Abstract

The aim of the project is to develop hand gesture recognition system using grid of IR proximity sensors. Various hand gestures like swipe, pan etc. can be recognized. These gestures can be used to control different devices or can be used in various applications. The system will recognize different hand gestures based on the values received from IR proximity sensors. We have used Qt to develop the application to demonstrate the working of the project.

Objectives & Introduction

We use various hand gestures in our day-to-day life to communicate while trying to explain someone something, direct them somewhere etc. It would be so cool if we could communicate with various applications running on the computers or different devices around us understand the hand gestures and give the expected output.

In order to achieve this, we are using a 3-by-3 grid of analog IR proximity sensors and connecting these sensors via multiplexers to the ADC pins on SJOne Board. As a hand is moved in front of the sensors, the sensor values would in a particular pattern enabling us to detect the gesture and instruct the application to perform the corresponding action.

Team Members & Responsibilities

- Harita Parekh

- Implementing algorithm for gesture recognition

- Implementation of sensor data filters

- Shruti Rao

- Implementing algorithm for gesture recognition

- Interfacing of sensors, multiplexers and controller

- Sushant Potdar

- Implementation of final sensor grid

- Development of the application module

Schedule

| Week#

|

Start Date

|

End Date

|

Task

|

Status

|

Actual Completion Date

|

| 1

|

3/22/2015

|

3/28/2015

|

Research on the sensors, order sensors and multiplexers

|

Completed

|

3/28/2015

|

| 2

|

3/29/2015

|

4/4/2015

|

Read the data sheet for sensors and understand its working. Test multiplexers

|

Completed

|

4/04/2015

|

| 3

|

4/05/2015

|

4/11/2015

|

Interfacing of sensors, multiplexers and controller

|

Completed

|

4/15/2015

|

| 4

|

4/12/2015

|

4/18/2015

|

- Implementation of sensor data filters

- Implement algorithm to recognize left-to-right movement

|

Completed

|

4/25/2015

|

| 5

|

4/19/2015

|

4/25/2015

|

- Implementation of final sensor grid

- Implement algorithm to recognize up-to-down movement

- Implement algorithm to recognize right-to-left movement

|

Completed

|

5/02/2015

|

| 6

|

4/26/2015

|

5/02/2015

|

- Implement algorithm to recognize down-to-up movement

- Develop the Qt application

|

Completed

|

5/09/2015

|

| 7

|

5/03/2015

|

5/09/2015

|

Testing and bug fixes

|

Completed

|

5/15/2015

|

| 8

|

5/10/2015

|

5/16/2015

|

Testing and final touches

|

Completed

|

5/22/2015

|

| 9

|

5/21/2015

|

5/24/2015

|

Report Completion

|

Completed

|

5/24/2015

|

| 10

|

5/25/2015

|

5/25/2015

|

Final demo

|

Scheduled

|

5/25/2015

|

Parts List & Cost

| SR#

|

Component Name

|

Quantity

|

Price per component

|

Total Price

|

| 1

|

Sharp Distance Measuring Sensor Unit (GP2Y0A21YK0F)

|

9

|

$14.95

|

$134.55

|

| 2

|

STMicroelectronics Dual 4-Channel Analog Multiplexer/Demultiplexer (M74HC4052)

|

3

|

$0.56

|

$1.68

|

| 3

|

SJ-One Board

|

1

|

$80

|

$80

|

| 4

|

USB-to-UART converter

|

1

|

$7

|

$7

|

| Total (excluding shipping and taxes)

