Difference between revisions of "S20: Nimble"

(→Technical Challenges) |

(→DBC File) |

||

| Line 362: | Line 362: | ||

<Show your CAN bus hardware design> | <Show your CAN bus hardware design> | ||

| − | + | VERSION "" | |

| − | |||

| − | |||

| + | NS_ : | ||

| + | BA_ | ||

| + | BA_DEF_ | ||

| + | BA_DEF_DEF_ | ||

| + | BA_DEF_DEF_REL_ | ||

| + | BA_DEF_REL_ | ||

| + | BA_DEF_SGTYPE_ | ||

| + | BA_REL_ | ||

| + | BA_SGTYPE_ | ||

| + | BO_TX_BU_ | ||

| + | BU_BO_REL_ | ||

| + | BU_EV_REL_ | ||

| + | BU_SG_REL_ | ||

| + | CAT_ | ||

| + | CAT_DEF_ | ||

| + | CM_ | ||

| + | ENVVAR_DATA_ | ||

| + | EV_DATA_ | ||

| + | FILTER | ||

| + | NS_DESC_ | ||

| + | SGTYPE_ | ||

| + | SGTYPE_VAL_ | ||

| + | SG_MUL_VAL_ | ||

| + | SIGTYPE_VALTYPE_ | ||

| + | SIG_GROUP_ | ||

| + | SIG_TYPE_REF_ | ||

| + | SIG_VALTYPE_ | ||

| + | VAL_ | ||

| + | VAL_TABLE_ | ||

| + | BS_: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

BU_: DBG DRIVER IO MOTOR SENSOR BRIDGE GPS COMPASS CMP | BU_: DBG DRIVER IO MOTOR SENSOR BRIDGE GPS COMPASS CMP | ||

| Line 407: | Line 402: | ||

SG_ MOTOR_CMD_SPEED : 8|8@1+ (1,-25) [-25|25] "" MOTOR | SG_ MOTOR_CMD_SPEED : 8|8@1+ (1,-25) [-25|25] "" MOTOR | ||

| − | BO_ 200 SENSOR_DATA: 8 | + | BO_ 151 MOTOR_DATA: 4 MOTOR |

| + | SG_ MOTOR_DATA_RPM: 0|32@1+ (1,0) [0|0] "" DRIVER | ||

| + | |||

| + | BO_ 200 SENSOR_DATA: 8 BRIDGE | ||

SG_ SENSOR_SONARS_left : 0|16@1+ (1,0) [0|0] "cms" DRIVER | SG_ SENSOR_SONARS_left : 0|16@1+ (1,0) [0|0] "cms" DRIVER | ||

SG_ SENSOR_SONARS_mid : 16|16@1+ (1,0) [0|0] "cms" DRIVER | SG_ SENSOR_SONARS_mid : 16|16@1+ (1,0) [0|0] "cms" DRIVER | ||

| Line 414: | Line 412: | ||

BO_ 300 GPS_DESTINATION_INFO: 8 BRIDGE | BO_ 300 GPS_DESTINATION_INFO: 8 BRIDGE | ||

| − | + | SG_ GPS_DESTINATION_LAT : 0|32@1+ (0.000001,-90.000000) [-90|90] "degrees" DRIVER,GPS,MOTOR | |

| − | + | SG_ GPS_DESTINATION_LONG : 32|32@1+ (0.000001,-180.000000) [-180|180] "degrees" DRIVER,GPS,MOTOR | |

BO_ 301 GPS_CURRENT_INFO: 8 GPS | BO_ 301 GPS_CURRENT_INFO: 8 GPS | ||

| − | + | SG_ GPS_CURRENT_LAT : 0|32@1+ (0.000001,-90.000000) [-90|90] "degrees" DRIVER,BRIDGE,MOTOR | |

| − | + | SG_ GPS_CURRENT_LONG : 32|32@1+ (0.000001,-180.000000) [-180|180] "degrees" DRIVER,BRIDGE,MOTOR | |

BO_ 302 COMPASS: 6 GPS | BO_ 302 COMPASS: 6 GPS | ||

| Line 426: | Line 424: | ||

SG_ CMP_DISTANCE : 32|16@1+ (0.01,0) [0|0] "meters" DRIVER,BRIDGE | SG_ CMP_DISTANCE : 32|16@1+ (0.01,0) [0|0] "meters" DRIVER,BRIDGE | ||

| − | + | BO_ 105 SENSOR_DEBUG: 1 BRIDGE | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | BO_ 105 SENSOR_DEBUG: 1 | ||

