Difference between revisions of "F16: The-Nine"

Proj user8 (talk | contribs) (→Schedule) |

Proj user8 (talk | contribs) (→Master Control Systems) |

||

| Line 1,047: | Line 1,047: | ||

<center><b>Team Members: </b> | <center><b>Team Members: </b> | ||

Steven Hwu, Adam Iglesias</center> | Steven Hwu, Adam Iglesias</center> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=== Schedule === | === Schedule === | ||

Revision as of 23:05, 20 December 2016

Contents

- 1 Project Title

- 2 Abstract

- 3 Objectives & Introduction

- 4 Project Schedule Overview

- 5 Team Members & Responsibilities

- 6 Parts List & Cost

- 7 Bluetooth Communications (Communication Bridge)

- 8 Obstacle Detection Systems (Sensor Controller)

- 9 Localization and Positioning (GPS)

- 10 Propulsion Systems and Speed Tracking (Motor Controller)

- 11 Master Control Systems

- 12 Conclusion

- 13 Project Video

- 14 Project Source Code

- 15 References

Project Title

The-Nine: Self Driving Car

Abstract

Nearly every car manufacturer today is in the process of developing fully autonomous vehicles. There are some that are on the brink of winning the development race as their systems are safer than many human drivers. However currently no one has been able to fully implement autonomous navigation requiring nothing but a destination while having the full support and trust of the community to remove the driver from the equation. Autonomous vehicles are incredibly difficult to create as there are a huge number of difficulties of autonomy that must be taken into account. The purpose of this project is to introduce the basic technologies in application of the types of systems that can be used in autonomy. The overall project goal is to make an autonomous RC car that utilizes five SJSU-One-Boards that intercommunicate with each other through CANbus; each controlling a major functionality. The RC car must be able to be given a destination through an interfacing application and it must be able to travel to that location.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

Project Schedule Overview

| Task # | Start Date | End Date | Team Task Description | Bluetooth Communications | Obstacle Detection Systems | Localization and Positioning (GPS) | Propulsion Systems and Speed Tracking | Master Control Systems | Status | Actual End Date |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 9/14/2016 | 9/20/2016 | Assigned tasks to one another and strategized approach. Read Previous Reports | Completed | 9/20/2016 | |||||

| 2 | 9/21/2016 | 9/27/2016 | Set up Version Control System and Basic Project Documentation Research Project Components |

Research of web application frameworks for mobile. | Research of sensor systems and sensor types needed. | * Researched and decided upon the GPS module and Compass module. * Ordered GPS module and compass module. |

Work with team leader to devise version control strategy. | Research different RC cars for the project. | Completed | 9/27/2016 |

| 3 | 9/28/2016 | 10/04/2016 | Discuss controllers' responsibilities and communication | Started development of DBC and finalized hardware choices. | Completed | 10/04/2016 | ||||

| 4 | 10/05/2016 | 10/19/2016 | Order Project Components Individual Prototyping and Module Design |

Research Bluetooth device HC-06 for the RC car. | Interface IMU and ultrasonic sensors to board. | * Parse GPS data and format the data to be transmitted * Test code to get compass reading information |

Research what encoders and/or tachometers to use, help the team leader choose an RC car to purchase, and decide what motor driver to use | Implement Decision Tree for obstacle detection/autonomous car control. Decide on Message ID system over the CANBUS/Types of Data being Transmitted | Completed | 10/19/2016 |

| 5 | 10/20/2016 | 10/27/2016 | Status Update: Demoing first round of Prototyping to the group | Develop Bluetooth serial receiver library & web application. | Develop IMU and ultrasonic sensor libraries. | Interface GPS module and compass module to SJOne board. | Make the motors spin and the servo control the steering. Receive can signals and control the motor and steering servo. | * Implement Decision Tree for obstacle detection/autonomous car control. Decide on Message ID system over the CANBUS/Types of Data being Transmitted * Program obstacle detection/autonomous car control algorithms |

Completed | 10/27/2016 |

| 6 | 10/28/2016 | 11/18/2016 | Adding a level of complexity to designs: Interfacing Motor, Sensor, GPS, and Bluetooth Modules with the Master Controller over CAN bus | Integrate web application, SJOne board and DBC messages | Use implemented DBC to transmit sensor data over CAN. | * Calibrating the compass module.Integration of GPS and compass module. Interfacing of GPS and compass module to Android. * Integration with Master through CAN bus. |

* Validate and calibrate the motor controller and steering code. Receive the Tachometer and magnetic polarity strip. * Merge motor_test/tach with master. * Reorganize code for readability. * Finalize and test speed feedback system. |

* Program obstacle detection/autonomous car control algorithms * Test RC car obstacle detection and autonomous control interfaced with Sensor Module over CAN * Interface GPS module with Master Controller * Interface Android/Bluetooth module with Master Controller.Test Waypoint System |

Completed | 11/18/2016 |

| 7 | 11/19/2016 | 11/25/2016 | Integration Testing between Modules, System Validation | Fine-tuning of web application | Debug sensor library and work on integration | Testing and calibrating with other modules. | Test with the rest of the group * Fine tune nominal speed. Add LCD to display debug information. |

* Interface Android/Bluetooth module with Master Controller.Test Waypoint System * Debug any issues with Master controller and other modules |

