Difference between revisions of "S15: Self-Balancing Robot"

Proj user21 (talk | contribs) (→Software Design) |

Proj user21 (talk | contribs) (→Testing & Technical Challenges) |

||

| (56 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

== Project Title == | == Project Title == | ||

Two Wheel Self-Balancing Robot | Two Wheel Self-Balancing Robot | ||

| Line 34: | Line 22: | ||

== Schedule == | == Schedule == | ||

| − | + | ||

{| class="wikitable" | {| class="wikitable" | ||

| Line 82: | Line 70: | ||

== Parts List & Cost == | == Parts List & Cost == | ||

| − | + | ||

{| class="partsListTable" | {| class="partsListTable" | ||

| Line 134: | Line 122: | ||

== Design & Implementation == | == Design & Implementation == | ||

| − | + | ||

=== Hardware Design === | === Hardware Design === | ||

| − | + | ||

<br> | <br> | ||

| Line 153: | Line 141: | ||

<br>The problem with this is that it is a very unstable system and a control algorithm must be used to stabilize it. For this project, the group decided to use a PID algorithm because of its simplicity | <br>The problem with this is that it is a very unstable system and a control algorithm must be used to stabilize it. For this project, the group decided to use a PID algorithm because of its simplicity | ||

<br>compared to other control algorithms. It is also readily available which is a plus considering the time we have to finish this project. | <br>compared to other control algorithms. It is also readily available which is a plus considering the time we have to finish this project. | ||

| + | <br> | ||

| + | [[File:S15_146_G8_PID.png|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center"> Figure 3. PID controller implementation.<div style="text-align:left"> | ||

| + | <br> | ||

| + | <br>The PID controller is both software and hardware implementation. The angle reading from the MPU6050 module and the desired angle are fed to the PID algorithm — which calculates the error and outputs a control signal. The control signal is fed to the motorController which is responsible for driving the stepper motors. | ||

| + | <br>The PID algorithm relies heavily on the three constant parameters: Kp Ki Kd, where Kp is the proportional constant, Ki is the integral constant, and Kd is the derivative constant. | ||

| + | <br>The constants are multiplied with their respective terms P, I, and D terms. | ||

| + | <br>The P term is responsible for calculating the proportional error or present error. | ||

| + | <br>The I term is responsible for calculating the accumulation of the past errors. | ||

| + | <br>The D term is responsible for calculating the prediction of future errors based on DT (rate of change). | ||

| + | <br>By summing up these three terms, the PID controller is able to output a control signal that drives the system towards the target output (desired angle). | ||

| + | <br> | ||

| + | <br> | ||

| + | [[File:S15_146_G8_robotFrontSmall.jpg|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center"> Figure 4. Self Balancing Robot Hardware (Front). Take note that the MPU6050 module is located below the battery (between the stepper motors) <div style="text-align:left"> | ||

| + | <br> | ||

| + | <br> | ||

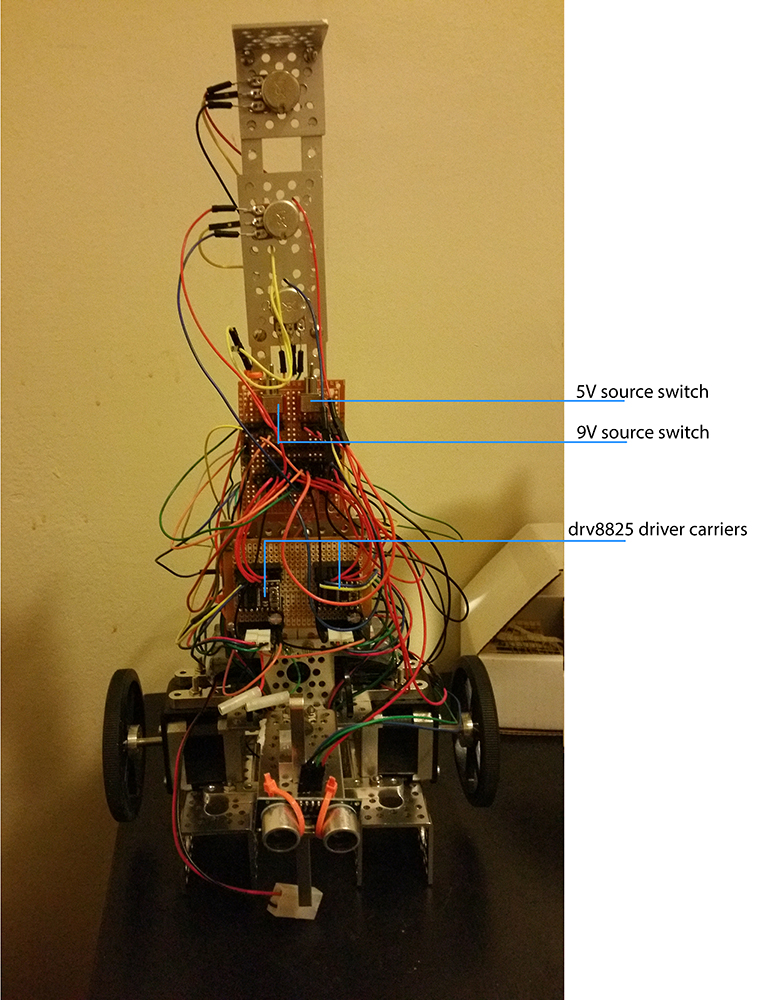

| + | [[File:S15_146_G8_robotBackLabeledSmall.jpg|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center"> Figure 5. Self Balancing Robot Hardware (Back)<div style="text-align:left"> | ||

| + | <br> | ||

=== Hardware Interface === | === Hardware Interface === | ||

| − | + | ||

<br> | <br> | ||

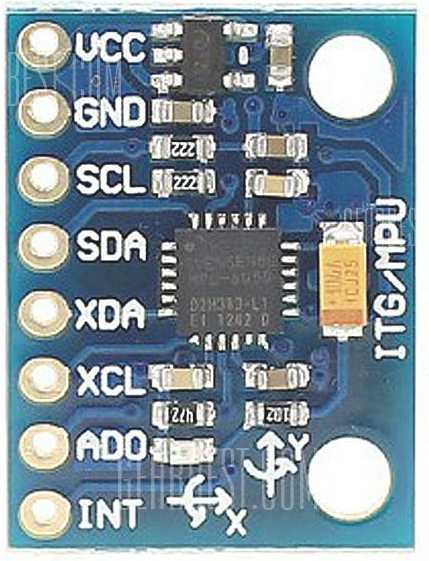

[[File:S15_146_G8_mpu6050.PNG|center]] | [[File:S15_146_G8_mpu6050.PNG|center]] | ||

