S17: Smart Health Gear

Contents

- 1 Smart Health Gear

- 2 Abstract

- 3 Objectives & Introduction

- 4 Project Schedule

- 5 Parts List & Cost

- 6 Design & Implementation

- 6.1 Hardware Design

- 6.2 Software Design

- 6.3 Implementation

- 7 Testing

- 8 Technical Challenges

- 9 Future Scope

- 10 Conclusion

- 11 References

Smart Health Gear

Abstract

In today's fast paced Environment, more and more people are taking benefits of the latest technologies to keep track of their own fitness level and health. This helps them to make wise health decisions or take immediate action to improve their health by continuously monitoring vital health stats. Smart Health Gear is one such wearable device which will help in monitoring various aspects of a person's health like heart rate, blood oxygen level, footsteps count and body temperature. The device comes with a display unit that provides the user with current time as well as the aforementioned health stats on the go. It also comes with a compatible Bluetooth based Android application which will record the same details and makes it to available to the user. These can be recorded on a day-to-day basis which will enable in tracking these details over a period of time.

Objectives & Introduction

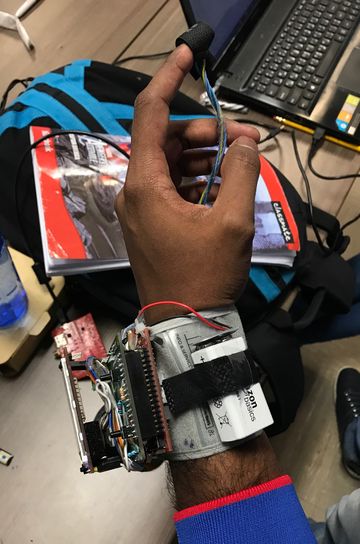

Smart Health Gear (SHG) is a wearable device that dubs as a fitness band and clock. The heart rate and oximeter sensor is connected on the I2C interface to the SJ1 board. (SHG) uses heart rate and pulse oximeter sensor to continuously monitor the heart rate and oxygen level in blood. . It is also connected to a body temperature sensor wrapped around the wrist band to determine the body temperature. The user can toggle between the clock (fetched from RTC) and health stats using "navigation" switch and can turn off display to save power through "lock/unlock" switch. SHG has a notification screen that appears when something abnormal is detected in any of the health stats. A blue-tooth module is interfaced with the device so that it can be paired with user's smartphone. An android application has also been developed so that the user can view these details via the app when connected via bluetooth.

The objectives are as follows:

- To be able to continuously calculate and monitor the heart rate

- To be able to continuously calculate and monitor oxygen level in blood

- To be able to continuously calculate and monitor the body temperature

- To be able to continuously calculate the step count of the person

- To be able to view all the vital details on a wearable device via LCD

- To be able to display current time on the LCD

- To be able to turn off the display on press of "lock/unlock" switch

- To be able to view the same details on an Android app

Team Members & Responsibilities

- PCB Design, LCD & Integration of All the tasks

- Drivers for Heart Rate Calculation, Step Count, temperature and Oxygen

- Drivers for Heart Rate & Oxygen Calculation, temperature measurement

- Android Application & PCB Design

- LCD Interface & Screens

Project Schedule

| Sr. No. | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 03/2/2017 | 03/2/2017 |

|

Completed | 03/2/2017 |

| 2 | 03/15/2017 | 03/30/2017 |

|

Completed | 03/30/2017 |

| 3 | 04/05/2017 | 04/16/2017 |

|

Completed | 04/20/2017 |

| 4 | 04/10/2017 | 04/16/2017 |

|

Completed | 04/25/2017 |

| 5 | 04/25/2017 | 04/30/2017 |

|

Completed | 05/06/2017 |

| 6 | 04/28/2017 | 05/04/2017 |

|

Completed | 05/08/2017 |

| 7 | 05/05/2017 | 05/10/2017 |

|

Completed | 05/12/2017 |

| 8 | 05/13/2017 | 05/16/2017 |

|

Completed | 05/20/2017 |

| 9 | 05/17/2017 | 05/21/2017 |

|

Completed | 05/25/2017 |

| 10 | 05/23/2017 | 05/23/2017 |

|

Completed | 05/25/2017 |

Parts List & Cost

| Item# | Part | Manufacturer | Part number | Cost($) |

|---|---|---|---|---|

| 1 | SJ One Board | Preet | N/A | 80.00 |

| 2 | Heart-Rate Monitor and Pulse Oximeter Sensor | Maxim | MAXREFDES117 | 20.00 |

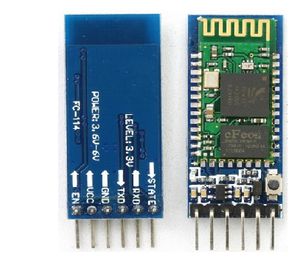

| 3 | HC-06 wireless bluetooth transceiver | Banggood | Datasheet | 6.55 |

| 4 | 10K Precision Epoxy Thermistor - 3950 NTC | Adafruit | Lookup Table | 4.00 |

| 5 | LCD module | Aliexpress | SEN-10988 | 32.30 |

| 6 | Hardware | Excess Solution | Berg strips, Jumper wires, Connectors, Standoffs | 5.00 |

