S22: Firebolt

Contents

FireBolt RC Car

Abstract

Firebolt is battery powered autonomous RC car. The car uses four microcontrollers for communication between the nodes- driver node, motor node, bridge & sensor node, and geological node over the CAN bus. It is interfaced to the mobile application which sends GPS coordinates for the destination location to the driver node and reaches the destination by avoiding any obstacles that comes in the path. For obstacle detection and avoidance it uses Ultrasonic Sensor and makes the decision of steering and maintaining speed based on the bridge and sensor node's input.

Objectives & Introduction

Objectives

- RC car can communicate with an Android application to:

- Receive new coordinates to travel to

- Send diagnostic information to the application

- Emergency stop and start driving

- RC car can travel to received coordinates in an efficient path while avoiding obstacles

- RC car can maintain speed when driving on sloped ground

- Design printed circuit board (PCB) to neatly connect all SJ2 boards

- Design and 3D print sensor mounts for the ultrasonic sensors

- Design a simple and intuitive user interface for the Android application

- Design a DBC file

Introduction

The Firebolt RC car uses 4 SJ2 boards as nodes on the CAN bus

- Driver Node

- GEO Node

- Sensors and Bridge Node

- Motor Node

- Mobile Application

Team Members & Responsibilities

- Priyanka Rai

- Geo Controller

- Bridge and Sensor Controller

- Wiki Page Update

- Ritu Patil

- Motor Controller

- Android Application

- Integration Testing

- Ritika Beniwal

- Driver Node

- PCB Designing

- Wiki Page Update

- Utsav Savaliya

- Sensor Controller

- Driver Node

Schedule

| Week# | Start Date | Target Date | Task | Completion Date | Status |

|---|---|---|---|---|---|

| Week 1 |

|

|

|

|

|

| Week 2 |

|

|

|

|

|

| Week 3 |

|

|

|

|

|

| Week 4 |

|

|

|

|

|

| Week 5 |

|

|

|

|

|

| Week 6 |

|

|

|

|

|

| Week 7 |

|

|

|

|

|

| Week 8 |

|

|

|

|

|

| Week 9 |

|

|

|

|

|

| Week 10 |

|

|

|

|

|

| Week 11 |

|

|

|

|

|

| Week 12 |

|

|

|

|

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Traxxas [1] | ||

| 2 | CAN Transceivers MCP2551-I/P | Comimark [2] | ||

| 3 | Ultrasonic Sensors | Max Botix[3] | ||

| 4 | GPS and Antenna | Adafruit[4] | ||

| 5 | HC05 bluetooth RF Transreceiver | HiLetgo[5] | ||

| 6 | Triple-axis Accelerometer | Adafruit[6] | ||

| 7 | Traxxas RPM Sensor | Traxxas[7] | ||

| 8 | Discrete Electronic Components | Generic[8] | ||

| 9 | Buck-Boost Voltage Regulator | Generic[9] | ||

| 10 | Traxxas Telemetry Trigger magnet & holder | Traxxas[10] | ||

| 11 | Acrylic Sheet | Tap Plastic | ||

| 12 | Battery | |||

| 13 | Traxxas Battery and Charger |

Printed Circuit Board

PCB Schematic

PCB Design

CAN Communication

We use controller area network to broadcast data between the 4 nodes. All nodes are connected to each other through a physically conventional two wire bus. The wires are a twisted pair with 120 Ω resistors at each ends of the bus. 1s and 0s are transmitted as CAN High(0V difference) and Can Low(2v difference). A CAN frame has the following contents:

- Data Length Code (4bits)

- Remote Transmission Request.

- ID extend bit.

- Message ID (11 bit or 29 bit)

- Data bytes( depends on DLC)

- CRC

Arbitration: No two nodes will transmit at the same time because if arbitration. A lower Message-ID has a Higher priority on the CAN bus since 0 is the dominant bit.

Bit Stuffing: CAN bus stuffs extra bits when a long chain of multiple 1's or 0's occur to improve CAN integrity.