<br> | <br> | ||

| − | <div style="text-align:center">Figure | + | <div style="text-align:center">Figure 6. MPU6050 module<div style="text-align:left"> |

<br> | <br> | ||

<br> | <br> | ||

| Line 179: | Line 190: | ||

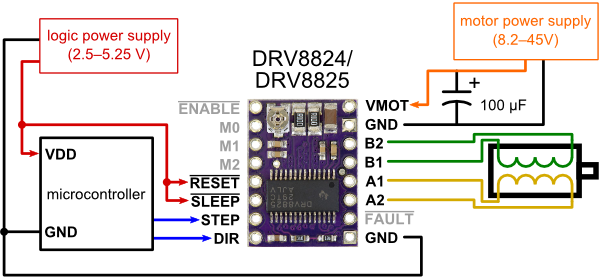

[[File:S15_146_G8_drv8825.png|center]] | [[File:S15_146_G8_drv8825.png|center]] | ||

<br> | <br> | ||

| − | <div style="text-align:center">Figure | + | <div style="text-align:center">Figure 7. drv8825 driver carrier. The image was obtained from: https://www.pololu.com/picture/view/0J4232<div style="text-align:left"><br><br> |

<br>This module was used to control one bipolar stepper motor, so a total of two drv8825 driver carriers were used for this project. | <br>This module was used to control one bipolar stepper motor, so a total of two drv8825 driver carriers were used for this project. | ||

| Line 185: | Line 196: | ||

<br>The group wrote their own driver to produce a step frequency and direction signal. This implementation took a while to finish because the group needed to understand how the PWM Motor Control is implemented on LPC1758 mcu | <br>The group wrote their own driver to produce a step frequency and direction signal. This implementation took a while to finish because the group needed to understand how the PWM Motor Control is implemented on LPC1758 mcu | ||

<br>This interface uses two PWM pins for step frequencies, and two regular I/O pins for direction signal. | <br>This interface uses two PWM pins for step frequencies, and two regular I/O pins for direction signal. | ||

| + | |||

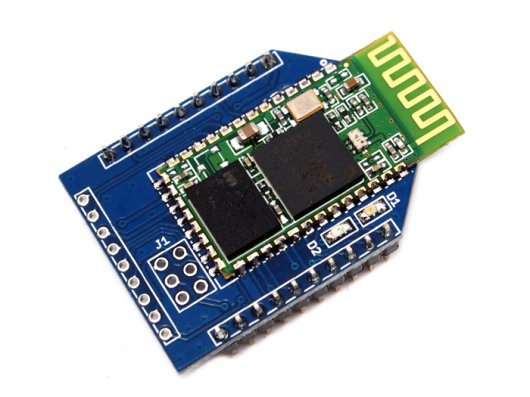

| + | [[File:S15_146_G8_bluetoothmod.jpeg|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center">Figure 8. WLS04051P SeeedStudio Bluetooth Bee Standalone. The image was obtained from: http://www.seeedstudio.com/depot/Bluetooth-Bee-Standalone-p-1157.html<div style="text-align:left"><br><br> | ||

| + | |||

| + | <br>This module was used to create a communication between an android phone (via an app) and the robot. The WLS04051P bluetooth module contains an ATMEGA 168 which is used from reprogramming the module. It is also compatible to the XBee socket of the SJOne Board. The XBee Socket can be set up to use either UART2 or UART3 using an on board switch located in the socket. The Tx and Rx goes through which UART port is set. The module also have an command set with it. The command set is used for initializing the module settings. The commands are used by sending them through the UART port. The module contains two LEDs (blue and red) which indicates its status. The LEDs alternate between red and blue when it is inquiring for devices. Once it is paired with a device, the blue LED will start flashing once per two seconds. | ||

| + | [[File:S15_146_G8_ultrasonicsensor.png|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center">Figure 9. HC-SR04 Ultrasonic Ranging Module. The image was obtained from: http://www.micropik.com/PDF/HCSR04.pdf<div style="text-align:left"><br><br> | ||

| + | [[File:S15_146_G8_hcsr04_block_diagram.jpeg|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center">Figure 9. HC-SR04 Module Hardware Interface<div style="text-align:left"><br><br> | ||

| + | |||

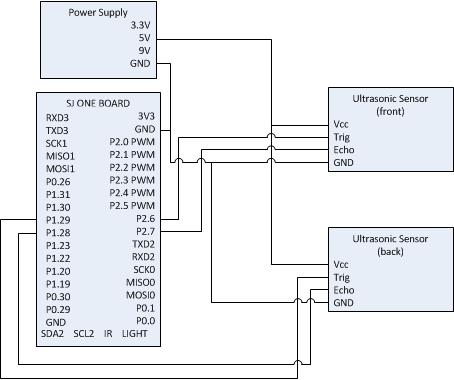

| + | <br> This module was used for the collision avoidance function of the robot. An ultrasonic sensor was placed at the front and back of the robot. When it detects an object about 10cm from it, the direction is overridden and the robot is stopped. The module requires Vcc, GND, and two GPIO pins. The GPIO pins are used for Trig and Echo pins of the module. The Trig pin is an input to the module which serves as a request from the CPU. The Echo pin turns high after some time with the Trig pin is setup. It will remain high until the signal from the module bounces back from an object infront of it. | ||

=== Software Design === | === Software Design === | ||

| − | + | ||

<br> | <br> | ||

[[File:S15_146_G8_software_design.png|center]] | [[File:S15_146_G8_software_design.png|center]] | ||

