Difference between revisions of "F17: Tata Nano"

Proj user3 (talk | contribs) (→Ultrasonic Sensor) |

Proj user3 (talk | contribs) (→Testing & Technical Challenges) |

||

| Line 365: | Line 365: | ||

Include sub-sections that list out a problem and solution, such as: | Include sub-sections that list out a problem and solution, such as: | ||

| − | |||

| − | |||

| − | |||

===LCD=== | ===LCD=== | ||

Revision as of 00:29, 29 November 2017

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

PAGE UNDER CONSTRUCTION

Tata Nano

Self-Navigation Vehicle Project

Abstract

Embedded system is a collection of hardware and software that are designed for a specific function that is a part of a larger system. Self driving car provides a challenge and opportunity to design a unique system that will solve a problem of getting from point A to point B. This project is focus on the industry standard and will go through a complete product lifecycle using the practice knowledge acquired in classroom with scrum methodology practiced by the team.

Key components of this self driving car are:

- Android App interface with car

- Obstacle detection and avoidance

- Auto speed adjustment

- GPS Navigation

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

- Master Controller

- Manan Mehta

- Shivam Chauhan

- Geographical Controller

- Kalki Kapoor

- Aditya Deshmukh

- Communication Bridge + Android Application + LCD

- Ashish Lele

- Venkat Raja

- Motor and I/O Controller

- Aditya Choudari

- Shashank Iyer

- Sensor Controller

- Pushpender Singh

- Hugo Quiroz

- Module Level Testing

- Manan Mehta

- Shashank Iyer

Project Schedule

Legend: Motor & I/O Controller , Master Controller , Communication Bridge Controller, Geographical Controller, Sensor Controller , Team Goal

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 09/12/2017 | 09/19/2017 |

|

Completed |

| 2 | 09/19/2017 | 09/26/2017 |

|

Completed |

| 3 | 09/26/2017 | 10/03/2017 |

|

Completed |

| 4 | 10/03/2017 | 10/10/2017 |

|

Completed |

| 5 | 10/10/2017 | 10/17/2017 |

|

Completed |

| 6 | 10/17/2017 | 10/24/2017 |

|

Completed |

| 7 | 10/24/2017 | 10/31/2017 |

|

Completed |

| 8 | 10/30/2017 | 11/7/2017 |

|

Completed |

| 9 | 11/7/2017 | 11/14/2017 |

|

Completed |

| 10 | 11/14/2017 | 11/21/2017 |

|

Completed |

| 11 | 11/21/2017 | 11/28/2017 |

|

In-Progress |

| 12 | 11/28/2017 | 12/05/2017 |

|

|

| 13 | 12/05/2017 | 12/12/2017 |

|

- |

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car - Traxxas 1/10 Slash 2WD | Amazon | 1 | $189.95 |

| 2 | Traxxas 2872X 5000mAh 11.1V 3S 25C LiPo Battery | Amazon | 1 | $56.99 |

| 3 | Traxxas 7600mAh 7.4V 2-Cell 25C LiPo Battery | Amazon | 1 | $70.99 |

| 4 | Traxxas 2970 EZ-Peak Plus 4-Amp NiMH/LiPo Fast Charger | Amazon | 1 | $35.99 |

| 5 | Bluetooth Module HC-05 | Amazon | 1 | $8.99 |

| 6 | 4D systems 32u LCD | 4D systems | 1 | $41.55 |

| 7 | LV Maxsonar EZ0 Ultrasonic sensors | Robotshop | 5 | $124.75 |

| 8 | LIDAR Sensor | Robotshop | 1 | $190 |

| 9 | Ultimate GPS breakout | Adafruit | 1 | $49.95 |

| 10 | CAN tranceivers | Microchip Samples | 10 | Free |

| 11 | SJOne Boards | Provided by Preet | 5 | $400.0 |

DBC File Link

https://gitlab.com/shivam5594/Autonomous-car/blob/embedded/common_dbc/243.dbc

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Lidar Sensor

Lidar Sensor is interfaced using a UART Protocol. As shown below the Lidar Sensor sends 5 bytes per data point over UART to the Sensor Controller. These 5 bytes include 1 byte for quality of data, 2 bytes for angle of reading, and 2 bytes for distance of reading. The Sensor Board initiates the Lidar Sensor readings by sending a start command opcode. The Lidar Sensor responds by sending a start scan confirmation followed by continuous data readings.

