F16: Spartan and Furious

Contents

- 1 Project Title

- 2 Abstract

- 3 Objectives & Introduction

- 4 Team Members & Responsibilities

- 5 Schedule

- 6 Parts List & Cost

- 7 Car Framework and Components

- 8 CAN BUS Design

- 9 ECUs

- 10 Motor Controller

- 11 Android and Communication Bridge

- 12 Geographical Controller

- 13 Sensor and I/O

- 14 Master Controller

- 15 Conclusion

- 16 References

Project Title

Android Application controlled Self-Driving Car using CAN bus.

Abstract

This section should be a couple lines to describe what your project does.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

- Android and Communication Bridge:

- Geographical Controller:

- Master Controller:

- Motor Controller

- Sensor and I/O Controller:

Schedule

Legend:

Motor Controller , Master Controller , Android Controller, Geo Controller, Sensor and I/O Controller , Team Goal

| Week# | Date | Task | Actual | Status |

|---|---|---|---|---|

| 1 | 9/17/2016 |

|

|

Complete. |

| 2 | 9/24/2016 |

|

|

Complete |

| 3 | 10/01/2016 |

|

|

Complete |

| 4 | 10/08/2016 |

|

|

Complete |

| 5 | 10/15/2016 |

|

|

Complete |

| 6 | 10/22/2016 |

|

|

Complete. |

| 7 | 10/29/2016 |

|

|

Complete. |

| 8 | 11/05/2016 |

|

Integration and Testing completed for the first demo. | Complete. |

| 9 | 11/12/2016 |

|

|

Complete. |

| 10 | 11/19/2016 |

|

|

Complete |

| 11 | 11/26/2016 |

|

|

Complete |

| 12 | 12/03/2016 |

|

|

Complete |

| 13 | 12/10/2016 |

|

In Progress |

Parts List & Cost

| Item# | Part Description | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | SJ One Board (LPC 1758) | From Preet | 6 | $480 |

| 2 | RC Car | Sheldon Hobbyist | 1 | $309.99 |

| 3 | Accelerometer/Magnetometer LSM303 | Adafruit | 2 | $40.00 |

| 4 | Bluetooth Module | From Preet | 2 | $0 |

| 5 | CAN Transceivers | From Microchip. | 10 | $0 (Free Samples) |

| 6 | Battery Pack | From Sheldon Hobbist | 1 | $49.99 |

| 7 | Ultra Sonic Sensor | From Maxbotix | 5 | $91.15 (at 40% student discount) |

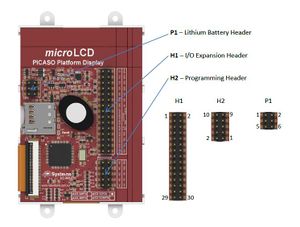

| 8 | LCD Display | From Digikey | 1 | $94.21 |

| 9 | GPS Module | From Adafruit | 1 | $43.34 |

| 10 | General Components | From HSC electronics | - | $83.17 |

| 11 | DC Current Sensor | From Adafruit | 1 | $14.39 |

| 12 | PCB | From Amazon | 1 | $10.66 |

| 13 | Corrugated Sheet for chasis | From Home Depot | 1 | $6.74 |

Car Framework and Components

Stampede 4X4 is built on the advanced shaft-driven 4WD system and innovative modular design of the Slash 4X4. The chassis fully integrates the electronics and battery compartment for an efficient and compact layout, and maintains the high center ground clearance. It uses just three gear meshes to drive all four wheels, eliminating the need for a multi-gear transmission. The highly efficient drive train spins effortlessly on rubber-sealed ball bearings, and is integrated seamlessly into the unique chassis for optimum performance and easy maintenance. A single center driveshaft connects the front and rear drive assemblies for maximum power transfer. To harness the torque of the Titan 12-turn motor, Traxxas bolted in the high-performance, waterproof XL-5 electronic speed control. EZ-Set one-button setup makes it easy to adjust or change profiles.