Completed | 11/28/2016 |

| 8 | 11/26/2016 | 12/02/2016 | Overall System Optimization | Fine-tuning of sensor readings | Testing and calibrating with other modules. | * Replace motor driver with higher amperage driver. * Adjust steering offset to reduce error. |

* Debug any issues with Master controller and other modules * Final debug/testing of RC CAR |

Completed | 12/04/2016 | |

| 9 | 12/03/2016 | 12/09/2016 | Finalization, Preparing for Demonstration | Completed | 12/08/2016 | |||||

Team Members & Responsibilities

Application & Control Interface

- Khalil Estell

Bluetooth Communications

- Khalil Estell

Obstacle Detection Systems

- Charles MacDonald

- John Strube

Localization and Positioning (GPS)

- Sara Sepasian

Propulsion Systems and Speed Tracking

- Derek Tran

- Matthew Boyd

Master Control Systems

- Steven Hwu

- Adam Iglesias

Parts List & Cost

Give a simple list of the cost of your project broken down by components. Do not write long stories here.

| Item # | Part Description | Vendor | QTY | Cost |

|---|---|---|---|---|

| 1 | RC Car | Nor-Cal Hobbies | 1 | $200 |

| 2 | SJSUOne Board | Preet Kang | 5 | $400.00 |

| 3 | HC-06 Bluetooth Module | Amazon | 1 | $8.99 |

| 4 | Magnetic Tachometer | Digikey | 1 | $8.53 |

| 5 | Radial Magnet cube magnets | Digikey | 10 | $8.80(Total) |

| 6 | Pololu 5V Step-Up/Step-Down Voltage Regulator | Polulu | 1 | $14.95 |

| 7 | Pololu 6V Step-Up/Step-Down Voltage Regulator | Polulu | 1 | $14.95 |

| 8 | High Power Motor Driver | Polulu | 1 | $39.95 |

| 9 | 2000mAH 3 Cell Lipo Battery | HobbyKing | 1 | $25.00 |

Bluetooth Communications (Communication Bridge)

Schedule

| Task # | Start Date | End Date | Task Description | Status | Actual End Date |

|---|---|---|---|---|---|

| 1 | 9/14/2016 | 9/20/2016 | Assigned tasks to one another and strategize approach. | Completed | 9/20/2016 |

| 2 | 9/21/2016 | 9/27/2016 | Research of web application frameworks for mobile. | Completed | 9/27/16 |

| 3 | 9/28/2016 | 10/04/2016 | Started development of DBC and finalized hardware choices. | Completed | 10/04/2016 |

| 4 | 10/05/2016 | 10/19/2016 | Research Bluetooth device HC-06 for the RC car. | Completed | 10/19/2016 |

| 5 | 10/20/2016 | 10/27/2016 | Develop Bluetooth serial receiver library & web application. | In Progress | |

| 6 | 10/20/2016 | 11/18/2016 | Integrate web application, SJOne board and DBC messages | In Progress | |

| 7 | 11/19/2016 | 12/02/2016 | Fine-tuning of web application | Not started | |

| 8 | 12/03/2016 | 12/09/2016 | Final integration | Not started |

Design & Implementation

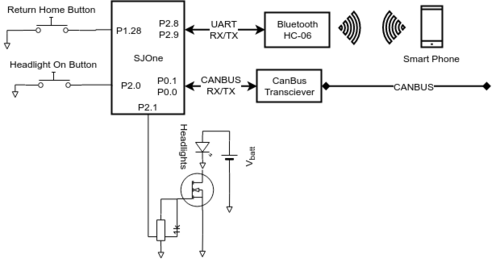

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Obstacle Detection Systems (Sensor Controller)

Schedule

| Task # | Start Date | End Date | Task Description | Status | Actual End Date |

|---|---|---|---|---|---|

| 1 | 9/14/2016 | 9/20/2016 | Assigned tasks to one another and strategized approach. | Complete | 9/20/2016 |

| 2 | 9/21/2016 | 9/27/2016 | Research of sensor systems and sensor types needed. | Complete | 9/27/2016 |

| 3 | 9/28/2016 | 10/04/2016 | Started development of DBC and finalized hardware choices. | Complete | 10/04/2016 |

| 4 | 10/05/2016 | 10/19/2016 | Interface IMU and ultrasonic sensors to board. | Complete | 10/19/2016 |

| 5 | 10/20/2016 | 10/27/2016 | Develop IMU and ultrasonic sensor libraries. | Complete | 10/19/16 |

| 6 | 10/20/2016 | 11/18/2016 | Use implemented DBC to transmit sensor data over CAN. | Complete | 10/19/16 |

| 7 | 11/19/2016 | 11/25/2016 | Debug sensor library and work on integration | Complete | 11/25/16 |

| 8 | 11/26/2016 | 12/02/2016 | Fine-tuning of sensor readings | Complete | 12/1/16 |

| 9 | 12/03/2016 | 12/09/2016 | Final integration | Complete | 12/8/16 |

Design & Implementation

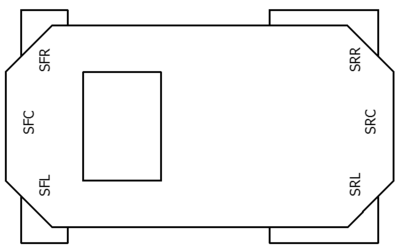

The obstacle detection system covers two areas: detecting obstacles and determining vehicle orientation.

