Difference between revisions of "S15: Drone"

Proj user20 (talk | contribs) (→PID formula) |

Proj user20 (talk | contribs) (→PID formula) |

||

| Line 391: | Line 391: | ||

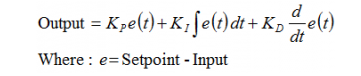

==== PID formula ==== | ==== PID formula ==== | ||

| − | [[File:S15_244_PID_formula_drone.png| | + | [[File:S15_244_PID_formula_drone.png|500px|thumb|center|Fig 2. PID]] |

There are 3 variables in a PID controller, namely P(Proportional), I(Integral), and D (Derivative). P depends on the present error, I on the accumulation of past errors, and D is a prediction of future errors, based on current rate of change of the Quadcopter. | There are 3 variables in a PID controller, namely P(Proportional), I(Integral), and D (Derivative). P depends on the present error, I on the accumulation of past errors, and D is a prediction of future errors, based on current rate of change of the Quadcopter. | ||

Revision as of 02:36, 24 May 2015

Contents

- 1 Grading Criteria

- 2 Quadcopter

- 3 Abstract

- 4 Objectives & Introduction

- 5 Schedule

- 6 Parts List & Cost

- 7 Design & Implementation

- 8 Testing & Technical Challenges

- 9 Conclusion

- 10 References

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Quadcopter

Abstract

Unmanned Aerial Vehicles (UAVs) are gaining popularity in military operations as surveillance and weapons platforms, UAV's are being produced more than the conventional aircrafts. A recent rule in 2012, where an UAV less than a 55 pounds can be used for commercial purpose has brought lot of research in industries. A commonly used UAV is a quad-copter, which is used widely in commercial applications like delivering pizzas's, couriers,etc. Apart from commercial use, a quadcopter could can save someone's life by reaching the spot in emergency situations before an ambulance and deliver first aid kit.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

The goal of the project is to design an autonomous Quadcopter capable of self-sustained flight via wireless communications utilizing SJ-One board which is used as a flight control board. The Flight control board is the brain of the multirotor and it takes continuous measurements from the sensors and adjusts the speed of every motor inorder to be stable. The brushless motors are controlled by the AfroESC.

PID Brief Introduction: PID (proportional-integral-derivative) is a closed-loop control system that try to get the actual result closer to the desired result by adjusting the input. Quadcopters or multicopters use PID controller to achieve stability.

Team Members & Responsibilities

- Bhushan Gopala Reddy

- Karthik Govindaswamy

- Rishikesh Nagare

- Mayur Salve

- Manuj Shinkar

Basics of Quadcopter

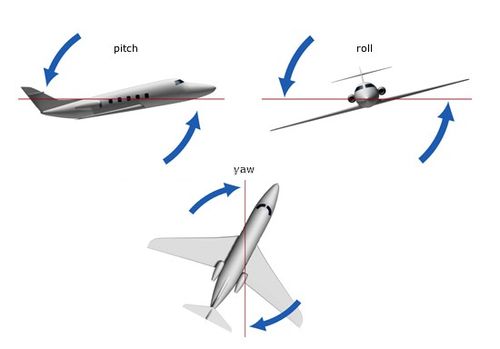

This figure shows the Yaw, Pitch and Roll movement of a quadcopter.

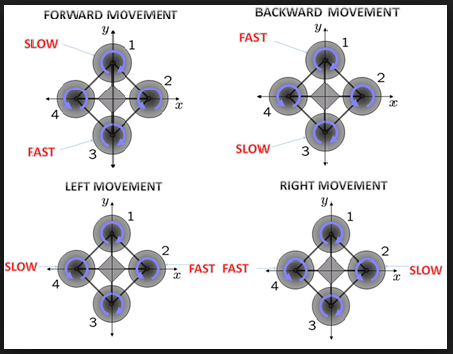

- Our Quadcopter is implemented using the + orientation.

- FigureX shows the ESC and motor setup where CW is clockwise and CCW means counter-clockwise.

- The CW and CCW setup of the motor and propellers is very important to have control over the yaw parameter.

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

| Sl.No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 03/17/2015 | 03/24/2015 | Ordered parts for quad-copter | Completed | 09/24/2015 |

| 2 | 03/25/2015 | 03/31/2015 | Assembled quad-copter and Tested it using pre-programmed board (KK 2.1.5). | Completed | 03/31/2015 |

| 3 | 04/01/2015 | 04/07/2015 | Interfaced Motors and RC to SJOne Board. | Completed | 04/07/2015 |

| 4 | 04/07/2015 | 04/14/2015 | Study quad-copters software framework provided by Preet | Ongoing | --/--/2015 |

| 5 | 04/14/2015 | 04/21/2015 | Interface and test 10-DOF IMU sensor by Adafruit. | Ongoing | --/--/2015 |

| 6 | 04/21/2015 | 05/05/2015 | Understanding and Tuning PID values. | --/--/2015 | |

| 7 | 05/05/2015 | 05/19/2015 | Final Testing. | --/--/2015 |

Parts List & Cost

Give a simple list of the cost of your project broken down by components. Do not write long stories here.