<br> | <br> | ||

| − | <div style="text-align:center">Figure | + | <div style="text-align:center">Figure 10. PID Design (software)<div style="text-align:left"> |

| + | <br> | ||

| + | <br> | ||

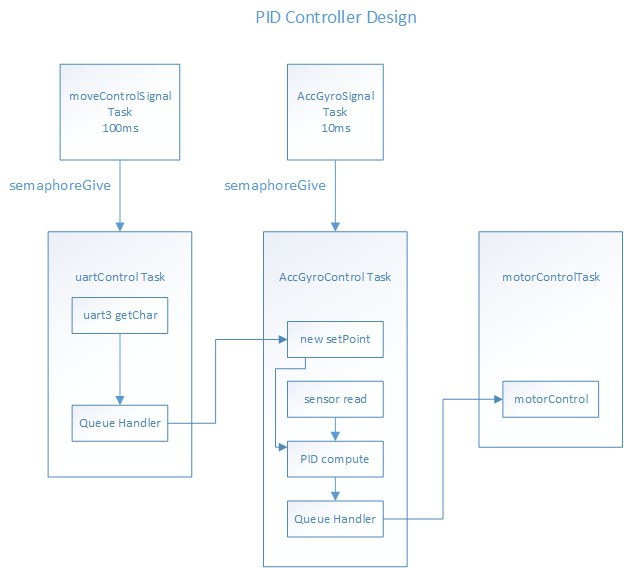

| + | The group tried to make the software design as simple as possible. There are two Signal tasks that activates their respective 'worker' tasks. The worker tasks only activates when they receive a semaphore signal. | ||

| + | <br>The moveControlSignal task is responsible for sending a signal every 100ms to the uartControl task — which reads the uart data register. The uartControl task then sends the read data to the AccGyroControl task. | ||

| + | <br>The AccGyroSignal task is responsible for sending a signal every 10ms to the AccGyroControl task. | ||

| + | <br>The AccGyroControl task is responsible for the sensor reading and computation of the PID controller. This task is also responsible for sending the output of the PID controller to motorControl task. | ||

| + | <br>The motorControl task is responsible for driving the motors. | ||

| + | |||

| + | <br> | ||

| + | [[File:S15_146_G8_bt_sensor_sjoneboard_swdesign.jpeg|center]] | ||

| + | <br> | ||

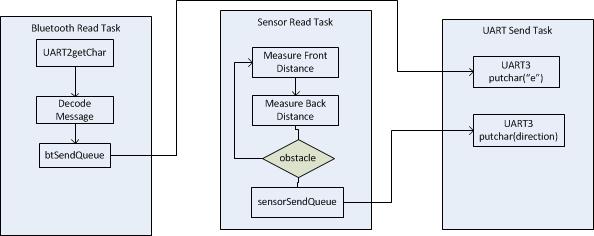

| + | <div style="text-align:center">Figure 11. SJOne Board with Bluetooth and Ultrasonic Sensor Software Design<div style="text-align:left"> | ||

| + | <br> | ||

| + | <br>The responsibility of one of the two boards used was to provide the direction to the motor control. This board incorporates the bluetooth module and the ultrasonic sensor together. The robot can be manually controlled using an app from an android device. The provided direction is transmitted to the SJOne board through bluetooth communication via the bluetooth module. The robot was also designed with collision avoidance. This is where the ultrasonic sensors were used. When an obstacle is detected by the sensors, it overrides whichever direction is given by the user and tells the robot to stop. | ||

| + | |||

| + | <br>Three tasks were created for this portion of the software design as shown in Fig. 11. The bluetooth task reads two characters from the UART. Those two characters are decoded to find the direction. The app that was used to control the robot provides five controls: forward, reverse, left, right, and stop. Those exact words are transmitted through the UART for the specified direction. Due to the varying message lengths, only two characters are read at a time. Once the direction is decoded, the rest of the message is read. The direction is then indicated using one character such that 'a' is forward, 'b' is reverse, 'c' is left, 'd' is right, and 'e' is stop. The one character direction is sent to the UART_send_task using a shared queue. | ||

| + | |||

| + | The sensor read task reads the distance of the front and back sensors. If any of the two sensors shows an obstacle or an object within 10 cm of the robot, an integer is sent to the UART_send_task using a shared queue. Otherwise, the sensor read task does not do anything and loops back. | ||

| + | |||

| + | The purpose of the UART_send_task is to send the direction to the other board using UART interface. The data it chooses to send is indicated by the shared queues from the other two tasks. If the shared queue with the sensor is not empty, this task sends a the character 'e' (stop). Else, if the shared queue with the bluetooth task is not empty, then it sends the direction. Otherwise, the task does not do anything. | ||

| + | |||

| + | <br> | ||

| + | [[File:S15_146_G8_android_app.png|center]] | ||

<br> | <br> | ||

| + | <div style="text-align:center">Figure 12.Remote Controller Android App<div style="text-align:left"> | ||

<br> | <br> | ||

| + | <br> The android app features four directional control and a stop button in the middle. When the bluetooth button is pressed, it scans for nearby devices it can pair to. This app was taken from http://www.instructables.com/id/How-to-make-a-voice-control-direction-control-remo/. | ||

