Difference between revisions of "Self-driving Car"

Proj user13 (talk | contribs) (→Part 2: CAN Rx Task) |

Proj user13 (talk | contribs) (→Part 2: CAN Rx Task) |

||

| Line 399: | Line 399: | ||

{ | { | ||

can_msg_t msg; | can_msg_t msg; | ||

| − | controller_id_t msgid; | + | const controller_id_t *msgid = (controller_id_t *)(&(msg.msg_id)); |

while(1) { | while(1) { | ||

if (CAN_rx(can1, &msg, portMAX_DELAY)) { | if (CAN_rx(can1, &msg, portMAX_DELAY)) { | ||

| − | |||

/* TODO This is psuedocode, so add your real logic here */ | /* TODO This is psuedocode, so add your real logic here */ | ||

| − | if (msgid | + | if (msgid->dst != cid_broadcast && msgid->dst != OUR_CONTROLLER_ID) { |

LOG_ERROR("CAN acceptance filter must be incorrect (0x%08X)!", msg.msg_id); | LOG_ERROR("CAN acceptance filter must be incorrect (0x%08X)!", msg.msg_id); | ||

} | } | ||

Revision as of 23:57, 3 November 2014

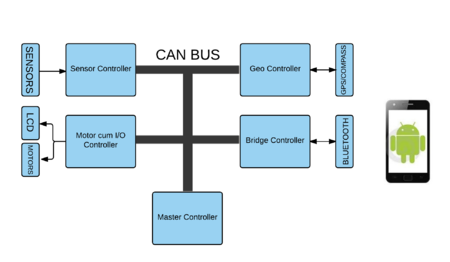

This project is about a large team getting a car to self-drive to a selected destination. This involves working with an RTOS running on a low power processor and various different processor boards working together over a CAN bus.

Gitlab

Create a "master" Gitlab project that contains sub-folders of each project. Please provide me the access (username: preet) to your master project so I can peek at all of your source code when needed. The Gitlab will track your commit history so I would also know how much work each person or team is contributing.

The folder structure should be:

- TeamX_CmpE_Fall2014

- Sensor

- IO

- <other controller projects>

Schedule

| Week | Milestone |

| October (Week1) |

|

| October (Week2) |

|

| October (Week3) |

|

| October (Week4) |

|

| October (Week5) |

|

| November (Week6) |

|

| November (Week7) |

|

| November (Week8) |

|

| November (Week9) |

|

| December(Week10) |

|

| December(Week11) | Project Demonstration |

Parts

Controllers

Given below are the controllers, their duties, and the number of people involved. It is possible that one team gets done with their part, but that doesn't mean your job is done. If you are done, help others. If you are done, and the primary objective is met (the car can self-drive), then add more features. There are many things you can do, and the 16-week semester definitely won't provide an opportunity to sit and relax. Get up and learn!.

| Sensor Controller

(2 members) |

|

| Motor Controller

(2 members) |

|

| I/O Unit

(2 members) |

|

| Communication Bridge + Android

(3 members) |

|

| Geographical Controller

(3 members) |

|

| Central Controller

(3 members) |

|

Communication

Each controller shall provide a means to communicate with the other controllers. Before you read any further, it requires that you have deep knowledge of the CAN bus. CAN is a BROADCAST communication bus, but in our software we can add addressing such that we can have 1:1 communication (rather than 1:many). Each controller shall pick a controller number. The controller with the highest priority shall pick the lowest ID. Using this protocol, each controller can specifically send a message to any other controller, and likewise, upon a received message, we can tell who it came from.

Recommended CAN Message ID format

We split the 29-bit CAN message ID into 3 portions to support peer-to-peer communication. When a CAN message arrives, we will have its 29-bit ID, and out of this, we can determine who sent it, and what message number they sent.

You should configure your CAN hardware filter based on your controller ID. So if your controller is ID 0x50, you should accept all messages in this range: 0x50.00.000 - 0x50.FF.FFF. In particular, your CAN hardware filter needs a single EXTENDED GROUP filter.

You should use 0xFF as a "BROADCAST" address. So if a node sends a message with destination address 0xFF and message number is 0x101, then ALL controllers should respond to this command. So this means you need another acceptance filter with this range: 0xFF.00.000 - 0xFF.FF.FFF

| Reserved bit | Destination Controller | Source Controller | Message number |

1-bit : B28

|

8-bit : B27:B20

|

8-bit : B19:B13

|

12-bit: B12:B00

|

| Reserved | 0x000 - 0x0FF

|

| Common commands | 0x100 - 0x1FF

|

| Common responses | 0x200 - 0x2FF

|

| Controller specific commands | 0x300 - 0x3FF

|

| Reserved | 0x400 - 0x4FF

|

| Data messages | 0x500 - 0x5FF

|

Example Controller Communication Table

| Message Number | Purpose / Data layout |

| 0x101 | Get version and boot info (0x201 will be sent) |

| 0x102 | Get general info (0x202 will be sent) |

| 0x103 | Synchronize (set) time:

byte [0-3] : System time |

| 0x201 |

byte [0-3] : Version Info byte [4-7] : boot timestamp |

| 0x202 |

byte [0-3] : Current time byte [4] : CPU usage % |

| Message Number | Purpose | Data layout |

| 0x301 | Set GPS destination |

byte [0-3] : (float) Longitude byte [4-7] : (float) Latitude |

| 0x501 | GPS Data Message |

byte [0-3] : (float) Longitude byte [4-7] : (float) Latitude |

| 0x502 | Compass Data Message |

byte [0-1] : (uint16) Current compass degree byte [2-3] : (uint16) Destination compass degree |

| Message Number | Purpose | Data layout |

| 0x501 | Sensor Data Message |

byte [0] : Front sensor value in inches byte [1] : Left sensor value in inches byte [2] : Right sensor value in inches etc. |

How will communication work?

After startup, begin to send your data messages at the desired periodic rates using the periodic API as listed below in the example. Whichever controller wants to listen to your periodic message shall intercept your message and use it for its needs.

You can have global variables for the CAN data messages, and tasks should update the data within these messages. Assuming that you've added periodic message to be sent to broadcast address (0xFF), the periodic tasks will always grab the latest CAN message and send it out for you.

Features

The first feature to develop is the self-drive capability and everything else comes later. While some people in the team may be focusing on delivering this primary feature, other members can focus on other things such as automatic headlights, variable speed settings through Android interface etc. If your product team fails, then just like it would happen in the industry, you will get laid off, and I will see you again in the course ;(

Quick and Easy Features

These features are mandatory, just to help you debug faster.

- Each controller shall display its version information at startup, for example:

- "Version 1.2"

- "Fixed rear sensor reporting zero value"

- "Version 1.1"

- "Added rear sensor value"

- Each controller shall use the 2-digit LED display to display meaningful info

- Maybe Geo Controller can display # of feet to destination

- Central controller can display number of CAN messages received per second.

- Each controller shall use the 4-LED lights for some indication

- LED0 should be lit if an error happens (common to everyone)

- Each LED should be labeled about what it means(maybe with a label machine?)

Robustness

Your project is one project as a whole. So if it doesn't work, do not blame it on "hey, their controller crashed". If a controller crashes it will restart, and you will have live with missing data messages. So your code should be robust, and self-recover from any crashed event or any brief power disruptions.

Likewise, if you send a message, and it fails (in case the other controller is down), your CAN bus may go to abnormal state and turn off. In this condition, all of your messages will fail, and you will have to handle this. I recommend the following:

- Attach a BUS off callback function that gives "can_bus_crashed" semaphore.

- If the semaphore is ever given, reset your CAN bus after a 3 second timeout.

Startup Tests

Since we rely on multiple controllers, it is critical to be able to test each controller quickly, reliably, and easily. So here is a startup test the Central Controller must process upon each boot:

- Central controller sends a message requesting boot information from each controller

- Central controller checks responses after about 100 ms:

- Each controller must have responded

- Each controller's boot code (normal, abnormal) should be validated.

Considerations

You should consider and design your software for all of these events:

- Where is the kill switch?

- Can you remotely shut down the car in 3 seconds?

- Where is the kill switch?

- If your controller goes down, will it fully recover to "last known configuration"?

- If critical sensor data stops coming, how will you stop the car?

- How can you quickly discover one or more controllers reaching an error state?

- Log the data on the SD card as much as possible.

- If something wrong happens, you need to know what happened.

- Each controller must log its "startup" time, to debug when a controller crashes and restarts

Grade

Your grade is relative. The best team earns the best grade. Remember than three out of three features working 100% is far better than nine out of ten features working. Focus on less features, with highest quality.

Sample Code

Part 1: Basic structure and CAN initialization

/************** can_msg_id.h *************/

#ifndef CAN_MSG_ID_H_

#define CAN_MSG_ID_H_

/**

* Have an enumeration of controller IDs

*/

typedef enum :uint8_t {

cid_geographical_controller = 1,

cid_central_controller = 2,

cid_broadcast = 0xff

} cid_t;

/// TODO Each controller shall set its own ID

#define OUR_CONTROLLER_ID (cid_central_controller)

/**

* Create a "union" whose struct overlaps with the uint32_t of CAN message id

*/

typedef union {

/// This "raw" overlaps with <DST> <SRC> <ID>

uint32_t raw;

/// Struct members overlap with "raw"

struct {

uint32_t msg_num : 12; ///< Message number

uint32_t src : 8; ///< Source ID

uint32_t dst : 8; ///< Destination ID

};

