ABSTRACT

Bucephalus is a Self Driving RC car using CAN communication based on FreeRTOS(Hard RTOS). The RC car takes real time inputs and covert it into the data that can be processed to monitor and control to meet the desired requirements. In this project, we aim to design and develop a self-driving car that autonomously navigates from the current location to the destination (using Waypoint Algorithm )which is selected through an Android application and at the same time avoiding all the obstacles in the path using Obstacle avoidance algorithm . It also Increases or Decreases speed on Uphill and downhill (using PID Algorithm)as well as applies breaks at required places. The car comprises of 4 control units communicating with each other over the CAN Bus using CAN communication protocol, each having a specific functionality that helps the car to navigate to its destination successfully.

INTRODUCTION

Objectives of the RC Car:-

1) Driver Controller:- Detection and avoidance of the obstacles coming in the path of the RC car by following Obstacle detection avoidance.

2) Geographical Controller:- Getting the GPS coordinates from the Android Application and traveling to that point using Waypoint Algorithm

3) System hardware communication using PCB Design.

4) Bridge and Sensor Controller:- Communication between the Driver Board and Android Mobile Application using wireless bluetooth commmunication.

5) Motor Controller:- Control the Servo Motor for Direction and DC motor for speed. Implementation of PID Algorithm on normal road uphill and down hill to maintain speed

The project is divided into six main modules:

|

CORE MODULES OF RC CAR

|

- Android Mobile Application

- Bridge and Sensor Controller

- Geographic Controller

- Driver and LCD Controller

- Motor Controller

- Hardware Integration and PCB Designing

|

Team Members & Responsibilities

<Team Picture>

Bucephalous GitLab - [1]

- Mohit Ingale GitLab LinkedIn

- Driver and LCD Controller

- Hardware Integration (PCB Designing)

- Testing Team / Code Reviewers

- Shreya Patankar GitLab LinkedIn

- Geographical Controller

- Hardware Integration (PCB Designing)

- Testing Team / Code Reviewers

- Wiki Page

- Nicholas Kaiser GitLab LinkedIn

- Bridge and Sensor Controller

- Wiki Page

- Hardware Integration (PCB Designing)

- Hari Haran Kura GitLab LinkedIn

- Motor Controller

- Testing Team / Code Reviewers

- Hardware Integration (PCB Designing)

- Basangouda Patil GitLab LinkedIn

- Android Mobile Application

- Testing Team / Code Reviewers

- Abhinandan Burli GitLab LinkedIn

- Driver and LCD Controller

- Testing Team / Code Reviewers

- Hardware Integration (PCB Designing)

Schedule

| Week#

|

Start Date

|

End Date

|

Task

|

Status

|

| 1

|

02/16/2020

|

02/22/2020

|

- Setup a team Google Docs folder

- Brainstorm RC car design options

- Research past semester RC car projects for ideas and parts needed

- Put together a rough draft parts list

- Setup a team GitLab repository

|

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 2

|

02/23/2020

|

02/29/2020

|

- Decide on and order chassis

- Discuss possible GPS modules

- Discuss schedule for meeting dates and work days (Tuesdays are for code review and syncing, Saturdays are work days)

- Discuss bluetooth communication approach (1 phone on car, 1 phone in controller's hands)

- Discuss vehicle's driving checkpoints (checkpoints calculated after point B is specified)

- Discuss wiring on RC car (1 battery to power motors and 1 power bank for everything else)

- Discuss GitLab workflow (mirror our repo with Preet's, 3 approvals to merge to "working master" branch, resolve conflicts on "working master" branch, then can merge to master branch)

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 3

|

03/01/2020

|

03/07/2020

|

- Decide on sensors (4 ultrasonic sensors: 3 in front, 1 in back)

- Decide on a GPS module (Adafruit ADA746)

- Research GPS antennas

- Decide on CAN transceivers (SN65HVD230 IC's)

- Request 15 CAN transceiver samples from ti.com

- Discuss tasks of all 4 board nodes (geographical, driver, motors, bridge controller/sensors)

