Difference between revisions of "F16: AutoNav"

Proj user16 (talk | contribs) (→Geographical Controller Hardware Design Components) |

Proj user16 (talk | contribs) (→Geographical Controller Hardware Design Components) |

||

| Line 961: | Line 961: | ||

We chose this part because it provided the base functionality we needed along with many other functions that would be fun to play with and try to include in the project. The antennae options and voltage regulator were also very enticing. | We chose this part because it provided the base functionality we needed along with many other functions that would be fun to play with and try to include in the project. The antennae options and voltage regulator were also very enticing. | ||

| − | We get raw GPS "NMEA sentence" output from module. The most important NMEA sentences include the GGA which provides the current Fix data, the RMC which provides the minimum gps sentences information, and the GSA which provides the Satellite status data. We are filtering the data for GGA (Time, Position and Fix data), which will look similar to: | + | We get raw GPS "NMEA sentence" output from module. The most important NMEA sentences include the GGA which provides the current Fix data, the RMC which provides the minimum gps sentences information, and the GSA which provides the Satellite status data. We are filtering the data for GGA (Time, Position and Fix type data), which will look similar to: |

$GPGGA,123519,4807.038,N,01131.000,E,1,08,0.9,545.4,M,46.9,M,,*47 | $GPGGA,123519,4807.038,N,01131.000,E,1,08,0.9,545.4,M,46.9,M,,*47 | ||

Revision as of 01:19, 19 December 2016

Contents

- 1 Project Title

- 2 Abstract

- 3 Objectives & Introduction

- 4 Team Members & Responsibilities

- 5 Schedule

- 6 Parts List & Cost

- 7 DBC File Implementation

- 8 Design & Implementation

- 9 Sensor Controller

- 10 Motor & I/O Controller

- 11 Bluetooth and Bridge(Android) Connections

- 12 Geographical Controller

- 13 Master Controller

- 14 Testing & Technical Challenges

- 15 Conclusion

- 16 References

Project Title

- Autonomous RC Car

Abstract

This project report describes an attempt to develop an autonomous RC car which navigates from a source point to destination avoiding any obstacles in between. The project was divided into five modules namely Motor & Input/output Controller, Sensor Controller, Geo Controller, Communication Bridge & Android Controller and Master Controller, each performing specific set of tasks. Each of the five modules were established using SJOne Boards. Communication between all the five modules was established using CAN Bus.

- Motor & I/O Controller - This controller was responsible for driving Brushless DC Motor interfaced through ESC, driving the stepper motor for steering and displaying the status of the RC car (speed, obstacle distance etc.) on the LCD.

- Sensor Controller - This controller was responsible for obstacle detection and avoidance, interfacing done with Ultrasonic Ping Sensors.

- Geo Controller - This controller focused on providing orientation (heading and bearing) and navigation route to the car.

- Communication Bridge & Android Controller - Co-ordinates for navigation were provided by this controller using an android application. Communication was established via Bluetooth.

- Master Controller - This controller was responsible for collecting the data from all the controllers, develop and implement obstacle avoidance algorithm to guide the car towards the final destination.

Objectives & Introduction

The main objectives of this project include:

- To develop an autonomous RC Car.

- To navigate from a set source to destination.

- To avoid any obstacles in between.

- To establish all communication between controllers via CAN bus.

The following peripherals of LPC 1758 were used to establish communications:

- CAN Peripheral: Communicate between all the controllers on a common CAN bus.

- UART Peripheral: Communicate between GEO Controller and GPS module, Bluetooth controller and Bluetooth module.

- GPIO: Communicate between sensors and sensor controller.

- PWM: Vary the speed of Brushless DC motor and Stepper motor via ESC interfaced through Motor Controller.

The block diagram below gives an overview of the various peripherals used:

Team Members & Responsibilities

Sensor Controller:

- Vishwanath Balakuntla Ramesh

Motor & I/O Controller:

- Sameer Saran

- Jaswanth Bhimanapalli

Bluetooth (Communication Bridge) & Android Controller:

- Sucharitha

- Karthikeya Rao G V

Geographical Controller:

- Arpita Ramanath

- Veena Manasa Kanakamalla

Master Controller:

- Ajai Krishna Velayutham

- Goutam Madhukeshwar Hegde

Schedule

Consolidated Team Schedule

| SI No. | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 09/13/2016 | 09/27/2016 |

|

Completed | 09/26/2016 |

| 2 | 09/27/2016 | 10/11/2016 |

|

Completed | 10/11/2016 |

| 3 | 10/12/2016 | 10/18/2016 |

|

Completed | 10/20/2016 |

| 4 | 10/19/2016 | 10/30/2016 |

|

Completed | 11/01/2016 |

| 5 | 10/31/2016 | 11/08/2016 |

|

Completed | 11/12/2016 |

| 6 | 11/09/2016 | 11/27/2016 |

|

Completed | 11/29/2016 |

| 7 | 11/27/2016 | 12/15/2016 |

|

In Progress |

Parts List & Cost

| Item# | Part Description | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | RChobby Explosion | 1 | $190 |

| 2 | RC Car Battery | Amazon | 1 | $27.29 |

| 3 | CAN Transceiver | Texas Instruments | 15 | Free |

| 4 | M-F,F-F,M-M Jumper Wires | Amazon | 120 | 7.97 |

| 5 | Printed Circuit Boards | Amazon | 1 | $9.72 |

| 6 | Ultrasonic Parallax Ping Sensor | Fry's Electronics | 3 | $98.85 |

| 7 | 9 DOF Razor IMU module | SparkFun | 1 | $74.95 |

| 8 | Bluetooth Module | Amazon | 1 | $9.99 |

| 9 | GPS Sensor | Adafruit | 1 | $44.38 |

| 10 | Black/White line detection sensor - RPM sensor | Amazon | 1 | $10.10 |

| 11 | SJOne Boards | From Preet | 5 | $400 |

| 12 | LCD | 4D systems | 1 | $111 |

DBC File Implementation

DBC files are widely used to define the system of CAN messages and their constituent signals. This allows CAN data to be accessed in terms of human-usable signal values, with different data types and scaling, instead of just raw message bytes. Below is the DBC file that we implemented in our project.

