Difference between revisions of "S16: Expendables"

Proj user3 (talk | contribs) (→Schedule) |

Proj user3 (talk | contribs) (→Parts List & Cost) |

||

| Line 107: | Line 107: | ||

== Parts List & Cost == | == Parts List & Cost == | ||

| − | + | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! scope="col"| Sl. No | ||

| + | ! scope="col"| Part Name | ||

| + | ! scope="col"| Source of purchase | ||

| + | ! scope="col"| Quantity | ||

| + | ! scope="col"| Cost($) | ||

| + | |- | ||

| + | |- | ||

| + | |1 | ||

| + | |Raspberry Pi 3 | ||

| + | |https://www.adafruit.com/products/3055 | ||

| + | |1 | ||

| + | |44.49 | ||

| + | |- | ||

| + | |- | ||

| + | |2 | ||

| + | |LED panels | ||

| + | |Preet | ||

| + | |4 | ||

| + | |0 | ||

| + | |- | ||

| + | |- | ||

| + | |3 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |- | ||

| + | |4 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |- | ||

| + | |5 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |- | ||

| + | |6 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |- | ||

| + | |7 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |- | ||

| + | |8 | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |- | ||

| + | |} | ||

== Design & Implementation == | == Design & Implementation == | ||

Revision as of 22:11, 10 May 2016

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

Abstract

This section should be a couple lines to describe what your project does.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

Schedule

| Sl. No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 3/07/2016 | 3/13/2016 | Components buying | Completed | 3/18/2016 |