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG | SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG | ||

SG_ IO_DEBUG_sensor_init : 1|1@1+ (1,0) [0|0] "" DBG | SG_ IO_DEBUG_sensor_init : 1|1@1+ (1,0) [0|0] "" DBG | ||

| Line 447: | Line 430: | ||

SG_ IO_DEBUG_bus_off : 3|1@1+ (1,0) [0|0] "" DBG | SG_ IO_DEBUG_bus_off : 3|1@1+ (1,0) [0|0] "" DBG | ||

| − | BO_ 106 MOTOR_DEBUG: | + | BO_ 106 MOTOR_DEBUG: 6 MOTOR |

| − | SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG | + | SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG,DRIVER |

| − | SG_ IO_DEBUG_bus_off : 1|1@1+ (1,0) [0|0] "" DBG | + | SG_ IO_DEBUG_bus_off : 1|1@1+ (1,0) [0|0] "" DBG,DRIVER |

| − | SG_ | + | SG_ IO_DEBUG_Steering : 2|8@1+ (1,-2) [-2|2] "" DBG,DRIVER |

| − | SG_ | + | SG_ IO_DEBUG_RPM : 10|32@1+ (1,0) [0|0] "" DBG,DRIVER |

BO_ 107 DRIVER_DEBUG: 1 DRIVER | BO_ 107 DRIVER_DEBUG: 1 DRIVER | ||

| Line 471: | Line 454: | ||

CM_ BU_ DRIVER "The driver controller driving the car"; | CM_ BU_ DRIVER "The driver controller driving the car"; | ||

CM_ BU_ MOTOR "The motor controller of the car"; | CM_ BU_ MOTOR "The motor controller of the car"; | ||

| − | |||

CM_ BU_ BRIDGE "The bridge controller of the car"; | CM_ BU_ BRIDGE "The bridge controller of the car"; | ||

CM_ BU_ GPS "The GPS controller of the car"; | CM_ BU_ GPS "The GPS controller of the car"; | ||

| Line 480: | Line 462: | ||

BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; | BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; | ||

BA_DEF_ SG_ "FieldType" STRING ; | BA_DEF_ SG_ "FieldType" STRING ; | ||

| + | |||

BA_DEF_DEF_ "BusType" "CAN"; | BA_DEF_DEF_ "BusType" "CAN"; | ||

BA_DEF_DEF_ "FieldType" ""; | BA_DEF_DEF_ "FieldType" ""; | ||

| Line 485: | Line 468: | ||

BA_ "GenMsgCycleTime" BO_ 100 1000; | BA_ "GenMsgCycleTime" BO_ 100 1000; | ||

| − | |||

BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd"; | BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd"; | ||

VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ; | VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ; | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Sensor ECU == | == Sensor ECU == | ||

Revision as of 06:17, 20 May 2020

Contents

Nimble

<Pic of the car>

Abstract

In this project, an autonomous vehicle framework for an RC car is presented using dedicated ECUs for motor control, on-board LCD display, steering control, sensor information handling, and communication bridging. A mobile application was also developed that allows for a user to set a destination, and receive updates on the RC car's position via a Bluetooth connection to the GPS unit. CAN communication between sensors and ECUs was defined via a DBC file. Code was developed using test-driven design principles in order to lower time spent debugging. Unit testing was performed using the CMock framework.

Introduction

The project was divided into these modules:

- Sensor node

- Motor node

- Driver node

- GPS node

- Bridge control node

- LCD node

- Mobile application

The objective was to create an autonomous vehicle that could navigate to a given GPS coordinate sent via a mobile application. The vehicle moves towards the target position Using a pre-compiled list of checkpoints, and handles obstacles along the way via its ultrasonic and infrared sensors. Updates on Nimble's position are sent to the mobile application via bluetooth.