CAN BUS Design

CAN 11-bit ID Format

| SRC | DST | MSG |

|---|---|---|

| 3 bits (10-8) | 4 bits (7-4) | 4 bits (3-0) |

Controller ID Table

| Controller ID | Controller Type |

|---|---|

| 0 | System Command |

| 1 | Master Controller |

| 2 | Sensor Controller |

| 3 | BLE Controller |

| 4 | Geo Controller |

| 5 | Motor Controller |

| 5 | I/O Controller |

CAN Communication Table

| Sr. No | Message ID | Message function | Message Data | To |

|---|---|---|---|---|

| System Commands | ||||

| 1 | 10 | System communication command | 0 - Communication Stop 1 - Communication Start |

Master |

| Master Controller Commands | ||||

| 2 | 100 | Master System Command for the all modules to start or stop processing | 0 - System Stop 1 - System Start |

BLE, Geo, I/O, Motor, Sensor |

| 3 | 151 | Steer and Drive command for the Motor module | Motor, I/O | |

| 4 | 162 | Display the active state of each module and Can bus utilization | BLE, I/O | |

| Sensor Controller Commands | ||||

| 5 | 211 | Obstacle Data | Master, I/O | |

| 6 | 214 | Heartbeat | Master | |

| BLE Controller Commands | ||||

| 7 | 314 | Heartbeat | Master | |

| 8 | 341 | Checkpoints | Geo | |

| 9 | 361 | Start location of the car | I/O | |

| 10 | 362 | End location of the car | I/O | |

| Geo Controller Commands | ||||

| 11 | 411 | Calculated Direction for the car | Master | |

| 12 | 413 | Destination Reached flag | Master, I/O | |

| 13 | 414 | Heartbeat | Master | |

| 14 | 431 | Start point | Master | |

| 15 | 461 | Compass data | I/O | |

| Motor Controller Commands | ||||

| 16 | 514 | Heartbeat | Master | |

| 17 | 561 | Car speed | I/O | |

| I/O Controller Commands | ||||

| 18 | 614 | Heartbeat | Master | |

DBC File

ECUs

Motor Controller

Group Members

Design & Implementation

The motor controller is responsible for generating the driving and steering action of the car. For this purpose, we have two types motors viz DC motor for driving and Servo motor which is used for changing directions of the car. The motor controller is also interfaced with a speed encoder for generating a feedback mechanism to automatically control and monitor the speed of the car. Our car came equipped with a Servo motor and brushed DC motor which is connected Electronic Speed Control (ESC).

Hardware Design

- Hardware Specifications

- 1. DC Motor

Our car came with Titan 12T 550 brushed motor and waterproof ESC. The ESC drives the DC motor based on the Pulse Width modulation (PWM) applied to it. The power supply required for this motor is 8.4 V. Maximum speed of upto 30mph can be achieved. The rotational speed is proportional to the EMF generated in its coil and the torque is proportional to the current.The main connection pins driving the motor are VCC,GND and the Control pin (PWM). The pin P2.1 of SJ-one board is connected to supply the required PWM to the motor. The basic working principle of DC motor is illustrated in the following figure : Since the preprogrammed controller has to be replaced by using our design ,the DC motor is then tested with Digital Oscilloscope for getting the frequency of operation and equivalent PWM values for full throttle condition in the forward as well as backward condition. It was observed from the waveform that the frequency of operation is 100Hz. The range of operational duty cycle is 10% to 20% with 15% being the neutral value or the stop condition. In order to accelerate the car a PWM value in the range of 15.6%-20.0% is applied. The 15.6 is the minimum pickup PWM that should be supplied in order to get the car moving at full load.

- 2. Servo Motor

The servomotor used in the car is #2056 a waterproof all weather-action and double the steering power as compared to standard servos. The servo motor is responsible for controlling the steering action of right or left by applying a suitable PWM pulse. The servo motor can be driven with 3.3 V power supply. The pin P2.0 of SJ-one board is connected to supply the required PWM to the motor. After testing the servo motor, we found that the frequency of operation is 100Hz and the operational duty cycle range is 10.0%-20.0% with 15% being the neutral value. For a full right deflection, we provide input PWM pulse ranging from 15.0-20.0% and for full deflection to the left we apply 10.0-15.0% of PWM.

- 3. Speed Sensor

The speed feedback is monitored through the speed encoder which works on the Hall-effect principle. The Hall-effect speed sensor works as a transducer whose output voltage varies in response to the magnetic field. The sensor is mounted on the Spur gear instead of the wheel. The sensor would detect the rotation of axle. The motor controller would detect whenever the magnet is aligned with the sensor. This would generate a pulse. The pulse is detected in the form of rising-edge interrupt. This gives the wheel rotation count. The wheel rotates for every 1/4th rotation of the spur gear. The rotation count can then be converted to rpm to calculate the speed of the car.