| 2 | 3/14/2016 | 3/20/2016 | LED panels study | Completed | 3/20/2016 |

| 3 | 3/28/2016 | 4/03/2016 | Raspberry Pi 3 study | Completed | 4/03/2016 |

| 4 | 4/04/2016 | 4/10/2016 | Pixel Driver Design | Completed | 4/20/2016 |

| 5 | 4/11/2016 | 4/17/2016 | PCB Design | Completed | 3/30/2016 |

| 6 | 4/18/2016 | 4/24/2016 | Testing Text Display | Completed | 4/20/2016 |

| 7 | 4/25/2016 | 5/01/2016 | UI Webserver | Ongoing | |

| 8 | 5/02/2016 | 5/08/2016 | Final Testing and Debugging | Ongoing |

Parts List & Cost

| Sl. No | Part Name | Source of purchase | Quantity | Cost($) |

|---|---|---|---|---|

| 1 | Raspberry Pi 3 | https://www.adafruit.com/products/3055 | 1 | 44.49 |

| 2 | LED panels | Preet | 4 | 0 |

| 3 | ||||

| 4 | ||||

| 5 | ||||

| 6 | ||||

| 7 | ||||

| 8 |

Design & Implementation

Hardware Design

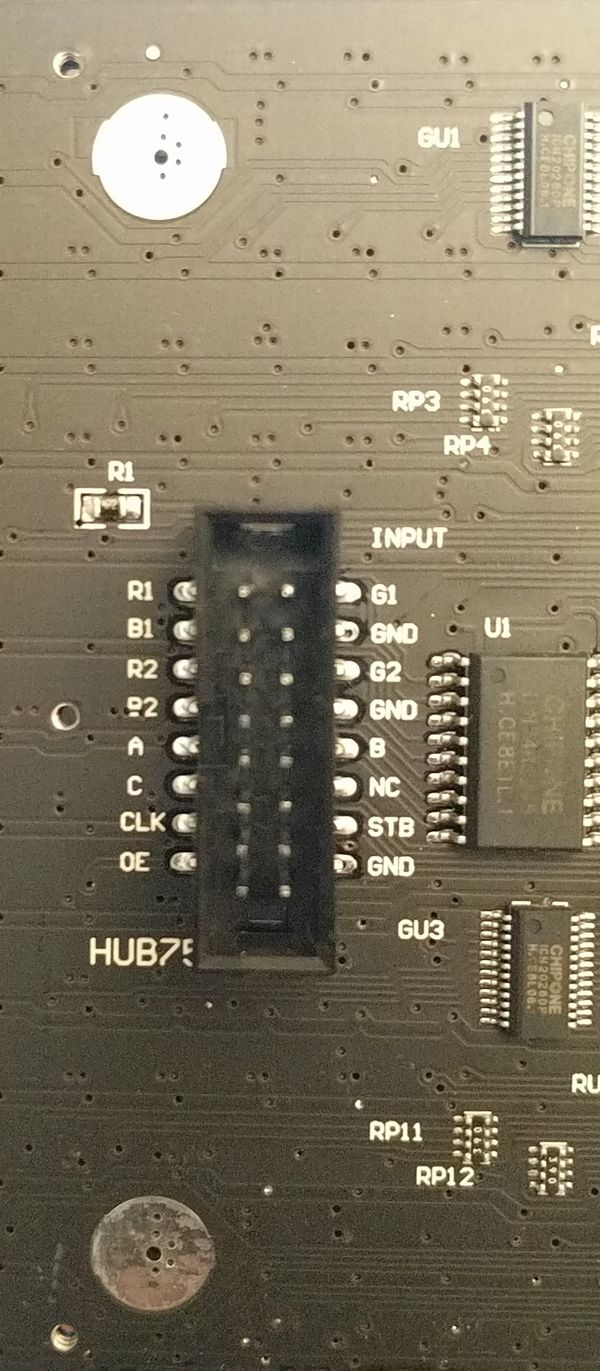

LED Panels

The display panels use multiplexing to draw picture information, which means that the rows and columns are updated fast than the human eye can process. If the updating speed is fast enough, eyes will see a complete picture without flickering. The updating process is as follows

- Select the row to be updated.

- Output the desired column data on selected row.

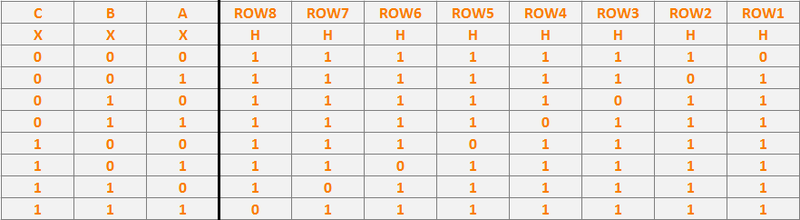

Row Selection

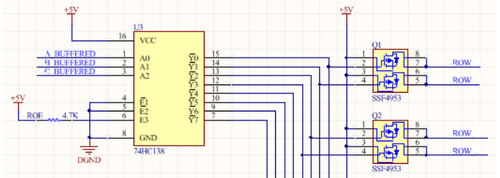

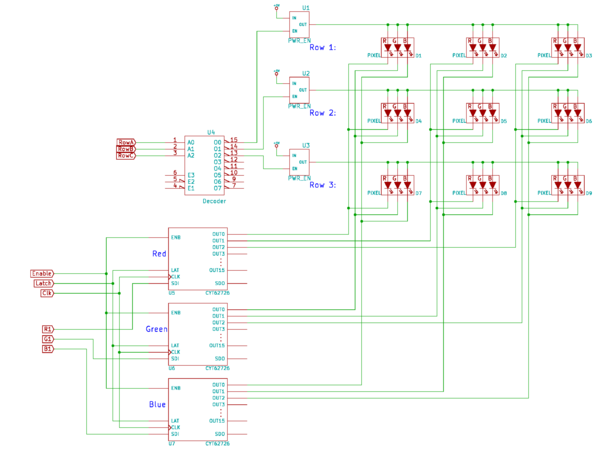

Row selection is done by using a 3-to-8 address decoder (74HC138D). There are three address inputs to the display marked A, B and C. Based on the truth table, only one input is active (low) at a time.