| Sr. No | Message ID | Message function | Receivers |

|---|---|---|---|

| Driver Controller | |||

| 1 | speed and steering direction for the motor. | Motor | |

| 2 | Destination reached | Sensor | |

| Sensor Controller | |||

| 1 | Sensor sonars from front, back, left ,right sensor | Driver | |

| Motor Controller | |||

| 8 | motor speed, motor direction | Driver | |

| Geo and Bridge Controller | |||

| 1 | Bearing, Heading and Distance | Driver | |

| Debug messages | |||

| 1 | Driver Debug | SENSOR,MOTOR,GEO_AND_BRIDGE | |

| 1 | Motor Debug | SENSOR,MOTOR,GEO_AND_BRIDGE | |

| 1 | Sensor Debug | SENSOR,MOTOR,GEO_AND_BRIDGE | |

Hardware Design

DBC File

Sensor ECU

Hardware Design

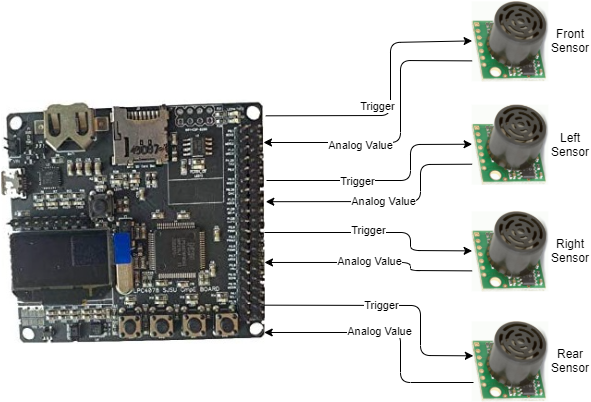

Sensor Controller Schematic

Board Pin Connections

Sensors are interfaced with combination of GPIO, ADC Pins on SJTWo board. Below is the descriptive pin layout:

Software Design

VERSION ""

NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_

BS_:

BU_: DRIVER MOTOR BRIDGE_SENSOR GEO

BO_ 100 DRIVER_HEARTBEAT: 1 DRIVER

SG_ DRIVER_HEARTBEAT_cmd : 0|8@1+ (1,0) [0|0] "" BRIDGE_SENSOR,MOTOR,GEO

BO_ 200 SENSOR_SONARS: 5 BRIDGE_SENSOR

SG_ SENSOR_SONARS_left : 0|10@1+ (1,0) [0|0] "cm" DRIVER SG_ SENSOR_SONARS_right : 10|10@1+ (1,0) [0|0] "cm" DRIVER SG_ SENSOR_SONARS_middle : 20|10@1+ (1,0) [0|0] "cm" DRIVER SG_ SENSOR_SONARS_rear : 30|10@1+ (1,0) [0|0] "cm" DRIVER

BO_ 250 DESTINATION_LOCATION: 8 BRIDGE_SENSOR

SG_ DEST_LATITUDE : 0|28@1+ (0.000001,-90.000000) [-90|90] "Degrees" GEO SG_ DEST_LONGITUDE : 28|28@1+ (0.000001,-180.000000) [-180|180] "Degrees" GEO

BO_ 300 DRIVER_TO_MOTOR: 2 DRIVER

SG_ DRIVER_TO_MOTOR_speed : 0|8@1+ (1,0) [-99|99] "mph" MOTOR SG_ DRIVER_TO_MOTOR_direction : 8|8@1- (1,-2) [-2|2] "degree" MOTOR

BO_ 600 MOTOR_SPEED: 4 MOTOR SG_ MOTOR_SPEED_info : 0|16@1- (0.01,-30.01) [-30.01|30.01] "mph" DRIVER, BRIDGE_SENSOR SG_ MOTOR_SPEED_pwm : 16|16@1+ (0.01, 0) [0.01|20.01] "pwm" DRIVER, BRIDGE_SENSOR

BO_ 400 GEO_CONTROLLER_COMPASS: 8 GEO

SG_ HEADING : 0|12@1+ (0.1,0) [0|359.9] "Degrees" DRIVER,BRIDGE_SENSOR SG_ BEARING : 12|12@1+ (0.1,0) [0|359.9] "Degrees" DRIVER,BRIDGE_SENSOR SG_ DISTANCE_TO_DESTINATION: 24|16@1+ (0.1,0) [0|359.9] "Degrees" DRIVER,BRIDGE_SENSOR

CM_ BU_ DRIVER "The driver controller driving the car";

CM_ BU_ MOTOR "The motor controller of the car";

CM_ BU_ SENSOR "The sensor controller of the car";

CM_ BO_ 100 "Sync message used to synchronize the controllers";

CM_ BU_ GEO "To provide raw GPS and compass heading";

CM_ SG_ 100 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver";

//VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ; VAL_ 300 DRIVER_TO_MOTOR_direction -2 "MOTOR_direction_HARD_LEFT" -1 "MOTOR_direction_SOFT_LEFT" 0 "MOTOR_direction_STRAIGHT" 1 "MOTOR_direction_SOFT_RIGHT" 2 "MOTOR_direction_HARD_RIGHT" ;

Technical Challenges

Neighboring Sensor Interference:

Frequent noisy measurements:

Motor ECU

Hardware Design

Software Design

Technical Challenges

Geographical And Bridge Controller

Hardware Design

Software Design

Technical Challenges

Driver Node

Hardware Design

The Driver Node has one peripheral connected to it and that is the LCD screen.

Software Design

- Driver Node Flow Chart

Technical Challenges

Mobile Application

User Interface

Software Design

This app has mainly two activities, The main activity and maps activity.

Maps Activity

Bluetooth/WIFI

Technical Challenges

Conclusion

Project Video

Project Source Code

Advise for Future Students

Acknowledgement

References

http://socialledge.com/sjsu/index.php/Industrial_Application_using_CAN_Bus