VERSION "" NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_ BS_: BU_: DRIVER BLUETOOTH SENSOR MOTOR GEO BO_ 100 KILL_SWITCH: 1 DRIVER SG_ killSwitch : 0|1@1+ (1,0) [0|0] "Stop=1" MOTOR BO_ 110 STOP_CMD: 1 BLUETOOTH SG_ BLUETOOTH_STOP_CMD_signal : 0|1@1+ (1,0) [0|0] "Stop=1" DRIVER BO_ 120 MOTOR_SYNC: 1 MOTOR SG_ Motor_Sync : 0|1@1+ (1,0) [0|0] "MotorSync=1" DRIVER BO_ 130 GEO_SYNC: 1 GEO SG_ Geo_sync_cmd : 0|1@1+ (1,0) [0|0] "GeoSync=1" DRIVER BO_ 140 BLUETOOTH_SYNC_CMD: 1 BLUETOOTH SG_ BLUETOOTH_SYNC_CMD_signal : 0|1@1+ (1,0) [0|0] "BluetoothSync=1" DRIVER BO_ 150 SENSOR_SYNC: 1 SENSOR SG_ Sensor_Sync : 0|1@1+ (1,0) [0|0] "SensorSync=1" DRIVER,MOTOR,BLUETOOTH BO_ 160 ERROR_COMM_DRIVER: 1 DRIVER SG_ Sync_Miss_Info : 0|8@1+ (1,0) [0|0] "ErrorMsgType" MOTOR BO_ 170 DRIVER_SYNC_ACK: 1 DRIVER SG_ Sync_Miss_Info : 0|1@1+ (1,0) [0|0] "DriverSync=1" MOTOR,BLUETOOTH,SENSOR,GEO BO_ 180 MOTOR_CONTROL: 2 DRIVER SG_ steer : 0|8@1+ (1,0) [0|0] "DirectionType" MOTOR SG_ speed : 8|8@1+ (1,0) [0|0] "SpeedType" MOTOR BO_ 181 MOTOR_RPS: 2 MOTOR SG_ Rps_Sensor : 0|8@1+ (1,0) [0|0] "RotationsPerSecondENum" DRIVER,BLUETOOTH SG_ Rps_Value : 8|8@1+ (1,0) [0|0] "RotationsPerSecondValue" BLUETOOTH,DRIVER BO_ 190 SENSOR_SONAR: 5 SENSOR SG_ Sensor_Sonar_Front : 0|8@1+ (1,0) [0|0] "FrontDistance" DRIVER,MOTOR,BLUETOOTH SG_ Sensor_Sonar_FrontRight : 8|8@1+ (1,0) [0|0] "FRightDistance" DRIVER,MOTOR,BLUETOOTH SG_ Sensor_Sonar_FrontLeft : 16|8@1+ (1,0) [0|0] "FLeftDistance" DRIVER,MOTOR,BLUETOOTH SG_ Sensor_Sonar_Back : 24|8@1+ (1,0) [0|0] "BackDistance" DRIVER,MOTOR,BLUETOOTH BO_ 200 GEO_SEND_LOCATION: 8 GEO SG_ Geo_latitude : 0|32@1+ (0.000001,-90.000000) [-90|90] "latitude" DRIVER,BLUETOOTH,MOTOR SG_ Geo_longitude : 32|32@1+ (0.000001,-180.000000) [-180|180] "longitude" DRIVER,BLUETOOTH,MOTOR BO_ 210 GEO_SEND_HD_BR: 8 GEO SG_ Geo_heading : 0|29@1+ (0.000001,0) [0|360] "" DRIVER,MOTOR SG_ Geo_bearing : 29|29@1+ (0.000001,0) [0|360] "" DRIVER,MOTOR BO_ 220 NAVIGATION_WAYPOINT: 2 BLUETOOTH SG_ Bluetooth_CurrWaypoint : 0|5@1+ (1,0) [0|0] "CurrentWaypointNumber" DRIVER,GEO SG_ Bluetooth_NumWaypoint : 5|5@1+ (1,0) [0|0] "NumberOfWaypoints" DRIVER,GEO BO_ 250 LATITUDE_LONGITUDE: 8 BLUETOOTH SG_ Bluetooth_latitude : 0|32@1+ (0.000001,-90.000000) [-90|90] "latitude" DRIVER,GEO SG_ Bluetooth_longitude : 32|32@1+ (0.000001,-180.000000) [-180|180] "longitude" DRIVER,GEO BO_ 230 START_CMD: 1 BLUETOOTH SG_ BLUETOOTH_START_CMD_signal : 0|8@1+ (1,0) [0|0] "" DRIVER BO_ 240 SENSOR_BATTERY: 8 SENSOR SG_ Sensor_Battery_Voltage : 0|8@1+ (0.1,0) [0|0] "Volts" DRIVER,MOTOR,BLUETOOTH SG_ Sensor_Battery_SOC : 8|10@1+ (0.1,0) [0|0] "Percent" DRIVER,MOTOR,BLUETOOTH SG_ Sensor_Light : 18|10@1+ (0.1,0) [0|0] "LightPercentValue" DRIVER,MOTOR,BLUETOOTH SG_ Sensor_Tilt_X : 28|12@1+ (0.1,0) [0|0] "TiltValueX" DRIVER,MOTOR,BLUETOOTH SG_ Sensor_Tilt_Y : 40|12@1+ (0.1,0) [0|0] "TiltValueY" DRIVER,MOTOR,BLUETOOTH BO_ 500 DRIVER_TEST: 1 DRIVER SG_ Driver_Test_Msg : 0|8@1+ (1,0) [0|0] "" MOTOR,GEO,SENSOR,BLUETOOTH BO_ 600 MOTOR_TEST: 1 MOTOR SG_ Motor_Test_Msg : 0|8@1+ (1,0) [0|0] "" DRIVER,GEO,SENSOR,BLUETOOTH BO_ 700 SENSOR_TEST: 1 SENSOR SG_ Sensor_Test_Msg : 0|8@1+ (1,0) [0|0] "" DRIVER,MOTOR,GEO,BLUETOOTH BO_ 800 GEO_TEST: 1 GEO SG_ Geo_Test_Msg : 0|8@1+ (1,0) [0|0] "" DRIVER,MOTOR,SENSOR,BLUETOOTH BO_ 900 BLUETOOTH_TEST: 1 BLUETOOTH SG_ Bluetooth_Test_Msg : 0|8@1+ (1,0) [0|0] "" DRIVER,MOTOR,GEO,SENSOR CM_ BU_ DRIVER "The DRIVER controller driving the car"; CM_ BU_ MOTOR "The motor controller of the car"; CM_ BU_ SENSOR "The sensor controller of the car"; CM_ BU_ GEO "The geo controller of the car"; CM_ BU_ BLUETOOTH "The bridge controller of the car"; CM_ BO_ 100 "Sync message used to synchronize the controllers"; BA_DEF_ "BusType" STRING ; BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; BA_DEF_ SG_ "FieldType" STRING ; BA_DEF_DEF_ "BusType" "CAN"; BA_DEF_DEF_ "FieldType" ""; BA_DEF_DEF_ "GenMsgCycleTime" 0; BA_ "GenMsgCycleTime" BO_ 500 10; BA_ "FieldType" SG_ 180 steer "steer"; BA_ "FieldType" SG_ 180 speed "speed"; BA_ "FieldType" SG_ 181 Rps_Sensor "Rps_Sensor"; BA_ "FieldType" SG_ 190 Sensor_Sonar_Front "Sensor_Sonar_Front"; BA_ "FieldType" SG_ 190 Sensor_Sonar_FrontRight "Sensor_Sonar_FrontRight"; BA_ "FieldType" SG_ 190 Sensor_Sonar_FrontLeft "Sensor_Sonar_FrontLeft"; BA_ "FieldType" SG_ 190 Sensor_Sonar_Back "Sensor_Sonar_Back"; VAL_ 190 Sensor_Sonar_Front 3 "far_f" 2 "mid_f" 1 "near_f" 0 "danger_f" ; VAL_ 190 Sensor_Sonar_FrontRight 2 "far_fr" 1 "mid_fr" 0 "near_fr" ; VAL_ 190 Sensor_Sonar_FrontLeft 2 "far_fl" 1 "mid_fl" 0 "near_fl" ; VAL_ 190 Sensor_Sonar_Back 2 "far_b" 1 "mid_b" 0 "near_b" ; VAL_ 180 steer 4 "right" 3 "sright" 2 "sleft" 1 "left" 0 "straight" ; VAL_ 180 speed 4 "brake" 3 "reverse" 2 "normal" 1 "slow" 0 "stop" ; VAL_ 181 Rps_Sensor 2 "high" 1 "equal" 0 "low" ;

