Difference between revisions of "S18: Team Nemesis(SJSU Cam)"

Proj user8 (talk | contribs) (Created page with "== Team Nemesis(SJSU Cam) == == Abstract == A simple video streaming over TFT LCD using CMOS camera using SJONE board. == Objectives & Introduction == With this project, w...") |

Proj user8 (talk | contribs) (→Algorithm:) |

||

| (243 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | == | + | == '''SJSU Cam''' == |

| − | + | [[File:CMPE244_cam_top.png|800px|SJSU_CAM|center]] | |

| − | + | == '''Abstract''' == | |

| + | This project records live stream through camera and displays it on LCD through SJ One microcontroller which is LPC 1758. This camera has longer battery as it runs through portable battery powering microcontroller. As there are many High Quality Cameras available in market, purpose of this camera is found in applications where streaming of medium quality video/photo is required for longer period of time and camera has to survive longer on single battery, which can’t be provided by handy digital camera. Another functionality provided by this project is to enable user to capture images on SD card and view it on LCD providing different resolution and modes as option through interactive UI designed on LCD. Project Hardware enclosed in small box 3D designed for this project enables portability and ease of access to user. | ||

| − | == Objectives & Introduction == | + | == '''Objectives & Introduction''' == |

| + | The objective of this project was to learn how timing and buffer play an important role in capturing the pixels from the camera and displaying them on the LCD screen. The following objectives were set for the project: | ||

| − | + | <br/>1. Write a driver for the SPI camera ov2640, which has a better rate of capturing the image with the SJONE board. | |

| − | + | <br/>2. Write the driver for the LCD display (Adafruit 5' TFT) and integrate it by choosing the right resolution. | |

| − | + | <vr/>3. Implement a menu class for different options of the camera on the LCD and program external buttons for navigating across the menu. | |

| − | + | <br/>3. Integrate the camera and LCD by displaying the output of the camera on the LCD. | |

| − | + | <br/>4. Store the output of the camera on the SD card, if capture mode is selected from LCD menu. | |

| − | + | <br/>5. Read the image from the SD card and display on the screen. | |

| − | |||

| − | <br> | ||

=== Team Members & Responsibilities === | === Team Members & Responsibilities === | ||

| − | + | * Chhavi Mehta | |

| − | * | + | ** Camera implementation, integration with SD card |

| − | + | * Deeksha Prakash Kankalale | |

| − | * | + | ** PCB Design, Camera driver implementation. |

| + | * Parth Gujar | ||

| + | ** LCD Driver, 3D design. | ||

| + | * Sagar Kalathia | ||

| + | ** LCD interfacing, implementing graphics library | ||

| + | * Saurabh Badenkal | ||

| + | ** LCD Driver, Integration of camera and LCD and data pipelining. | ||

| − | == Schedule == | + | == '''Schedule''' == |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| − | ! scope="col"| | + | ! scope="col"| Week# |

| − | ! scope="col"| | + | ! scope="col"| Date |

| − | ! scope="col"| | + | ! scope="col"| Task |

| − | ! scope="col"| | + | ! scope="col"| Actual |

|- | |- | ||

! scope="row"| 1 | ! scope="row"| 1 | ||

| − | | | + | | 4/17 |

| − | | | + | | 1. Placing order for the components required in the project. <br/> 2. Division of module development. |

| − | | | + | | Completed! <br/> Problems Encountered: Finding the right components after going through various datasheets. |

|- | |- | ||

! scope="row"| 2 | ! scope="row"| 2 | ||

| − | | | + | | 4/24 |

| − | | | + | | 1. Making interface with LCD.<br/>2. Drawing simple shapes. <br/>3. Work on the overall design of the menu for LCD. |

| − | | | + | | Completed! <br/> Problems Encountered: Setting appropriate initial frequency for the LCD to light up. |

|- | |- | ||

! scope="row"| 3 | ! scope="row"| 3 | ||

| − | | | + | | 5/1 |

| − | | | + | | 1. Interfacing the camera <br/>2. Implementing menu class with sub-menus and items. <br/>3. Designing hardware prototype for 3D printing. |

| − | | | + | | Completed! <br/> Problems Encountered: Not enough RAM for displaying more than 1 picture of size 100x100, Using interrupts for UART receive instead of normal function call. |

|- | |- | ||

! scope="row"| 4 | ! scope="row"| 4 | ||

| − | | | + | | 5/8 |

| − | | | + | | 1. Design PCB and place order. <br/>2. Integrating file explorer of the SD card onto LCD with GUI.<br/>3. Capturing image from the camera, saving it on the SD card. |

| − | | | + | | Completed! <br/> Problems Encountered: Heavy resource utilization while saving and retrieving the file from SD card. |

|- | |- | ||

! scope="row"| 5 | ! scope="row"| 5 | ||

| − | | | + | | 5/15 |

| − | | | + | | 1. Displaying the image on the LCD. <br/>2. Integrating the modules together with the 3D case having the LCD on one side and SJONE and camera on the other with buttons. |

| − | | | + | | Completed! <br/> Problems Encountered: Resource constraints only allow a resolution of 320p. Extremely low frame rate due to SD read speeds. |

|- | |- | ||

! scope="row"| 6 | ! scope="row"| 6 | ||

| − | | | + | | 5/22 |

| − | + | | 1. Final testing and debugging of the system as a whole. | |

| − | | | + | | Completed! <br/> Problems Encountered: PCB arrived late. |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | | | ||

| − | ! | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|} | |} | ||

| − | == | + | == '''Parts List & Cost''' == |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

