Difference between revisions of "S23: X Æ A-13"

(→Software Design) |

(→Periodic Callback Functions) |

||

| Line 632: | Line 632: | ||

- The motors start-up sequence is designed. <br> | - The motors start-up sequence is designed. <br> | ||

<b>Periodic Callback: 10Hz</b><br> | <b>Periodic Callback: 10Hz</b><br> | ||

| − | - | + | - Decode the driving speed and steering sent by the Driver node after reading all CAN messages. <br> |

=== Technical Challenges === | === Technical Challenges === | ||

Revision as of 00:45, 27 May 2023

Contents

Project Title

<Team Name>

Abstract

<2-3 sentence abstract>

Introduction

The project was divided into N modules:

- Sensor ...

- Motor..

- ...

- Android

Team Members & Responsibilities

<Team Picture>

The source code of our car can be found here: X Æ A-13 Gitlab Repository

|

Team Members |

Administrative Roles |

Technical Roles | ||

|---|---|---|---|---|

| ||||

| ||||

| ||||

| ||||

| ||||

Schedule

| Task# | Start Date | End Date | Task | Status | Point of Contact |

|---|---|---|---|---|---|

| 1 | 02/13/2023 | 02/18/2023 |

|

Completed | Team |

| 2 | 02/19/2023 | 02/22/2023 |

|

Completed | Iftiza |

| 3 | 03/03/2023 | 03/10/2023 |

|

Completed | Sharan, Prabhat, Tushara |

| 4 | 03/11/2023 | 03/17/2023 |

|

Completed | Team |

| 5 | 03/18/2023 | 03/21/2023 |

Work on the RC Car Infrastructure Task

|

Completed |

|

| 6 | 03/22/2023 | 04/04/2023 |

Work on the Geo Controller Task

|

Completed |

|

| 7 | 04/05/2023 | 04/18/2023 |

Work towards the Prototype 1 Task

|

Completed |

|

| 8 | 04/19/2023 | 04/25/2023 | Work towards the Prototype 2 Task

|

Completed |

|

| 9 | 04/20/2023 | 05/02/2023 | Work towards the Prototype 3 Task

|

Completed |

|

| 10 | 05/03/2023 | 05/09/2023 | Work towards the Prototype 4 Task

|

Completed |

|

| 11 | 05/10/2023 | 05/24/2023 | Work towards the final demo

|

Completed |

|

| 12 | 05/10/2023 | 05/26/2023 | Project Wrap-up

|

Ongoing |

Team |

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Maverick Quantum MT [1] | 1 | $180.00 |