| 7 | 9V Battery | Amazon | 9.50 |

- Total Cost: 157.35$

Design & Implementation

Hardware Design

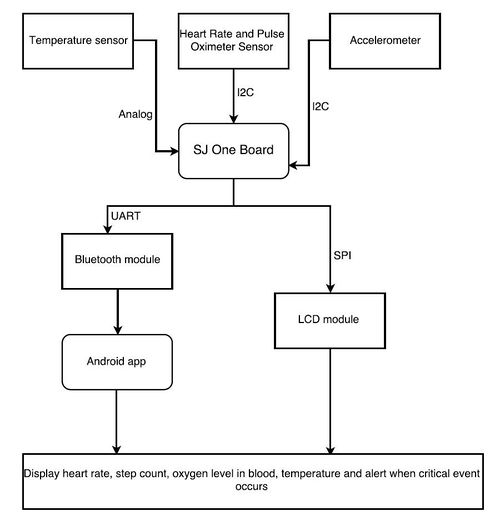

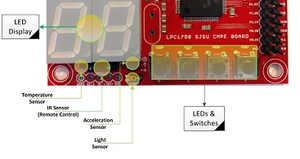

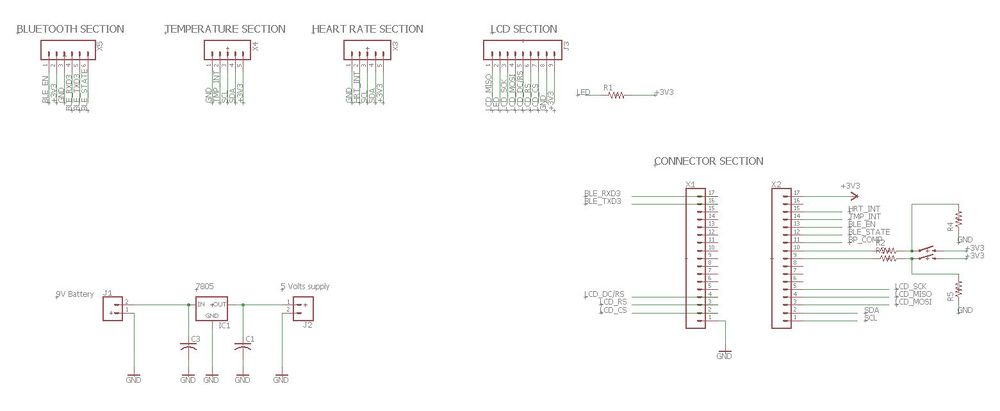

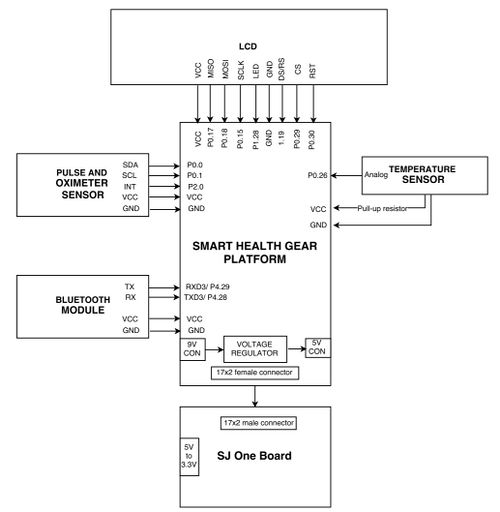

The below figure shows system design of our project including the interfaces for each sensor.

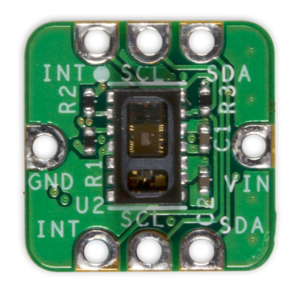

Heart Rate Sensor and Oximeter Sensor

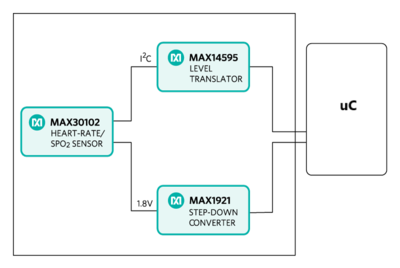

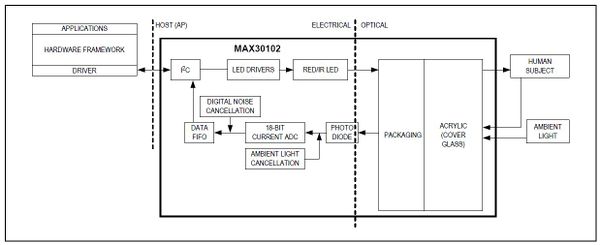

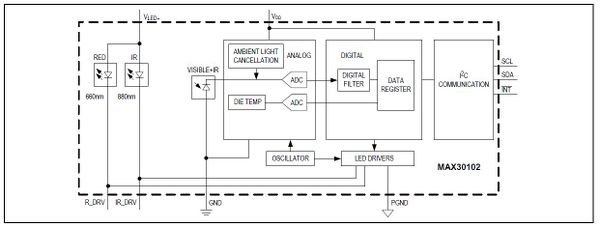

The Heart-Rate Monitor and Pulse Oximeter Sensor (MAXREFDES117) design is a Photoplethysmogram (PPG) based heart rate and SpO2 monitor subsystem. The module contains heart-rate/SpO2 sensor (MAX30102), a low-power step-down converter (MAX1921), and a level translator (MAX14595). The circuit utilizes the MAX30102 heart-rate/SpO2 sensor with integrated red and IR LEDs to detect heart rate and pulse ox on a person’s fingertip, earlobe. It should be powered on using a 2V to 5.5V supply. The step-down converter MAX1921 converts the 2V to 5.5V supply input and generates the 1.8V rail for the heart-rate sensor. The MAX14595 level translator provides an interface between the heart-rate/SpO2 sensor and the controller board, which generally use a different logic level.