} __attribute__((packed)) controller_id_t;

/**

* Creates a message ID based on the message ID protocol

* @param [in] dst The destination controller ID

* @param [in] msg_num The message number to send to the dst controller

*

* @returns The 32-bit message ID created by the input parameters

*/

static inline uint32_t make_id(uint8_t dst, uint16_t msg_num)

{

controller_id_t cid = { 0 };

cid.msg_num = msg_num;

cid.src = OUR_CONTROLLER_ID;

cid.dst = dst;

return cid.raw;

}

#endif /* CAN_MSG_ID_H_ */

/************** main.cpp ************/

#include "can_msg_task_mgr.hpp"

#include "can.h"

int main(void)

{

/* Initialize CAN Bus and set the acceptance filter(s) */

CAN_init(can1, 100, 10, 10, NULL, NULL);

/* TODO Initialize acceptance filters */

CAN_reset_bus(can1);

/* This creates all of the periodic message tasks */

can_msg_task_init();

/* TODO Add more tasks... */

/* Start the scheduler to run all the tasks */

scheduler_start();

return 0;

}

Part 2: CAN Rx Task

Only one FreeRTOS task should be responsible to receive CAN messages (while any task can send a CAN message). This receiving task should "route" the incoming messages to the appropriate "consumers" in your code.

/* Either a "plain vanilla" FreeRTOS task, or run() method of scheduler_task */

void rx_fanout_task(void *p)

{

can_msg_t msg;

const controller_id_t *msgid = (controller_id_t *)(&(msg.msg_id));

while(1) {

if (CAN_rx(can1, &msg, portMAX_DELAY)) {

/* TODO This is psuedocode, so add your real logic here */

if (msgid->dst != cid_broadcast && msgid->dst != OUR_CONTROLLER_ID) {

LOG_ERROR("CAN acceptance filter must be incorrect (0x%08X)!", msg.msg_id);

}

else if (common_command_message) { /* 0x100 - 0x1FF */

handle_common_cmd(msg); /* 0x200 - 0x2FF */

}

else if (other_controller_response_msg) { /* 0x200 - 0x2FF */

handle_cmd_rsp_msg(msg);

}

else if (our_command_message) { /* 0x300 - 0x3FF */

handle_our_cmd(msg);

}

else if (other_controller_data_message) { /* 0x500 - 0x5FF */

handle_data_msg(msg);

}

else {

LOG_ERROR("Unexpected Message ID: 0x%08X", msg.msg_id);

}

}

}

}

Part 3: Infrastructure code for sending CAN messages periodically

can_msg_task.hpp

#ifndef CAN_TASK_HPP_

#define CAN_TASK_HPP_

#include <stdint.h>

#include "can.h"

#include "vector.hpp"

#include "scheduler_task.hpp"

/**

* The task that sends out the periodic messages of a list at the defined frequency.

*/

class canMsgTask : public scheduler_task

{

public:

canMsgTask(can_t canBusNum, ///< The CAN bus to use

float rateHz, ///< The message rate of this task

uint8_t capacity, ///< The max capacity of the message list

uint8_t priority ///< The priority of this task

);

/// Init function

bool init(void);

/// FreeRTOS task method

bool run(void *p);

/// Add a periodic message to be sent by this task

/// You probably cannot access it directly, so use can_msg_task_mgr.hpp's API

bool addPeriodicMsg(uint8_t dst, ///< Destination address

uint16_t msgNum, ///< Message number

can_msg_t *pCanMsg ///< Actual CAN message pointer

);

private:

/**

* Structure of a periodic message

*/

typedef struct {

uint8_t dstAddr; ///< The destination address of a node

uint16_t msgNum; ///< The message number for the node

can_msg_t *canMsgPtr; ///< Pointer to the actual CAN message pointer

} periodicMsg_t;

canMsgTask(); ///< Private default constructor, do not use.

const float mTaskRateHz; ///< The run duration of the task

const can_t mCanBusNum; ///< The CAN Bus number

VECTOR<periodicMsg_t> mPeriodicMsgList; ///< The periodic message list

};

#endif /* CAN_TASK_HPP_ */can_msg_task.cpp

#include "can_msg_task.hpp"

#include "can_msg_id.h"

#include "file_logger.h"

canMsgTask::canMsgTask(can_t canBusNum, float rateHz, uint8_t capacity, uint8_t priority) :

scheduler_task("sendMsg", 3 * 512, priority), ///< base class constructor calls

mTaskRateHz(rateHz), ///< Task rate in Hz

mCanBusNum(canBusNum), ///< CAN Bus to use

mPeriodicMsgList(capacity) ///< Construct the list

{

/* Nothing to do */

}

bool canMsgTask::init(void)

