Difference between revisions of "S14: Autonomous Control System"

Proj user20 (talk | contribs) (→My Issue #1) |

Proj user20 (talk | contribs) (→Schedule) |

||

| Line 78: | Line 78: | ||

| | | | ||

*pod goes from one station to another using hard coded instructions | *pod goes from one station to another using hard coded instructions | ||

| − | |||

| − | |||

|- | |- | ||

! scope="row"| 5 | ! scope="row"| 5 | ||

Revision as of 02:14, 17 May 2014

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

Autonomous Control System

Abstract

A control system that, when loaded to a vehicle, can autonomously navigate a given track design. Given a source and destination location, the vehicle (pod) would be able to navigate the track and, via wireless communication, send or receive messages from other pods in the system. Such a control system may be used in a transportation network that runs on a guideway where a fixed track design is known.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

- Elizabeth Poche

- Driver & Line Follower Development

- Eriberto Velazquez

- FreeRTOS Software Design

- Trent Smith

- SNAP Communication

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 3/28 |

|

|

| 2 | 4/4 |

|

|

| 3 | 4/11 |

|

|

| 4 | 4/18 |

|

|

| 5 | 4/25 |

|

|

| 6 | 5/2 |

|

|

| 7 | 5/9 |

|

|

| 8 | 5/16 |

|

|

Parts List & Cost

Give a simple list of the cost of your project broken down by components. Do not write long stories here.

| Part | Quantity | Cost Each | Total Cost |

|---|---|---|---|

| Pod Chassis | 3 | $15 | $45 |

| H-Bridge | 3 | $-- | $-- |

| IR LED/Sensor | 15 | $-- | $-- |

| DC Battery | 3 | $-- | $-- |

| SJOne Board | 3 | $60 | $180 |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Project Superway’s control system employed known architectures used in many systems, such as peer-to-peer and distributed systems. These architectures were utilized in Superway’s design and modified them to fit with our system. Overall, the system had a wireless mesh network architecture. The state machine represented the center of the mesh which connected communication between peripherals. The peripherals received instructions from the master controller and communicated necessary information to the master controller. Shown in Figure 4.2, the state machine was the central server that had access to all pods through SNAP wireless and had the authority to override any current commands and other controllers.

To implement the pod system, small steps had to be taken to avoid periods if the

design does not work and cannot isolate the issue. In the event the design did not work

there was a previous design that worked. The design process started with a baseline using

a simple prototype. A simple line follower was built to learn the basics of the line

follower. To make the pod intelligent, a microprocessor was integrated. To get the line

follower working, hardware and software were combined. Hardware controlled the pod,

which followed the line and software gave user the control over the pod’s path traversal.

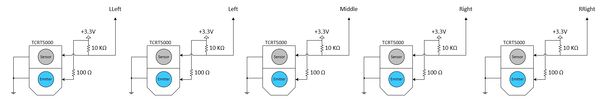

The line follower followed a line using IR emitters and receivers, which pointed

down, toward the ground. The emitter sent a constant IR signal. If the signal hit white

part of the track layout, the signal reflected, and if the signal hit black tape, the signal did

not reflect. Using this technology, Left and Right IR signals were used to follow the line.

LLeft and RRight were signals to inform the microprocessor that the pod has reached a

node.

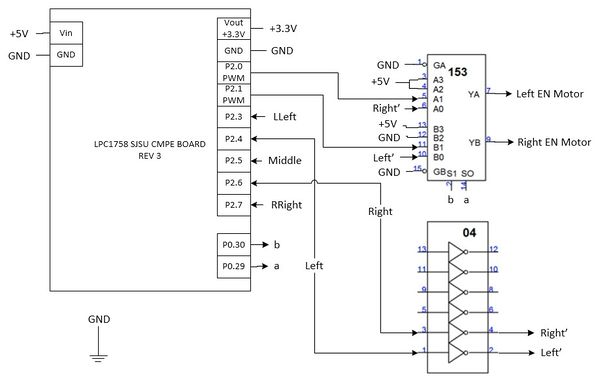

Figure 4.5 shows the fork, merge, and station design of the line. When the pod reached a node it tok a new instruction from the state machine to either continue straight, turn right, or stop. The pod had four modes it can be in: straight mode, right mode, RC mode, and software mode, shown in Table 4.A. If the pod was instructed to continue straight through node, the software chose straight mode and turned on both wheels until either Left AND Right, OR LLeft AND Left AND RRight, OR LLeft AND Right AND RRight signals saw white. If the pod was instructed to turn right, the software chose right mode and turned off the right wheel and turned on the left wheel until LLeft AND Left OR LLeft AND Right signals saw white. If the pod was instructed to stop, the software went into RC mode and since the station was black, the sensors did not see a reflection and therefor stopped both wheels. The pod remained stopped and waited for the next instruction. Figure 4.5 shows the station design of the tape. Each black block represented a node where the pod received the next instruction from the instructions queue.