Design & Implementation

Please refer to the system block diagram below:

Description

Assuming the car would be given the necessary connections and be powered up to navigate, we would give the first signal to start the car from the Bluetooth device by sending a start signal of "1". Once the Start signal is received by the Master controller, it would receive the signals from the sensors and the GPS as well. Based on the data from all these systems, Master controller decides the command to be given to the Motor controller. Motor on receiving the instructions from the Master would move in a particular direction suggested by Master. Motor would also revert the path in which it is going, RPM values to Master, Bluetooth and LCD display over the CAN. Meanwhile the Bluetooth would be fetching the messages from the CAN and would filter out on the messages by their ID's and later send the required signals such as GPS and RPM values to the Android device, which is displayed to the user in their respective text boxes.

Sensor Controller

Team Members:

Vishwanath Balakuntla Ramesh

Hardware Design

We used 3 Parallax Ping ultrasonic distance sensors for obstacle detection and avoidance. Non-contact distance can be measured from about 2 cm (0.8 inches) to 3 meters (3.3 yards).

The PING))) sensor works by transmitting an ultrasonic burst and providing an output pulse that corresponds to the time required for the burst echo to return to the sensor. By measuring the echo pulse width, the distance to target can easily be calculated.

Three sensors were placed in front (front_left, front_center, front_right).

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Parralax Ping Sensor Operation

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

| Task Name | Purpose | ||||

|---|---|---|---|---|---|

| Period Init | Can bus initialization | Enable LPC timer | Initialize LPC timer | Initialize rising edge GPIO interrupt | Initialize falling edge GPIO interrupt |

| Periodic 1Hz Callback | Check can bus off | ||||

| Periodic 10Hz Callback | Get and Send Sensor Data |

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Motor & I/O Controller

Team Members:

Sameer Saran Jaswanth Bhimanapalli

Hardware Design

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Hardware/Software Interface

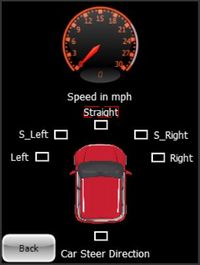

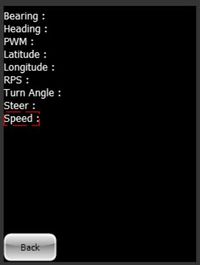

Below are the snaps of the LCD Screens:

| Screen No. | Description |

|---|---|

| 1 | Welcome Screen |

| 2 | Displaying the menu |

| 3 | Displaying Sensor data |

| 4 | Displaying motor data |

| 5 | Displaying data to debug along with GPS data |

Tasks

| Task Name | Purpose |

|---|---|

| Period Init | Can bus initialization, Motor and LCD initialization |

| Periodic 1Hz Callback | Check can bus off and Print data on LCD |

| Periodic 10Hz Callback | Drive car according to received data from Master controller |

| Periodic 100Hz Callback | Receive CAN bus data |

| Periodic 1000Hz Callback | Receive touch data from LCD and check RPM sensor |

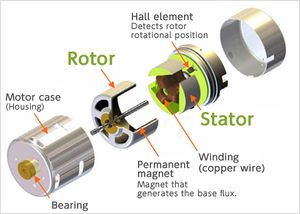

Brushless DC Motor

|

Our car came with 3650 Brushless inrunner motor, 2080KV with 60A ESC(with Reverse). This motor has the power to run the car at a maximum speed of the 35mph.