{| class="wikitable" | {| class="wikitable" | ||

|- | |- | ||

| − | ! scope="col"| | + | ! scope="col"| Components |

| − | ! scope="col"| | + | ! scope="col"| Model Number |

| − | ! scope="col"| | + | ! scope="col"| Cost |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | ! scope="row" | | + | ! scope="row"| SJONE board |

| − | | | + | | LPC 1758 |

| − | | | + | | 80$ |

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | ! scope="row" | | + | ! scope="row"| LCD |

| − | | | + | | 5 inch TFT LCD screen |

| − | + | | 32$ | |

| − | |||

| − | |||

| − | | | ||

|- | |- | ||

| − | ! scope="row" | | + | ! scope="row"| LCD driver |

| − | | | + | | RA8875 |

| − | | | + | | 10$ |

| − | |||

| − | |||

| − | |||

|- | |- | ||

| − | ! scope="row" | | + | ! scope="row"| Camera |

| − | | | + | | OV 2640 |

| − | | | + | | 20$ |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

| + | ! scope="row"| PCB | ||

| + | | - | ||

| + | | 50$ | ||

|} | |} | ||

| − | ==== | + | == Design & Implementation == |

| + | This design section outlines the hardware and software design of the project. | ||

| − | + | === Hardware Design === | |

| − | |||

| − | |||

| − | |||

| − | |||

| + | The main hardware components used in the project are discussed in detail below. | ||

| − | + | ''LCD Display:'' | |

| − | + | This is a 5.0" TFT screen with 800x480 pixels. These screens are commonly seen in consumer electronics, such as miniature TV's, GPS's, handheld games car displays, etc. A 40-pin connector has 8 red, 8 green, and 8 blue parallel pins, for 24-bit color capability. The display is supposed to be constantly refreshed, at 60Hz, with a pixel clock. The backlight requires a constant-current mode boost converter that can go as high as 24V. Hence along with the display we use an RA8875 driver board. | |

| − | |||

| − | |||

| − | |||

| − | + | [[File:CMPE244_nemesis_l.jpg|thumb|400px|center|Figure 1: 5 inch LCD screen]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | ''LCD Driver :'' | ||

| + | The RA8875 is a powerful TFT driver chip, it has 768KB of RAM, so it can buffer the display (and depending on the screen size also have double overlaying).The RA8875 can also handle standard 4-wire over the SPI interface. | ||

| − | + | [[File:CMPE244_nemesis_ld.jpg|thumb|400px|Figure 2: RA8875 Driver|center]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ''Camera:'' | |

| − | + | The OV2640 Camera Module is a small image sensor, works at low operating voltages. It provides all functions of a single chip of VGA camera and image processor. Through Serial Camera bus control, the sensor can output the whole frame, sampling at various resolution 8 bits of data. The product VGA image can reach up to a maximum of 30 frames per second. We can control the image quality, data format, and transmission mode. All the process of image processing functions can through the SCCB programming interface, including gamma curve, white balance, saturation, and chrome. | |

| − | |||

| − | |||

| + | [[File:CMPE244_nemesis_c.jpg|thumb|300px|Figure 3: OV2640 camera|center]] | ||

| − | + | ||

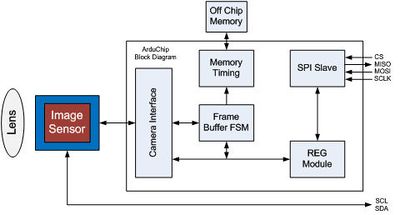

| + | [[File:CMPE244_nemesis_Cam_Module.jpg|thumb|400px|center|Figure 4: Block diagram of the camera module]] | ||

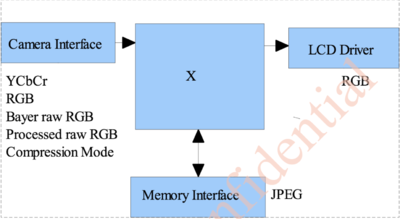

| − | The | + | OV2640 support 4 output format: YcbCr422,YCbCr420, RGB565, Bayer raw RGB and GRB, YUV422 JPEG. How to choose the right output format for camera phone design or other applications? The data format at LCD driver are always RGB. For example, RGB444, RGB565, RGB555, RGB888 etc. The data format and memory interface are always JPEG. The JPEG data is compressed from YCbCr data. So Both RGB and YCbCr data are needed inside the back-end chip. The “X” block is different for different back-end chips. |

| − | + | The general diagram of back-end chip is as below: | |

| − | + | [[File:CMPE244_nemesis_backend-cam.png|thumb|400px|center|Figure 5: Back-end chip ]] | |