| Item# | Part Desciption | Vendor | Part Number | Qty | Cost |

|---|---|---|---|---|---|

| 1 | Motors and Propellers | tiger motors | 2 | $89.99 | |

| 2 | Afro ESC 30 Amp Speed Controller (SimonK Firmware) | Turnigy | 6 | $84 | |

| 3 | Turnigy 9X 9Ch Transmitter w/ Module & 8ch Receiver (Mode 2) (v2 Firmware) | Turnigy | 1 | $59.99 | |

| 4 | Turnigy nano-tech 4000mAh 3S1P 25-50C Lipo Pack | Turnigy | 1 | $26.90 | |

| 5 | Hobbyking SK450 Glass Fiber Quadcopter Frame 450mm | Hobbyking | 1 | $17.99 | |

| 6 | Landing Kit set | Hobbyking | 1 | $9.49 | |

| 7 | Hobbyking Quadcopter Power distribution board | Hobbyking | 1 | $3.39 | |

| 8 | Hobbyking Lipoly low voltage alarm | Hobbyking | 1 | $2.15 | |

| 9 | Turnigy Battery Strap | Hobbyking | 1 | $1.59 | |

| 10 | Mounting pad | Hobbyking | 1 | $1.99 | |

| 11 | 4mm bullet heads to connect battery to power distribution board | polymax | 1 | $2.83 | |

| 12 | Vibration damping balls | 1 | $9.10 | ||

| 13 | 3.5 mm bullet heads for power break distribution board | 1 | $1.83 | ||

| 14 | iMax B6 Battery Charger | 1 | $33.46 | ||

| 15 | TOTAL | 1 | $650 |

Design & Implementation

This section describes the hardware and software implementation. The quadcopter consist of the main frame, flight controller board (SJ-One Board), motors with ESC and the battery system. The Airframe used in this project is Hobbyking SK450 Glass Fiber Quadcopter Frame 450mm.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

System Design

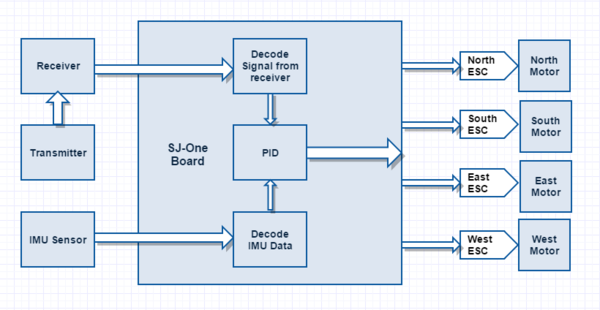

The quadcopters flight controller system is discussed in the block diagram shown below. The subsystem consists of following:

- SJ- One Board

- RX - Receiver Turnigy

- Adafruit 10-DOF IMU sensor

- Brushless Motors

- ESC(Electronic speed control)

The power is fed to the motors using the power distribution board. The power comes from 3S 11.2V LIPO battery Pack.

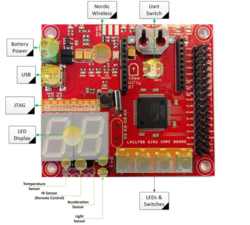

SJ-One Board

The flight control board used for this project is SJ-One Board. This control board will receive values continuously from the sensor and remote. The values applied from the RC and the current sensor values are used to calculate the values to be applied to the propellers. The SJ-One board uses ARM Cortex -M3 MPU to calculate few hundred times a second.

Brushless Motors

Brushless motors are the best when it comes to speed and low power consumption. The motors used for this project are AIR Gear 350 brushless motors. These motors have 920Kv rating and have low noise and high speed response. The propellers used came with the same motors and were self tightening and bullets holders. The motors are made of good quality material and are suitable for 1400-1700 g quadcopter.

ESC(Electronic speed control)

The PWM signals generated by the Flight control board is fed to the ESC's which provide signal to the motors. The ESCs are running on SimonK firmware which gives a smooth power response and is suitable for multi-rotor use without the need to program or adjust settings.

Calibration:

The calibration of the ESC's were done manually. Below is the step wise discussion of manual calibration method.

- First, remove all propellers! Disconnect the power to the ESCs. Connect the ESC PWM input directly to the receiver's throttle channel, or to a servo tester.

- Set the radio throttle or servo tester to the highest position, then connect power to the ESC. The motor should produce a series of initialization beeps increasing in pitch, followed by another beep

matching the pitch of the last initialization beep. This indicates that the calibration mode has been entered, and the pulse length has been learned.

- Move the stick or knob to the lowest position. Two beeps of the same pitch should be emitted. This indicates that the low pulse length has been learned. If the RC Car-style reversible mode has been

enabled (RC_PULS_NEUTRAL), move the stick or knob to the center, and wait for three beeps. This indicates that the neutral (center) pulse length has been learned.

- The ESC will then save the settings and exit calibration mode. If the input is still at the same position, the ESC will arm (producing a higher pitched, long beep), and function normally.

Inertial Measurement Unit

The Inertial Measurement Unit (IMU) is an integrated sensor device which measures accleration and tilt by Accelerometer,

angular velocity and orientation by Gyroscope and gravitational forces by Magnetometer.