|

$223.23

|

Design & Implementation

Hardware Design

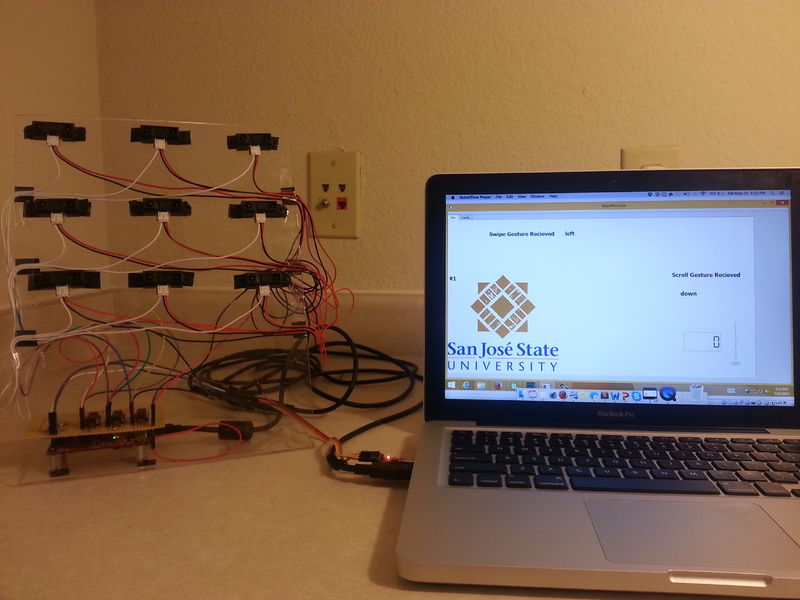

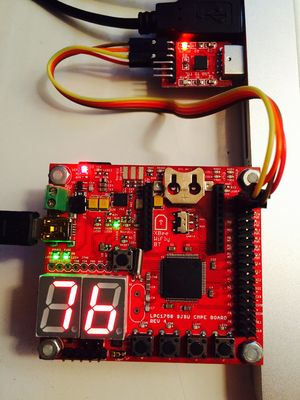

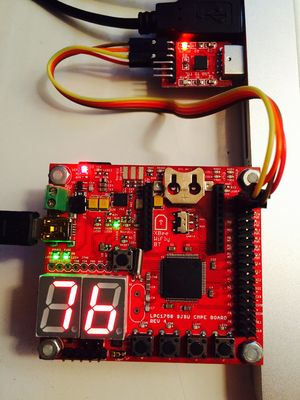

The image shows the setup of the project.

Figure : Setup of the project

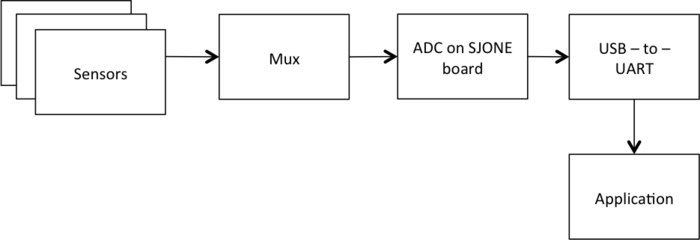

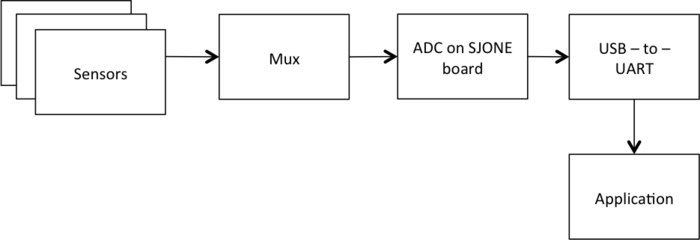

System Block Diagram:

|

Figure : System Block Diagram

|

The system consists of 9 IR proximity sensors, which are arranged in 3x3 grid. The output of the sensors is given to the Analog-to-Digital convertor on the SJOne Board to get the digital equivalent of the voltage given by the sensors. Since there are only 3 ADC channels exposed on the pins on the board, we cannot connect all the sensors directly to the board. For these we have used three multiplexers, which has 3 sensors each connected to its input. The output of the multiplexers is connected to ADC. SJOne board is connected to the laptop via UART-to-USB connection.

|

Proximity Sensor:

This sensor by Sharp measures the distance from an obstacle by bouncing IR rays off the obstacle. This sensor can measure distances from 10 to 80 cms. The sensor returns an analog voltage corresponding to the distance from the obstacle. Depending on which sensor returns valid values, validations could be made and hand movement can be determined. The voltage returned by the sensor increases as the obstacle approaches the sensor. There is no external circuitry required for this sensor. The operating voltage recommended for this sensor is 4.5V to 5.5V.