| − | |||

| − | |||

| − | |||

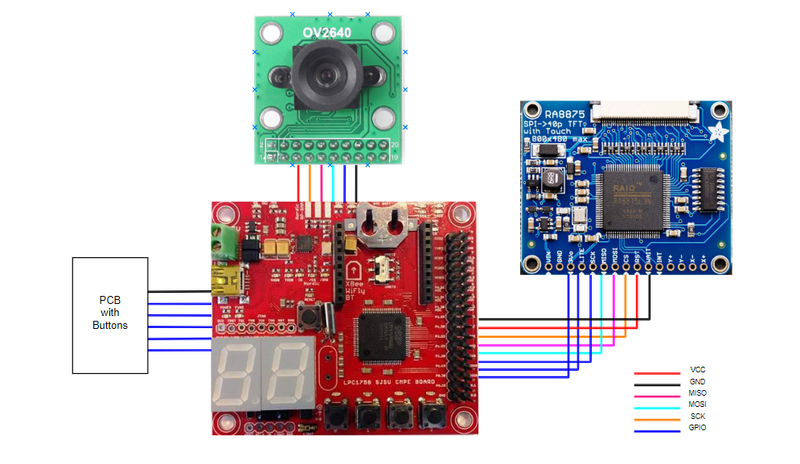

| − | + | '''System block diagram :''' The integral part of the entire system is the SJOne board which is the main controller for the LCD as well as the camera. Both the LCD and camera are interfaced via an SPI bus with the SJOne board. Apart from the power supply and ground pins, the LCD has one pins, namely, reset which is connected to the general purpose Input-Output pin of the controller. This pin is used while initializing the display. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[File: | + | [[File:CMPE244_nemesis_block.png|thumb|800px|center|System Block diagram]] |

| + | === Hardware Interface === | ||

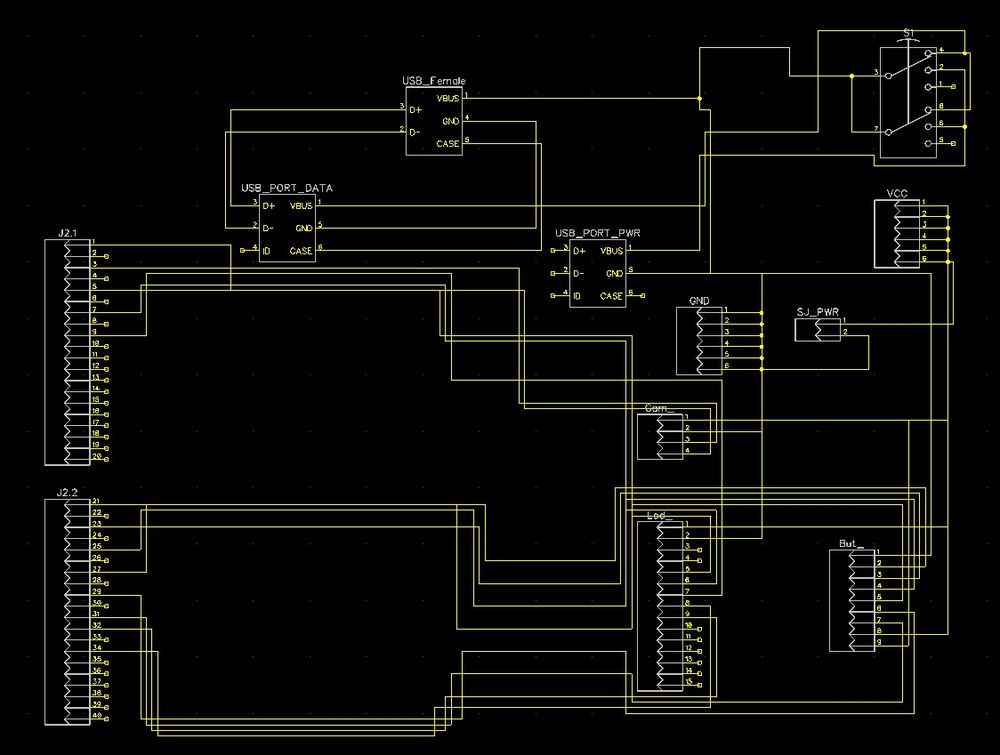

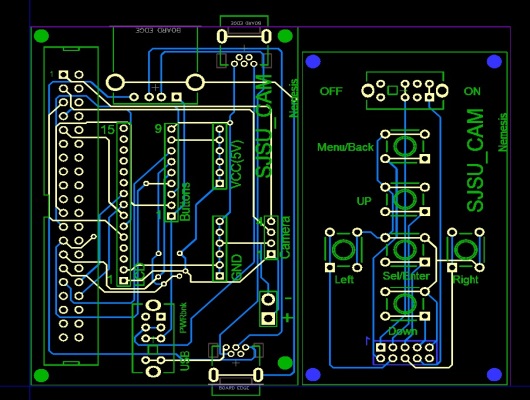

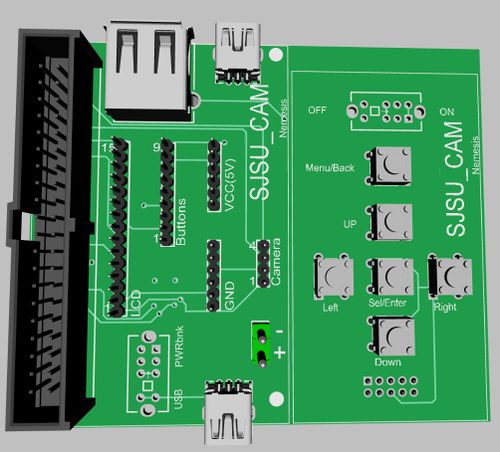

| − | + | The PCB design was done on Dip Trace, which is a CAD software for creating schematic diagrams and printed circuit boards. The SPI interface is done to both the camera and the driver board of the LCD display. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | The PCB was designed in such a way that it can be powered by two sources, USB from PC or from PowerBank, by flipping a switch. Using this feature SJONE can be directly connected to PC via the PCB without any direct connection from PC to SJONE, for easier deployment of code once the whole project was packaged inside the camera box. | |