Ultrasonic Sensor

LV‑MaxSonar‑EZ1 ultrasonic sensor by MaxBotix is used for a wide range object detection. Ultrasound sensors are configured as 2 ultrasound sensors in the front and one in the rear, this configuration helps to work in conjuncture with Lidar sensor mounted on the center of the car. LV‑MaxSonar‑EZ1 can detect objects from 0 inches to 254 inches, the object detected within 0-6 inches are provided with range information of 6 inches and the resolution is 1 inch. LV‑MaxSonar‑EZ1 provides three output formats pulse width output, analog output, and RS232 serial output. This project is using pulse width as the output from ultrasound sensors.

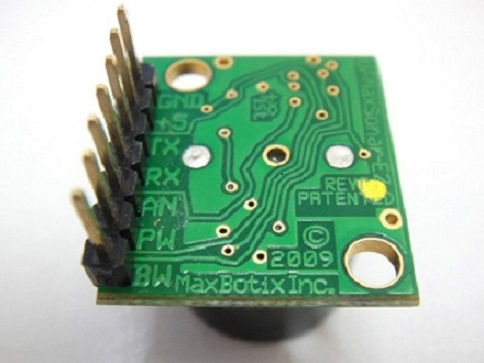

The following figure shows the pinout of the LV‑MaxSonar‑EZ1 ultrasonic sensor.

Pin Out description

Pin 1-BW- When BW pin is held high the TX output sends a pulse suitable for low noise chaining.(Not Used)

Pin 2-PW- This pin outputs a pulse width representation of range. The distance can be calculated using the scale factor of 147uS per inch.

Pin 3-AN- Outputs analog voltage with a scaling factor of (Vcc/512) per inch.(Not Used).

Pin 4-RX– This pin is internally pulled high. The LV-MaxSonar-EZ will continually measure range and output if RXdata is left unconnected or held high. If held low the sensor will stop ranging. Bring high for 20uS or more to command a range reading.

Pin 5-TX- When the *BW is open or held low, the TX output delivers asynchronous serial with an RS232 format.(Not Used)

Pin 6-+5V- Vcc – Operates on 2.5V - 5.5V. Recommended current capability of 3mA for 5V, and 2mA for 3V. Please reference page 4 for minimum operating voltage verses temperature information. Pin 7-GND- Return for the DC power supply.

GND- must be ripple and noise free for best operation.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

LCD DISPLAY

uLCD-32PTU communicates with the SJ1 board over UART. The steps taken for interfacing the LCD display with the SJ1 board are listed below:

- Creating a project using Workshop 4 IDE and programming the LCD display

- After finalizing the design of the LCD's layout, a genie project was created using Workshop 4.

- The layout was split into different forms (pages) and appropriate buttons and gauges were added for display.

- uLCD-32PTU was programmed with the help of programming cable provided by 4D systems.

- Programming SJ1 Board for LCD Display

- As raw data often cannot be displayed on the LCD directly, the values to be displayed had to be converted to appropriate byte-sized values.

- Communication with SJ1 board was established at the baud rate of 115200 bps.

- Commands for writing data and reading acknowledgment for various gauges were coded in the SJ1 board.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

LCD

- Problem: The SJ1 Board was rebooting frequently while sending data for all metrics at once.

- Resolution: The metrics were split into different forms for display and the data belonging to the active form alone was sent.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

LCD

- uLCD 32 PTU datasheet http://www.4dsystems.com.au/productpages/uLCD-32PTU/downloads/uLCD-32PTU_datasheet_R_2_1.pdf

- Workshop 4 user guide http://www.4dsystems.com.au/productpages/4D-Workshop-4-IDE/downloads/Workshop-4_userguide_R_2_1.pdf

Appendix

You can list the references you used.