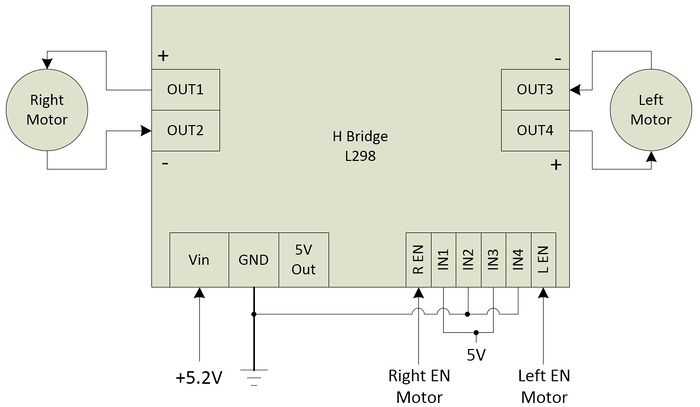

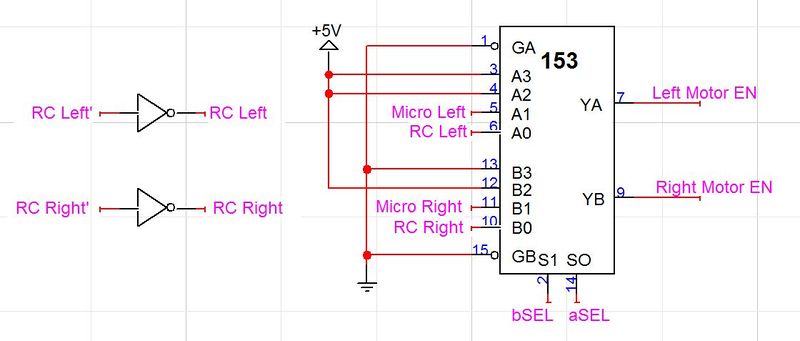

Figure 4.5: Station Design Other hardware components of the pod consisted of the SJOne Board microcontroller, L298 H-bridge, logic gates, and voltage converters. Figure 4.6 shows the hardware’s logic.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Design Constraints

The design constraints for this project were: initially, there was track to test the software on. Since the mechanical engineering team was not ready with their track and pod, the computer engineers had to find an alternative way to demonstrate pods on a track that would be inexpensive and simple to build. The goal was to make the pods intelligent and the 1/12th scale model track did was not ready to have intelligent pods.

Design Problems and Challenges

The component that was the most difficult to design program were the pod’s movements. The parts purchased were very inexpensive and caused difficulties later in making the pod more accurate. Using hardware to have the pod follow the line was simple and reliable. Using software to control the pod to follow the line became a challenge because the objective was to make the software as efficient and reliable as the hardware. During the first test phases of the line follower, a white flexible mat was used as a track and black electrical tape was used as the line. However, the tape stretched and caused the mat to have ripples in it. When the pod traveled over the ripples, it needed a certain amount speed to travel over the bump. If the speed was too fast, the pod would go off track. Another problem was the tape on the track. When the pod made a right turn, it went off track. The electrical tape was black but it still had a little of reflection. A less reflective tape was tested and improved slightly. Non-reflective tape was also tested but did not improve the performance of the pod turning right and continuing straight.

Design Solutions and Trade-Offs

Since the first design track mat had problems with the ripples, another track was made using particle board and the same tape. This allowed the pod to go slower and lower the chances of the pod getting off track. Software controlling the line following was slower than the hardware. Hardware was used to control the line following and software for the decision making at each node. The hardware followed the line decently but software could have made it more intelligent to follow the line. This work was not pursued because the main focus of this project was to build a control system, not a line follower. The line follower was used only to provide a visual for our software-based control system.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

Send me your zipped source code and I will upload this to SourceForge and link it for you.

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.