| − | |||

| − | [[File: | + | [[File:CMPE244_nemesis_Schemetic.jpeg|thumb|1000px|Schematic|center]] |

| − | |||

| − | |||

| + | [[File:CMPE244_nemesis_pcb.jpeg|thumb|1000px|PCB Design|left]] | ||

| − | [[File: | + | [[File:Cmpe244_S18_NEMESIS_PCB_3D.jpeg|thumb|500px|3D view of PCB Design|right]] |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ||

| − | |||

| − | |||

| − | + | === Software Design and Flowchart === | |

| − | |||

| − | |||

| − | |||

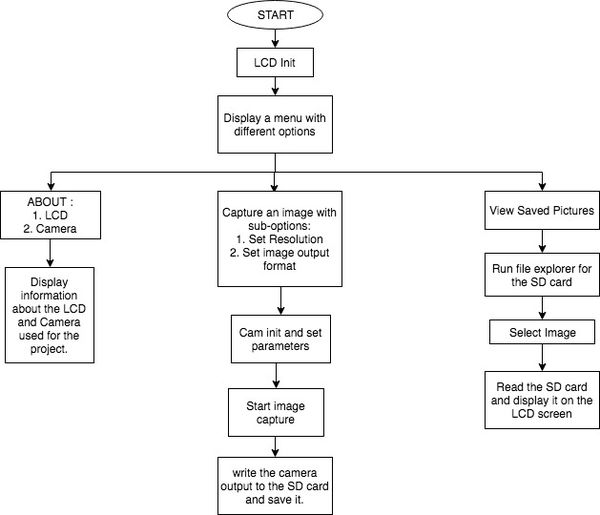

| − | + | The general flow of our project can be explained by the flowchart shown below: | |

| − | The | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | [[File:CMPE244_Nemesis_Flowchart.jpg|thumb|600px|center|Program Flow]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | === Implementation === | |

| + | The camera is interfaced to the board where Image Sensor Configuration is done through I2C Protocol and Sending pixel data through SPI communication protocol. The raw pixels are read from the camera to the SJONE board. There are five buttons on the camera. One of them used to capture an image and store it on the SD card. The LCD screen is interfaced through SPI communication protocol. The raw pixels received from the camera are displayed on to the LCD screen. | ||

| − | + | === Algorithm: === | |

| − | + | The first step for making the LCD and the camera work is the initialization of these components. The algorithm for it is as described: | |

| − | ''' | + | '''1. Initialization of the LCD: ''' |

| + | * According to the desired resolution(as the LCD driver supports two resolutions 800x480 & 480x272), the resolution is first set and the basic touch.non-touch config is made. In our case the LCD is non-touch. | ||

| + | * After setting the chip-select and reset pins as outputs, the SPI is initialized. SSP1 was configured to be used for LCD interfacing. | ||

| + | * Register at address 0x00 is read for getting the version of the LCD over SPI. | ||

| + | * PLL is initialized and the HSYNC, VSYNC and Pixel clock([https://www.nxp.com/wcm_documents/techzones/microcontrollers-techzone/Presentations/graphics.lcd.technologies.pdf terminologies described here]) parameters are set according to the resolution chosen. (as per the [https://cdn-shop.adafruit.com/datasheets/RA8875_DS_V19_Eng.pdf RA8875 ADafruit Datasheet]) | ||

| + | * Active window X and window Y are set by writing to the appropriate registers. | ||

| + | * Clear the entire window. | ||

| + | * Set SPI clock frequency.{There's a [https://github.com/saurabhrb/CMPE_244_Project_CAM/blob/master/FINAL%20DEMOed%20Code/LCD.cpp#L87 trick] in this as well, the adafruit RA8875 first responds to 2MHz SPI only, and after initializing the PLL and other timing related configs, it listens to up to 30MHz SPI} | ||

| − | + | '''2. Initialization of the Camera: ''' | |

| + | * I2C is initialized for Image Sensor Configuration, this configuration was retrieved from the [Software notes of OV2640 Camera https://github.com/saurabhrb/CMPE_244_Project_CAM/blob/master/OV2640_fifo/OV2640%20Camera%20Module%20Software%20Application%20Notes.pdf]. | ||

| + | * SPI is initialized with the desired frequency(only up to 8MHz) for receiving the pixel data from the buffer. | ||

| + | * According to the resolution, appropriate I2C sensor registers are set later. | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | The | + | In Terms of Pseudo Code & Algorithm, the following is the methodology we followed which consists of API's and its functions. The design is mainly of two parts: |