Team Members & Responsibilities

<Team Picture>

- Yuming Cheng [ LinkedIn] Gitlab

- GPS Module

- Master Module

- Motor Module

- LCD display

- Wiki

- Naeem Mannan [ LinkedIn] Gitlab

- Wiki

- Mobile Application

- Francesco Vescio [ LinkedIn] Gitlab

- Wiki

- Lawrence Wan LinkedIn Gitlab

- Master Module

- GPS Module

- Motor Controller

- LCD display

- Sensor Module

- Wiki

Team Deliverables Schedule

| WEEK |

START DATE |

END DATE |

TASK DETAILS |

STATUS |

|---|---|---|---|---|

| 1 | Feb 2020 | 4 March 2020 |

|

|

| 2 | 05 March 2020 | 12 March 2020 |

|

|

| 3 | 13 March 2020 | 19 March 2020 |

|

|

| 4 | 20 March 2020 | 26 March 2020 |

|

|

| 5 | 27 March 2019 | 09 April 2019 |

|

|

| 6 | 10 April 2020 | 16 April 2020 |

|

|

| 7 | 17 April 2020 | 23 April 2020 |

|

|

| 8 | 24 April 2020 | 30 April 2020 |

|

|

| 9 | 1 May 2020 | 7 May 2020 |

|

|

| 10 | 8 May 2020 | 21 May 2020 |

|

|

| 11 | 22 May 2020 |

|

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Traxxas - Amazon [1] | 1 | $168.84 |

| 2 | CAN Transceivers MCP2551-I/P | Robotshop [2] | 6 | $ 6.00 per unit including shipping fee |

| 3 | GPS | Amazon [] | 1 | $ .00 per unit including shipping fee |

| 4 | Compass | Amazon [] | 1 | $ .00 per unit including shipping fee |

| 5 | Ultrasonic sensors(LV-MaxSonar-EZ0) | SparkFun [3] | 1 | $ 29.95 |

| 6 | Ultrasonic sensors (LV-MaxSonar-EZ1) | SparkFun [4] | 2 | $ 51.90 |

| 7 | IR sensors (GP2Y0A21YK) | SparkFun [5] | 1 | $ 34.23 including shipping fee and tax |