| 2 | RC Car Battery | Lithium Polymer Two-Cell | 1 | $20.0 |

| 3 | CAN Transceiver Modules | SN65HVD230 | 4 | $43.56 |

| 4 | SJTwo Microcontroller Development Board | SJSU | 5 | $250 |

| 5 | Ultrasonic Sensor | Adafruit US 100[2] | 4 | $48.69 |

| 6 | GPS Module | Adafruit PA1616S [3] | 1 | $32 |

| 7 | Compass Module | CMPS12 - RobotShop [4] | 1 | $39.77 |

| 8 | LCD Module | LCD1602 [5] | 2 | $12.02 |

Printed Circuit Board

<Picture and information, including links to your PCB>

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management etc.>

Hardware Design

<Show your CAN bus hardware design>

DBC File

Gitlab link to the X Æ A-13 DBC file

VERSION "2.5" NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_ BS_: BU_: GEOLOGICAL SENSOR DRIVER MOTOR BO_ 101 CHKPT_GPS_POSITION: 8 GEOLOGICAL SG_ CHKPT_GPS_LATITUDE_SCALED : 0|32@1- (1,0) [-90000000|90000000] "degree" DRIVER SG_ CHKPT_GPS_LONGITUDE_SCALED : 32|32@1- (1,0) [-180000000|180000000] "degree" DRIVER BO_ 102 CURRENT_GPS_POSITION: 8 GEOLOGICAL SG_ CURRENT_GPS_LATITUDE_SCALED : 0|32@1- (1,0) [-90000000|90000000] "degree" DRIVER SG_ CURRENT_GPS_LONGITUDE_SCALED : 32|32@1- (1,0) [-180000000|180000000] "degree" DRIVER BO_ 103 GEO_STATUS: 8 GEOLOGICAL SG_ GEO_STATUS_COMPASS_ANGLE : 0|10@1+ (1,0) [0|359] "degree" DRIVER SG_ GEO_STATUS_BEARING_ANGLE_TO_DESTINATION : 10|10@1+ (1,0) [0|359] "degree" DRIVER SG_ GEO_STATUS_DISTANCE_TO_DESTINATION : 20|16@1+ (1,0) [0|2000] "meter" DRIVER SG_ GEO_STATUS_BEARING_ANGLE_TO_CHKPT : 36|10@1+ (1,0) [0|359] "degree" DRIVER SG_ GEO_STATUS_DISTANCE_TO_CHKPT : 46|16@1+ (1,0) [0|2000] "metre" DRIVER BO_ 104 GEO_ANGLE_DELTA: 4 GEOLOGICAL SG_ GEO_ANGLE_DIFF_TO_DEST : 0|16@1- (1,0) [-359|359] "degree" DRIVER SG_ GEO_ANGLE_DIFF_TO_CHKPT : 16|16@1- (1,0) [-359|359] "degree" DRIVER BO_ 105 GEO_LOCK: 1 GEOLOGICAL SG_ GEO_LOCK_TO_DESTINATION : 0|8@1+ (1,0) [0|1] "boolean" DRIVER BO_ 201 SENSOR_SONARS: 5 SENSOR SG_ SENSOR_SONARS_left : 0|10@1+ (1,0) [0|1000] "cm" DRIVER SG_ SENSOR_SONARS_right : 10|10@1+ (1,0) [0|1000] "cm" DRIVER SG_ SENSOR_SONARS_middle : 20|10@1+ (1,0) [0|1000] "cm" DRIVER SG_ SENSOR_SONARS_rear : 30|10@1+ (1,0) [0|1000] "cm" DRIVER BO_ 202 DEST_GPS_POSITION: 8 SENSOR SG_ DEST_GPS_LATITUDE_SCALED : 0|32@1- (1,0) [-90000000|90000000] "degree" GEOLOGICAL,DRIVER SG_ DEST_GPS_LONGITUDE_SCALED : 32|32@1- (1,0) [-180000000|180000000] "degree" GEOLOGICAL,DRIVER BO_ 203 CAR_HEARTBEAT: 1 SENSOR SG_ HEARTBEAT_DATA : 0|8@1+ (1,0) [0|1] "boolean" DRIVER BO_ 302 MOTOR_CMD: 3 DRIVER SG_ MOTOR_CMD_steer: 0|8@1- (1,-5) [-5|5] "" MOTOR SG_ MOTOR_CMD_drive : 8|16@1- (1,-9) [-9|9] "kph" MOTOR BO_ 401 LCD_DATA_FROM_MOTOR_NODE: 3 MOTOR SG_ RPM_SENSOR_SPEED: 0|6@1+ (1,0) [0|50] "kph" DRIVER SG_ SERVO_PWM: 6|7@1+ (1,0) [0|100] "percent" DRIVER SG_ MOTOR_PWM: 13|7@1+ (1,0) [0|100] "percent" DRIVER BO_ 901 DEBUG_CHK: 8 GEOLOGICAL SG_ GPS_PASS_COUNTER: 0|16@1+ (1,0) [0|64000] "count" DRIVER SG_ GPS_FAIL_COUNTER: 16|16@1+ (1,0) [0|64000] "count" DRIVER SG_ CMPS_PASS_COUNTER: 32|16@1+ (1,0) [0|64000] "count" DRIVER SG_ CMPS_FAIL_COUNTER: 48|16@1+ (1,0) [0|64000] "count" DRIVER CM_ BU_ DRIVER "The driver node of the car"; CM_ BU_ MOTOR "The motor controller node of the car"; CM_ BU_ SENSOR "The sensor controller node of the car"; CM_ BU_ GEOLOGICAL "The geoposition and geodirection controller of the car"; CM_ BO_ 101 "Sync message used to synchronize the controllers from driver node"; CM_ BO_ 102 "Sync message used to synchronize the controllers from sensor node"; CM_ SG_ 101 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver";