It can be interfaced with using I2C communication and is fully adjustable through software registers, and the digital output data can be stored in a 32-deep FIFO within the IC. The SDA(P0.0) and SCL(P0.1) are connected on the I2C1 of the SJ-one board and interrupt is connected to GPIO pin on port 2 (P2.0) as shown on interface diagram. An interrupt is generated whenever it the FIFO gets filled and the samples are read as it gets filled.

Due to the form factor of the IC, it is ideal for wearable and it is can be clipped onto the finger of the person.

Temperature Sensor

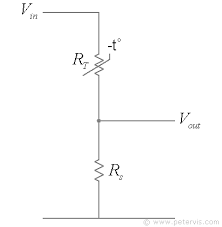

An NTC thermistor is used to compute the body temperature connected to the analog pin of the SJ-one board. A voltage divider circuit is connected to the analog pin of the board. A 10K resistor and thermistor are used in voltage divider circuit whose Vout is connected to analog pin as shown in the figure. Now you just measure the voltage in the middle, as the resistance changes, the voltage changes too, according to the simple voltage divider equation.

Features

- Resistance at 25 degrees C: 10K +- 1%

- B25/50 = 3950+- 1%

- Thermal time constant <= 15 seconds

- Thermistor temperature range -55 °C to 125 °C

- 28 AWG PVC Wire

Accelerometer sensor

The SJOne board has an accelerometer which is interfaced on the I2C2 bus. Accelerometers are electromechanical devices that sense either static or dynamic forces of acceleration. Static forces include gravity, while dynamic forces can include vibrations and movement. Based on the values generated we determine the the movement and step count of the person wearing it. The measurements are on a 3-axis and these values can be calibrated to find the values.

LCD

A LCD Display Screen is used to display the health stats collected from all the sensors of the user. It is interfaced to SJOne board via SPI. 2 GPIO pins are configured as Switches. Two Switches are used - One to switch on and off the LCD Interface, one more switch is used to Swap the screens from Timer Screen to Sensor Screen

Features:

- Display resolution: [240xRGB](H) x 320(V)

- a-TFT LCD driver with on-chip full display RAM: 172,800 bytes

- System Interface

- 3-line / 4-line serial interface [SPI/I2C]

- Display mode

- Full color mode (Idle mode OFF): 262K-color

- Reduce color mode (Idle mode ON): 8-color

- On chip functions

- Timing generator

- Oscillator

- DC/DC converter

- Line/frame inversion

- 4 preset Gamma curves with separate RGB Gamma correction

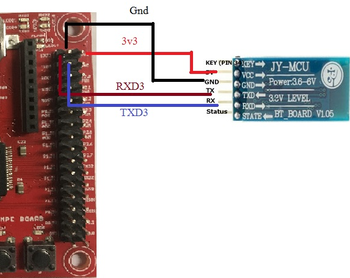

HC-05 Bluetooth Module

The HC-05 module is easy to use Bluetooth SPP (Serial Port Protocol) module, designed for transparent wireless serial connection setup. Serial port Bluetooth module is fully qualified Bluetooth V2.0+EDR (Enhanced Data Rate) 3Mbps Modulation with complete 2.4GHz radio transceiver and baseband. It uses CSR Bluecore 04-External single chip Bluetooth system with CMOS technology and with AFH(Adaptive Frequency Hopping Feature). It has the footprint as small as 12.7mmx27mm.

Hardware Features

- Typical -80dBm sensitivity

- Up to +4dBm RF transmit power

- Low Power 1.8V Operation, 1.8 to 3.6V I/O

- PIO control

- UART interface with programmable baud rate

- With integrated antenna

- With edge connector

Software Features

- Default Baud rate: 38400, Data bits:8, Stop bit:1, Parity: No parity, Data control: has.

Supported baud rate: 9600,19200,38400,57600,115200,230400,460800.

- Given a rising pulse in PIO0, the device will be disconnected.

- Status instruction port PIO1: low-disconnected, high-connected;

- PIO10 and PIO11 can be connected to red and blue led separately. When master and slave

are paired, red and blue led blinks 1time/2s in the interval, while disconnected only blue led blinks 2times/s.

- Auto-connect to the last device on power as default.

- Permit pairing device to connect as default.

- Auto-pairing PINCODE:"1234" as default

- Auto-reconnect in 30 min when disconnected as a result of beyond the range of connection.