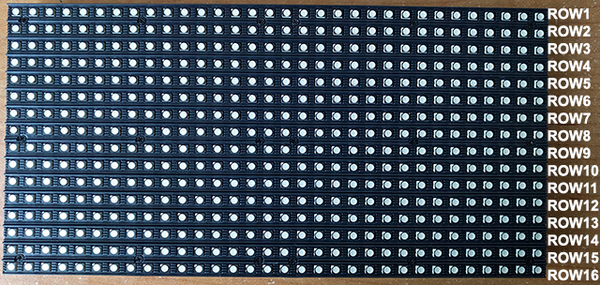

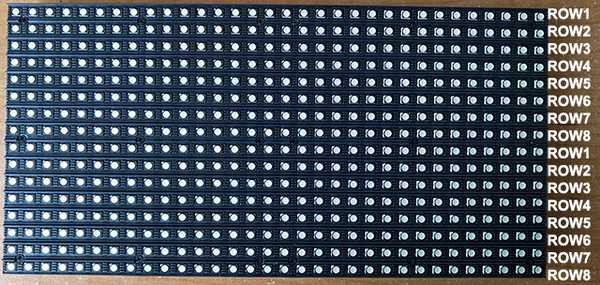

Since the panels has 16 rows, the 3-to-8 address decoder select rows in parallel. For example, when the 1st row (Row1) is selected, it also selects the 9th row (Row9). Using this technique implies that we must supply data for the columns for two unique rows at a time.

The outputs of the decoder is connected to a P-Channel MOSFET, because the decoder itself can only handle low currents and cannot drive a row of LEDs directly. The P-Channel MOSFET provides the high current needed to drive a row of LEDs.

The decoder outputs are shared between every 8 outputs (1 and 9, 2 and 10, repeating that pattern until row 8 and 16).

Column Selection

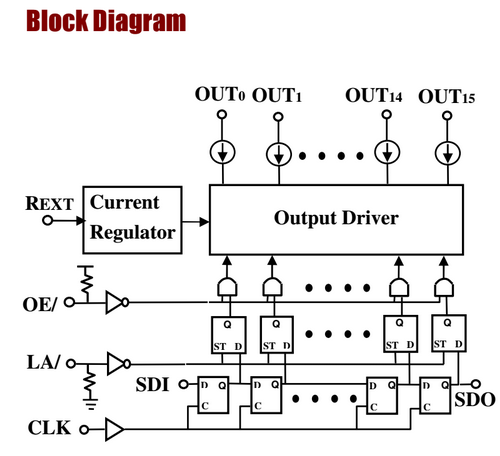

The column data is stored in a 16-bit serial-in, parallel-out shift register. Since the display is 32 pixels wide, two shift registers must be chained together. The shift register is designed to work with LEDs and implements a constant-current system that ensures the LED brightness remains uniform. The panels that we are using utilize SCT2026 shift registers. These are 16-bit Serial-In/Parallel-Out registers.

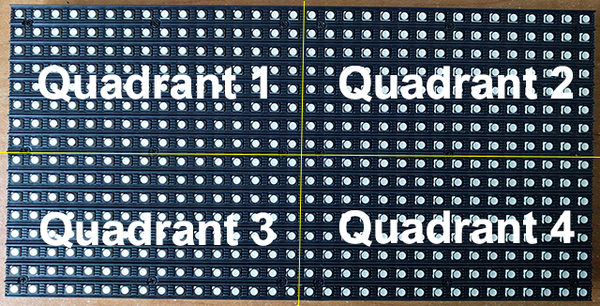

There are 12 of these shift registers on the display. 3 each are used to hold the Red, Green, and Blue data for 1 of 4 quadrants of the display. (3 colors * 4 quadrants = 12 chips)

For drawing 16 rows using the 8 outputs of the decoder, we must have unique data for each row pair. When Row 1 and Row 9 are selected, we must provide each row with unique data. This forces us to use two different shift registers for each row pair, an upper register and a lower register. Because of this, the display is divided into an upper half and a lower half. The data is shifted into the top half via the R1, G1 and B1 signals on the connector. The bottom half’s data is supplied by the R2, G2 and B2 signals on the connector. Then, since our display is 32 pixels wide, we must use 2 shift registers to hold all 32 bits of pixel data for a single row. This creates the left and right halves of the display.