Hardware Interface

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

The motor controller receives all its signals from Master controller from the CAN bus. The motor controller receives the steer and drive command from the master. The motor controller receives the System start command which boots and decodes further drive signals to the motor controller. Upon receiving the drive command the motor controller decodes the steering action. Upon receiving suitable data about the obstacle from sensor controller the master controller relays appropriate steering action. To achieve better performance in steering, the turn is categorized as FULL and HALF. This gives better precision in turning.

- Speed Regulation:

Upon detection of uphill the pulse received from the speed encoder reduces. This is detected and the motor feedback is designed such that the speed is increased by providing higher value of PWM value to drive the DC motor. Similarly, for downhill the pulse count received increases which is detected by the speed encoder and the speed is reduced by applying reduced PWM.

Testing & Technical Challenges

- Wheel Alignment Error

Though the neutral value of PWM is 15% at which the servo is supposed to be aligned straight. In practice, however when we tested the car for straight run slight deflection towards right was observed when the PWM pulse width was set to 15.0 %. Thus, to correct this, we provided correction value of -0.98 giving a resultant PWM pulse width of 14.02%. Thus, we fixed the wheel alignment and obtained the desired straight path traversal.

Android and Communication Bridge

Group Members

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Geographical Controller

Group Members

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Sensor and I/O

Group Members

SENSOR

Design & Implementation

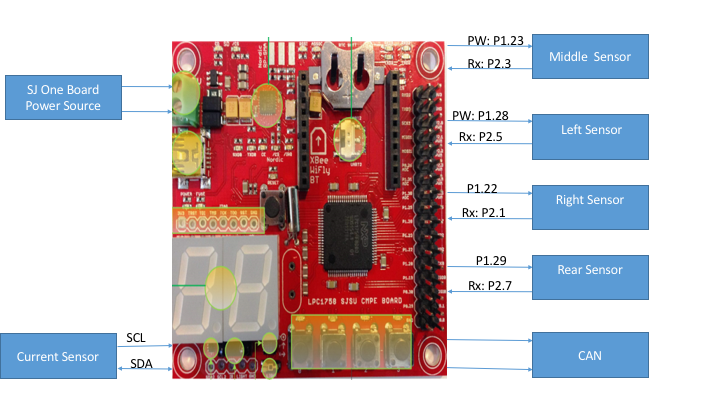

We are using Maxbotix LV-EZ Ultrasonic sensors (MB1000). The configuration of the sensor is 3:1 that is three sensors in the front separated by 60 degrees apart and one in the rear. The ultrasonic sensors mounted on the car are used to detect the obstacle on its route. These sensors are connected to the SJOne board and work with a 5.0V power supply. The SJ One board then sends the sensors message with the help of CAN bus.

The pin description of Maxbotix LV-EZ Ultrasonic sensors is as follows:

Pin 1-BW- Unused, leave disconnected or connect to circuit common ground.

Pin 2-PW- Digital Proximity Logic, outputs a High/Low logic voltage level depending on proximity detection. High means an object has been detected in the detection zone. Low means no object is present. There is a ~2.5 second delay on acquiring targets and a ~1.5 second delay for releasing a target once detected. This hysteresis improves sensor reliability.

Pin 3-AN- Unused, leave disconnected or connect to circuit common ground.

Pin 4-RX- This pin is internally pulled high. The LV-ProxSonar-EZ will continually measure proximity information and output send to data. Leave the pin disconnected or hold the pin high for proximity information. Hold low to stop all sensor activity and reset acquire timers. Upon returning to a high state, the sensor will initiate a calibration sequence.

Pin 5-TX- The TX output delivers asynchronous serial with an RS232 format, except voltages are 0-Vcc

Pin 6-+5V- Vcc – Operates on 2.5V - 5.5V. Recommended current capability of 3mA for 5V, and 2mA for 3V.

Pin 7-GND- Return for the DC power supply. GND (& Vcc) must be ripple and noise free for best operation.

Hardware Design

The ultrasonic sensor is interfaced through GPIO, each sensor requires 2 pins, PW and RX, in addition to the two pins required for powering up the sensor. The PW pins for each sensor is configured as an interrupt.