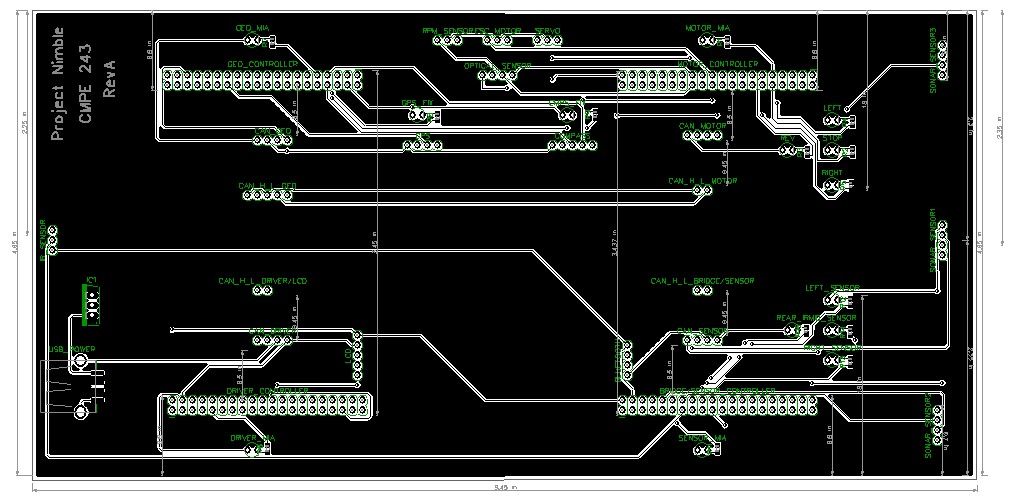

Printed Circuit Board

Design and Architecture

The PCB made for the Project Nimble RC car was initially designed in EAGLE, however, due to the board size limitations, the PCB had to be designed using DipTrace instead. This design was the first and only iteration in designing the layout of the PCB. The design of the PCB was designed around the four SJTWO LPC4078 micro-controllers required for us to use for the project, the DRIVER, MOTOR, GEOGRAPHICAL, and BRIDGE/SENSOR nodes. The PCB layout consists of four through-hole "slots" where the controllers will be connected (with respect to the controllers' orientation and ports/pins) to the PCB. The power section includes a USB socket as well as a through-hole mount for a LM7805 regulator. Through-hole header pins are also included for the components needed for their respective controllers such as the sensors, LCD, GPS, Compass, etc.. LED circuits were added to provide visual information for the user to indicate the motor and servo motion states, as well as to indicate if a sensor has detected an object. Lastly, the design for the CAN bus includes the connections needed for power, RX/TX, and the CAN low and CAN high bus. The dimensions of the PCB are approximately 4 by 9 inches.

Fabrication

Fabrication of the PCB design was done by JLCPCB located in Hong Kong. The PCB was designed using 2-layers and lead-free coating. The fabrication was done relatively quickly, however, due to the COVID-19 outbreak, delivery of the PCB was delayed.

Challenges

Some challenges encountered when designing the PCB was the delay in pinout information needed to begin designing the PCB. It is advised to order parts early and determine what ports/pins are needed as soon as possible to begin designing and ordering the PCB. Another challenge was some issues with the files needed to be manufactured. Since the design had to be designed using DipTrace instead of EAGLE, exporting the necessary files needed to order for fabrication is slightly different than EAGLE.

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management etc.>

Hardware Design

<Show your CAN bus hardware design>

VERSION ""

NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_

BS_:

BU_: DBG DRIVER IO MOTOR SENSOR BRIDGE GPS COMPASS CMP

BO_ 150 MOTOR_CMD: 3 DRIVER

SG_ MOTOR_CMD_STEERING : 0|8@1+ (1,-2) [-2|2] "" MOTOR SG_ MOTOR_CMD_SPEED : 8|8@1+ (1,-25) [-25|25] "" MOTOR

BO_ 151 MOTOR_DATA: 4 MOTOR

SG_ MOTOR_DATA_RPM: 0|32@1+ (1,0) [0|0] "" DRIVER

BO_ 200 SENSOR_DATA: 8 BRIDGE

SG_ SENSOR_SONARS_left : 0|16@1+ (1,0) [0|0] "cms" DRIVER SG_ SENSOR_SONARS_mid : 16|16@1+ (1,0) [0|0] "cms" DRIVER SG_ SENSOR_SONARS_right : 32|16@1+ (1,0) [0|0] "cms" DRIVER SG_ SENSOR_IR_rear : 48|16@1+ (1,0) [0|0] "cms" DRIVER

BO_ 300 GPS_DESTINATION_INFO: 8 BRIDGE SG_ GPS_DESTINATION_LAT : 0|32@1+ (0.000001,-90.000000) [-90|90] "degrees" DRIVER,GPS,MOTOR SG_ GPS_DESTINATION_LONG : 32|32@1+ (0.000001,-180.000000) [-180|180] "degrees" DRIVER,GPS,MOTOR

BO_ 301 GPS_CURRENT_INFO: 8 GPS SG_ GPS_CURRENT_LAT : 0|32@1+ (0.000001,-90.000000) [-90|90] "degrees" DRIVER,BRIDGE,MOTOR SG_ GPS_CURRENT_LONG : 32|32@1+ (0.000001,-180.000000) [-180|180] "degrees" DRIVER,BRIDGE,MOTOR

BO_ 302 COMPASS: 6 GPS

SG_ CMP_DEST_BEARING : 0|16@1+ (0.1,0) [0|359.9] "degrees" DRIVER,BRIDGE,MOTOR SG_ CMP_CURRENT_HEADING : 16|16@1+ (0.1,0) [0|359.9] "degrees" DRIVER,BRIDGE,MOTOR SG_ CMP_DISTANCE : 32|16@1+ (0.01,0) [0|0] "meters" DRIVER,BRIDGE