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 4

|

03/08/2020

|

03/14/2020

|

- Assemble car chassis and plan general layout

- Delegate tasks for each 2 person teams

- Create branches for all nodes and add motor and sensor messages to DBC file

- Discuss and research possible GPS antennas

- Design block diagrams for motor node, bridge controller/sensor node, and full car

- Solve GitLab branches vs folders issue (1 branch per node, or 1 folder per node)

- Order 4 + 1 extra ultrasonic sensors (MaxBotix MB1003-000 HRLV-MaxSonar-EZ0)

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 5

|

03/15/2020

|

03/21/2020

|

- Decide what to include on PCB board

- Begin researching filtering algorithms for ultrasonic sensors

- Read previous student's reports to decide on a compass module (CMPS14)

- Start learning Android app development

- Order GPS antenna

- Driver node is able to respond correctly based on sensor obstacle detection scenarios (correct LED's light up)

- Ultrasonic sensor values are converted to centimeters and transmit to driver node

- Research ultrasonic sensor mounts

- Transmit CAN messages from sensor to driver node, and from driver to motor node

- Decide movement and steering directions based on all possible sensor obstacle detection scenarios

- Begin research on PID implementation to control speed of RC car

- Add GPS node messages (longitude, latitude, heading) and bridge sensor node messages (destination latitude and longitude) to DBC file

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 6

|

03/22/2020

|

03/28/2020

|

- Draw block diagrams with pin information for each board and begin PCB design based on these diagrams

- Start implementing a basic Android app without Google maps API and create a separate GitLab repo for app

- Geological node is able to transmit a heading message to the driver node

- Bridge sensor node is able to transmit a destination latitude and longitude coordinates message to geological node

- Decide on ultrasonic sensor mounts and order extra if needed

- Order a new compass module (CMPS14)

- Finish designing team logo and upload to Wiki page

- Continue research on PID controller design and begin basic implementation

- Finalize parts list and place orders for remaining unordered items

- Decide on tap plastic acrylic sheet dimensions and PCB dimensions

- Integrate driver board diagnostic testing with LEDs and ultrasonic sensors (car goes left, left LEDs light up, etc.)

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 7

|

03/29/2020

|

04/04/2020

|

- Finish a basic implementation of filtering ultrasonic sensor's ADC data

- Geological node is able to compute the destination heading (0-360 degrees) and send to driver node

- Add PWM functionality to motor board code and test on DC and servo motors

- Complete a basic implementation of encoder code on motor board

- Bluetooth Module driver is finished, can connect to Android phone, and can receive "Hello World" data from phone

- Complete rough draft of schedule and upload to Wiki page

- Learn how to integrate Google maps API into Android app

- Geological node is able to parse the GPS NMEA string to extract latitude and longitude coordinates

- Complete rough draft of DBC file messages and signals

- Geological node is able to receive a current heading (0-360 degrees) from the compass module

- Geological node is able to receive an NMEA string from the GPS

- Design a block diagram for optimal ultrasonic sensor placement

- Purchase tap plastic acrylic sheet

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 8

|

04/05/2020

|

04/11/2020

|

- Finish ultrasonic filtering algorithm for ultrasonic sensor's ADC data

- Google maps API is fully integrated into Android App

- Bluetooth Module is able to receive data from Android app

- Test obstacle avoidance algorithm (indoor)

- Design ultrasonic sensor shields to minimize sensor interference with each other

- Complete motor board code controlling RC car's DC motor and servo motor

- Begin car chassis wiring on a breadboard

- Finalize and review PCB schematic

- Complete a rough draft car chassis block diagram for the placement of all boards and modules

- Complete "push button" motor test (servo turns wheels left and right, and DC motor spins wheel forwards and backwards)

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 9

|

04/12/2020

|

04/18/2020

|

- Test obstacle avoidance algorithm (indoor)

- Complete car chassis wiring on a breadboard

- Establish and test CAN communication between all boards

- Display sensor and motor data on Android app

- Finish GPS module integration with geographical controller

- Design and solder a prototype PCB board in case PCB isn't delivered in time

- Test existing motor board code on RC car's motors

- Mount sensors, motors, LCD, and all four sjtwo boards onto car chassis

- Bluetooth module is able to receive "dummy" destination latitude and longitude coordinates from Android app