Obstacle detection is performed using ultrasonic sensors placed around the perimeter of the vehicle, concentrated at the front (three sensors) and less so in the back (one sensor) as the vehicle is primarily driven in the forward direction.

Vehicle orientation is accomplished using an inertial measurement unit, which is used to determine the speed and bearing of the vehicle.

Hardware Design

Ultrasonic sensors

Ultrasonic sensors are controlled using GPIO. The sensor consists of a trigger-input signal which causes it to emit sound at a specific frequency, and a echo-output signal which is pulsed when a reflection of the same frequency is received. The echo response is detected by the edge-sensitive GPIO interrupt, and the trigger is produced by a software-generated pulse.

Our original design called for six ultrasonic sensors, with three forward-facing (sensors SFL, SFC, SFR) and three rear-facing (sensors SRL, SRC, SRR). In practice only one center rear-facing sensor was needed, but the design still supports six. The sensors are arranged around the car as follows:

|

Compass

A magnetometer is used to calculate the heading of the car. The magnetometer being used is the HMC5883L. The magnetometer measures the magnetic field of The Earth in units of Tesla as scalars in the X, Y and Z axis. The SJOne board communicates with the magnetometer using I2C at address 0x3C. An accelerometer onboard the SJOne board is used for tilt compensation. The magnetometer is oriented such that X axis faces forward, Z axis faces up, and Y axis faces to the left.

Hardware Interface

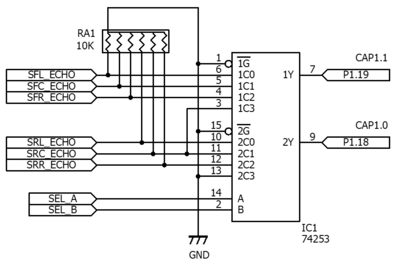

I/O expander

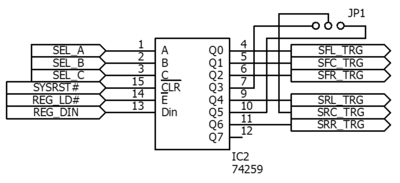

To utilize the limited number of available capture inputs across four to six ultrasonic sensors, an I/O expansion circuit was developed.

It consists of a 74HCT253 dual 4-to-1 multiplexer, and a 74HCT259 8-bit addressable latch. The multiplexer routes the sensor inputs to the two capture pins such that the front and rear sensors can be captured in parallel. To keep our final design compatible with the code developed for our prototype, the rear-center sensor was also mapped to the fourth input of the front-sensor multiplexer inputs such that iterating over four inputs would cover the front three sensors and rear single sensor on the same capture channel.

|

|

| Select | Input on CAP1.0 | Input on CAP0.0 | Addressed register |

|---|---|---|---|

| 0 | SFL_ECHO | SRL_ECHO | SFL_TRG |

| 1 | SFC_ECHO | SRC_ECHO | SFC_TRG |

| 2 | SFR_ECHO | SRR_ECHO | SFR_TRG |

| 3 | SRC_ECHO | Always '0' | SRC_TRG (see JP1) |

| 4 | SFL_ECHO | SRL_ECHO | SRL_TRG |

| 5 | SFC_ECHO | SRC_ECHO | SRC_TRG (see JP1) |

| 6 | SFR_ECHO | SRR_ECHO | SRR_TRG |

| 7 | Always '0' | Always '0' | Not used |

Compass

The SJOne board communicates with the HMC5883L using I2C bus 2, using slave address 0x3C. The magnetometer is oriented such that the X axis faces forward, the Y axis faces left, and the Z axis faces up. SDA and SCL pins are connected to the SDA2 and SCL2 pins on the SJOne, GND is connected to GND, and VCC is connected to 3.3V.

Software Design

Ultrasonic sensors

A sensor polling loop starts every second (1 Hz). Within this loop all four sensors are read, the distances are calculated and output on the CAN bus, and the elapsed time is determined. If there is enough time remaining to do a worst-case read of all four sensors (approximately 200ms), the sensors are read again. This process repeats until all available time has elapsed. The sensor refresh rate is dynamic and ranges from a worst case of 200ms (5 Hz) to a best case of 20ms (20 Hz), averaging about 15 Hz.

Battery voltage monitor

The battery voltage is read after the sensors are polled using the ADC. This data is sent to the rest of the system over the CAN bus.

Compass

The compass headings are calculated 10 times a second using the period_10Hz task in period callbacks. An exponential moving average is used to smooth out the raw magnetometer and accelerometer data. A weight of .5 was used to smooth out the magnetometer, and a weight of .1 was used to smooth out the accelerometer. The magnetic and acceleration vectors as measured from the magnetometer and accelerometer are then normalized such that the length of the vectors is 1.0. Because a gyroscope is not being used to assist in tilt compensation, a very low weight must be used to compensate for the car accelerating forward and backward. Tilt compensation is used to ensure an accurate compass reading when the car is titled. The tilt compensation algorithm uses the roll and pitch as calculated from the accelerometer and the X Y and Z components of the normalized magnetometer vector. The calculated heading is then converted from radians to degrees. The magnetic declination offset angle is then added to the heading to account for the differences between magnetic and true north. The heading will then be sent to Master, BlueTooth, and Debug over Can bus.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Compass

To communicate with the magnetometer sensor, a singleton class named IMU_Sensor was created. The class stores sensor data in a local struct, and handles initialization of the sensor, and reading raw magnetometer sensor data.