|

Figure : IR Proximity Sensor

|

|

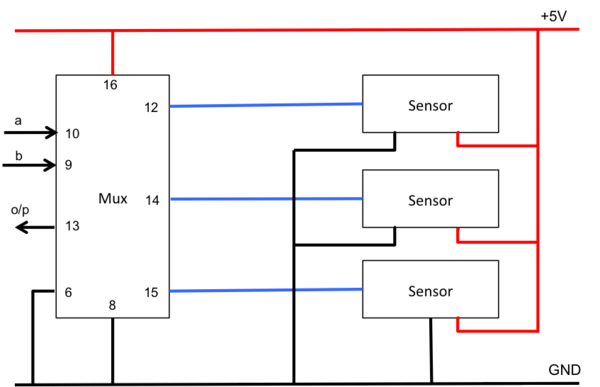

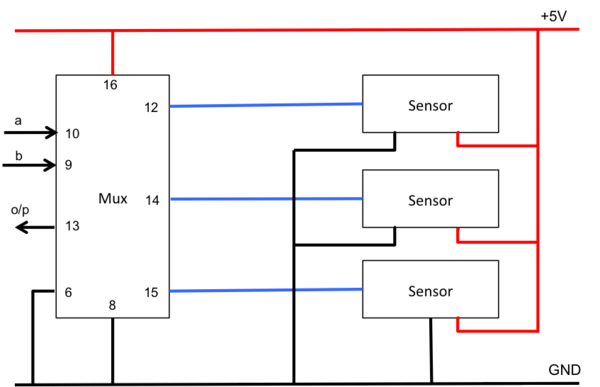

Multiplexer:

The chip used in the project is M74HC4052 from STMicroelectronics. This is a dual 4-channel multiplexer/demultiplexer. Due to shortage of ADC pins to interface with the sensors, use of multiplexer is required. The multiplexer takes input from three sensors and enables only one of them at the output. The program logic decides which sensor’s output should be enabled at the multiplexer’s output. A and B control signals select one of the channel out of the four. The operating voltage for the multiplexer is 2 to 6V.

|

Figure : 4-Channel Dual Multiplexer

|

|

USB-to-UART converter:

To communicate to SJONE board over UART there is a need an USB to serial converter and a MAX232 circuit to convert the voltage levels to TTL, which the SJONE board understands. Instead it’s better to use a USB-to-UART converter to avoid the multiple conversions. This is done using CP2102 IC, which is similar to a FTDI chip.

|

Figure : USB-to-UART chip

|

Hardware Interface

|

Pin connections for IR Sensor to Multiplexer:

Figure : Pin connections for IR Sensor to Multiplexer

|

|

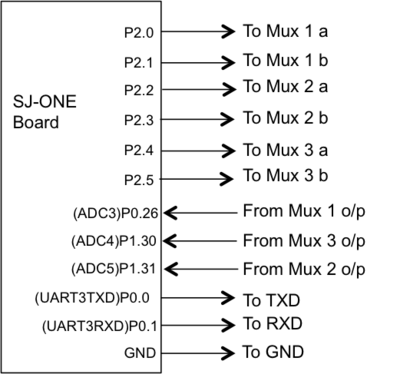

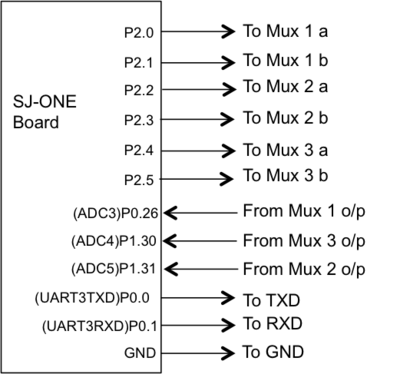

Pin connections on SJOne board:

Figure : Pin connections on SJOne board

|

Connections between SJOne board and USB-to-UART Converter:

Figure : Connections between SJOne board and USB-to-UART Converter

|

Software Design

|

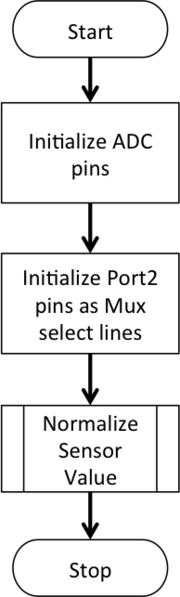

Initialization

SJOne board has 3 ADC pins exposed on Port 0 (0.26) and Port 1 (1.30 and 1.31). To use these pins as ADC, the function should be selected in PINSEL.

The GPIO pins on Port 2 are connected to the select pins on multiplexer. These pins should be initialized as output pins.