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''1. Design for LCD''' : | |

| − | + | LCD would continuously display a menu on its right with different options based on the currently selected menu. Menu driver is programmed dynamically using pointers & function Pointer to create sub-menus and sub-items inside sub-menus. A main menu object pointer is created in the main function which is propagated along the menu-tree to choose which should be the menu which needs to be displayed on the LCD currently. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Various API & functions as follows: | |

| − | |||

| − | |||

| − | |||

| − | + | * ''Add_Menu'' API, whenever gets called would add one more node to the linked list. | |

| − | + | * ''Add_Submenu'' API would create Linked List inside that Node. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | * "Navigate" API enables a user to navigate through Menus. This API navigates pointer to different nodes and calling respective functions such as capture image or going inside sub_menu. | |

| − | |||

| − | |||

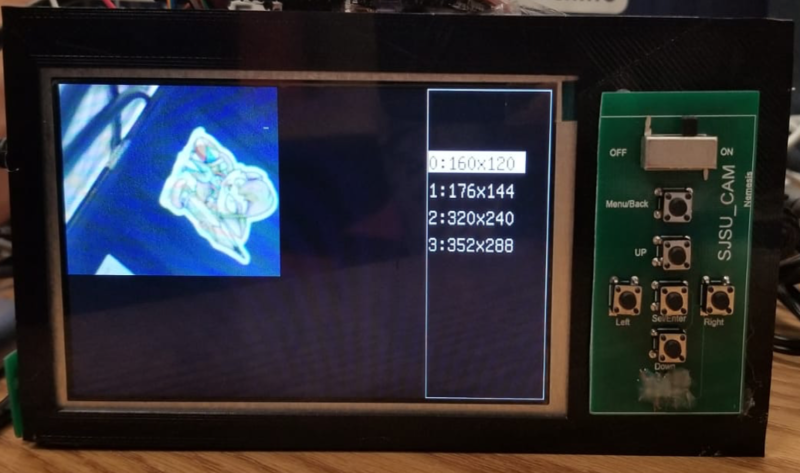

| − | + | [[File:Cmpe244_S18_NEMESIS_LCD_MENU_DRIVER.jpg|thumb|600px|LCD Menu working|center]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | With this dynamic functionality, we can create menus as required inside which we can call the respective function to be performed according to the submenu. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | ''Psuedo Code for LCD_Menu - '' | |

| − | + | A menu was designed for the LCD screen using an LCD_MENU class. This class included functions like adding sub-menu, displaying them or loading previous ones. It helped in dynamically adding options for the innumerous camera settings like changing image resolution and format.The private members of this class are as shown: | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | private: | |

| − | + | type myType; //to know if current object is itemType or menuType | |

| − | * | + | str myName; //name of this object |

| − | * | + | LCD_MENU *ParentMenu; //parent menu of current menu object |

| − | + | LCD_MENU *CurrentMenu; //reference to global CurrentMenuG | |

| − | + | VECTOR<Element> all_elements; //to store all elements by Element .name .id and .type | |

| − | + | VECTOR<str> all_elements_name; //to store all elements by name to use by Find function | |

| − | + | int highlighted; //to track currently highlighted sub-element | |

| − | + | Similar to this class, a file_explorer class was implemented for navigating through the SD card files. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | '''2. Design for SJOne & CAM''' : | |

| − | + | The controller has to Configure camera, receive data from the camera and send this to LCD as soon as it gets the data. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | Function includes : | |

| − | + | * Configuration of Camera Module by configuring different registers specified in datasheet & setting image format. | |

| − | + | * To receive Data from Camera at 8 MHz through SPI. After receiving One Frame, it is sent to LCD via SPI. In both the case, Controller is Master and another device is a slave. | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | + | * To Store Image in SD card, the whole frame is sent to SD card through SPI, and a new text file with a unique name is created and pixel values in that text file would be ASCII characters coming from 16-bit image buffer. | |

| + | == '''Testing & Technical Challenges''' == | ||

| − | |||

| − | + | ''' Problem 1: ''' Making any camera work on SJOne can be little tricky, due to its less RAM to store one full B/W or RGB frame. Also interfacing the regular CMOS camera modules with Pixel Clks requires perfect timing to get a proper or any image at all. | |

| − | + | ''' Solution: ''' The solution was to use the already buffered and stored camera frame and then transfer it one by one based on SJONE's reading speed(via SPI/I2C) to display it on the LCD pixel by pixel. After trying a number of cameras like OV7670 without fifo and VC0706 serial camera(which had unsupported output format), we were able to solve the problem by using OV2640 SPI camera with fifo buffer which made capturing and retrieving the image easier because the buffer saved the whole frame, and cleared only after SJONE has finished reading the frame. | |

| − | + | ''' Problem 2: ''' The camera displayed two frames on the LCD screen for resolutions greater than 352x288. This was because the buffer size of the camera could only hold upto 16bits pixels of max 352x288 resolution, as the buffer size is [http://www.arducam.com/arducam-mini-released/ ~384KBytes]. | |

| − | + | ''' Solution: ''' This could be avoided by upgrading the buffer size on the camera module or by using an external buffer to store the whole image before previewing on LCD. | |

| − | + | ''' Problem 2: ''' The camera was displaying image in form of random pixel values. | |

| − | + | ''' Solution: ''' After taking a closer look at datasheet we realized that we were configuring the CMOS registers for wrong/unsupported format (by LCD) and not RGB565 format. After configuring the registers for RGB565 with different resolution types, the LCD displayed proper images. | |