Measuring the raw sensor data

The IMU_Sensor class communicates with the magnetometer using I2C at address 0x3C. The period_init function in periodic callbacks calls the init function, which sets the two configuration registers and the mode register using the I2C2 class. Ten times per second the periodic scheduler calls the getXYZ() function. Six registers are read, starting at 0x03, which store the high and low bites for the X, Z, and Y axis of the magnetometer. If the readRegisters function returns false, the getXYZ function returns false. A zero byte is then written to register 0x03 to reset the internal pointer and prepare for the next measurement. The table below lists the relevant registers.

| Address Location | Name |

|---|---|

| 0x00 | Configuration Register A |

| 0x01 | Configuration Register B |

| 0x02 | Mode Register |

| 0x03 | Data Output X MSB Register |

| 0x04 | Data Output X LSB Register |

| 0x05 | Data Output Z MSB Register |

| 0x06 | Data Output Z LSB Register |

| 0x07 | Data Output Y MSB Register |

| 0x08 | Data Output Y LSB Register |

Calculating Heading

The period_10Hz reads the raw values from both the magnetometer using the IMU_Sensors class, and from the accelerometer using a built in class. The raw data is then filtered using an exponential moving average, with a weight of 0.5 for the magnetometer and 0.1 for the accelerometer. The magnetometer and accelerometer vectors are then normalized. Roll and pitch are then calculated using the normalized accelerometer vector. The roll is calculated by taking the arcsin of the negative X component, and the pitch is calculated by taking the arcsin of the Y component. The following formula is used to calculate the tilt compensated vector.

hy = normHy * cos(roll) + normHx * sin(roll) * sin(pitch) - normHz * cos(pitch) * sin(roll)

hx = normHx * cos(pitch) + normHz * sin(pitch)

The heading in radians is then calculated by taking the arctan of the Y and X components of the tilt compensated vector. The declination angle (13 degrees for San Jose) is then added to the current heading. The heading in radians is then converted into degrees. The heading in degrees is then sent over Can Bus to be received by Master, Bluetooth, and Debug.

Testing & Technical Challenges

Compass

Initial Testing

Initial testing was done by connecting the magnetometer to the SJOne board and printing out the calculated heading over serial. By rotating the magnetometer, the current heading can be verified by using a real compass.

Testing on the car

The magnetometer was then installed on the car. Using the bluetooth app, the current heading can be displayed. The car was then successfully tested indoors. During the outdoor test runs, it was discovered that the compass loses accuracy when the car is on a slope. This was due to the lack of tilt compensation, because only the X and Y axis of the magnetometer are used to calculate heading.

A tilt compensation algorithm was then implemented using the accelerometer onboard the SJOne board. Again, the magnetometer was tested first off the car by using the serial console. The compass was tested by rotating and tilting and observing the calculated heading. After the tilt compensation was verified outside the car, it was again installed in the car. The car was tested by driving around campus. The tilt compensated compass worked as expected, although a small difference was noticed between calculated heading and actual heading. The observed difference is due to magnetic declination, the difference between magnetic and true north. The magnetic declination for San Jose, CA was determined to be 13 degrees. An offset of 13 degrees was added to the calculated heading.

After further testing with the car with the PCB installed, it was determined that the tilt compensation algorithm was not working correctly. The tilt compensation was disabled, and the car was tested without it. It was determined that the compass without tilt compensation works well enough, so the tilt compensation was disabled for the final build.

Ultrasonic sensors

Calibration

The MB1010 sensor calibrates itself when power is applied. To prevent improper calibration, it's important to have no objects blocking the sensors during power-up. When testing we elevated the front of the car to point the sensors upwards and out into open air where there were no obstacles. A similar procedure was used when testing the rear sensors as well. During outdoors testing we had to be mindful about turning on the car while not blocking sensors either.

Recalibration

According to the manufacturer the MB1010 requires recalibration when the operating voltage, temperature, or location changes. While these criteria are mostly constant during testing, they can fluctuate somewhat. Specifically this need manifested itself as a condition where after normal operation for some duration of time, a sensor begins to report the minimum distance (~14cm) regardless of what is in front of the sensor. This behavior persists until power is cycled, at which point recalibration occurs and normal operation resumes.

Our solution was to add a TPS2034 two-channel power switch to manually cycle the sensor power rails under software control. One channel was for the forward-facing sensors, another for the rear-facing sensors. To determine when recalibration is needed, the past history of sensor readings are scanned to see if any are stuck and are consistently reporting the same minimum value. If any are stuck the power is cycled using the TPS2034. This allowed the sensors to be recalibrated automatically during operation. In addition, during calibration a status signal is sent to

The TPS2034 is a two-rail switch and was used to control the front (3) and rear (1) sensors. In retrospect a better use would be the TPS2054 which has four independent outputs, such that individual sensors could be recalibrated without disturbing the other ones.