Once, initialization is completed, the function for normalizing the sensor values is called.

|

Figure : Flowchart for initialization of ADC and multiplexer

|

|

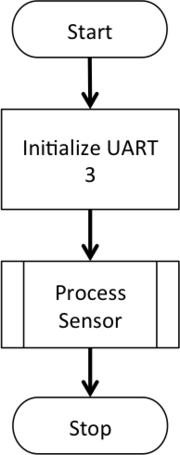

SJOne board uses UART 3 to communicate with the QT application. UART 3 is initialized to baud rate of 9600 with receiver buffer as 0 and transmission buffer as 32 bytes. Once initialization is completed, the function for processing sensor values is called.

|

Figure : Flowchart for initialization of UART and process

|

|

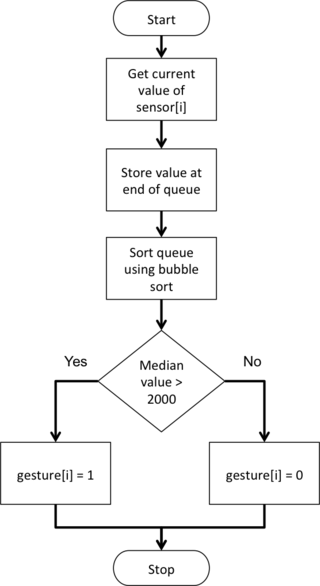

Filter Algorithm

The current value of sensor is fetched by setting the corresponding values on the multiplexer select pins and reading the output of the ADC. A queue of size 5 is maintained and the fetched value is inserted at the tail of the queue. This queue is sorted using bubble sort. The median value of the queue is checked to be greater than 2000 (sensor returns a voltage corresponding to a value greater than 2000 when the hand is near enough to it) and gesture array for that sensor is set accordingly.

|

Figure : Flowchart for filter algorithm

|

|

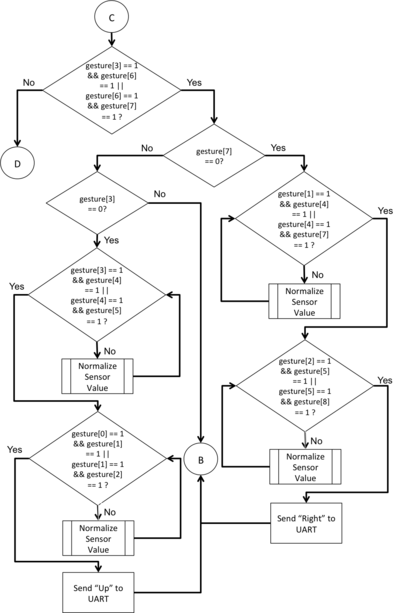

Gesture Recognition Algorithm

Different sets of sensors are monitored in order to recognize a valid pattern in the sensor output and thereby recognize the gesture pattern.

(We have assumed that the sensors are numbered 0 through 8 and the corresponding value for the sensor is set by the filter algorithm in gesture[] array).

|

|

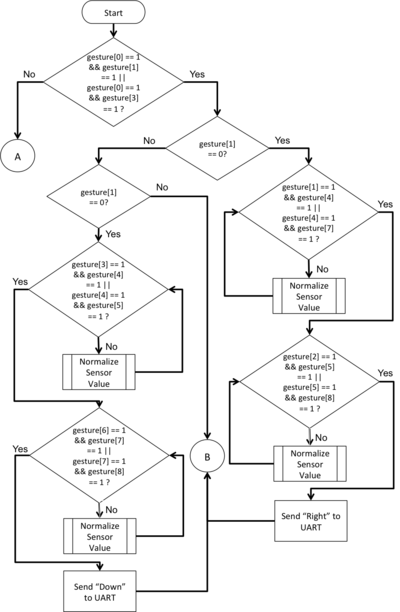

Pattern 1:

Figure : Flowchart for selection of pattern 1

|

Here the three sensors present at the top left corner are monitored.

- If sensor1 value is zero

- Check the values of sensors in the second column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the third column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Right” to UART 3.

|

|

- If sensor3 value is zero

- Check the values of sensors in the second row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the third row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Down ” to UART 3.