- Discuss checkpoint algorithm

- Begin wheel encoder implementation and unit testing

- Finish routing PCB and review to verify the circuitry

|

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

- Completed

|

| 10

|

04/19/2020

|

04/25/2020

|

- Complete motor control code with optimal speed and PWM values without PID control

- Test drive outdoors to check obstacle avoidance algorithm

- Test checkpoint algorithm on car (outdoor)

- Begin unit testing the PID control algorithm

- Design car state machine

- Finish wheel encoder implementation and unit testing

- Make final changes to PCB and place order

- Complete basic implementation and unit testing of checkpoint algorithm

- Android app is able to send start and stop commands to the car

- Bluetooth module is able to receive actual destination latitude and longitude coordinates from Android app

- Mount a pipe on car chassis for GPS and compass modules to reduce interference

- Test drive the soldered PCB board to ensure everything is working properly

|

- Completed

- Completed

-

-

-

-

-

-

- Completed

-

-

- Completed

|

| 11

|

04/26/2020

|

05/02/2020

|

- Mount GPS and compass modules onto car chassis

- Finalize obstacle avoidance algorithm

- Finalize checkpoint algorithm

- Test drive from start to destination (indoor)

- LCD display is able to display car's speed, destination coordinates, and current heading data

- Fully integrate wheel encoder onto car chassis

- Finish basic implementation of PID control and test on RC car

- GEO controller can compute the heading from Android app's actual destination coordinates, and send to driver board

|

|

| 12

|

05/03/2020

|

05/09/2020

|

- Test drive from start to destination (outdoor)

- Finalize DBC file

- Upload rough draft version of report to Wiki page

- Test PID control implementation (outdoor)

- Test obstacle avoidance algorithm on car (outdoor)

- Test checkpoint algorithm on car (outdoor)

- Finalize PID control implementation and test on car (indoor)

- Integrate PCB onto RC car chassis

|

|

| 13

|

05/10/2020

|

05/16/2020

|

- Upload final version of report to Wiki page

- Push final code to GitLab

- Test drive from start to destination (outdoor)

- Finalize PID control implementaion based on feedback from last week's test drives

- Finalize obstacle avoidance algorithm based on feedback from last week's test drives

- Finalize checkpoint algorithm based on feedback from last week's test drives

- Test PID control implementation (outoor)

- Test obstacle avoidance algorithm on car (outdoor)

- Test checkpoint algorithm on car (outdoor)

|

|

| 14

|

05/17/2020

|

05/23/2020

|

- Demo

- Push final code to GitLab

- Submit individual contributions feedback for all team members

- Make final updates to Wiki report

|

|

Parts List & Cost

| Item#

|

Part Desciption

|

Vendor

|

Qty

|

Cost

|

| 1

|

RC Car Chassis

|

Traxxas

|

1

|

$250.00

|

| 2

|

Lithium-Ion Battery

|

|

1

|

|

| 3

|

Battery Charger

|

|

1

|

|

| 4

|

Tap Plastics Acrylic Sheet

|

|

1

|

|

| 5

|

Ultrasonic Sensors

|

Amazon [2]

|

4

|

|

| 6

|

GPS Module

|

|

1

|

|

| 7

|

GPS Antenna

|

|

1

|

|

| 8

|

Compass Module

|

|

1

|

|

| 9

|

UART LCD Display

|

|

1

|

|

| 10

|

Bluetooth Module

|

|

1

|

|

| 11

|

CAN Transceivers SN65HVD230DR

|

|

15

|

Free Samples

|

| 12

|

Sjtwo Board

|

Preet

|

4

|

$50.00

|

| 13

|

12" Pipe

|

|

1

|

|

| 14

|

Android Mobile Phone

|

|

1

|

|

| 15

|

Sensor Mounts

|

|

4

|

|

Hardware Integration:- Printed Circuit Board

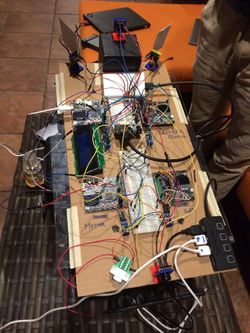

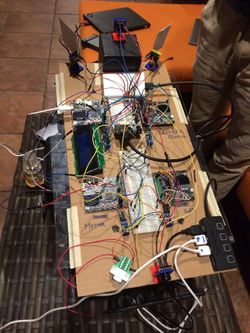

We Initially started with a very basic design of mounting all the hardware on a cardboard sheet for our first round of Integrated hardware testing.