RS-232 testing

The MaxBotix LV-MaxSonar-EZ1 (P/N# MB1010) has several interfaces used to indicate the distance to an obstacle that it has sensed. One of the simplest is a RS-232 output which is enabled by grounding the BW pin or leaving it unconnected (floating). The output is logic-level compatible with RS-232 (where a logic '1' is 0V and a logic '0' is Vcc) but not voltage-level compatible. MaxBotix designed the RS-232 output like this to allow direct connection to a RS-232 compliant serial port, but it means the logic levels are inverted with respect to the LPC1758 which has no on-chip provisions for inverting the logic level. Therefore an inverter (such as the 74LVC1G04) is required between the TX output of the MB1010 and the LPC1758's UART RX input for proper operation.

Localization and Positioning (GPS)

Schedule

| Task # | Start Date | End Date | Task Description | Status | Actual End Date |

|---|---|---|---|---|---|

| 1 | 09/16/2016 | 09/22/2016 | Researched and decided upon the GPS module and Compass module. | Completed | 09/22/2016 |

| 2 | 9/23/2016 | 9/30/2016 | Ordered GPS module and compass module. | Completed | 09/30/2016 |

| 3 | 10/01/2016 | 10/14/2016 | Parse GPS data and format the data to be transmitted Test code to get compass reading information |

Completed | 10/04/2016 |

| 3 | 10/15/2016 | 10/25/2016 | Interface GPS module and compass module to SJOne board. | Completed | 10/19/2016 |

| 4 | 10/26/2016 | 10/30/2016 | Calibrating the compass module.Integration of GPS and compass module. Interfacing of GPS and compass module to Android. | Completed | 10/19/2016 |

| 5 | 11/01/2016 | 11/13/2016 | Integration with Master through CAN bus. | Completed | 10/19/2016 |

| 6 | 11/15/2016 | 12/10/2016 | Testing and calibrating with other modules. | Completed | 12/08/2016 |

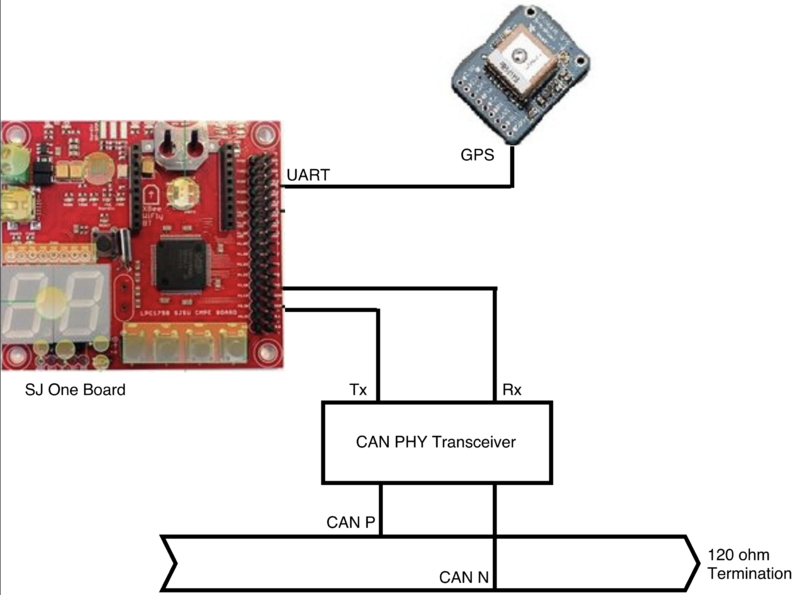

Design & Implementation

The GEO Controller is responsible for calculating/ providing the location which the car is currently at and target direction to the master controller and bluetooth. The GEO controller will receives the way-points from the Bluetooth Controller and calculates the target heading to the closest waypoint an. The Master Controller is still responsible for controlling the logic of forward, backward, left, and right to reach the final destination. We were able to receive data from GPS module at 10Hz and communicate at 38400bps through UART. We sent specific data packets to receive the GPS module to be able to read the $GPGGA( Global Positioning System Fix Data) string over the UART from the module.

Hardware Design

GPS module used in our project is Adafruit Ultimate GPS Breakout - 66 channel w/10 Hz updates - Version 3 and GPS external active antenna. We were able to configure this module at 10Hz and communicate at 38400bps through UART. The GPS module had 10Hz update rate with low current draw which helped power usage very low. The GPS module GPS can also be configured to operate and communicate at various speed though the provided Graphical User Interface. This module has got an on-board flash to store these configuration which us a built in data-logging capability.

