverse commands (no datasheets available).

Motor Controller Issue #2

PROBLEM: Braking during movement.

RESOLUTION: Go into neutral throttle and move wheels in the opposite direction of movement for a small amount of time.

FUTURE RECOMMENDATIONS: Try to learn how the ESC does a real brake, which should lock up the motor, thus preventing movement.

Motor Controller Issue #3

PROBLEM: How to vary speeds when going up a slope.

RESOLUTION: Use a speed sensor/wheel encoder to speed up car. (not able to implement)

FUTURE RECOMMENDATIONS: Prioritize mounting a hall sensor with magnetic strips as soon as motor module is able to control car movement.

I/O Team Issues

I/O Team Issue #1

PROBLEM:

Tasks blocking each other, thus slowing down performance

RESOLUTION:

Restructured task architecture

FUTURE RECOMMENDATIONS:

Draw out architecture first, then code

I/O Team Issue #2

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Communication Bridge + Android Team Issues

Communication Bridge + Android Issue #1

PROBLEM: The xbee that the group first purchased did not work, initial values were not being set to the xbee and a device would not recognize it.

RESOLUTION: The group came to the conclusion that the device was faulty, since the LEDs would not turn on. The group changed the xbee module, and ran the same code. This resulted in a successful communication from a bluetooth device and the SJone board.

FUTURE RECOMMENDATIONS: Buy a backup bluetooth xbee just in case one does not work.

Communication Bridge + Android #2

PROBLEM:

RESOLUTION:

FUTURE RECOMMENDATIONS:

Geographical Controller Issues

Geographical Controller Issue #1

PROBLEM: Received a blend of multiple formats from the GPS module.

RESOLUTION:

FUTURE RECOMMENDATIONS:

Geographical Controller Issue #2

PROBLEM: Values from the accelerometer were not stable.

RESOLUTION: Implemented functions to calibrate. Upon boot, offsets are calculated by polling and averaging the values of x,y, and z at standstill and subtracting all those values from 0 (because 0 is the supposed values for x,y, and z during standstill). Whenever the accelerometer task grabs the values from the registers in the gps module, it will add the value of the corresponding offset, producing calibrated values.

FUTURE RECOMMENDATIONS: Create code to calibrate all modules to make sure the data produced are the same data that you're looking for before piecing the components together.

Master Controller Team Issues

Master Controller Issue #1

BACKGROUND Each of our sensors were supposed to transmit a value between 0 and 255 in centimeters. All sensor values are updated over CAN at a 10hz periodic rate.

PROBLEM: The consistency of a sensor value would fluctuate dramatically and never stay consistent with a tolerance of 5cm.

RESOLUTION: Ask the sensor team to filter their data.

FUTURE RECOMMENDATIONS: Make the sensor team filter their data.

Master Controller Issue #2

BACKGROUND Geo were supposed to transmit valid heading over CAN at a 10hz periodic rate.

PROBLEM: The consistency of a heading value would fluctuate dramatically and never stay consistent with a tolerance of 5 degrees.

RESOLUTION: Ask geo team to calibrate their heading data, that didnt work so go in and refactor their code.

FUTURE RECOMMENDATIONS: Make geo team to calibrate their heading data.

Master Controller Issue #3

BACKGROUND Geo were supposed to transmit valid gps latitude and longitude over CAN at a 10hz periodic rate.

PROBLEM: The consistency of the gps latitude and longitude value wouldn't update at a 10hz periodic rate

RESOLUTION: Ask geo team to fix freeRTOS priority and timing issues with updating GPS latitude and longitude.

FUTURE RECOMMENDATIONS: Make geo team to fix their priority and timing issues with updating GPS latitude and longitude.

Master Controller Issue #4

BACKGROUND Geo were supposed to transmit valid bearing over CAN at a 10hz periodic rate.

PROBLEM: The geo module would miss/drop CAN message from master that contains the next GPS destination.

RESOLUTION: Ask geo team to ensure no CAN messages are dropped or missed.

FUTURE RECOMMENDATIONS: Make geo team to ensure no CAN messages are dropped or missed.

Master Controller Issue #5

BACKGROUND The vehicle would compare current GPS location to destination GPS location to determine if the vehicle should stop

PROBLEM: The algorithm to compare current GPS latitude and longitude to destination GPS latitude and longitude was comparing current latitude minus destination longitude. Because of this, the GPS comparison would be remotely close.

RESOLUTION: Fix current latitude to compare with destination latitude and current longitude with destination longitude.

FUTURE RECOMMENDATIONS: Don't make mistakes.

Conclusion

Overall, as one of the pilot teams for this 243 course, the team can conclude this project to be a success. Even though the weather, GIT, hardware, and FreeRTOS may have been common obstacles everyone faced, the team was able to successfully create a a self driving GPS RC car via 6 subsystems using CAN communication. The team learned other important skills as well, including: team dynamics, hardware interference, various protocols, algorithms, and team workflow. These skills that were gained through this project can be scaled into other projects within the field.

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.