=== Implementation === | === Implementation === | ||

| − | + | ||

| + | === PID controller driver === | ||

| + | Take target angle | ||

| + | <br>Take input angle | ||

| + | <br>Take constant parameters | ||

| + | <br>Take rate of change | ||

| + | <br>Calculate output based on the above inputs | ||

| + | <br>Return output value to the caller | ||

| + | |||

| + | === MotorControl driver === | ||

| + | Initialize output pins (PWM and I/O pins) | ||

| + | <br>read output of PID controller | ||

| + | <br>set direction (forward or backward) | ||

| + | <br>limit acceleration | ||

| + | <br>calculate speed | ||

| + | <br>convert speed data to step frequency | ||

| + | <br>Use the new step frequency to drive the motors | ||

| + | |||

| + | === Accelerometer and Gyroscope driver === | ||

| + | Initialize module | ||

| + | <br>set offsets | ||

| + | <br>set initial setpoint (should be close to zero degrees) | ||

| + | <br>read data | ||

| + | <br>call Kalman filter function to get accurate angle measurement | ||

| + | <br>output the filtered angle | ||

| + | |||

| + | |||

| + | === Bluetooth Module driver === | ||

| + | <br> | ||

| + | [[File:S15_146_G8_bt_logic_diagram.jpeg|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center">Figure 13. Ultrasonic Sensor Module Logic Diagram<div style="text-align:left"> | ||

| + | |||

| + | <br>Initialize UART to 38400 baud rate | ||

| + | <br>Delay 1000ms | ||

| + | <br> send "\r\n+STWMOD=0\r\n" | ||

| + | <br> send "\r\n+STNA=CMPE146\r\n" | ||

| + | <br> send "\r\n +STPIN=0000\r\n"); | ||

| + | <br> delay 2000ms | ||

| + | <br> send "\r\n+INQ=1\r\n" | ||

| + | <br> delay 2000ms | ||

| + | |||

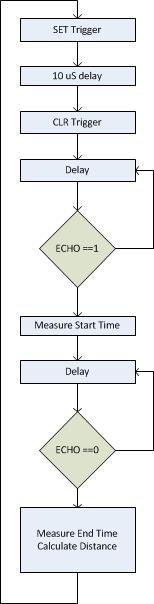

| + | === Ultrasonic Sensor Module driver === | ||

| + | <br> | ||

| + | [[File:S15_146_G8_sensor_logic_diagram.jpeg|center]] | ||

| + | <br> | ||

| + | <div style="text-align:center">Figure 13. Ultrasonic Sensor Module Logic Diagram<div style="text-align:left"> | ||

| + | |||

| + | <br>Trig output = 1 | ||

| + | <br>Delay 10us | ||

| + | <br>Trig output = 0 | ||

| + | <br>Wait for Echo to go to high | ||

| + | <br>Save system time in us as start time | ||

| + | <br>Wait for Echo to go to low | ||

| + | <br>Save system time in us as end time | ||

| + | <br> Calculate distance = (end time - start time)/58.82 (58.82 is specific to calculating distance in cm) | ||

== Testing & Technical Challenges == | == Testing & Technical Challenges == | ||

| − | |||

| − | |||

<br> | <br> | ||

| − | + | The testing of the balancing mostly relied on the PID controller. This of course assumed that the accelerometer+gyroscope sensor provides accurate angle readings. | |

| − | The testing of the balancing | ||

The PID controller has three constant parameters, which are needed to be tuned perfectly to be able to balance the robot. | The PID controller has three constant parameters, which are needed to be tuned perfectly to be able to balance the robot. | ||

<br> | <br> | ||

| Line 214: | Line 316: | ||

<br> | <br> | ||

<br> | <br> | ||

| + | The bluetooth module was tested using various apps that was available online. The group later realized that trying to develop an app was too time consuming especially since both members have no experience with android app development. The test consists of simply sending and receiving messages from both the SJOne board and an android phone. | ||

| + | <br> | ||

| + | <br> | ||

| + | The issue with testing was harder when it comes to the ultrasonic sensors compared to the bluetooth module. Setting up the module was not difficult but the robot itself was delicate. There were times when the sensors were properly working and accurately gave the distance to an object (measured using a ruler) but there are also times when the sensors are not working. An example of this is that the sensors does not respond to a trigger signal and remain low. It was hypothesized that it could have been shorted. | ||

=== My Issue #1 === | === My Issue #1 === | ||

Stepper Motors. Stepper motors have high torque and can be controlled precisely (e.g. 1/4 revolution, 350 steps, etc) but writing own drivers for the stepping frequency | Stepper Motors. Stepper motors have high torque and can be controlled precisely (e.g. 1/4 revolution, 350 steps, etc) but writing own drivers for the stepping frequency | ||

| Line 224: | Line 330: | ||

=== My Issue #3 === | === My Issue #3 === | ||

PID controller: Besides how people view this as a very simple control algorithm, it is very hard to implement. The reader should research ahead of time about the PID controller. | PID controller: Besides how people view this as a very simple control algorithm, it is very hard to implement. The reader should research ahead of time about the PID controller. | ||