Challenges:- The wires were an entire mess and the car could not navigate properly due to the wiring issues as all the wires were entangling and few had connectivity issues.

Hence we decided to go for a basic dot matrix Design before finalizing our final PCB Design as a Prototype board for testing if anything goes haywire.

Initial Mounting on Cardboard Sheet

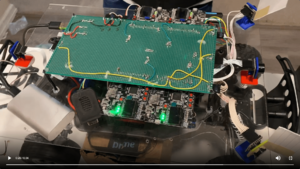

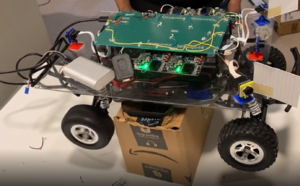

The Prototype Board just before the actual PCB board was created on a dot matrix PCB along with all the hardware components for the Intermediate Integrated testing phase is as follows:

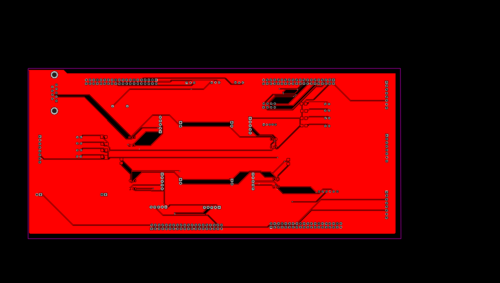

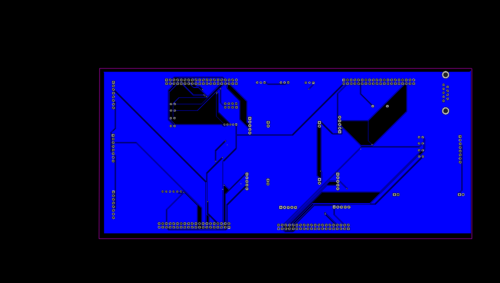

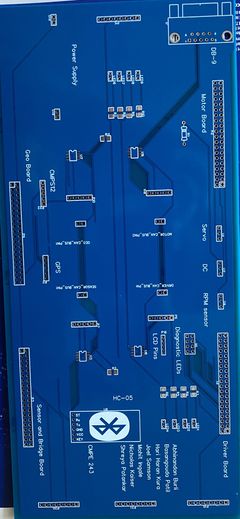

1) To avoid all the above challenges We designed the custom PCB using EasyEDA in which we implemented connections for all the controller modules(SJTwo Board LPC4078) all communicating/sending data via CAN bus. The data is sent by individual sensors to the respective controllers. GPS and Compass are connected to Geographical Controller. RPM sensor, DC and Servo Motors are connected to Motor Controller.

2) Ultrasonic are connected to Bridge and Sensor Controller. LCD is connected to Driver Controller. Bluetooth is connected to Bridge and Sensor Controller. CAN Bus is implemented using CAN Transceivers SN65HVD230 terminated by 120 Ohms; with PCAN for monitoring CAN Debug Messages and Data. Some Components need 5V while some sensors worked on 3.3V power supply. Also it was difficult to use separate USB's to power up all boards.Hence we used CorpCo breadboard power supply 3.3V/5V.

3) PCB was sent to fabrication to JLCPCB China which provided PCB with MOQ of 5 with the lead time of 1 week. We implemented 2 layers of PCB with most of the parts in top layer GPS sensor and Compass sensor. We implemented rectangular header connector for SJTwo boards, RPM sensor, DC & Servo Motor on the bottom layer. There were 2 iterations of this board.

4) Challenges :-We also need to change the header for LCD since it was having different pitch.

DESIGNING:-

AFTER DELIVERY:-

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management etc.>

Hardware Design

<Show your CAN bus hardware design>

DBC File

DBC File

Bridge and Sensor Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Motor Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Geographical Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Driver Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

Advise for Future Students

<Bullet points and discussion>

Acknowledgement

=== References ===