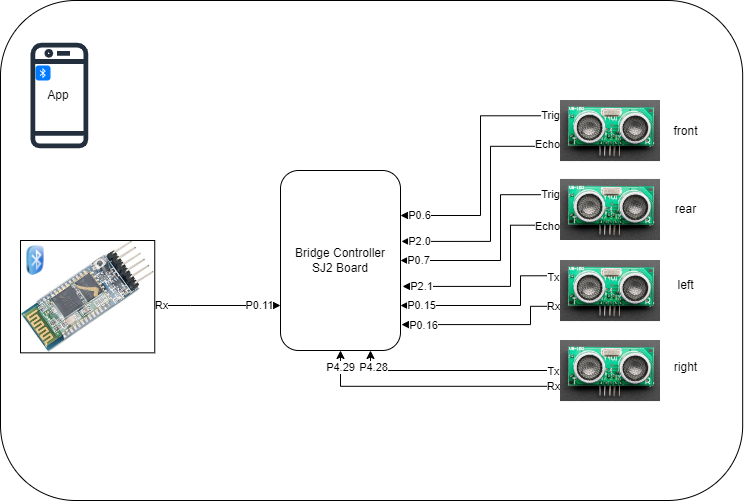

Sensor ECU

<Picture and link to Gitlab>

Hardware Design

Adafruit US-100 Ultrasonic Range Finder

- Detection Range(reliable): 2 cm to 250 cm.

- 3-5V operation range.

- UART Output, PWM output.

- Accuracy: 3mm

- Measuring angle covered: <15°

- Operating Current: <15mA

- Operating Frequency: 40Hz

We employed a set of four Adafruit US-100 Ultrasonic Range Finders as sensory components in our project. These ultrasonic sensors were integrated into the RC car system with the objective of enabling effective obstacle avoidance. To achieve this, we strategically positioned three sensors on the front side of the RC car, while the remaining sensor was placed at the rear. The sensors were powered by a +5V supply voltage. An indicative sign of successful data retrieval was the toggling of LED3 on the SJ2 board.

The operational principle is as follows: When the trigger pin is set to a HIGH state for a minimum duration of 10 microseconds, the module automatically emits a 40 kHz ultrasonic wave from the Ultrasonic transmitter. This wave propagates through the air and, upon encountering an obstruction, it reflects back towards the sensor. The Ultrasonic receiver module detects this reflected wave. As soon as the wave returns, the Echo pin becomes HIGH for a specific duration, equivalent to the time it took for the wave to travel back to the sensor.

for UART: To establish communication with the sensor, a UART baud rate of 9600 is utilized. In UART mode, a command is sent by transmitting the hexadecimal value 0x55 to the sensor. Following the command transmission, two bytes (a 16-bit value) are read back, representing the distance in millimeters (mm).

The SJ2 board measures the length of time during which the Echo pin remains HIGH, providing information about the duration of the wave's round trip. Utilizing this information, the distance is calculated, as described in the previous section. The formula used to measure the distance to the object is Distance = Speed × Time, where the speed represents the speed of sound.

Software Design

Among these sensors, two employed UART communication to transmit distance data to the SJ2 microcontroller, whereas the other two utilized interrupt-based communication. To facilitate communication with the SJ2 microcontroller, UART1 and UART3 were designated for the right and left sensors, respectively. Additionally, pins P0.6 and P0.7 were allocated as trigger pins, while pins P2.0 and P2.1 served as echo pins for the front and rear sensors.

Sensors were divided into two groups:

- Front and Rear

- Left and Right

Each group utilizes a frequency of 10Hz. The provided code demonstrates its periodic invocation.

void periodic_callbacks__10Hz(uint32_t callback_count) {

get_sonar_values();

if ((ultrasonic_can_tx()) && (car_heartbeat_tx_10hz()) && (destination_coordinate_tx_10hz())) {

gpio__toggle(board_io__get_led3());

}The following code snippet demonstrates the initialization of the triggers for the front and rear sensors in 100Hz.

void periodic_callbacks__100Hz(uint32_t callback_count) {

ultrasonic_implementation__initiate_ultrasonics_range();

}Technical Challenges

- Issue: The presence of noise in the sensor measurements is causing instability in the car's steering, resulting in a wobbly motion.