The following table and figure shows the pin connections for all the sensors to the SJOne board.

| Sr.No | SJOne Pin Number | Sensor Pin Function |

|---|---|---|

| 1 | P1.23 | Middle Sensor PW |

| 2 | P 2.3 | Middle Sensor Rx |

| 3 | P 1.28 | Left Sensor PW |

| 4 | P 2.5 | Left Sensor Rx |

| 5 | P1.22 | Right Sensor PW |

| 6 | P 1.29 | Rear Sensor Pw |

| 7 | P 2.7 | Rear Sensor Rx |

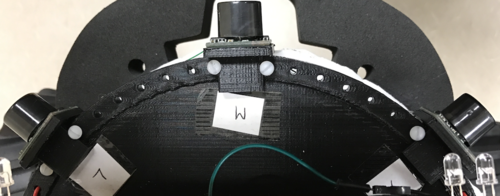

The figure below shows the design for the 3D mount for the front sensors.

Ultrasonic Sensor

There are three ultrasonic sensors for the front of the car positioned at different angles to provide a wide ultrasonic "vision" for the car. The mount for the sensors was 3D printed such that we have the flexibility to change the angle of the sensor at a later stage when debugging the sensor.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

The readings from the sensor is taken in the form of PWM signals with the help of interrupts. The following steps should be performed to take readings and calculating distance from the sensor

1) Configure the PW pin of sensor as input.

2) Configure RX pin of the sensor as output and set it high.

3) Enable the Rising and the Falling edge interrupt on the PW pin of the sensor.

4) Start timer at the rising edge of the interrupt (time T1).

5) At falling Edge of the interrupt stop the timer (time T2).

6) The distance of the obstacle is = (T2-T1)/147 inches.

7) Apply average filter. That is take 3 readings of each sensor and perform average of it.

8) Send this average value in a 10Hz task on CAN bus to Master and IO controller.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

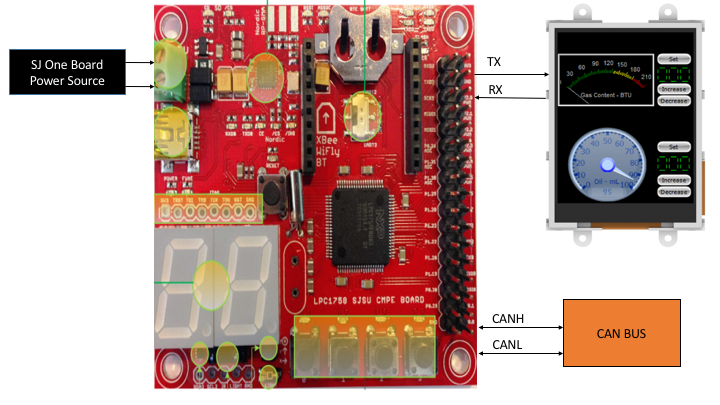

I/O

Design & Implementation

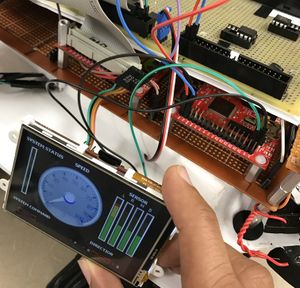

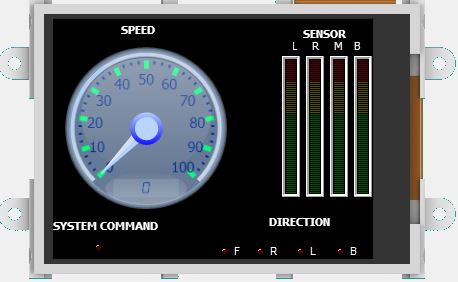

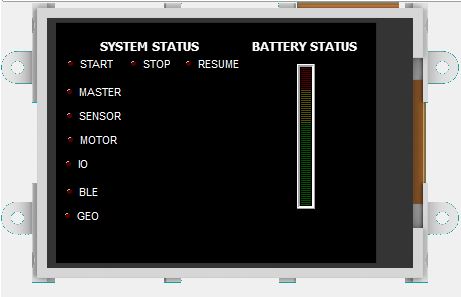

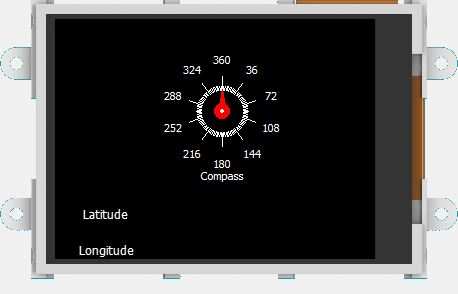

The IO section for the car consists of two main components, an LCD screen and LED indicators.