BO_ 105 SENSOR_DEBUG: 1 BRIDGE

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_sensor_init : 1|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_sensor_data : 2|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_bus_off : 3|1@1+ (1,0) [0|0] "" DBG

BO_ 106 MOTOR_DEBUG: 6 MOTOR

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG,DRIVER SG_ IO_DEBUG_bus_off : 1|1@1+ (1,0) [0|0] "" DBG,DRIVER SG_ IO_DEBUG_Steering : 2|8@1+ (1,-2) [-2|2] "" DBG,DRIVER SG_ IO_DEBUG_RPM : 10|32@1+ (1,0) [0|0] "" DBG,DRIVER

BO_ 107 DRIVER_DEBUG: 1 DRIVER

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_bus_off : 1|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_DRIVER : 3|1@1+ (1,0) [0|0] "" DBG

BO_ 108 GPS_DEBUG: 1 GPS

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_bus_off : 2|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_GPS : 3|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_Compass : 5|1@1+ (1,0) [0|0] "" DBG

BO_ 109 BRIDGE_DEBUG: 1 BRIDGE

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_bus_off : 2|1@1+ (1,0) [0|0] "" DBG SG_ IO_DEBUG_Bridge : 4|1@1+ (1,0) [0|0] "" DBG

CM_ BU_ DRIVER "The driver controller driving the car"; CM_ BU_ MOTOR "The motor controller of the car"; CM_ BU_ BRIDGE "The bridge controller of the car"; CM_ BU_ GPS "The GPS controller of the car"; CM_ BO_ 100 "Sync message used to synchronize the controllers"; CM_ SG_ 100 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver";

BA_DEF_ "BusType" STRING ; BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; BA_DEF_ SG_ "FieldType" STRING ;

BA_DEF_DEF_ "BusType" "CAN"; BA_DEF_DEF_ "FieldType" ""; BA_DEF_DEF_ "GenMsgCycleTime" 0;

BA_ "GenMsgCycleTime" BO_ 100 1000; BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd";

VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ;

Sensor ECU

<Picture and link to Gitlab>

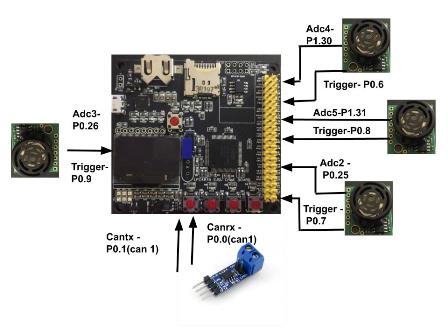

The sensor and bridge controller consists of sensor module that is responsible for object detection. Nimble uses ultrasonic sensors to achieve this task. As the name suggests, an ultrasonic sensor emits ultrasonic signal or beam from its head, and on encountering an object, returns back. This technique is better known as echolocation as we used sound signals to do so. The distance of the object is calculated based on the output and this ensures object detection. The distance measured is continuously passed on to driver node through can transceiver. The driver controller further processes the distance values of all the sensors on nimble and acts in accordance with the values to achieve obstacle avoidance.

Hardware Design

We have embedded 4 sensors on Nimble. We have arranged 3 LV-MaxSonar-EZ series Maxbotix ultrasonic sensors in the front section of the car; one at right, one at left and one in the center. The fourth Ultrasonic sensor is placed at the rear end of the car. These sensors provide very short to long-range detection. It provides sonar range information from 6-inches out to 254-inches with 1-inch resolution.

A maxbotix sensor gives out 3 types of output- analog, RS232, and Pulse width. We have used analog output and hence, utilized on-board analog to digital converters- ADC2 (P0.25), ADC3 (P0.26), ADC4 (P1.30), and ADC5 (P1.31). To trigger all the four ultrasonic sensors, we used P0.6, P0.7, P0.8 and P0.9 of SJTWO board. The analog output is converted to digital and transmitted to the driver controller. The converted adc distance data is passed to driver by Can transceiver. P0.0 is used as CAN RX and P0.1 as CAN TX on the Sensor module.