Inertial Measurement Unit by Adafruit provides 10 DOF(actually 11) i.e 3-axis accelerometer, 3-axis gyroscope, 3-axis magnetometer barometric pressure sensor and temperature sensor.

These values are sent to SJ-1 board over I2C, where the further processing is done by SJ-1 board to determine the angular position and orientation of the Quadcopter.

| Pin Number | Function |

| SDA | |

| SCK | |

| VCC | |

| GND |

Remote Controller

Need to change according to our final setup

Binding Procedure

- Insert the special cable (loop) in the channel 'BAT' of the receiver and not in the channel 'BIND' as indicated. Connect power supply to the receiver in position 'BIND' and wait until the LED flashes red.

- Press the button 'Test Range bind' the transmission module (back of radio) and, without releasing it, turn on the transmitter, the LED will stop flashing and remain lit constantly.

- Release the button and turn off the radio module. Then remove the special cord and disconnect the receiver battery, the receiver is ready.

- The effect is immediate and does not allow more than 3sec button 'test range bind' button.

| Pin Number | Function |

| P0.0 | RC-Ch1 - Roll |

| P0.1 | RC-Ch2 - Pitch |

| P0.29 | RC-Ch3 - Throttle |

| P0.30 | RC-Ch4 - Yaw |

| P | RC-Ch5 - Gear |

Note: Use a LiPo battery pack of 11.1V 1700mAh to power the transmitter. This is very convenient to use as opposed to using (8x) AA batteries as they discharge quickly.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

| Sl. No | Port and Pin Number | Pin Type | Purpose |

|---|---|---|---|

| 1 | P0.0 and P0.1 | UART 3 | IMU Communication (Arduino) |

| 2 | P2.4, P2.5, P2.6, P2.7, P0.26, P0.29, P0.30 | GPIO Input | Remote Control Receiver Input |

| 3 | P2.0, P2.1, P2. 2, P2.3 | PWM | PWM output to motors |

| 4 | P2.8, P2.9 | UART2 | ZigBee telemetry |

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Flowchart

PID

PID (proportional-integral-derivative) is a closed-loop control system that tries to get the actual result from IMU sensors closer to the desired result from the RC transmitter by computing the output values. The popularity of PID controllers can be attributed partly to their robust performance in a wide range of operating conditions and partly to their functional simplicity, which allows engineers to operate them in a simple, straightforward manner.

PID formula

There are 3 variables in a PID controller, namely P(Proportional), I(Integral), and D (Derivative). P depends on the present error, I on the accumulation of past errors, and D is a prediction of future errors, based on current rate of change of the Quadcopter.

The effect of P,I and D

- Proportional Gain Coefficients

Kp = Proportional element of the PID, reduces large part of the overall error.

- Increasing Kp will overshoot and oscillate, but reach the desired state faster.

- Increasing Kp will reduce steady state error, but after a certain limit, increasing Kp will only increase the overshoot.

- Kp reduces the rise time.

- Integral Gain Coefficients

Ki = Integral element of the PID, reduces the final error accumulated over time.

- Ki eliminates the steady state error, but after a certain limit, increasing Ki will only increase the overshoot.

- Ki reduces the rise time.

- Derivative Gain Coefficients

Kd = Derivative element of the PID, counteracts Kp, and Ki when the output changes quickly.

- Kd decreases the overshoot.

- Kd reduces the settling time.

To obtain the control and stability of the quadcopter we do the following, for example consider we are doing it for pitch axis, the user provides some input to the quadcopter which becomes the requested value, at the same time sensor outputs the present value for the pitch axis for the quadcopter. The three alogorithms P, I and D finds the difference between the requested and the present values which is calculated as an error and apply these values on the motor which are the applied values to reduce the error. Similarly it is done for other 2 axis i.e Roll and Yaw to obtain the overall stability of the Quadcopter.

There wre few parameter which were addressed while writing the PID algorithm

- Sample Time - The PID algorithm functions best if it is evaluated at a regular interval. If the algorithm is aware of this interval, we can also simplify some of the internal math.

- Derivative Kick - Not the biggest deal, but easy to get rid of, so we’re going to do just that.

- On-The-Fly Tuning Changes - A good PID algorithm is one where tuning parameters can be changed without jolting the internal workings.

- Reset Windup Mitigation -We’ll go into what Reset Windup is, and implement a solution with side benefits

- On/Off (Auto/Manual) - In most applications, there is a desire to sometimes turn off the PID controller and adjust the output by hand, without the controller interfering

- Initialization - When the controller first turns on, we want a “bumpless transfer.” That is, we don’t want the output to suddenly jerk to some new value

- Controller Direction - This last one isn’t a change in the name of robustness per se. it’s designed to ensure that the user enters tuning parameters with the correct sign.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Tuning of pitch axis for the Quadcopter https://www.youtube.com/watch?v=Ztgx5FDS018

Project Source Code

References

Preetpal Kang, Professor of CMPE 244, Computer Engineering, Charles W. Davidson College of Engineering, San Jose State University, Feb-May 2015.

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.