Table3: DC Motor Duty Cycle v/s Speed Control |

|

DC motor is controlled with the help of three wires coming out of the ESC. These wires are VCC, GND and Speed control. The VCC line is not used as required voltage is directly given to the motor through a battery, via ESC. The GND line and Speed control lines are connected to the ground and PWM pin of SJOne board.

DC Motor Pin Connections To drive the DC motor, we are using pwm2 i.e. pin P2.1 of the SJOne board. We are using the in-build PWM generation function which requires two parameters, one is pin being used and the other being the frequency. To set the required duty cycle, the in-build set function is used.

void drive(steer_E steer,speed_E speed)

{

static int servoVal,servo_Currentval=STRAIGHT*100;

servoVal = get_Servopwm(steer);

while(servoVal!=servo_Currentval)

{

if(servo_Currentval>servoVal)

{

servo_Currentval-=5;

MotorCtrl.set_servo(servo_Currentval*0.01);

delay_ms(5);

}

else if(servo_Currentval<servoVal)

{

servo_Currentval+=5;

MotorCtrl.set_servo(servo_Currentval*0.01);

delay_ms(5);

}

}

if(servoVal==servo_Currentval)

{

MotorCtrl.set_servo(servo_Currentval*0.01);

delay_ms(5);

}

|

Servo Motor

|

Our car came with a waterproof digital servo motor. This motor works without ESC. We can directly control this motor by giving PWM signal from our SJOne board. The below table contains information about PWM (duty cycle) given to the motor and the corresponding turns taken by the car.

Servo Motor Duty Cycle v/s Turn |

|

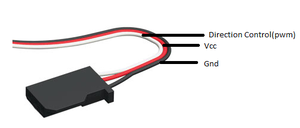

Servo motor is controlled with the help of three wires coming out of the servo motor. The wires are VCC, GND and Direction control. The VCC is connected to the 3.3v. GND and direction control are connected to the ground and pwm pins of SJOne board.

Servo Motor Pin Connections We control the Servo motor using pwm1 i.e. pin P2.0 of the SJOne board. We configure the PWM pin using an in-build function which requires two parameters, one is the pin that we are using and the other is the frequency of the pwm. To set the duty cycle, in-build set function is used in which we are passing the duty cycle at which we want servo motor to work. |

class MotorCtrl : public SingletonTemplate<MotorCtrl>

{

public:

MotorCtrl() : steerServo(PWM::pwm1),driveDc(PWM::pwm2)

{

//Constructor

}

void set_servo(float value) {steerServo.set(value);}

void set_dc(float value){driveDc.set(value);}

friend class SingletonTemplate<MotorCtrl>;

private:

PWM steerServo;

PWM driveDc;

};

#define MotorCtrl MotorCtrl::getInstance()

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Bluetooth and Bridge(Android) Connections

Team Members:

Sucharitha Sirigreddy Karthikeya Rao GV

This section includes high level implementation details regarding the Android app connectivity with the Bluetooth module of the RC car. It gives a overview of building the android app, communication between the Bluetooth and Android app on a mobile device, routing mechanisms during the navigation.

Hardware Design

Bluetooth Controller Pin Connections

| Node A Source | Node A Pin | Node B Source | Node B Pin | Description |

|---|---|---|---|---|

| Power Supply | 3.3V | SJOne Board | 3V3 | SJOne Power |

| Power Supply | GND | SJOne Board | GND | SJOne Ground |

| CAN Transceiver | CAN Tx | SJOne Board | P0.1 (Tx) | SJOne - CAN Tx |

| CAN Transceiver | CAN Rx | SJOne Board | P0.0 (Rx) | SJOne - CAN Rx |

| Bluetooth Module | TXD | SJOne Board | RXD3 | SJOne RX3- Bluetooth module TXD |

| Bluetooth Module | RXD | SJOne Board | TXD3 | SJOne TX3- Bluetooth module RXD |

| Bluetooth Module | Bluetooth module VCC(3.3V) | Power Supply | 3.3V | Bluetooth module - Power supply 3.3V |

| Bluetooth Module | Bluetooth module GND | Power Supply | GND | Bluetooth module - Power supply GND |

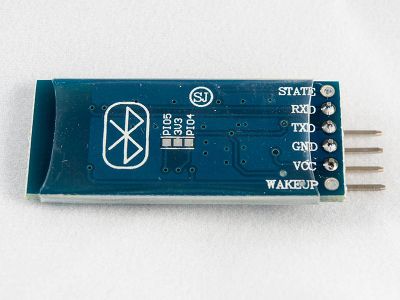

Below attached is the image of the Bluetooth Module HC-06.