- Solution: To address the issue of noise in the sensor measurements and stabilize the car's steering, we have implemented an average buffer. This buffer calculates the average value based on the last 10 readings rather than relying on a single value. By taking into account multiple readings over a period of time, the average buffer helps to reduce the impact of noise and provide a more stable steering response for the car.

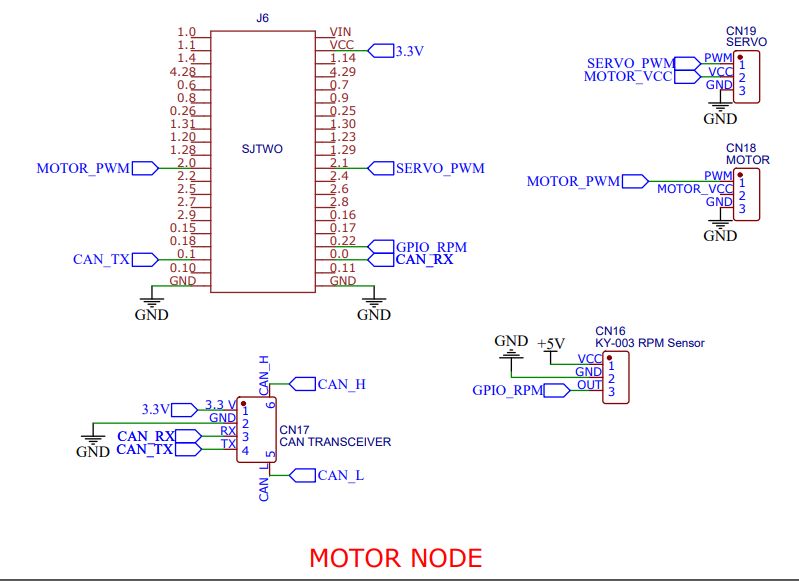

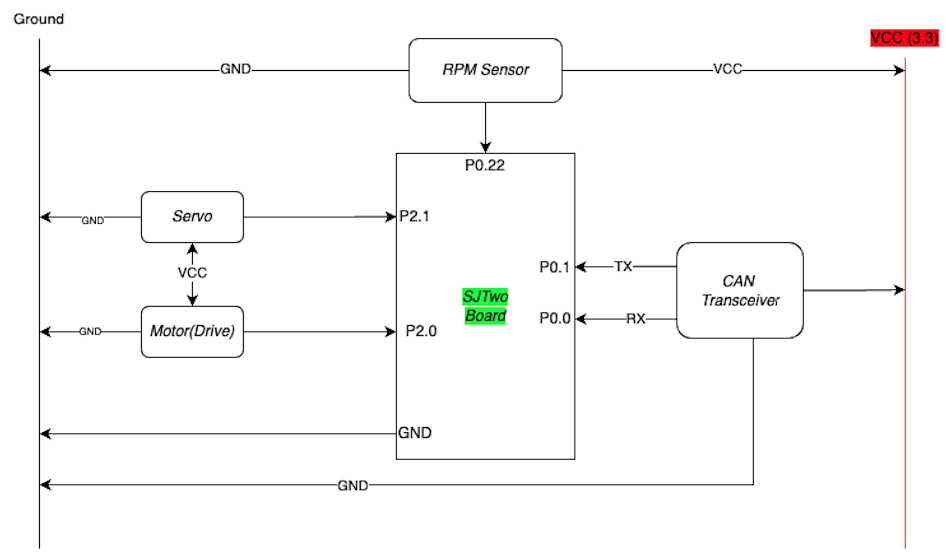

Motor ECU

<Picture and link to Gitlab>

The primary function of this module involves establishing a communication interface with the Driver Node, employing the CAN (Controller Area Network) communication protocol. Through this communication protocol, the module receives and retrieves the desired speed and steering angle information from the Driver Node. The CAN protocol facilitates the exchange of data between the module and the Driver Node, enabling seamless transmission of control signals for speed and steering angle adjustments.