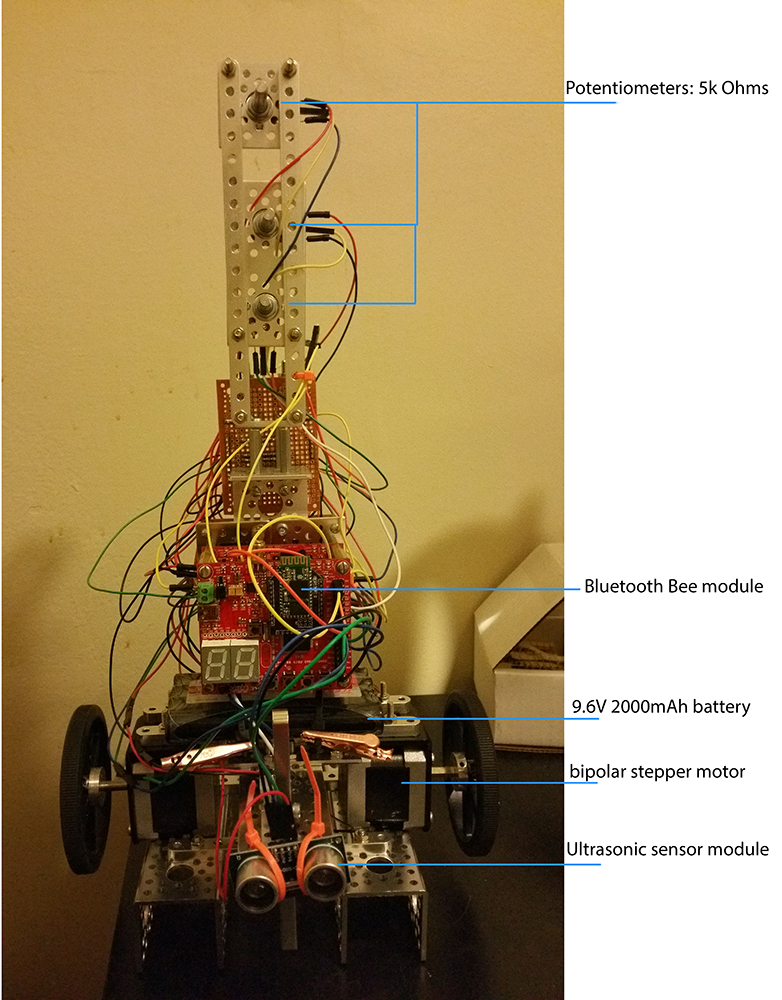

| − | <br>PID controller constants: These three constants are needed to be tuned perfectly, thus the group suggests that these three parameters should be modifiable in real time. The group realized this too late that's why a lot of time was wasted just by changing the constants. Three 5k Ohms potentiometer connected to ADC | + | <br>PID controller constants: These three constants are needed to be tuned perfectly, thus the group suggests that these three parameters should be modifiable in real time. The group realized this too late that's why a lot of time was wasted just by changing the constants. Three 5k Ohms potentiometer connected to ADC pins was the perfect solution to this problem. |

=== My Issue #4 === | === My Issue #4 === | ||

Tuning: since this is the hardest part of the project, a lot of time should be devoted in tuning the controller. The group spent a total of 4 weeks just tuning the PID and still failed to make the robot balance. This problem is a combination of the PID controller implementation and the motor driver implementation. These two should be implemented properly in order to make the tuning possible. | Tuning: since this is the hardest part of the project, a lot of time should be devoted in tuning the controller. The group spent a total of 4 weeks just tuning the PID and still failed to make the robot balance. This problem is a combination of the PID controller implementation and the motor driver implementation. These two should be implemented properly in order to make the tuning possible. | ||

| + | |||

| + | === My Issue #5 === | ||

| + | Bluetooth task receive and send delay: The software for the bluetooth task was designed to read from the UART interface with the bluetooth module, decode the message, and output the appropriate direction to the UART interface with the other SJOne board. There were times when the controller sends a signal to the bluetooth module, it took a while for the message to be sent through the Tx pin of UART2(interface to other board) after it was received from the Rx pin of UART3(interface with bluetooth module). There were also times when the message was receive from the Rx of UART3 but it was not sent out to the other board. The group hypothesized that the issue came with the task delay. If the user sends the direction using the phone when the task is asleep, the message is ignored. The group tried to reorganize the code such that there is a separate task for sending the direction to the other board but the result was still the same. Another solution the group thought of but didn't have time to implement was to design their own android controller app. The android app used for the project only sends the message once when the button on the screen is pressed. If the app was designed to continuously send the control message to the bluetooth module then the group hypothesized that the issue would have been resolved. As mentioned before, trying to develop an app was too consuming for the group considering nobody had experience doing so and each member's schedule. | ||

| + | |||

| + | === My Issue #6 === | ||

| + | Ultrasonic Sensor: The group faced a hardware issue when trying to interface the two boards. This issue deals with the ultrasonic sensors. The development of the two boards was done separately. When the ultrasonic sensors were mounted onto the robot, the ultrasonic sensors became unstable. Sometimes it works properly such that the balancing boards receives a stop signal and the motors stop when either or both sensors are blocked. At other random times, the sensors does not respond to the trigger signal and the echo pin remains low. The sensors were probably shorted at some area in the robot. The issue was not resolved and the sensors were not used because it was too unstable. | ||

== Conclusion == | == Conclusion == | ||

| − | + | Even though a PID controller is popular because of its simplicity, the implementation of it is not so simple. The three constants that are used need to be tuned perfectly in able to obtain the desired output. The problem with this is that a lot of time is needed to tune these parameters perfectly. The lack of experience about PID controllers and the necessary preparation needed (e.g. interface sensor module, writing motor drivers, etc.) made this project incredibly difficult for the group. | |

| + | |||

| + | This project pushed the group to their limits. Although the group failed to make the robot balance, the group learned a lot regarding the behavior of unstable systems and what are the possible solutions to stabilize them. The group also learned a lot about the PID algorithm and its implementation. The group believes that given more time, a successful PID controller implementation is possible. | ||

| + | |||

=== Project Video === | === Project Video === | ||

| Line 244: | Line 359: | ||

=== References Used === | === References Used === | ||

List any references used in project. | List any references used in project. | ||

| + | |||

| + | <br>http://www.geekmomprojects.com/gyroscopes-and-accelerometers-on-a-chip/ | ||

| + | <br>https://solenerotech1.wordpress.com/2013/10/10/how-to-combine-data-from-gyro-and-accel/ | ||

| + | <br>http://www.instructables.com/id/Self-Balancing-Robot/ | ||

| + | <br>http://hyperphysics.phy-astr.gsu.edu/hbase/rotq.html | ||

| + | <br>http://jjrobots.com/b-robot/ | ||

| + | <br>http://letsmakerobots.com/node/38610 | ||

| + | <br>http://home.iitk.ac.in/~vipgupta/self-balancing-bot | ||

| + | <br>http://ww1.microchip.com/downloads/en/AppNotes/00964A.pdf | ||

=== Appendix === | === Appendix === | ||

You can list the references you used. | You can list the references you used. | ||

Latest revision as of 02:43, 27 May 2015

Contents

Project Title

Two Wheel Self-Balancing Robot

Abstract

The project is to build a two wheeled self-balancing robot. The robot is similar to a Segway machine but it uses sensors to alert the user when its path is blocked. The robot is also manually controlled using an Android phone via Bluetooth.