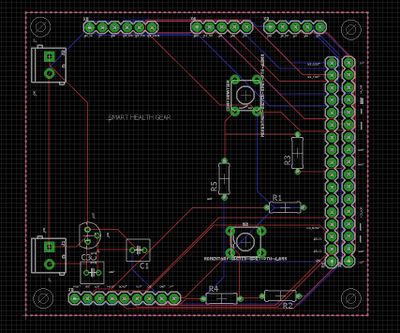

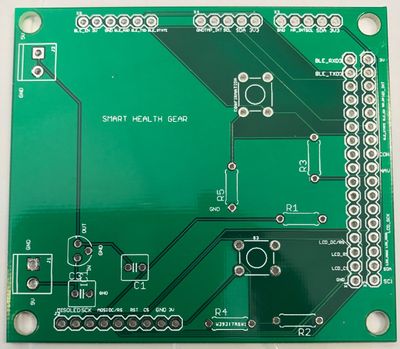

Printed Circuit Board

The PCB design was one of the challenging part of this project. The PCB design was created in Autodesk Eagle v8.1.0. Before proceeding with the schematic, we had decided to design a PCB that matches with the size of the SJ one board such that it could be mounted over it. Considering designing a wearable device, we had to keep in mind the form factor of the PCB. Initially we designed a PCB which turned out to be four-layer PCB including the blood pressure monitoring subsystem. However due to budget constraints we had to give up the blood pressure system as printing the same required a licensed version of Eagle.

Before starting the PCB schematic design, we decided on the location of sensors as it was vital for a wearable health monitoring device with a LCD display facing the user. Since surface mount soldering was not an option we decided to design the schematic with through hole connections. Another challenging part for our design was the libraries needed for schematic design. Since we didn’t have libraries for heart rate sensors, we had to design by creating it from scratch. However, we had some libraries from sparkfun, Eagle and Adafruit, the entire process took most of our time.

The first step in PCB design is to import all the libraries of the components that we would be using and create a schematic using the same. We made use of the Dimension tool in Eagle to match the PCB size with that of the SJ one board. We created the schematic by placing the required components and wiring them. The tutorial on Sparkfun website was very helpful in designing the same. It was very important for to ensure that all connections are verified properly before it gets printed. This was done using “DRC” Design Rule Check in Eagle which would show if any consistent errors existed.

EAGLE Schematic

EAGLE Connector List

| Section | Connector | Library | Package | Device |

|---|---|---|---|---|

| Power Connector | 2x2-pin | SparkFun-Connectors | SCREWTERMINAL-3.5MM-2 | CONN_023.5MM (CONN_02) |

| SJ-One Board | 2x17-pin | SparkFun-Connectors | 1X17 | CONN_17 |

| Bluetooth Module | 1x6-pin | SparkFun-Connectors | 1X06 | CONN_06SILK_FEMALE_PTH (CONN_06) |

| Temperature Sensor | 1x5-pin | SparkFun-Connectors | 1X05 | CONN_05 |

| Heart Rate Sensor | 1x5-pin | SparkFun-Connectors | 1X05 | CONN_05 |

| LCD Section | 1x9-pin | SparkFun-Connectors | 1X09 | CONN_09 |

| Resistor | 5x2-pin | resistor | 0207/7 | R-US_0207/7 (R-US_) |

| Capacitor | 2x2-pin | rcl | C025-050X050 | C-US025-050X050 (C-US) |

| Switch | 2x4-pin | SparkFun-Switches | TACTILE_SWITCH_PTH_6.0MM | MOMENTARY-SWITCH-SPST-PTH-6.0MM (MOMENTARY-SWITCH-SPST) |

| LM7805 Regulator IC | 1x3-pin | v-reg | 78LXX | 78LXX |

Once the schematic is created that can be easily converted to Board Layout using the Generate/Switch to board option in Eagle. But this would create the board by randomly placing the parts at different locations. Since we had to have an LCD mount over the PCB as well as match the 17x2 connectors with that of SJ one board we created the design accordingly. After ensuring that everything was in place we placed order for the PCB and verified the same again using a multi-meter if all the connections were correct.

Hardware Interface Diagram

The below figure shows the interface diagram the connects the SJOne board with PCB and the various sensors and external power supply. As shown, all the SJOne pins were mapped to the PCB using a 17x2 connector and the PCB schematic was designed to match the project requirements of connecting sensors on relevant interfaces. The mapping and interfaces are shown clearly in the figure below. A voltage regulator was built which steps down 9V battery power to provide 5V supply to SJone board from PCB using phoenix connector.

Software Design

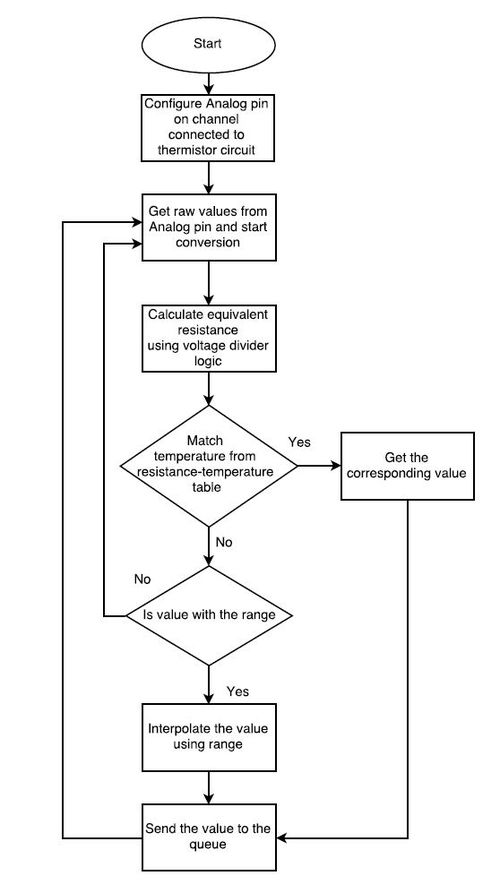

Body Temperature Calculation

- Thermistor (NTC) is connected to the analog pin through a voltage-divider circuit using a 10K resistor.