Motors work on the PWM (pulse width modulation) values which are given by the ESC. ESCs process input signals, convert them into digital values, use algorithms to determine motor speed, generate PWM signals with variable pulse width, calculate duty cycle, and drive motors through power transistors to control speed. Understanding these PWM values for motor movements is a critical task which has to be done when we start working on the project.

Hardware Design

The SJTwo board provided us with the necessary PWM pins, specifically P2.1 and P2.0, to which we connected the servo and DC motor, respectively. These pins were selected based on their capability to generate PWM signals required for precise control of the motors.

The SJTwo board is equipped with a powerful microcontroller, offering ample processing power and I/O capabilities. With its PWM functionality, we were able to modulate the output signals to control the servo and DC motor with high precision.

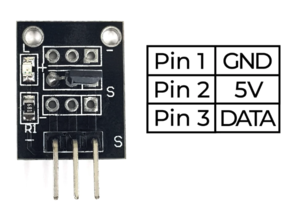

RPM Sensor

In our project, we have incorporated a Hall effect RPM sensor for monitoring the rotational speed of the vehicle's wheels. The RPM sensor is strategically positioned on the car's chassis, adjacent to the shock absorbers. This placement ensures accurate measurement of the wheel's rotational speed. The RPM sensor serves as a vital input for maintaining a consistent speed of the vehicle.

The RPM data obtained from the sensor is utilized by a PID (Proportional-Integral-Derivative) controller to regulate and fine-tune the vehicle's speed. By continuously monitoring the RPM, the PID controller makes necessary adjustments to ensure the vehicle maintains the desired speed. The RPM sensor acts as a critical source of speed information, enabling the PID controller to effectively and dynamically govern the vehicle's speed to achieve the desired stability and control.

Hacking the RF Module

In order to make the RC car autonomous, we faced the challenge of eliminating the need for the remote control typically used to operate the car. Our specific model, the Maverick Quantum MT, did not have its PWM (Pulse Width Modulation) sequence readily available in open-source form. Therefore, we had to delve into the process of detecting the PWM signals transmitted by the RC receiver to the Electronic Speed Controller (ESC) module.

To accomplish this, we employed an oscilloscope or a logic analyzer. However, we found that the logic analyzer was particularly advantageous due to its user-friendly interface and software capabilities for analyzing the obtained signals. By connecting the logic analyzer to the RC car's receiver, we were able to capture and analyze the PWM signals in detail.

Through the analysis, we were able to identify important parameters of the PWM signals, such as the duty cycle and frequency. These parameters corresponded to various actions performed by the servo and motor in the RC car. By understanding the relationship between these parameters and the desired actions, we gained the ability to replicate and control these actions autonomously, effectively replacing the functionality of the remote control.

This process of detecting and interpreting the PWM signals was essential for enabling autonomous control of the RC car. It allowed us to develop a custom control system that could replicate the desired actions based on the analyzed PWM signals. With this system in place, the RC car became capable of executing predefined maneuvers and tasks without relying on manual input from a remote control.

Overall, the utilization of an oscilloscope or logic analyzer, along with the analysis of PWM signals, played a crucial role in our endeavor to make the RC car autonomous. By gaining insights into the PWM parameters and implementing a custom control system, we were able to take control of the car's functions and pave the way for autonomous operation.

Here are the data we obtained

| Control Unit | Direction | Frequency (Hz) | Duty Cycle (%) |

|---|---|---|---|

| Servo Motor | Right Max | 61.02 | 5.9 |

| Left Max | 61.02 | 12.62 | |

| Motor | Forward Max Speed | 61.02 | 12.65 |

| Idling (Zero) Speed | 61.02 | 9.27 | |

| Reverse Max Speed | 61.02 | 5.66 |

The duty cycle for crawling the car at the slowest speed = 9.47%.

Software Design

Periodic Callback Functions

Periodic Callback: Init

- The CAN bus is initialized

- The RPM sensor interrupts are initialized.

- The Motor and servo PWM signals are initialized and set to default values.

Periodic Callback: 1Hz

- The motors start-up sequence is designed.

Periodic Callback: 10Hz

- Decode the driving speed and steering sent by the Driver node after reading all CAN messages.

Technical Challenges

< List of problems and their detailed resolutions>

Geographical Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

Advise for Future Students

<Bullet points and discussion>

Acknowledgement

=== References ===