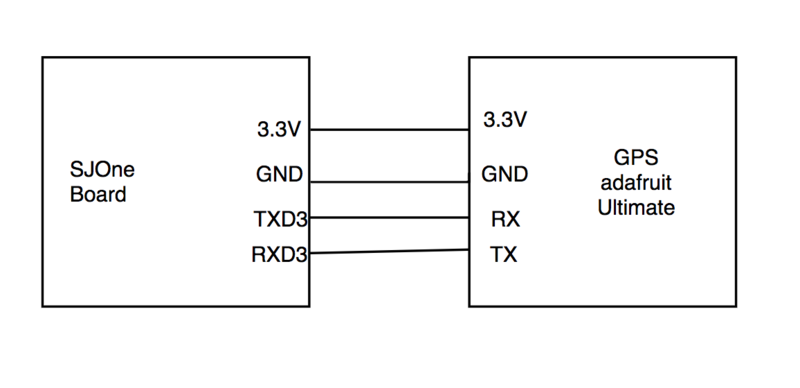

Hardware Interface

| Device | Port Source | Port Destination | Device |

|---|---|---|---|

| SJ One | 3v3 | Vin | Adafruit GPS |

| SJ One | GND | GND | Adafruit GPS |

| SJ One | TXD3 | RX | Adafruit GPS |

| SJ One | RXD3 | TX | Adafruit GPS |

Software Design

The GEO Controller is responsible for retrieving the data from GPS and parsing this information and calculate the needed values. After parsing the NMEA string, the current location is known and we can calculate the target value to the closest way point which has been received from bluetooth controller must be calculated to help the car move in the correct direction. When the correct heading is calculated, which target has been calculated we sent out the data over CAN communication to master and bluetooth controllers.

GPS Data Format

The Data that was retrieved from GPS is in NMEA 0183 format. NMEA is a combined electrical and data specification for communication between marine electronic devices such GPS receivers and many other types of instruments. The sting we received is in this format: $GPGGA,hhmmss.ss,llll.ll,a,yyyyy.yy,a,x,xx,x.x,x.x,M,x.x,M,x.x,xxxx*hh. Which each section describe an specific characteristic of the data. The following table shows format description of each substring within the received string from GPS module.

| Name | Example Data | Description |

|---|---|---|

| Sentence Identifier | $GPGGA | Global Positioning System Fix Data |

| Time | 170834 | 17:08:34 Z |

| Latitude | 4124.8963, N | 41d 24.8963' N or 41d 24' 54" N |

| Longitude | 08151.6838, W | 81d 51.6838' W or 81d 51' 41" W |

| Fix Quality | 1 | Data is from a GPS fix |

| # of Satellites | 05 | 5 Satellites are in view |

| Horizontal Dilution of Precision | 1.5 | Relative accuracy of horizontal position |

| Altitude | 170834 | 280.2 meters above mean sea level |

| Height of geoid above WGS84 ellipsoid | -34.0, M | -34.0 meters |

| Time since last DGPS update | blank | No last update |

| GGPS reference station id | blank | No station id |

| Checksum | *75 | Used by program to check for transmission errors |

System Flow Table

| Task Name | Purpose |

|---|---|

| Periodic 10Hz Callback |

|

| Periodic 100Hz Callback |

|

Algorithm

Finding the TARGET between two coordinates.

/*::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::*/

/*:: This function calculates heading based on the 2 coordinates :*/

/*::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::*/

double gps_heading(double lat1, double lon1, double lat2, double lon2){

double head = 0 , lon_difference = 0;

lat1 = (lat1 * PI)/ PI_DEGREES;

lon1 = (lon1 * PI)/ PI_DEGREES;

lat2 = (lat2 * PI)/ PI_DEGREES;

lon2 = (lon2 * PI)/ PI_DEGREES;

lon_difference = lon2 - lon1;

head = atan2((sin(lon_difference)*cos(lat2)), ((cos(lat1)*sin(lat2))-(sin(lat1)*cos(lat2)*cos(lon_difference)))) ;

head = (head * PI_DEGREES)/ PI;

if( head <= 0 )

head += 360;

return head;

}

Finding the distance between two coordinates.

/*::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::*/

/*:: This function calculates distance between the two coordinates in meters :*/

/*::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::*/

double distance(double lat1, double lon1, double lat2, double lon2) {

double theta, dist;

theta = lon1 - lon2;

dist = sin(deg2rad(lat1)) * sin(deg2rad(lat2)) + cos(deg2rad(lat1)) * cos(deg2rad(lat2)) * cos(deg2rad(theta));

dist = acos(dist);

dist = rad2deg(dist);

dist = dist * 60 * 1.1515;

dist = dist * 1609.344;

return (dist);

}

Testing & Technical Challenges

The GPS device should start transmitting NMEA sentences over the TX pin as soon as it is powered up, but the problem was that I wasn't able to retrieve data fast enough by sending out packages to the GPS module such as "$PMTK314,0,1,0,1,0,0,0,0,0,0,0,0,0,0,0,0,0,0,0*28" to turn ON the GGA first, which helped us exploring our other options to make commands that are capable changing the update rate and also put the GPS module in the stand by command. Adding an external antenna was helpful to get the fixed data faster and definitely having an external antenna helped making the processes much faster.

The most important part was that we tried writing a unit test for the GPS module and it took us awhile to actually write the test but the very nice part was that now the code and also the integration is much simpler and cleaner. Integrating with bluetooth and receiving data and also with the whole system in general became really easy after writing the unit test code which was able to go through the state machine and check the states and properly change and flow through the state machine.