- According to the simple voltage-divider equation, the resistance changes as the voltage changes.

- Based on the resistance value we can find the corresponding temperature value by matching it with the look-up table provided by the vendor.

- The calculation of the temperature value is as shown in flowchart.

Software flowchart:

float temp = ((LS.getRawValue() *THREE_POINT_THREE)/4096);

temp = THREE_POINT_THREE/temp;

resistance = TEN/(temp - 1);

//Match resistance with look up table.Heart rate Calculation

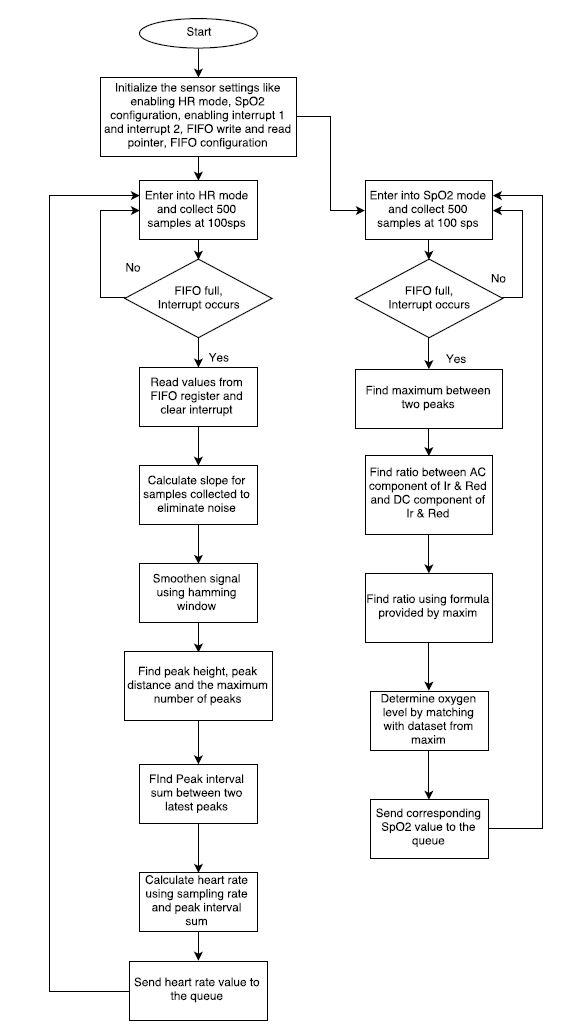

- The heart rate (bpm) is calculated by sensing the photoplethysmograph signal from the Pulse and Oximeter Sensor. By connecting the sensor on the I2C interface we get the raw values and collect about 100 samples every second.

- Initialize the sensor settings like enabling HR mode, SpO2 configuration, interrupt 1 and interrupt 2, FIFO write and read pointer, FIFO configuration by writing appropriate values into the registers as specified in the datasheet.

- The raw values contain noise as well so it is eliminated by finding derivative of the signal. For this purpose, we find the slope of the signal which would be series of either positive or negative number.

- To this derivative signal, a Hamming window is applied to smoothen out all edges and the signal is like a sine wave.

Software flowchart:

Algorithm Pseudocode:

- Read values from FIFO register whenever an interrupt occurs.

- Continuously take samples from MAX30102. The heart rate and SpO2 are calculated for every 1 second.

- Eliminate the first 100 samples from the register and calculate for every 500 samples by sliding the frame as samples occur.

- Find moving average of the sample raw values i.e slope calculation

- Apply Hamming window to the signal with window size as 5.

- Find peak height, peak distance and the maximum number of peaks.

- Find at most MAX_NUM peaks above MIN_HEIGHT separated by at least MIN_DISTANCE

- If the number of peaks < 2, find peak interval sum.

- Find the peak interval sum = time of the last peak – time of next peak.

- Based on the sampling rate, calculate the heart rate 6000/ peak interval sum and loop back to finding the peak.

- For SpO2 calculation, we need to assess DC and AC value of IR and red PPG.

- Find maximum between two peaks and use the ratio between AC component of Ir & Red and DC component of Ir & Red for SPO2.

- The accurate SPO2 is precalculated and save in uch_spo2_table[] per each ratio

- Ratio = -45.060*n_ratio_average* n_ratio_average/10000 + 30.354 *n_ratio_average/100 + 94.845

- Match the ratio as per the values in the table to get the correct SPO2 value.

if (n_npks>=2){

for (k=1; k<n_npks; k++)

n_peak_interval_sum += (an_dx_peak_locs[k]-an_dx_peak_locs[k -1]);

n_peak_interval_sum=n_peak_interval_sum/(n_npks-1);

*pn_heart_rate=(int32_t)(6000/n_peak_interval_sum);// beats per minutes

*pch_hr_valid = 1;