{

bool status = false;

const uint32_t rateMs = 1000 / mTaskRateHz;

/* The rate must be within reasonable bounds */

const uint32_t minMs = 1;

const uint32_t maxMs = 60 * 1000;

if (rateMs >= minMs && rateMs <= maxMs) {

setRunDuration(rateMs);

status = true;

}

return status;

}

bool canMsgTask::run(void *p)

{

can_msg_t msg;

const uint32_t timeoutMs = 50; /* Some reasonable time */

for (unsigned int i = 0; i < mPeriodicMsgList.size(); i++)

{

/* Use a const reference to avoid copying the item (it's like a const pointer) */

const periodicMsg_t &periodicMsg = mPeriodicMsgList[i];

/* Copy the CAN message from the CAN message pointer, this includes the

* data length field which should've been set by the caller of addPeriodicMsg()

* TODO: You may need a critical section here to avoid copying partial data

*/

msg = *(periodicMsg.canMsgPtr);

/* Form the message ID that we need to use */

msg.msg_id = make_id(periodicMsg.dstAddr, periodicMsg.msgNum);

/* We must be able to at least queue the message without a timeout otherwise

* either the CAN Bus is over-utilized or our queue sizes are too small.

*/

if (!CAN_tx(mCanBusNum, &msg, timeoutMs)) {

LOG_ERROR("Error sending message from %uHz task within %u ms",

mTaskRateHz, timeoutMs);

}

}

return true;

}

bool canMsgTask::addPeriodicMsg(uint8_t dst, uint16_t msgNum, can_msg_t *pCanMsg)

{

bool ok = false;

/* Populate the fields of the periodic message */

periodicMsg_t periodicMsg;

periodicMsg.dstAddr = dst;

periodicMsg.msgNum = msgNum;

periodicMsg.canMsgPtr = pCanMsg;

if (! (ok = (NULL != pCanMsg))) {

LOG_ERROR("pCanMsg was a NULL pointer (%uHz task)", mTaskRateHz);

}

else {

/* Add the periodic message to our list or if no capacity, log an error*/

if ((ok = (mPeriodicMsgList.size() < mPeriodicMsgList.capacity()))) {

/* TODO Double check if this message doesn't already exist */

mPeriodicMsgList.push_back(periodicMsg);

}

else {

LOG_ERROR("List capacity for %uHz task has exceeded maximum periodic messages of %u",

mTaskRateHz, mPeriodicMsgList.size());

}

}

return ok;

}can_msg_task_mgr.hpp

#ifndef CAN_MSG_TASK_MANAGER_HPP_

#define CAN_MSG_TASK_MANAGER_HPP_

#include "can_msg_task.hpp"

#include "scheduler_task.hpp"

/// Enumeration of message rate

typedef enum {

msgRate1Hz = 0,

msgRate10Hz,

msgRate50Hz,

/// Marks the last entry; do not use!

msgRateLast,

} msgRate_t;

/// Initializes all of the CAN periodic message tasks

void can_msg_task_init(void);

/**

* Adds a message periodic to be sent at the given rate.

* @param [in] rate The rate of the message

* @param [in] dst The node address of the destination

* @param [in] msgNum The message number of the CAN message ID

* @param [in] pCanMsg The pointer to the CAN message

*

* @returns true if the periodic was added successfully

*/

bool add_new_periodic_msg(msgRate_t rate, uint8_t dst, uint16_t msgNum, can_msg_t *pCanMsg);

#endif /* CAN_MSG_TASK_MANAGER_HPP_ */can_msg_task_mgr.cpp

#include "can_msg_task_mgr.hpp"

/// Private instances of the canMsgTask pointers we create

static canMsgTask *g_MsgTaskPtrs[msgRateLast] = { NULL };

void can_msg_task_init(void)

{

const can_t canbus = can1; // CAN bus to use for the periodic tasks

const uint32_t listCap = 10; // max periodic messages per periodic task (1Hz, 10Hz, 50Hz)

/* Create all of the tasks and add them to the scheduler */

scheduler_add_task((g_MsgTaskPtrs[msgRate1Hz] = new canMsgTask(canbus, 1, listCap, 1)));

scheduler_add_task((g_MsgTaskPtrs[msgRate10Hz] = new canMsgTask(canbus, 10, listCap, 2)));

scheduler_add_task((g_MsgTaskPtrs[msgRate50Hz] = new canMsgTask(canbus, 50, listCap, 3)));

}

bool add_new_periodic_msg(msgRate_t rate, uint8_t dst, uint16_t msgNum, can_msg_t *pCanMsg)

{

bool ok = false;

if (NULL != g_MsgTaskPtrs[rate]) {

ok = (g_MsgTaskPtrs[rate])->addPeriodicMsg(dst, msgNum, pCanMsg);

}

return ok;

}