|

|

|

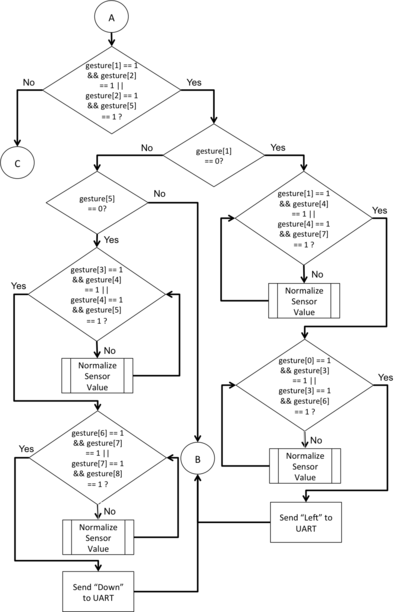

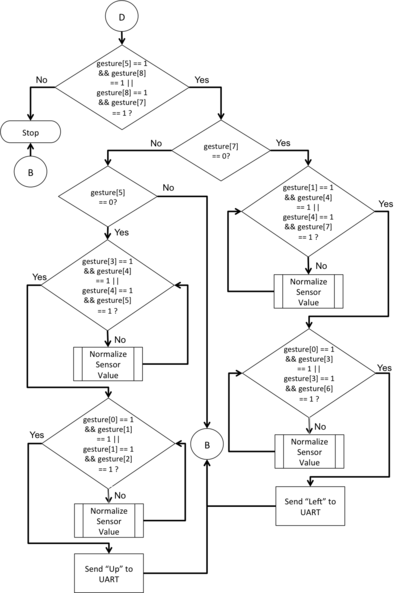

Pattern 2:

Figure : Flowchart for selection of pattern 2

|

Here the three sensors present at the top right corner are monitored.

- If sensor1 value is zero

- Check the values of sensors in the second column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the first column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Left ” to UART 3.

|

|

- If sensor5 value is zero

- Check the values of sensors in the second row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the third row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Down ” to UART 3.

|

|

|

Pattern 3:

Figure : Flowchart for selection of pattern 3

|

Here the three sensors present at the bottom left corner are monitored.

- If sensor7 value is zero

- Check the values of sensors in the second column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the third column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Right ” to UART 3.

|

|

- If sensor3 value is zero

- Check the values of sensors in the second row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the first row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Up ” to UART 3.

|

|

|

Pattern 4:

Figure : Flowchart for selection of pattern 4

|

Here the three sensors present at the bottom right corner are monitored.

- If sensor7 value is zero

- Check the values of sensors in the second column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the first column. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Left ” to UART 3.

|

|

- If sensor5 value is zero

- Check the values of sensors in the second row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Check the values of sensors in the first row. If the combination of first two or last two sensors is 1, go to next step. Else, update the gesture array for these sensors and check.

- Send “Up ” to UART 3.

|

|

|

Application Development

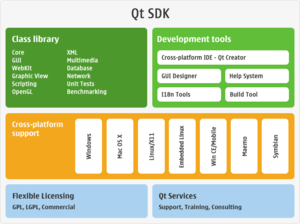

Qt Software

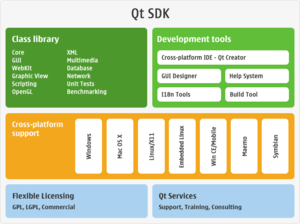

Qt is a cross-platform application framework that is widely used in developing application software that can be run on various software and hardware platforms with little or no change in the underlying codebase while having the speed and the power of native application.

It is mainly used to make GUI based applications but there can be applications such as consoles or command-line applications developed in Qt. Qt is preferred by many application programmers as it helps in developing GUI applications in C++ as it uses the standard C++ libraries for backend.

Platforms supported by Qt are:

- Android

- Embedded Linux

- Integrity

- iOS

- OSX

- QNX

- VxWorks

- Waylands

- Windows

- Windows CE

- Windows RT

- X11

Qt applications are highly portable from one platform to other as Qt first runs a Qmake function before compiling the source code. It is very similar to ‘cmake’ which is used for cross platform compilation of any source code. The qmake auto generates a makefile depending on the operating system and the compiler used for the project. So if a project is to be ported from windows to linux based system then the qmake auto generated a new makefile with arguments and parameters that the g++ compiler expects.

|

Figure : Devices supporting Qt

Figure : Qt-SDK

|

|

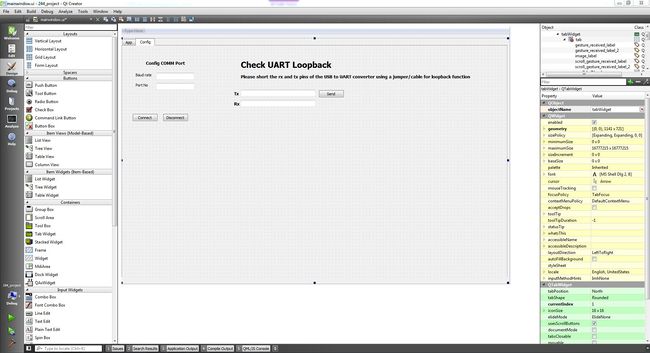

Gesture Recognition application on Qt

Once the gesture is recognized on the SJONE board, a message is sent over UART2 stating which gesture was sensed. The Qt application gets this message from the COMM port and scrolls the images left and right based on the left/right gesture and it moves a vertical slider up and down which in turn changes the value on a LCD screen display.