}

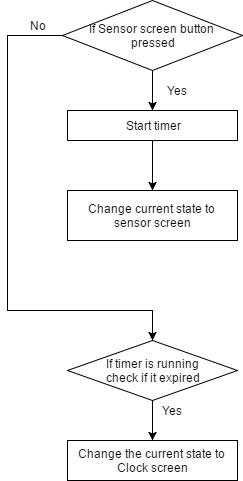

Display Driver Design

- Uses SPI interface to connect to the LCD

- The LCD interface is initialized by sending commands to set the power, frame rate, pixel depth etc.,

- The LCD screen is filled up pixel by pixel depending on what to display

- The Default Screen displays the current time and Sensor Screen has the data collected from all the sensors

- The data from each of the sensor tasks is sent to its dedicated queue and is received by the Display task

- Captures data continuously and displays on sensor screen

- There are two switches, one enables the user to turn on/off the LCD

- The user can also swap the screens by pressing the Sensor Screen button

- The timer will ensure that the sensor screen will swap back to the Timer screen after counting 300 times

Pseudocode

- The Timer is initialized to count every 100 milli seconds and give screen change semaphore if the timer counts 300 times i.e., after 30 seconds.

- The timer gives timer_increment semaphore once the timer counts till 300

- There are two tasks running Display Task and The Button Task

- The display task waits for screen change semaphore. It checks watch_skins variable for the screen which needs to be displayed on the LCD.

- If the Timer screen needs to be displayed a function is called to check for any updates in time

- The timer is also used to check for the minute change, hour change, day change or year change. A function called minute check is used to notify the display task of any updates in time

- For any change in the time a dedicated semaphore is given which is captured by the display task.

- The address window that needs to be updated is cleared and the updated time received from RTC timer and is displayed

- If Sensor screen needs to be displayed the default screen with time stamp is cleared and Sensor screen is displayed

- The screen change semaphore is given when the timer expires or when the Screen change button is pressed.

- The button task monitors the button press for Sensor screen and the timer count.

- If the Sensor Screen button is pressed it sets the watch_screens variable to sensor screen and gives Screen change semaphore

- If it timer_increment semaphore is received it sets the watch_screens variable to clock screen and gives the screen change semaphore

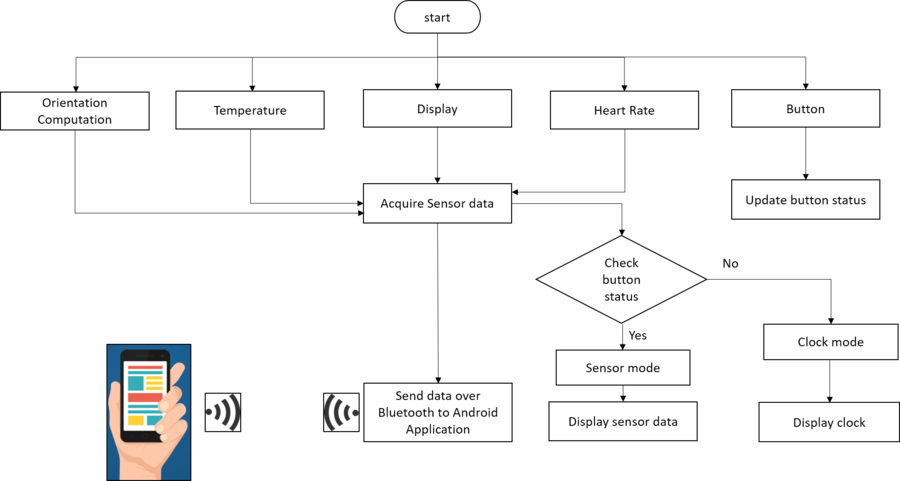

Software Flow Chart

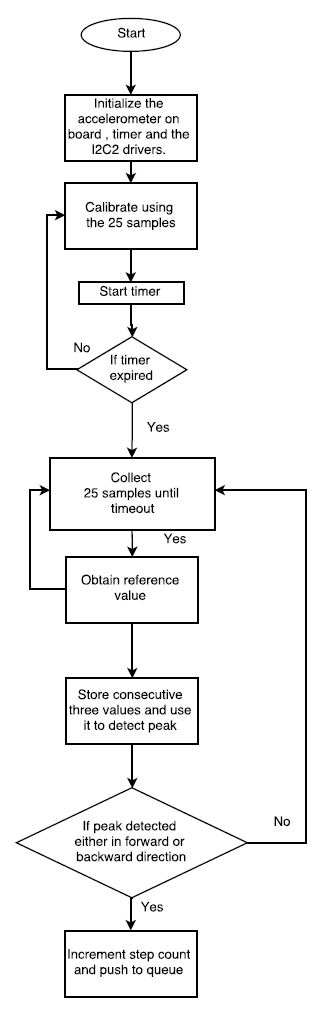

Step count Calculation

- The step count is calculated using the values from the accelerometer on the SJ-on board. The accelerometer is connected on the I2C2 interface.

- Initialize the sensor settings, timer configuration, and I2C2 driver settings and load appropriate values into the registers as specified in the datasheet.

- The API is used to get the x-direction, y-direction and z-direction values from the accelerometer.

- It is calibrated using the initial values and step count is determined as given in the below pseudocode.

Software flowchart:

Algorithm Pseudocode:

1. Initialize the accelerometer on board sensor, timer, and I2C2 drivers.

2. Calibrate the accelerometer by collecting 25 sample readings along the X, Y and Z axis.

3. The collected samples are sorted in ascending order.

4. The reference value along all the axis are calculated by averaging the least and the highest value of the sorted array.