Propulsion Systems and Speed Tracking (Motor Controller)

Schedule

| Task # | Start Date | End Date | Task Description | Status | Actual End Date |

|---|---|---|---|---|---|

| 1 | 9/14/2016 | 9/20/2016 | Assigned tasks to one another and strategized approach. | Completed | 9/20/2016 |

| 1 | 9/21/2016 | 9/27/2016 | Work with team leader to devise version control strategy. | Completed | 9/27/2016 |

| 2 | 9/28/2016 | 10/04/2016 | Started development of DBC and finalized hardware choices. | Completed | 10/04/2016 |

| 3 | 10/05/2016 | 10/19/2016 | Research what encoders and/or tachometers to use, help the team leader choose an RC car to purchase, and decide what motor driver to use | Completed | 10/22/2016 |

| 4 | 10/23/2016 | 10/27/2016 | Make the motors spin and the servo control the steering. Receive can signals and control the motor and steering servo. | Completed | 10/25/2016 |

| 5 | 10/26/2016 | 11/04/2016 | Validate and calibrate the motor controller and steering code. Receive the Tachometer and magnetic polarity strip. | Completed | 11/05/16 |

| 5 | 11/06/2016 | 11/11/2016 | * Merge motor_test/tach with master. * Reorganize code for readability. * Finalize and test speed feedback system. |

Completed | 11/11/2016 |

| 5 | 11/12/2016 | 11/18/2016 | validate the wheel speed control system and calibrate. | Completed | 11/18/2016 |

| 6 | 11/19/2016 | 11/25/2016 | Test with the rest of the group * Fine tune nominal speed. Add LCD to display debug information. |

Completed | 11/28/2016 |

| 7 | 11/29/2016 | 12/02/2016 | * Replace motor driver with higher amperage driver. * Adjust steering offset to reduce error. |

Completed | 12/04/2016 |

| 8 | 12/06/2016 | 12/09/2016 | Test with the rest of the group, and fix any minor issues that come up. * Finalize code and merge into master. |

In progress |

Design & Implementation

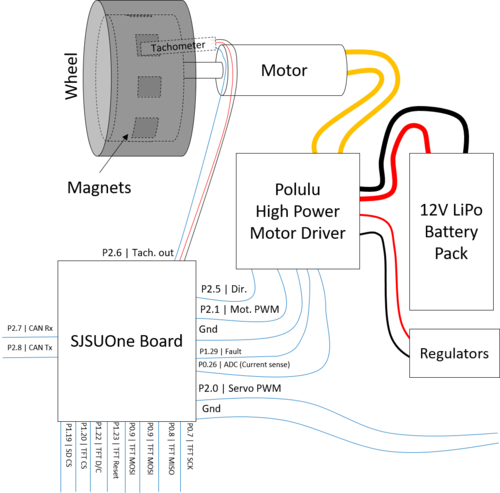

Hardware Design

The motor controller board takes charge of two main systems: motoring and steering.

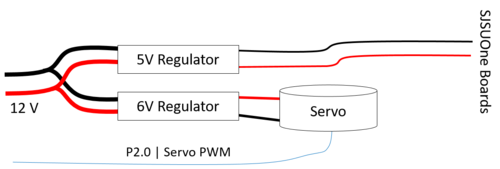

To accomplish motoring, a high power motor driver from Polulu is used to drive the RC car's motor. It takes a simple digital signal for direction and a PWM signal for speed. To help control speed accurately, a tachometer and a set of magnets in a wheel are used to feed back rotations per second (rps). For debugging, a TFT display was connected to the SJSUOne board and displayed tachometer readings versus commanded readings. The figure on the right shows how the SJSUOne board is connected to the display and the motor driver. In addition, the block diagram also shows power connections from the battery.

Steering controlled as simply as the motor. A single wire is needed to feed a PWM signal to the servo. The figure below the motor connections image shows how the servo is connected.

Hardware Interface

Motor

The interface to the motor consists of two sections: feedback and output. The feedback section involves connecting the SJSUOne board to the FAULT and Current sense pins. This allows the board to stop or slow down the motor if problems or overcurrent situations appear. Then the output section consists of a simple digital signal and a PWM signal. The simple digital output controls the direction of the motor: HIGH motors the car forward and LOW motors the car in reverse. To manipulate speed, the duty cycle of the PWM signal is changed according to a PI control algorithm in the SJSUOne board. In order to avoid overcurrent problems, the PWM signal is kept at a high frequency such as 20 kHz.

Tachometer

The tachometer provides information about wheel rotation speed by pulling the its output line low every time the tachometer passes over the south pole of a magnet.

Servo

Controlling the servo requires just one PWM signal. Instead of the duty cycle, the on-time of the signal determines how far the servo turns the car to the left or right. For the servo on this car, the range is 1.300 to 1.900 ms, where 1.5 ms means straight. With this time range, the best frequency for this signal would be 50 Hz. However, since the SJSUOne board provides only one PWM module, a software PWM module was implemented to produce the signal.

TFT Display

A board from Adafruit, the TFT display used for this project communicates with the SPI protocol. However, the board also provides a reset pin and an SD card, so there are a couple of extra pins to choose which device to connect to. The SD card port may be used to log debugging information. For drawing the actual characters, a library from Adafruit was imported.