Objectives & Introduction

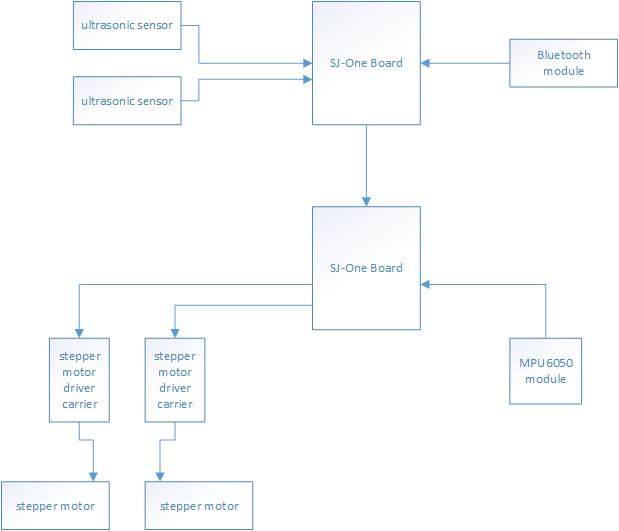

The purpose of this project is to design a two wheeled self-balancing robot. There are two parts to the system: motor controller and geographic controller. Each control system is implemented into different boards.

The motor control board is responsible for calibrating each motor to perform self-balancing and directional movements. In order for the robot to perform self-balancing, the motor control must implement a self-balancing algorithm which uses the input of an accelerometer and gyroscope module. The geographic control board provides directional movement the robot must execute such as turn left, go forward, stop, etc. The direction is mostly indicated by the user using an android phone via Bluetooth communication. The sensors are used to override user control for obstacle avoidance.

Team Members & Responsibilities

- Marvin Flores

- Stepper motor driver

- Accelerometer and gyroscope module driver

- Robot chassis

- Self balancing algorithm implementation

- Almon Otanes

- Bluetooth Communication

- Android App Development

- Sensor Interface

Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 4/3 | Build the Chassis of the robot | Completed: Yes. Problems Encountered: The battery is too heavy. The chassis needed to be reassembled a second time to fix the weight distribution problem. |

| 2 | 4/10 | Interface stepper motor driver carrier. | Completed:Yes Problems Encountered: We could not use the existing PWM driver, so we had to write our own to interface the stepper motor driver carrier |

| 3 | 4/17 | Bluetooth Communication Sensor Interface |

Completed: Yes |

| 4 | 4/24 | Interface Accelerometer and Gyroscope module. Android controller app |

Completed:Yes Problems Encountered: Had issue regarding I2C slave addressing. |

| 5 | 5/1 | Implement algorithm for self balancing Implement communications between two SJ-One boards Optimize drivers. |

Completed: Yes Problems Encountered: PID tuning. |

| 5 | 5/8 | Optimize algorithm implementation. Optimize drivers. |

Completed: No Problems Encountered: PID tuning. |

| 6 | 5/15 | Test. | Completed: No Problems Encountered: PID tuning. |

Parts List & Cost

| Quantity | Desctiption | Price |

|---|---|---|

| 2 | SJ-One development board | $80 ea |

| 2 | Stepper motor | $16.95 ea |

| 2 | Stepper motor driver carrier | $10.45 ea |

| 1 | MPU6050 Accelerometer + Gyroscope module | $4.47 |

| 1 | 9.2V battery pack | $16~ |

| 1 | Robot Chassis (standoffs, aluminum plates, screws, etc.) | $80~ |

| 1 | Bluetooth module | $27~ |

| 2 | Ultrasonic sensor module | $2~ ea |

| _______ | ||

| Estimated total | $350 |

Design & Implementation

Hardware Design

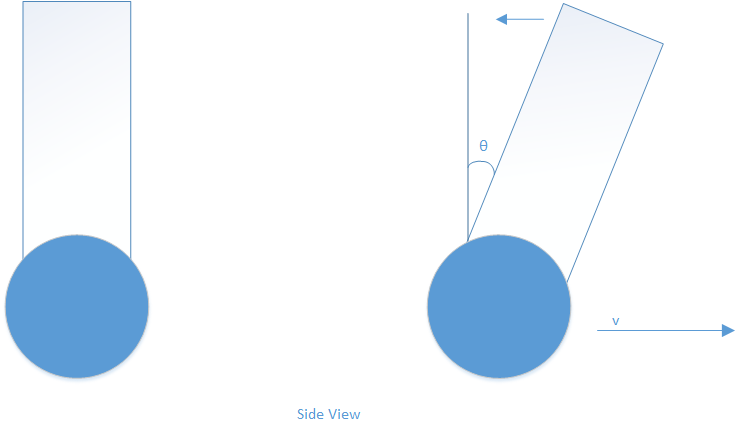

A self-balancing robot is an inverted-pendulum example problem. The idea is to keep the robot upright by driving the wheels towards the leaning angle theta.

I.e. when the robot is tilting forward, the wheels should be driven forward with a specific acceleration to counter the tilting. This will keep the robot in an upright position at all times.

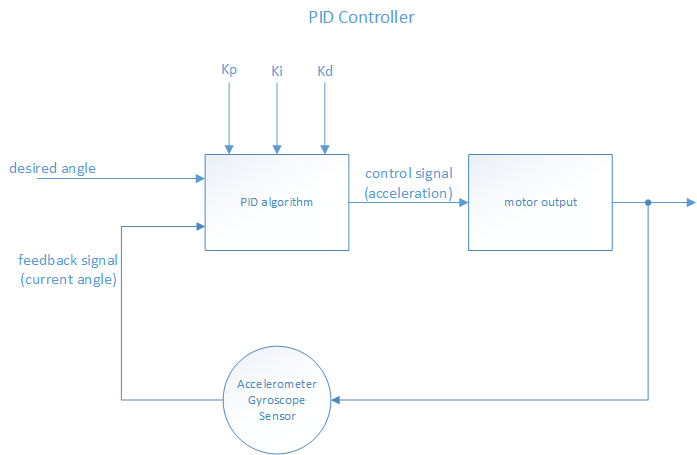

The problem with this is that it is a very unstable system and a control algorithm must be used to stabilize it. For this project, the group decided to use a PID algorithm because of its simplicity

compared to other control algorithms. It is also readily available which is a plus considering the time we have to finish this project.