| − | == | + | == '''Conclusion''' == |

| − | We | + | We have successfully designed and implemented a digital camera with a number of features. This project has helped us gain insight knowledge of the implementation of FreeRTOS concepts like prioritizing tasks and using semaphore and mutex for SD card reading and writing. We learned to implement communication protocol drivers such as SPI. Working with pixel data helped us go into deeper details of the SPI protocol as each byte had to be handled accurately. We have tried the PCB design on both Eagle and Dip Trace, we were able to complete the PCB design starting from schematic diagram to 3D imaging of the PCB. We were also able to learn the CAD design required for 3D printing. |

| − | |||

| − | |||

| − | |||

| − | + | Apart from the technical aspects of the project, a sense of cordial teamwork was also developed amongst the team members which led to the successful accomplishment of the project's objectives. | |

| − | + | === Project Video === | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | ==== | ||

| − | |||

| − | + | * [https://youtu.be/GtHGJm6FQZo SJSU_CAM Video Link] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=== Project Source Code === | === Project Source Code === | ||

| − | + | * [https://github.com/saurabhrb/CMPE_244_Project_CAM SJSU_CAM Github Link] | |

| − | https:// | ||

== References == | == References == | ||

=== Acknowledgement === | === Acknowledgement === | ||

| − | We would like to thank | + | We would like to thank our professor, Preetpal Kang for designing such a course where learning was his guidance and consistent feedback. We would also like to thank the ISA team for their valuable inputs as per their own experience of the course when taken and their support and motivation at every phase of this project. There were some unsung, selfless classmates who helped us whenever necessary, whenever any immediate hardware was required or any other guidance needed in spite of being from the rival teams. We would like to thank each one of them who forgot their differences or considered the course and project as a competition to selflessly help us when in need. |

=== References Used === | === References Used === | ||

| − | + | [1] Preetpal Kang's lecture notes of CMPE 244, Computer Engineering, San Jose State University, Jan-May 2018. | |

| − | + | ||

| − | + | [2] [http://www.arducam.com/camera-modules/2mp-ov2640/ OV2640 Technical Description] | |

| − | + | ||

| − | + | [3] [https://www.adafruit.com/product/1680 5.0" LCD & Datasheet] | |

| + | |||

| + | [4] [https://cdn-shop.adafruit.com/datasheets/KD50G21-40NT-A1.pdf/ RA8875 LCD Driver Description] | ||

Latest revision as of 18:20, 27 May 2018

Contents

SJSU Cam

Abstract

This project records live stream through camera and displays it on LCD through SJ One microcontroller which is LPC 1758. This camera has longer battery as it runs through portable battery powering microcontroller. As there are many High Quality Cameras available in market, purpose of this camera is found in applications where streaming of medium quality video/photo is required for longer period of time and camera has to survive longer on single battery, which can’t be provided by handy digital camera. Another functionality provided by this project is to enable user to capture images on SD card and view it on LCD providing different resolution and modes as option through interactive UI designed on LCD. Project Hardware enclosed in small box 3D designed for this project enables portability and ease of access to user.

Objectives & Introduction

The objective of this project was to learn how timing and buffer play an important role in capturing the pixels from the camera and displaying them on the LCD screen. The following objectives were set for the project:

1. Write a driver for the SPI camera ov2640, which has a better rate of capturing the image with the SJONE board.

2. Write the driver for the LCD display (Adafruit 5' TFT) and integrate it by choosing the right resolution.

<vr/>3. Implement a menu class for different options of the camera on the LCD and program external buttons for navigating across the menu.

3. Integrate the camera and LCD by displaying the output of the camera on the LCD.

4. Store the output of the camera on the SD card, if capture mode is selected from LCD menu.

5. Read the image from the SD card and display on the screen.

Team Members & Responsibilities

- Chhavi Mehta

- Camera implementation, integration with SD card

- Deeksha Prakash Kankalale

- PCB Design, Camera driver implementation.

- Parth Gujar

- LCD Driver, 3D design.

- Sagar Kalathia

- LCD interfacing, implementing graphics library

- Saurabh Badenkal

- LCD Driver, Integration of camera and LCD and data pipelining.

Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 4/17 | 1. Placing order for the components required in the project. 2. Division of module development. |

Completed! Problems Encountered: Finding the right components after going through various datasheets. |

| 2 | 4/24 | 1. Making interface with LCD. 2. Drawing simple shapes. 3. Work on the overall design of the menu for LCD. |

Completed! Problems Encountered: Setting appropriate initial frequency for the LCD to light up. |

| 3 | 5/1 | 1. Interfacing the camera 2. Implementing menu class with sub-menus and items. 3. Designing hardware prototype for 3D printing. |

Completed! Problems Encountered: Not enough RAM for displaying more than 1 picture of size 100x100, Using interrupts for UART receive instead of normal function call. |

| 4 | 5/8 | 1. Design PCB and place order. 2. Integrating file explorer of the SD card onto LCD with GUI. 3. Capturing image from the camera, saving it on the SD card. |

Completed! Problems Encountered: Heavy resource utilization while saving and retrieving the file from SD card. |

| 5 | 5/15 | 1. Displaying the image on the LCD. 2. Integrating the modules together with the 3D case having the LCD on one side and SJONE and camera on the other with buttons. |

Completed! Problems Encountered: Resource constraints only allow a resolution of 320p. Extremely low frame rate due to SD read speeds. |

| 6 | 5/22 | 1. Final testing and debugging of the system as a whole. | Completed! Problems Encountered: PCB arrived late. |

Parts List & Cost

| Components | Model Number | Cost |

|---|---|---|

| SJONE board | LPC 1758 | 80$ |

| LCD | 5 inch TFT LCD screen | 32$ |

| LCD driver | RA8875 | 10$ |

| Camera | OV 2640 | 20$ |

| PCB | - | 50$ |

Design & Implementation

This design section outlines the hardware and software design of the project.