The application opens up in a window that has 2 tabs, config and App. The config tab includes the fields required to open the COMM port and test the COMM port using a loopback connection.

Figure : Configuration Tab

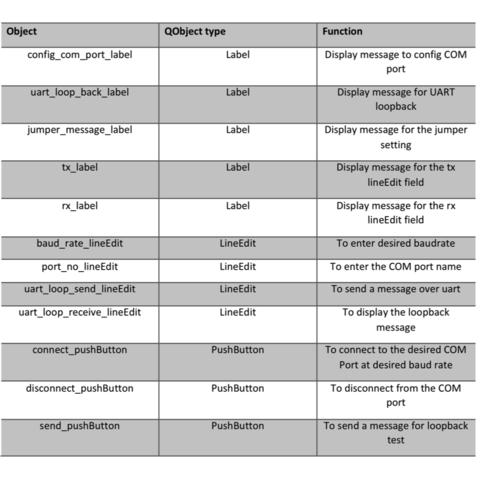

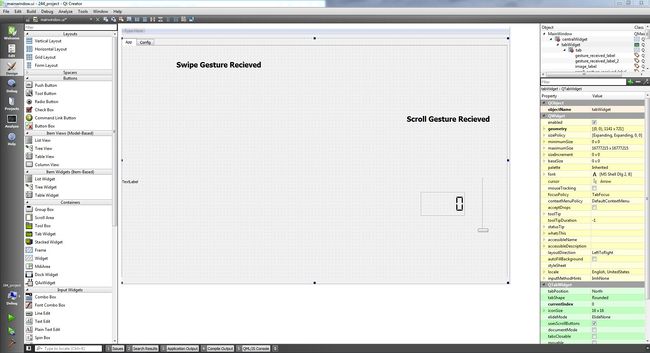

This tab has the following QObjects

Table 1: QObjects used for Configuration Tab

The App tab includes the objects required to change images and change the value in the vertical slider and lcd number display.

Figure : Application Tab

This tab has the following Qobjects

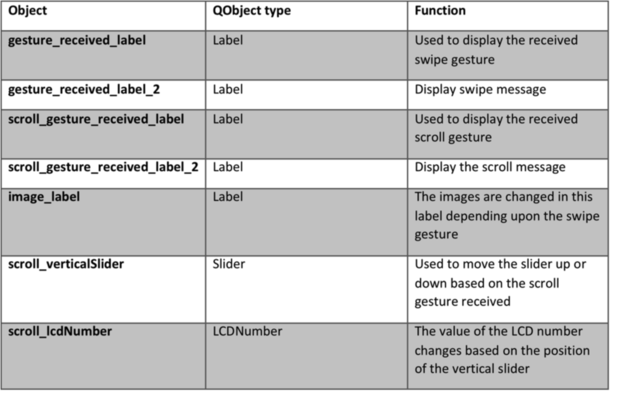

Table 2: QObjects used for Application Tab

|

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Challenge #1:

The sensor produces many spikes giving false positive outputs.

Resolution:

In order to overcome spikes received and deal with false positive, normalization of the sensor output is done. A circular queue of size 5 is maintained for each sensor and each value received from the ADC is stored at the end on the queue. This queue is then sorted and only the median value is considered for computation. This reduces the false positives to a great extent.

Challenge #2:

Number of sensors used was far greater than the available ADC pins.

Resolution:

Even if we had 9 ADC pins converting values of 9 sensors, we would still be reading the each sensor one by one. Keeping this in mind, in order to overcome the deficit of ADC pins, we have used multiplexer which takes the input from 3 sensors at a time and gives the output of only the selected sensor. In this way, we could read the output of any sensor at any given point of time. The introduction of multiplexer introduces a lag but this lag is not long enough to hinder the operation of the application.

Challenge #3:

Qt being a new application for all the team members, it was a challenge to learn its programming style and use the objects.

Challenge #4:

Setting up the serial port communication in Qt.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Gesture Recognition using IP Proximity Sensors

Project Source Code

References

Acknowledgement

All the components where procurred from Amazon, Adafruit and digikey. We are thankful to Preet for his continuous guidance during the project.

References Used

IR Sensor Data Sheet

LPC_USER_MANUAL

Multiplexer Data Sheet

QT Software

Filter code refered from Spring'14 project Virtual Dog