The PID controller is both software and hardware implementation. The angle reading from the MPU6050 module and the desired angle are fed to the PID algorithm — which calculates the error and outputs a control signal. The control signal is fed to the motorController which is responsible for driving the stepper motors.

The PID algorithm relies heavily on the three constant parameters: Kp Ki Kd, where Kp is the proportional constant, Ki is the integral constant, and Kd is the derivative constant.

The constants are multiplied with their respective terms P, I, and D terms.

The P term is responsible for calculating the proportional error or present error.

The I term is responsible for calculating the accumulation of the past errors.

The D term is responsible for calculating the prediction of future errors based on DT (rate of change).

By summing up these three terms, the PID controller is able to output a control signal that drives the system towards the target output (desired angle).

Hardware Interface

MPU6050

3-axis accelerometer, 3-axis gyroscope MODULE

The group used this module because the 3-axis accelerometer alone can't handle the complexity of the self-balancing robot. This module outputs raw data which need to be filtered in order to obtain the correct angle measurement

The group used Kalman filter to obtain the angle measurement. The source code for Kalman filter was obtained online to save time implementing it. The code can be found here: https://github.com/TKJElectronics/KalmanFilter/blob/master/examples/MPU6050/MPU6050.ino

This module uses I2C protocol for communication. The group needed to write their own driver for the MPU6050 in able to interface the module to the SJ-ONE board.

Only 4 pins are used in this module: Vcc, Gnd, SCL, SDA where SCL is the clock signal and SDA is the data signal.

This module was used to control one bipolar stepper motor, so a total of two drv8825 driver carriers were used for this project.

This driver carrier simplifies the method of controlling the stepper motors — it only needs a step frequency and a direction signal to control a single bipolar stepper motor

The group wrote their own driver to produce a step frequency and direction signal. This implementation took a while to finish because the group needed to understand how the PWM Motor Control is implemented on LPC1758 mcu

This interface uses two PWM pins for step frequencies, and two regular I/O pins for direction signal.

This module was used to create a communication between an android phone (via an app) and the robot. The WLS04051P bluetooth module contains an ATMEGA 168 which is used from reprogramming the module. It is also compatible to the XBee socket of the SJOne Board. The XBee Socket can be set up to use either UART2 or UART3 using an on board switch located in the socket. The Tx and Rx goes through which UART port is set. The module also have an command set with it. The command set is used for initializing the module settings. The commands are used by sending them through the UART port. The module contains two LEDs (blue and red) which indicates its status. The LEDs alternate between red and blue when it is inquiring for devices. Once it is paired with a device, the blue LED will start flashing once per two seconds.

This module was used for the collision avoidance function of the robot. An ultrasonic sensor was placed at the front and back of the robot. When it detects an object about 10cm from it, the direction is overridden and the robot is stopped. The module requires Vcc, GND, and two GPIO pins. The GPIO pins are used for Trig and Echo pins of the module. The Trig pin is an input to the module which serves as a request from the CPU. The Echo pin turns high after some time with the Trig pin is setup. It will remain high until the signal from the module bounces back from an object infront of it.

Software Design

The group tried to make the software design as simple as possible. There are two Signal tasks that activates their respective 'worker' tasks. The worker tasks only activates when they receive a semaphore signal.

The moveControlSignal task is responsible for sending a signal every 100ms to the uartControl task — which reads the uart data register. The uartControl task then sends the read data to the AccGyroControl task.

The AccGyroSignal task is responsible for sending a signal every 10ms to the AccGyroControl task.

The AccGyroControl task is responsible for the sensor reading and computation of the PID controller. This task is also responsible for sending the output of the PID controller to motorControl task.

The motorControl task is responsible for driving the motors.

The responsibility of one of the two boards used was to provide the direction to the motor control. This board incorporates the bluetooth module and the ultrasonic sensor together. The robot can be manually controlled using an app from an android device. The provided direction is transmitted to the SJOne board through bluetooth communication via the bluetooth module. The robot was also designed with collision avoidance. This is where the ultrasonic sensors were used. When an obstacle is detected by the sensors, it overrides whichever direction is given by the user and tells the robot to stop.

Three tasks were created for this portion of the software design as shown in Fig. 11. The bluetooth task reads two characters from the UART. Those two characters are decoded to find the direction. The app that was used to control the robot provides five controls: forward, reverse, left, right, and stop. Those exact words are transmitted through the UART for the specified direction. Due to the varying message lengths, only two characters are read at a time. Once the direction is decoded, the rest of the message is read. The direction is then indicated using one character such that 'a' is forward, 'b' is reverse, 'c' is left, 'd' is right, and 'e' is stop. The one character direction is sent to the UART_send_task using a shared queue.

The sensor read task reads the distance of the front and back sensors. If any of the two sensors shows an obstacle or an object within 10 cm of the robot, an integer is sent to the UART_send_task using a shared queue. Otherwise, the sensor read task does not do anything and loops back.

The purpose of the UART_send_task is to send the direction to the other board using UART interface. The data it chooses to send is indicated by the shared queues from the other two tasks. If the shared queue with the sensor is not empty, this task sends a the character 'e' (stop). Else, if the shared queue with the bluetooth task is not empty, then it sends the direction. Otherwise, the task does not do anything.

The android app features four directional control and a stop button in the middle. When the bluetooth button is pressed, it scans for nearby devices it can pair to. This app was taken from http://www.instructables.com/id/How-to-make-a-voice-control-direction-control-remo/.