5. A 100-millisecond timer is started and periodically 25 samples are collected, sorted and averaged to find the current acceleration along the three axes by a producer task.

6. Whenever a newly updated data is calculated, the preceding two values are stored to determine the peak condition. Hence, at any given time, consecutive three values (x_old, x_prev and x_th etc) are available for each axis, the current value being x_th)

7. Whenever the hand swings, the accelerometer readings significantly change and a peak condition is detected both during forward and backward swing.

8. As soon as a peak condition is detected the producer task increments the step count and passes it to the display task using a shared queue.

9. The system is re-calibrated at every 100 millisec timeout for accurate results.

if(((x_old + 10 < x_prev ) && (x_th + 10 < x_prev )) )

{

count = forw;

step_Count++;

}

else if(((x_old > x_prev + 10) && (x_th > x_prev + 10)))

{

count = back;

step_Count++;

}Android Application

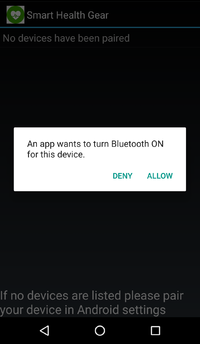

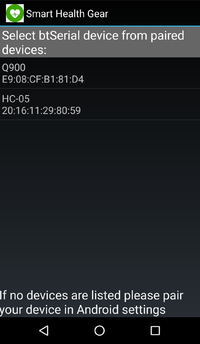

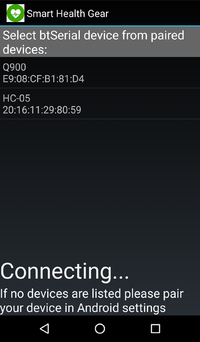

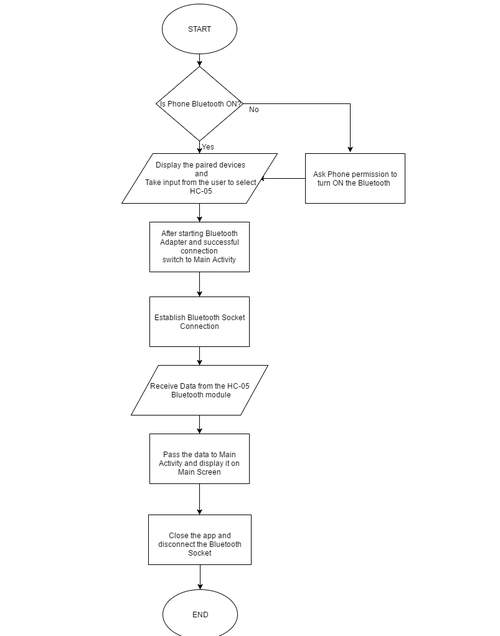

Development of the Android application is done using Android Studio Version 2.3.2. The application is connected to the HC-05 Bluetooth module using Bluetooth module. The HC-05, in turn, is interfaced with the SJOne board using Uart3 at the baud rate of 9600 bps. The connections are shown below. The data is sent to the module using serial communication nearly after every second and the value is simultaneously updated on the mobile application.

Android Studio is Android's official IDE. It offers tools custom-tailored for Android developers, including rich code editing, debugging, testing, and profiling tools. The Android app is built using 4 basic files namely AndroidManifest.xml, DeviceListActivity.java, MainActivity.java and activity_main.xml. Every application must have an AndroidManifest.xml file (with precisely that name) in its root directory. The manifest file provides essential information about your app to the Android system, which the system must have before it can run any of the app's code.

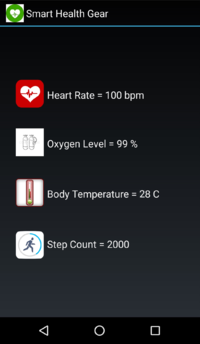

The layout of the Application has four text boxes to display the four different parameters of data i.e. Heart Rate, Body Oxygen Level, Body Temperature and Step Count.

Upon opening the Application, if the Bluetooth connection of the Phone is not ON, the app will request permission to turn on Bluetooth. The first page of the application will display all the paired devices with the Phone. After selecting HC-05 among the list of paired devices, the app will connect to the module HC-05 and is ready to receive data from the module.

All the four parameters are passed in the format shown below:

Uart3& uart_3 = Uart3::getInstance();

uart_3.init(9600);

uart_3.printf("#%3d+%3d+%3d+%4d+~",heartRate, bodyOxygen, bodyTemp, stepCount);On the application side, the above-received string is parsed accordingly to extract the value of each parameter and display it in the appropriate text box.

if (recDataString.charAt(0) == '#') //if it starts with # we know it is what we are looking for

{

String sensor0 = recDataString.substring(1, 4); //get sensor value from string between indices 1-5

String sensor1 = recDataString.substring(5, 8); //same again...

String sensor2 = recDataString.substring(9, 12);

String sensor3 = recDataString.substring(13, 17);

sensorView0.setText(" Heart Rate = " + sensor0 + " bpm"); //update the textviews with sensor values

sensorView1.setText(" Oxygen Level = " + sensor1 + " %");

sensorView2.setText(" Body Temperature = " + sensor2 + " C");

sensorView3.setText(" Step Count = " + sensor3 + "");

}Software flowchart:

Implementation

The software flow was designed in such a way that the interactive tasks such as display screen and Bluetooth module had to have high priority as it should be available to the user on demand. The sensor tasks each had a separate queue of depth 1 where the calculated values were sent. So, it gets dequeued in the display task and is updated whenever the screen is unlocked.