Hardware Interface

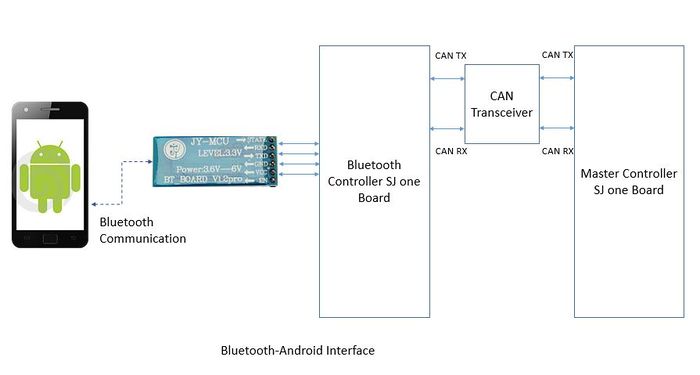

Below is the representation of the bridge communication.

Hardware Interface between the Bluetooth controller and the car system has been wired through the CAN bus. P0.1 is connected to CAN Tx and P0.0 is connected to CAN Rx, where communication between the Bluetooth module and other modules happen. RXD and TXD pins are connected to Bluetooth HC-06 to enable communication between the Android mobile device and the Bluetooth module. Power supply and Ground pins to SJone board i.e Bluetooth module is provided by battery, which would power up all the SJone boards. Power to the HC-06 module is given by the SJone Bluetooth board 3.3V and GND pins. Thus enabling the Interface between Bluetooth module and the other controllers.

Software Design

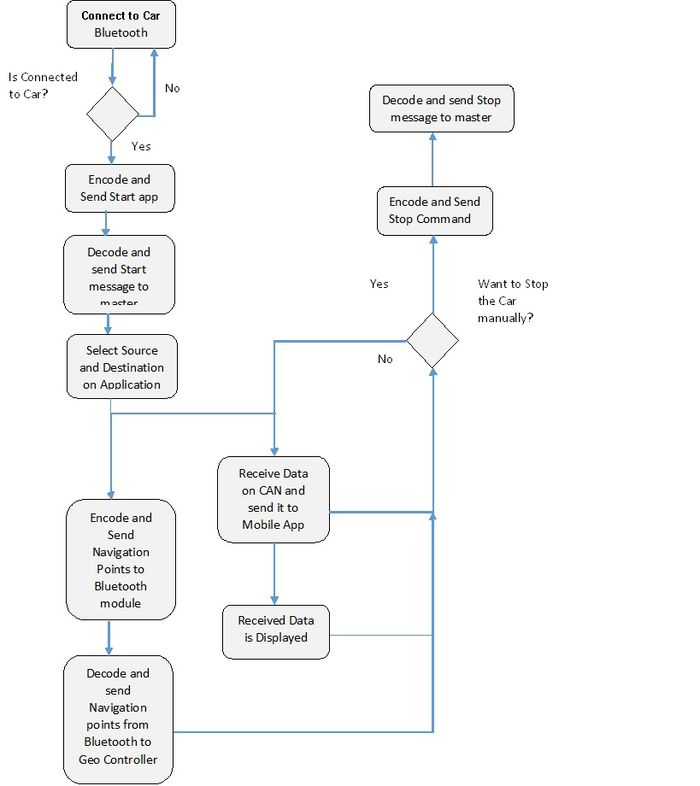

Software interface between HC-06 and Android device is enabled via Bluetooth transmission and reception.

Flow Chart:

Flow Chart of the Bluetooth and Android design is as follows.

Android-Bluetooth Controller Button's Functionality Table

| SI No. | Button | Functionality |

|---|---|---|

| 1 | BTON | User is prompted to Turn on Bluetooth device on the phone. User can either "allow" or "deny" the request. Application won't work till the request is allowed. |

| 2 | START | Sends string 1 over Bluetooth channel to indicate to to Master Controller to start of car. |

| 3 | STOP CAR | Sends string 0 over Bluetooth channel to indicate to Master Controller to stop the car(Wireless Kill switch). |

| 4 | BTOFF | Turns off the Bluetooth of the Android device. |

| 5 | LOC | Places a marker on Google Map based on cars Latitude and Longitude received from the GEO module on the car. |

| 6 | ROUTE | Send route from source to destination selected on map after filtering way-points to the Bluetooth Controller and to GEO controller there on. |

Implementation

through the Android application the Bluetooth would be paired with HC-06 module on click of BTon button, which turns on the Bluetooth on the android phone and connects to Car’s HC-06 Bluetooth device. Post which, we would send a start signal from the app, which would sync and start the car. This signal is hardcoded as ‘1’, and is encoded before sending from the android. This signal when received from the Bluetooth module, would decode and read the message and later encode and pass it on over the CAN to the Master.