Implementation

PID controller driver

Take target angle

Take input angle

Take constant parameters

Take rate of change

Calculate output based on the above inputs

Return output value to the caller

MotorControl driver

Initialize output pins (PWM and I/O pins)

read output of PID controller

set direction (forward or backward)

limit acceleration

calculate speed

convert speed data to step frequency

Use the new step frequency to drive the motors

Accelerometer and Gyroscope driver

Initialize module

set offsets

set initial setpoint (should be close to zero degrees)

read data

call Kalman filter function to get accurate angle measurement

output the filtered angle

Bluetooth Module driver

Initialize UART to 38400 baud rate

Delay 1000ms

send "\r\n+STWMOD=0\r\n"

send "\r\n+STNA=CMPE146\r\n"

send "\r\n +STPIN=0000\r\n");

delay 2000ms

send "\r\n+INQ=1\r\n"

delay 2000ms

Ultrasonic Sensor Module driver

Trig output = 1

Delay 10us

Trig output = 0

Wait for Echo to go to high

Save system time in us as start time

Wait for Echo to go to low

Save system time in us as end time

Calculate distance = (end time - start time)/58.82 (58.82 is specific to calculating distance in cm)

Testing & Technical Challenges

The testing of the balancing mostly relied on the PID controller. This of course assumed that the accelerometer+gyroscope sensor provides accurate angle readings.

The PID controller has three constant parameters, which are needed to be tuned perfectly to be able to balance the robot.

The testing of this project was the hardest part of all. Since the system is an unstable system and a PID controller was used to stabilize it, the success

of the project depends on how well the PID controller is implemented. Unfortunately, the group failed to make the robot to balance because of lack of background

regarding PID controllers. The PID controller is very popular because of its simplicity but its implementation is tougher than it looks. The issues below will

surely help future students that want to build their own self-balancing robot.

The bluetooth module was tested using various apps that was available online. The group later realized that trying to develop an app was too time consuming especially since both members have no experience with android app development. The test consists of simply sending and receiving messages from both the SJOne board and an android phone.

The issue with testing was harder when it comes to the ultrasonic sensors compared to the bluetooth module. Setting up the module was not difficult but the robot itself was delicate. There were times when the sensors were properly working and accurately gave the distance to an object (measured using a ruler) but there are also times when the sensors are not working. An example of this is that the sensors does not respond to a trigger signal and remain low. It was hypothesized that it could have been shorted.

My Issue #1

Stepper Motors. Stepper motors have high torque and can be controlled precisely (e.g. 1/4 revolution, 350 steps, etc) but writing own drivers for the stepping frequency is time consuming. The reader should avoid using stepper motors unless the reader has access to drivers or the reader has experience using stepper motors.

My Issue #2

Accelerometer + Gyroscope: Even though MPU6050 has a lot of examples online, most of them are written in Arduino. This means that the codes available online are not readily transferable to the SJ-One board. A thorough understanding of the module is needed to be able to implement it correctly. This module also has undocumented functionalities that can't be access easily; moreover, these hidden functionalities are only available in Arduino. This means that to implement it to the SJ-One board, one needs to convert an Arduino code into C code which will surely take a lot of time.

The group suggests that the reader should carefully choose a sensor module.

My Issue #3

PID controller: Besides how people view this as a very simple control algorithm, it is very hard to implement. The reader should research ahead of time about the PID controller.

PID controller constants: These three constants are needed to be tuned perfectly, thus the group suggests that these three parameters should be modifiable in real time. The group realized this too late that's why a lot of time was wasted just by changing the constants. Three 5k Ohms potentiometer connected to ADC pins was the perfect solution to this problem.

My Issue #4

Tuning: since this is the hardest part of the project, a lot of time should be devoted in tuning the controller. The group spent a total of 4 weeks just tuning the PID and still failed to make the robot balance. This problem is a combination of the PID controller implementation and the motor driver implementation. These two should be implemented properly in order to make the tuning possible.

My Issue #5

Bluetooth task receive and send delay: The software for the bluetooth task was designed to read from the UART interface with the bluetooth module, decode the message, and output the appropriate direction to the UART interface with the other SJOne board. There were times when the controller sends a signal to the bluetooth module, it took a while for the message to be sent through the Tx pin of UART2(interface to other board) after it was received from the Rx pin of UART3(interface with bluetooth module). There were also times when the message was receive from the Rx of UART3 but it was not sent out to the other board. The group hypothesized that the issue came with the task delay. If the user sends the direction using the phone when the task is asleep, the message is ignored. The group tried to reorganize the code such that there is a separate task for sending the direction to the other board but the result was still the same. Another solution the group thought of but didn't have time to implement was to design their own android controller app. The android app used for the project only sends the message once when the button on the screen is pressed. If the app was designed to continuously send the control message to the bluetooth module then the group hypothesized that the issue would have been resolved. As mentioned before, trying to develop an app was too consuming for the group considering nobody had experience doing so and each member's schedule.

My Issue #6

Ultrasonic Sensor: The group faced a hardware issue when trying to interface the two boards. This issue deals with the ultrasonic sensors. The development of the two boards was done separately. When the ultrasonic sensors were mounted onto the robot, the ultrasonic sensors became unstable. Sometimes it works properly such that the balancing boards receives a stop signal and the motors stop when either or both sensors are blocked. At other random times, the sensors does not respond to the trigger signal and the echo pin remains low. The sensors were probably shorted at some area in the robot. The issue was not resolved and the sensors were not used because it was too unstable.

Conclusion

Even though a PID controller is popular because of its simplicity, the implementation of it is not so simple. The three constants that are used need to be tuned perfectly in able to obtain the desired output. The problem with this is that a lot of time is needed to tune these parameters perfectly. The lack of experience about PID controllers and the necessary preparation needed (e.g. interface sensor module, writing motor drivers, etc.) made this project incredibly difficult for the group.

This project pushed the group to their limits. Although the group failed to make the robot balance, the group learned a lot regarding the behavior of unstable systems and what are the possible solutions to stabilize them. The group also learned a lot about the PID algorithm and its implementation. The group believes that given more time, a successful PID controller implementation is possible.

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

http://www.geekmomprojects.com/gyroscopes-and-accelerometers-on-a-chip/

https://solenerotech1.wordpress.com/2013/10/10/how-to-combine-data-from-gyro-and-accel/

http://www.instructables.com/id/Self-Balancing-Robot/

http://hyperphysics.phy-astr.gsu.edu/hbase/rotq.html

http://jjrobots.com/b-robot/

http://letsmakerobots.com/node/38610

http://home.iitk.ac.in/~vipgupta/self-balancing-bot

http://ww1.microchip.com/downloads/en/AppNotes/00964A.pdf