Each quadrant of the display is controlled by 3 shift registers, one for each color. First, Row 1 and Row 9 are selected. 32 bits of data are shifted into each color’s shift register (R1, G1, B1), and then latched. At the same time, 32 bits of data are also shifted into each color’s shift register for the bottom half (R2, G2, B2), and then latched. The process repeats 7 more times, each time incrementing which rows are selected, until every line has been updated.

Hardware Interface

The connector on the RGB panels is called a Hub75 interface. Each panel typically has two ports, one is the input and the other is the output to chain additional panels.

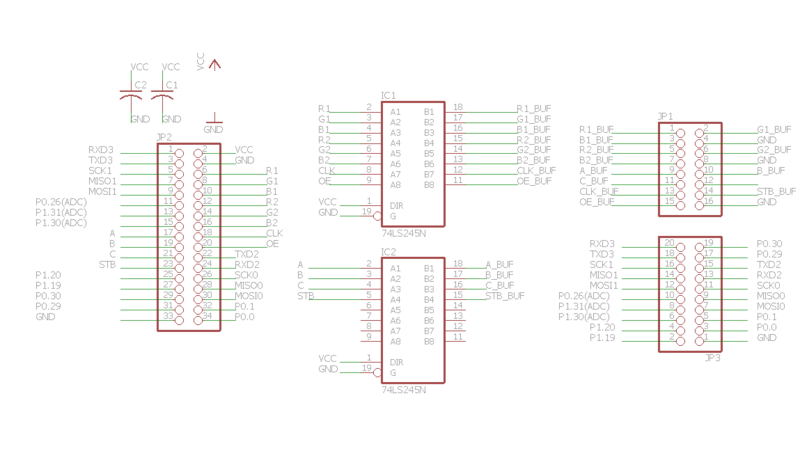

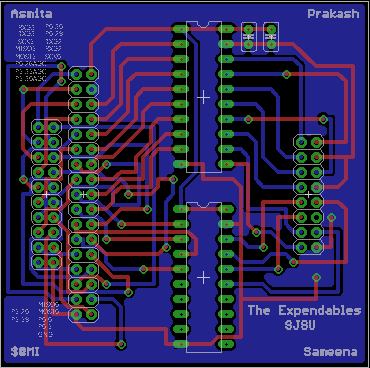

PCB Design

The LED panels use 74HC245 line drivers, these transceivers require 5v logic levels whereas the SJONE board only supports 3.3v logic. In order to drive the LED panels from 3.3v GPIO pins of the SJONE board, level-shifting IC is used to level shift signals from 3.3V to 5V and shield the SJONE board GPIOs from overloading. For this purpose, and to make it easier to connect the panels to the SJONE board a PCB was designed in EAGLE. The PCB attaches to GPIO pins of SJONE board and provides easily accessible, level-shifted output for the LED panels. The PCB also breaks-out free pins so that they can be used for other purposes.

Software Design

The code tries to use a technique called Binary Code Modulation to control the colors of the display. Driving with Pulse Width Modulation (PWM) would turn the LED on for an amount of time proportional to the desired brightness, then turn it off for the rest of the period. BCM divides the period into binary-length segments (1x, 2x, 4x, etc), and turns the LED on or off for each of these segments according to the bits of the LED’s desired brightness. The pixel data must be divided up into bitplanes. These bitplanes are nothing but an array in which each element is a single bit from a color value in the displayed image. Each pixel would require three separate bitplanes, one for each color element. However to drive the display, all three colors are written out for two different pixels at the same time. The code stores six bits, one from each bitplane, together in a byte. This way the bytes are immediately ready to be written to the GPIO port during the interrupt. The code refers to the arrays of ready-to-write bytes as “planes,”. In each interrupt (RGB::updateDisplay) a byte from the appropriate plane is written out to the GPIO port and the delay until the next interrupt is set.

void refreshISR(void)

{

activePanel->updateDisplay();

}

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.