Hardware Interface

Sensors are interfaced with combination of GPIO, ADC Pins on SJTWo board. Below is the descriptive pin layout:

| Sr. No. | SJTwo board Pin | Maxbotix sensor Pin | Function |

|---|---|---|---|

| 1 | ADC2-P0.25 | AN(Left) | ADC input from left sensor |

| 2 | ADC3-P0.26 | AN(Rear) | ADC input from rear sensor |

| 3 | ADC4-P1.30 | AN(Right) | ADC input from right sensor |

| 4 | ADC5-P1.31 | AN(Middle) | ADC input from middle sensor |

| 5 | P0.6 | RX(Right) | Trigger for right sensor |

| 6 | P0.7 | RX(Left) | Trigger for left sensor |

| 7 | P0.8 | RX(Middle) | Trigger for middle sensor |

| 8 | P0.9 | RX(Rear) | Trigger for rear sensor |

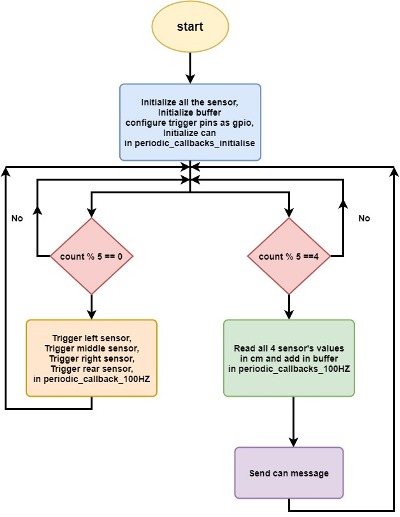

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Motor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

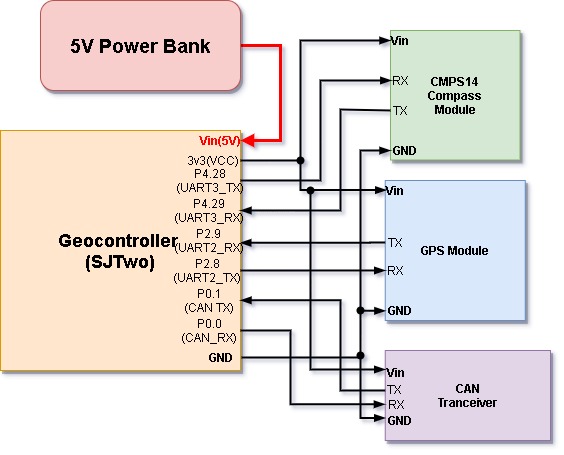

Geographical Controller

The geographical controller is responsible for interfacing with a GPS and Compass module in order to receive the current heading(in degrees) and the current destination in the form of GPS coordinates (in degrees, hours, minutes, seconds). It is also responsible for receiving the needed destination coordinates sent by the BRIDGE controller which are needed along with the current GPS location coordinates to calculate the destination heading angle and distance to destination and checkpoints. The current compass heading angle is also sent to the DRIVER controller such that it can be integrated into the driver logic to determine the heading angle to steer and drive towards the destination.

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

- Issue 1: Probably one of the most difficult challenges to deal with in this project was the inaccuracy of the GPS module. The default readings of this GPS module would be read were not even remotely close to its actual location.

- Solution: Although we did not fully fix this issue, the method that we dealt with the terrible accuracy was to implement manual calibration with respect to the actual location of the module using google maps, and either adding or subtracting an offset to the GPS coordinates received from the GPS module.

- Issue 2: Calibration of the compass was another issue. Each time the compass module would boot up, the readings of the heading angle would be off by a considerable amount.

- Solution: The solution to solve this was to send calibration commands to the compass module. Helpful commands to send to the compass was erasing the calibration profile and setting default calibration settings.

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

<Organized summary of the project>

<What did you learn?> Nimble was a great opportunity to learn test-driven design strategies, which helped lower the amount of time troubleshooting issues. It also taught us much about using Git for version control. The project also gave us experience working with embedded systems technologies such as CAN bus communications, DBC files, GPIO, and signal debugging with BusMaster.

Project Video

Project Source Code

Gitlab Project Link - [6]

Advise for Future Students

<Bullet points and discussion>