IO is integral to troubleshooting the working of the car. The team first decided upon the various important indicators that would be needed to troubleshoot the working of the car and then decided to translate them into either LED indicators or LCD screen elements. The table below summarizes the features for IO and which IO element was used to represent them on the car.

IO is integral to troubleshooting the working of the car. The team first decided upon the various important indicators that would be needed to troubleshoot the working of the car and then decided to translate them into either LED indicators or LCD screen elements. The table below summarizes the features for IO and which IO element was used to represent them on the car.

| Sr.No | LCD Element | Sensor Pin Function | LED Element Present |

|---|---|---|---|

| 1 | System Command (Start, Stop Resume) | An on screen LED that turns off/on for each command | Yes |

| 2 | Right Turn | An on screen LED that turns off/on | Yes |

| 3 | Left Turn | An on screen LED that turns off/on | Yes |

| 4 | Brake | An on screen LED that turns off/on | Yes |

| 5 | Forward | An on screen LED that turns off/on | Yes |

| 6 | Reverse | An on screen LED that turns off/on | Yes |

| 7 | Right Sensor | Gauge | No |

| 8 | Left Sensor | Gauge | No |

| 9 | Middle Sensor | Gauge | No |

| 10 | Rear Sensor | An on screen LED that turns off/on | Yes |

| 11 | System Status (Heatbeat) | Gauge | No |

| 12 | Speed. | Meter. | No |

| 13 | Battery Indicator | Gauge | No |

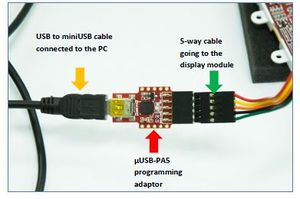

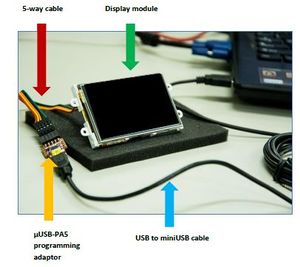

Hardware Interface

The hardware interface for the LCD is through UART for pins it is through GPIO. LCD Hardware interface: In order to communicate with the LCD we used UART3 ports on the SJOne board.

Software Design

Master Controller

Group Members

Introduction and Responsibilities

Master controller is the central processing unit of the car.

All the decisions are taken by the master module. Some of the major responsibilities of the master module are:

1) Obstacle avoidance :- Takes the sensor values & decides upon the turn to be taken by the motor.

2) GPS : Depending upon the GPS coordinates sent by the geo module decides about the turn and the speed that should be sent to the motor.

It also receives encoder data (speed) from motor module as a feedback to control the speed.

Hardware Design

- Interface of CAN Bus with six SJ-One controller boards on PCB was designed.

- Ribbon Cables were used instead of individual jumper wires to assist in designing less complex circuit.

Software Design

The software design of master controller is such that there are two modes for the car:

Free Run mode

• For switching to free run mode, the “FREE RUN” button needs to be selected from the app.

• After the free run mode is selected, master controller will send SYSTEM_CMD= START command to all of the modules, which notifies them that the Bluetooth communication via app has been initiated.

• As per the sensor data, the movement of the car is decided by the master controller.

• The following table depicts the motor command send by master to the motor controller as per the sensor values.

| Sr no | Left sensor value | Middle sensor value | Right sensor value | Critical value | Motor Command |

|---|---|---|---|---|---|

| 0 | 0 | 0 | 0 | 0 | STRAIGHT |

| 1 | 0 | 0 | 1 | 0 | HALF RIGHT |

| 2 | 0 | 1 | 0 | 0 | LEFT |

| 3 | 0 | 1 | 1 | 0 | RIGHT |

| 4 | 1 | 0 | 0 | 0 | HALF LEFT |

| 5 | 1 | 0 | 1 | 0 | STRAIGHT |

| 6 | 1 | 1 | 0 | 0 | LEFT |

| 7 | 1 | 1 | 1 | 0 | STOP |

| 8 | X | X | X | 1 | STOP |

• When STOP button is selected from the app,the BLE will advise the same to master controller and master will send SYSTEM_CMD= STOP to all the modules. This stop command notifies them that the Bluetooth communication via app has been deactivated.

GPS mode

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.