Hardware Design

The main hardware components used in the project are discussed in detail below.

LCD Display: This is a 5.0" TFT screen with 800x480 pixels. These screens are commonly seen in consumer electronics, such as miniature TV's, GPS's, handheld games car displays, etc. A 40-pin connector has 8 red, 8 green, and 8 blue parallel pins, for 24-bit color capability. The display is supposed to be constantly refreshed, at 60Hz, with a pixel clock. The backlight requires a constant-current mode boost converter that can go as high as 24V. Hence along with the display we use an RA8875 driver board.

LCD Driver :

The RA8875 is a powerful TFT driver chip, it has 768KB of RAM, so it can buffer the display (and depending on the screen size also have double overlaying).The RA8875 can also handle standard 4-wire over the SPI interface.

Camera:

The OV2640 Camera Module is a small image sensor, works at low operating voltages. It provides all functions of a single chip of VGA camera and image processor. Through Serial Camera bus control, the sensor can output the whole frame, sampling at various resolution 8 bits of data. The product VGA image can reach up to a maximum of 30 frames per second. We can control the image quality, data format, and transmission mode. All the process of image processing functions can through the SCCB programming interface, including gamma curve, white balance, saturation, and chrome.

OV2640 support 4 output format: YcbCr422,YCbCr420, RGB565, Bayer raw RGB and GRB, YUV422 JPEG. How to choose the right output format for camera phone design or other applications? The data format at LCD driver are always RGB. For example, RGB444, RGB565, RGB555, RGB888 etc. The data format and memory interface are always JPEG. The JPEG data is compressed from YCbCr data. So Both RGB and YCbCr data are needed inside the back-end chip. The “X” block is different for different back-end chips.

The general diagram of back-end chip is as below:

System block diagram : The integral part of the entire system is the SJOne board which is the main controller for the LCD as well as the camera. Both the LCD and camera are interfaced via an SPI bus with the SJOne board. Apart from the power supply and ground pins, the LCD has one pins, namely, reset which is connected to the general purpose Input-Output pin of the controller. This pin is used while initializing the display.

Hardware Interface

The PCB design was done on Dip Trace, which is a CAD software for creating schematic diagrams and printed circuit boards. The SPI interface is done to both the camera and the driver board of the LCD display.

The PCB was designed in such a way that it can be powered by two sources, USB from PC or from PowerBank, by flipping a switch. Using this feature SJONE can be directly connected to PC via the PCB without any direct connection from PC to SJONE, for easier deployment of code once the whole project was packaged inside the camera box.

Software Design and Flowchart

The general flow of our project can be explained by the flowchart shown below:

Implementation

The camera is interfaced to the board where Image Sensor Configuration is done through I2C Protocol and Sending pixel data through SPI communication protocol. The raw pixels are read from the camera to the SJONE board. There are five buttons on the camera. One of them used to capture an image and store it on the SD card. The LCD screen is interfaced through SPI communication protocol. The raw pixels received from the camera are displayed on to the LCD screen.

Algorithm:

The first step for making the LCD and the camera work is the initialization of these components. The algorithm for it is as described:

1. Initialization of the LCD:

- According to the desired resolution(as the LCD driver supports two resolutions 800x480 & 480x272), the resolution is first set and the basic touch.non-touch config is made. In our case the LCD is non-touch.

- After setting the chip-select and reset pins as outputs, the SPI is initialized. SSP1 was configured to be used for LCD interfacing.

- Register at address 0x00 is read for getting the version of the LCD over SPI.

- PLL is initialized and the HSYNC, VSYNC and Pixel clock(terminologies described here) parameters are set according to the resolution chosen. (as per the RA8875 ADafruit Datasheet)

- Active window X and window Y are set by writing to the appropriate registers.

- Clear the entire window.

- Set SPI clock frequency.{There's a trick in this as well, the adafruit RA8875 first responds to 2MHz SPI only, and after initializing the PLL and other timing related configs, it listens to up to 30MHz SPI}

2. Initialization of the Camera:

- I2C is initialized for Image Sensor Configuration, this configuration was retrieved from the [Software notes of OV2640 Camera https://github.com/saurabhrb/CMPE_244_Project_CAM/blob/master/OV2640_fifo/OV2640%20Camera%20Module%20Software%20Application%20Notes.pdf].

- SPI is initialized with the desired frequency(only up to 8MHz) for receiving the pixel data from the buffer.

- According to the resolution, appropriate I2C sensor registers are set later.