After this syncing, the Master would initiate other modules; post which GPS module would send the location signal over the CAN. This signal is again decoded and sent over to the Android as a line having latitude and longitude and prefixed with respective signals, ex: RPM for RPM values and post-fixed with “!” , for easier identification in the Android. Location button would enable the current location of the device, which would be marked on the map, this would be enabled on click of start itself. This would also enable Bluetooth module to detect the messages over the CAN to be displayed on the app, like RPM values and GPS data. These are again encoded and sent over to Android, which would display them in respective text boxes.

Route Button on the app would be initiated once we set these and the source and destination by 2 clicks on the maps in the app and start getting the GPS location from HC-06. Route Button on click would detect the GPS location from the car and send out next way points till the destination. The Kill switch is implemented as Stop Button, which sends of “0” signal, which is received by the Bluetooth and sent over the CAN Bus to master, to stop the Motor.

Geographical Controller

Team Members:

Veena Manasa Kanakamalla Arpita Ramanath

Hardware Design

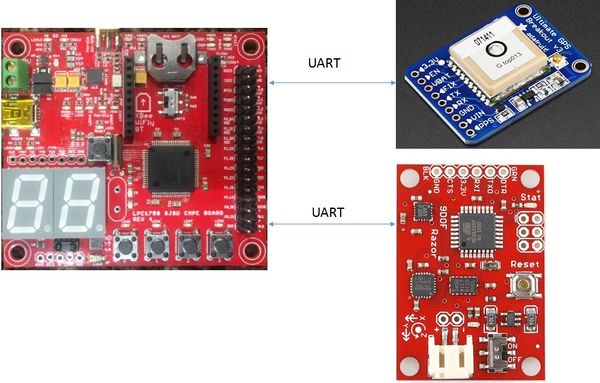

System Block Diagram

Geographical Controller Hardware Design Components

|

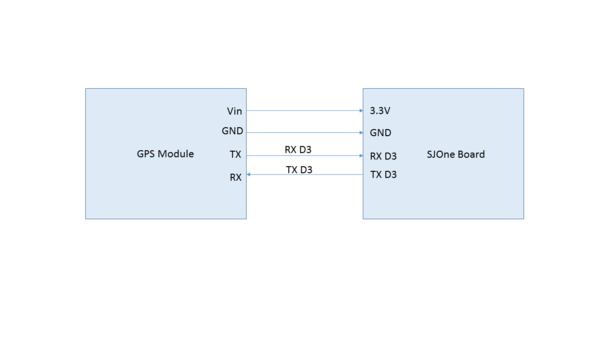

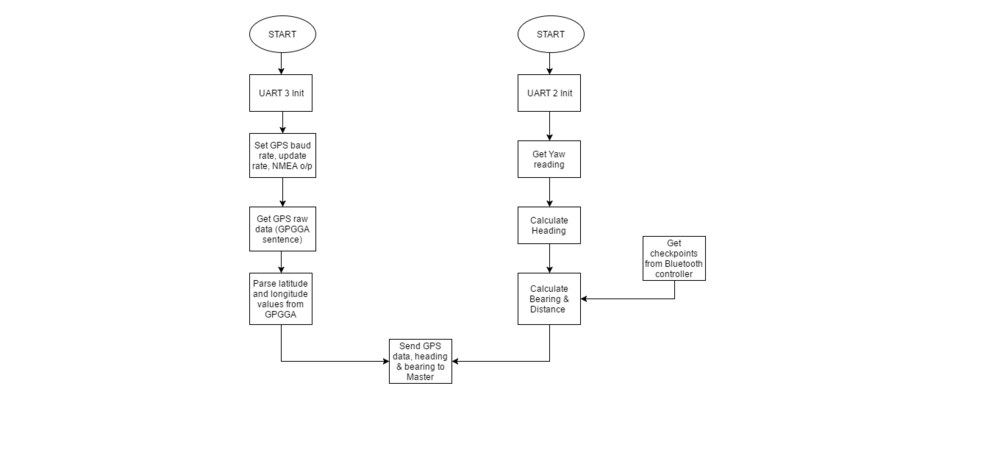

Adafruit MTK3339 GPS: This GPS unit is interfaced via UART with build in antenna. The GPS provides latitude and longitude accurately up to 5-10 meters with a strong satellite fix with update rate of 10Hz. By default, the baud rate is 9600bps. Power usage for this module is 20mA during navigation. The GPS module comes with following capabilities:

We chose this part because it provided the base functionality we needed along with many other functions that would be fun to play with and try to include in the project. The antennae options and voltage regulator were also very enticing. We get raw GPS "NMEA sentence" output from module. The most important NMEA sentences include the GGA which provides the current Fix data, the RMC which provides the minimum gps sentences information, and the GSA which provides the Satellite status data. We are filtering the data for GGA (Time, Position and Fix type data), which will look similar to: $GPGGA,123519,4807.038,N,01131.000,E,1,08,0.9,545.4,M,46.9,M,,*47

GGA Global Positioning System Fix Data

123519 Fix taken at 12:35:19 UTC

4807.038,N Latitude 48 deg 07.038' N

01131.000,E Longitude 11 deg 31.000' E

1 Fix quality

08 Number of satellites being tracked

0.9 Horizontal dilution of position

545.4,M Altitude, Meters, above mean sea level

46.9,M Height of geoid (mean sea level) above WGS84

ellipsoid

(empty field) time in seconds since last DGPS update

(empty field) DGPS station ID number

*47 the checksum data, always begins with *

|

||

|

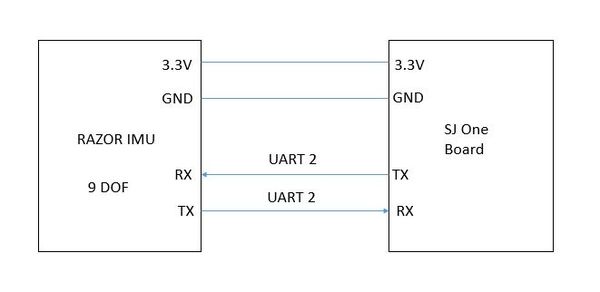

GPS Pin Connections 9 Degrees of Freedom- Razor IMU: In our project, we used IMU module to get the heading of the device. The 9DOF Razor IMU provides nine degree of inertial measurement incorporates three sensors - an ITG-3200 (MEMS triple-axis gyro), ADXL345 (triple-axis accelerometer), and HMC5883L (triple-axis magnetometer). The outputs of all sensors are processed by an on-board ATmega328 and output over a serial interface. UART interface is used for interfacing with SJ One board and it is connected via UART3 with LPC board and is operated at 3.3V. Features:

|

IMU Pin Connections

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

Flowchart

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Master Controller

Team Members:

Ajai Krishna Velayutham Goutam Madhukeshwar Hegde

Master Controller Schedule

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

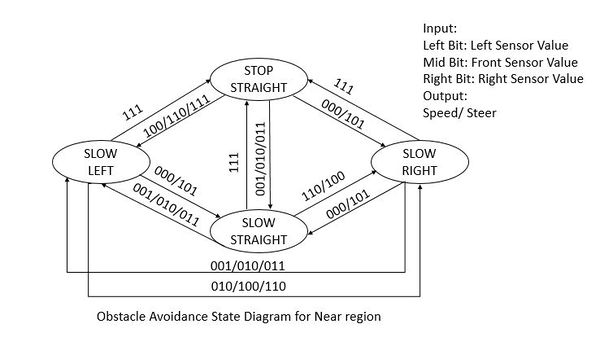

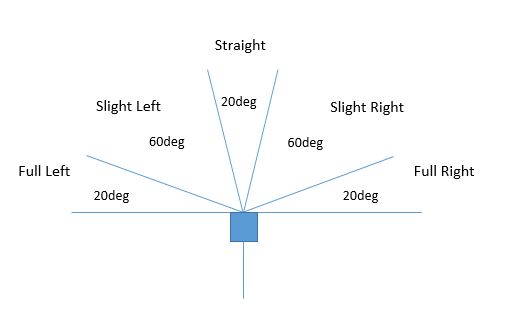

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Issue #1 (Motor I/O)

- One of our boards got burnt while testing Brushless DC Motor. We would highly recommend using an Optoisolator such as ILQ74 for additional protection from reverse current etc. if you are synchronizing with the ESC for the first time.

Issue #2 (Project Hardware)

Issue #3 (Project Hardware)

Issue #4 (Geo controller software)

Issue #5 (Motor Controller software)

Issue #6 (Master Controller software)

Miscellaneous Issues

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

GitLab Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.