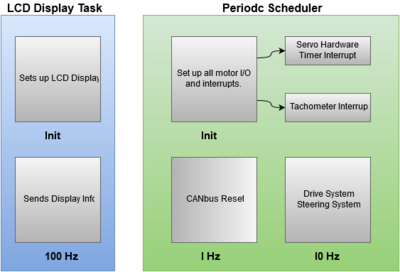

Software Design

Created Libraries

- Servo Driver (Uses a hardware timer attached to an interrupt to drives a servo at 50 HZ with 100 microseconds of resolution)

- Motor Controller (Runs the control loops that drive the main motor and steering)

- LCD Display Driver(Controls the LCD display. Most functions were imported from the Adafruit library for the device)

- Tachometer Driver (Sets-up/monitors an external interrupt and keeps track of the tachometer ticks)

All code on this SJSU-Oneboard software was separated into two running tasks, the Periodic Scheduler and the LCD Display task. The LCD Display was put into its own task due to the need for specific timing requirements that are randomized and large. Typically a custom delay system should be created and put into the periodic scheduler but the LDC display is a low priority objective and a separate task handles its requirements adequately. The periodic scheduler runs every other task on the system. The two subsystems of the periodic scheduler that run on different timing requirements are both the interrupts for the tachometer and the servo hardware timer. Both of these Interrupts are set as lower priority than the periodic scheduler interrupts and RTOS interrupts. This does causes a gap in the hardware timer's control signal for the servo, however the gap is not often enough to cause the servo issues. Furthermore the gap is outside the range of input to the servo so whenever the gap happens, the servo completely ignores it.

Implementation

Motor Control System

Using the 10 Hz periodic scheduler task with a counter, the Motor Control system runs every half a second. This amount of time was selected from the low resolution of eight tachometer ticks per rotation of the car's wheel. In general, the greater the resolution of your feedback in a closed loop system, the faster your control loop can run. Within the Control loop, a system similar to a PI(Proportion, Integral) system was used. When a command from the master controller is sent, that value will get multiplied by a constant and added with an offset. The offset is simply an incremented or decremented value that gets changed according to how far the motors actual speed is from its targeted speed. The Final value is then fed to the motors as a percentage to the PWM I/O that controls the motor's speed.

Servo Hardware Timer

The SJSU-One-Board's PWM controller can only be set to one frequency and with the Motor controller needing to be run at ultra-sonic frequencies, another method to control the servo was needed. To control a servo, a PWM signal running at 50 Hz is needed. Furthermore the positive portion of the PWM wave has to be timed to a specific microsecond value between 1000 microseconds and 2000 microseconds. The method to satisfy these requirements was to implement a hardware timer that triggers an interrupt every 100 microseconds. Inside of this interrupt, is a counter. At a count of zero, a GPIO is set to HIGH and then at a controlled count between 10 to 20, the value is set to LOW. Once the count hits 202, the count is reset.

Testing & Technical Challenges

Motor Driver control

Several times during testing, the SJSUOne board was powered up or reprogrammed while still connected to the motor driver, causing the motor to rev at full speed and destroy the motor driver. The first solution to avoid full speed upon board power up was to add a tri-state buffer between the output of the SJSUOne board and the motor driver. Later on, the team discovered that a single pull-down resistor on the line was sufficient to solve the issue. This taught the team that for future projects involving powered mechanical systems to always make sure the control line by default will keep the systems off, whether by pull-down resistors or tri-state buffers.

PWM accuracy

While testing servo control, the frequency of the generated PWM signal proved to be inaccurate. The generated signal would have a frequency 10 times greater than what is set in the program, leading to inaccurate on-times. The team soon found out that the problem was because of where the PWM object in the program was constructed. Initially, the PWM objects were created in the global scope, meaning the constructor would write to the registers before the main() function was entered. While this problem is not fully understood, it was solved by constructing the objects in init() functions, which were called after the main() function was entered. This shows that, for future drivers written for microcontrollers, driver behaviour would be much more well defined if all register manipulation happened in an init() member function rather than in a constructor. This way, client users do not have to worry about accidentally constructing driver objects in the global scope.

Master Control Systems

Schedule

| Task # | Start Date | End Date | Task Description | Status | Actual End Date |

|---|---|---|---|---|---|

| 1 | 9/14/2016 | 9/20/2016 | Assigned tasks to one another and strategized approach. | Complete | 9/20/2016 |

| 2 | 9/21/2016 | 9/27/2016 | Research different RC cars for the project. | Complete | 10/15/2016 |

| 3 | 10/16/2016 | 10/23/2016 | Implement Decision Tree for obstacle detection/autonomous car control. Decide on Message ID system over the CANBUS/Types of Data being Transmitted | Complete | 10/23/2016 |

| 3 | 10/24/2016 | 10/29/2016 | Program obstacle detection/autonomous car control algorithms | Complete | |

| 4 | 10/30/2016 | 11/06/2016 | Test RC car obstacle detection and autonomous control interfaced with Sensor Module over CAN | Complete | |

| 5 | 11/07/2016 | 11/13/2016 | Interface GPS module with Master Controller | Complete | |

| 6 | 11/14/2016 | 11/20/2016 | Interface Android/Bluetooth module with Master Controller.Test Waypoint System | Complete | |

| 7 | 11/21/2016 | 11/27/2016 | Debug any issues with Master controller and other modules | Complete | |

| 8 | 11/28/2016 | 12/12/2016 | Final debug/testing of RC CAR | Complete |

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

GitLab

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.