Below figure shows the complete implementation and task synchronization of the device.

Testing

Module testing

Heart Rate and Oxymeter measurement

Both the failure and the pass cases were effectively tested for the heart rate module. The device was powered on with the clip-on wrapped on the finger. The heart rate values were measured during the conditions when the person was at rest and when the person had done heavy cardio exercise. The values shown on the display screen were accurate, i.e. 99 bpm for rest case and 140 bpm after heavy exercise. Values of oxygen level was 98 % when finger connected to the clip-on. The device was tested with no finger placed on the sensor, the results displayed were 0.

Temperature measurement

The temperature measurement module was tested by connecting the thermistor to a hot body and a cold body. The values differed in both the testing scenarios. The hot body measured displayed a temperature of 33 C and the cold body displayed a temperature of 23 C.

Step count

The step count readings were tested by warping the device on the wrist of a person and making the person walk normally for 2 steps. The display on the LCD dynamically changed to 2 steps.

Android App

The android app was connected by pairing with the device tested by hard coding values in the required pattern "#100+98+28+2000~" and the sending over Bluetooth Uart. The displayed values corresponded to what was sent.

LCD Display

The LCD screen was tested by connecting the battery and RTC cell. The time value was compared to the system time and it exactly matched. The sensor screen was tested for time out condition. Buttons were pressed to lock and unlock the device and navigate through the display pages.

Integration testing

All the modules were integrated and tested. The device was worn on the wrist and the clip-on was wrapped on the finger. The device was then paired to a mobile phone using the Android App. The values on the display LCD and the Android App were cross checked. The values matched and were in the expected range. The buttons were pressed to navigate and lock the device. The time displayed on the screen was also verified with the the mobile phone time.

Technical Challenges

PCB Designing

- We used the free version of Eagle Studio to design the PCB and this posed us with various limitations.

- We tried to implement Blood pressure circuit within the PCB which included of three circuits including Signal Conditioning, Pump circuit, and Valve circuit. The free version did not provide the required dimensions of the PCB needed for this implementation.

- As a beginner, it was difficult to find the libraries for the exact parts we needed. After searching online for all the exact description of the components, we could successfully search for the libraries of the corresponding parts.

- Mirroring effect during PCB production was a factor that we undermined initially, but while reviewing the PCB before giving for production we noticed the alignment and corresponding connections of various modules with the PCB and changed the header pins accordingly.

- Soldering of the components needed to be done carefully so as not to damage any of the components or PCB.

Heart Rate Sensor

- After analyzing I2C clock on a Digital Oscilloscope, we realized that the frequency set by Preet was actually double the required frequency. So we divided the final frequency by 2 to get the required frequency.

- The sensor was very sensitive and hence required consistent pressure on the die to get proper readings.

- To solve this, we initially mounted the sensor within the band with sensor facing the wrist but the readings were not correct as it should be placed in any part of flesh extremity so we had to clip on the sensor to the finger to get proper readings.

Task synchronization issue

- Being a user interactive product, it was important that the LCD and Android app is available to the user on demand. So we had to give high priority for the interactive tasks such as LCD display task and Bluetooth task.

- As a result of this, the sensor tasks went into starvation which was at a lower priority.

- To mitigate this, we made the high priority tasks sleep whenever no event occurred. Also, we used semaphores and mutex locks for cooperative scheduling between the sensor tasks.

LCD refresh issue

- The LCD screen refresh by filling the address window with the background color is very slow.

- We are instead filling the existing pixels with the background color.

- This is reducing the time taken by the Display to refresh and so the user can check the data quickly

Future Scope

- User profiling and providing recommendations based on user's fitness.

- Track the activity of the patient and monitor its physiological data over time and perform Big data analysis.

- Add more features like Blood pressure measurement, calories, BMI and energy measurements

- The device can be made rechargeable.

- Provide notifications to user when something abnormal is detected.

Conclusion

This project has been successfully developed with almost all the decided features. The sensors work concurrently to communicate data to the Controller board. This real-time data is displayed on the LCD and also on the Android Application. We got to learn and implement various FreeRTOS features in this project to make this Project more robust while gaining knowledge about both the Hardware and Software fields. It was fun developing this project while integrating different sensors and output modules with the SJOne Board. We faced some issues at the start of the development phase but overcame those by taking appropriate decisions about the right sensors for Smart Health Gear project. We were also introduced to the world of PCB Designing which was exciting to learn and has given us a head start in a new doamin.

Project Video

Project Source Code

References

Acknowledgement

We would like to thank our Professor Preetpal Kang for all his teachings and inspirational lectures. This project has been an overall learning experience and precious life lessons. We would also like to thank the ISA members for always being ready to help with whatever issues we faced.

References Used

[1] FreeRTOS documentations [2] Adafruit thermistor [3] Adafruit LCD library [4] FreeRTOS API [5] MAXREFDES117 datasheet [6] CMPE 244 Lecture notes from Preetpal Kang, Computer Engineering, San Jose State University. Jan-May 2017.