In Terms of Pseudo Code & Algorithm, the following is the methodology we followed which consists of API's and its functions. The design is mainly of two parts:

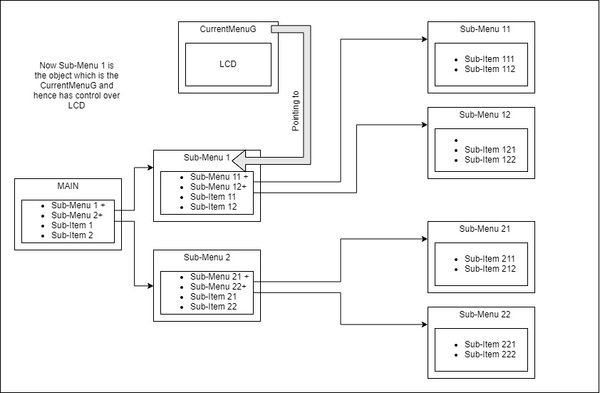

1. Design for LCD :

LCD would continuously display a menu on its right with different options based on the currently selected menu. Menu driver is programmed dynamically using pointers & function Pointer to create sub-menus and sub-items inside sub-menus. A main menu object pointer is created in the main function which is propagated along the menu-tree to choose which should be the menu which needs to be displayed on the LCD currently.

Various API & functions as follows:

- Add_Menu API, whenever gets called would add one more node to the linked list.

- Add_Submenu API would create Linked List inside that Node.

- "Navigate" API enables a user to navigate through Menus. This API navigates pointer to different nodes and calling respective functions such as capture image or going inside sub_menu.

With this dynamic functionality, we can create menus as required inside which we can call the respective function to be performed according to the submenu.

Psuedo Code for LCD_Menu -

A menu was designed for the LCD screen using an LCD_MENU class. This class included functions like adding sub-menu, displaying them or loading previous ones. It helped in dynamically adding options for the innumerous camera settings like changing image resolution and format.The private members of this class are as shown:

private: type myType; //to know if current object is itemType or menuType str myName; //name of this object LCD_MENU *ParentMenu; //parent menu of current menu object LCD_MENU *CurrentMenu; //reference to global CurrentMenuG VECTOR<Element> all_elements; //to store all elements by Element .name .id and .type VECTOR<str> all_elements_name; //to store all elements by name to use by Find function int highlighted; //to track currently highlighted sub-element

Similar to this class, a file_explorer class was implemented for navigating through the SD card files.

2. Design for SJOne & CAM : The controller has to Configure camera, receive data from the camera and send this to LCD as soon as it gets the data.

Function includes :

- Configuration of Camera Module by configuring different registers specified in datasheet & setting image format.

- To receive Data from Camera at 8 MHz through SPI. After receiving One Frame, it is sent to LCD via SPI. In both the case, Controller is Master and another device is a slave.

- To Store Image in SD card, the whole frame is sent to SD card through SPI, and a new text file with a unique name is created and pixel values in that text file would be ASCII characters coming from 16-bit image buffer.

Testing & Technical Challenges

Problem 1: Making any camera work on SJOne can be little tricky, due to its less RAM to store one full B/W or RGB frame. Also interfacing the regular CMOS camera modules with Pixel Clks requires perfect timing to get a proper or any image at all.

Solution: The solution was to use the already buffered and stored camera frame and then transfer it one by one based on SJONE's reading speed(via SPI/I2C) to display it on the LCD pixel by pixel. After trying a number of cameras like OV7670 without fifo and VC0706 serial camera(which had unsupported output format), we were able to solve the problem by using OV2640 SPI camera with fifo buffer which made capturing and retrieving the image easier because the buffer saved the whole frame, and cleared only after SJONE has finished reading the frame.

Problem 2: The camera displayed two frames on the LCD screen for resolutions greater than 352x288. This was because the buffer size of the camera could only hold upto 16bits pixels of max 352x288 resolution, as the buffer size is ~384KBytes.

Solution: This could be avoided by upgrading the buffer size on the camera module or by using an external buffer to store the whole image before previewing on LCD.

Problem 2: The camera was displaying image in form of random pixel values.

Solution: After taking a closer look at datasheet we realized that we were configuring the CMOS registers for wrong/unsupported format (by LCD) and not RGB565 format. After configuring the registers for RGB565 with different resolution types, the LCD displayed proper images.

Conclusion

We have successfully designed and implemented a digital camera with a number of features. This project has helped us gain insight knowledge of the implementation of FreeRTOS concepts like prioritizing tasks and using semaphore and mutex for SD card reading and writing. We learned to implement communication protocol drivers such as SPI. Working with pixel data helped us go into deeper details of the SPI protocol as each byte had to be handled accurately. We have tried the PCB design on both Eagle and Dip Trace, we were able to complete the PCB design starting from schematic diagram to 3D imaging of the PCB. We were also able to learn the CAD design required for 3D printing.

Apart from the technical aspects of the project, a sense of cordial teamwork was also developed amongst the team members which led to the successful accomplishment of the project's objectives.

Project Video

Project Source Code

References

Acknowledgement

We would like to thank our professor, Preetpal Kang for designing such a course where learning was his guidance and consistent feedback. We would also like to thank the ISA team for their valuable inputs as per their own experience of the course when taken and their support and motivation at every phase of this project. There were some unsung, selfless classmates who helped us whenever necessary, whenever any immediate hardware was required or any other guidance needed in spite of being from the rival teams. We would like to thank each one of them who forgot their differences or considered the course and project as a competition to selflessly help us when in need.

References Used

[1] Preetpal Kang's lecture notes of CMPE 244, Computer Engineering, San Jose State University, Jan-May 2018.