F15: Plant Control

Contents

Automated Plant Control System

Abstract

The Plant Control project introduces a plant incubator which allows for resource and energy efficiency while producing healthy flowering and vegetation. The incubator will utilize an SJOne development board, its on-board sensors (light/temperature), a moisture sensor, and LEDs in order to autonomously provide the optimal moisture level for growth in any lighting. The owner of the plant control system can be confident that his or her plant is growing in perfect conditions and will be notified otherwise via an LCD screen.

Objectives & Introduction

This project is a self watering, self lighting, and temperature alerting plant grower.

The entire system is controlled via an SJOne Board which utilizes an LPC1758 Microprocessor.

In addition to the onboard sensors, the project will require interfacing to:

- RGB LCD Screen

- Moisture Sensor

- Water Pump

- PWM controlled LED

Team Members & Responsibilities

- Moises Negrete

- LED and Water Pump Driver Circuit Design

- Temperature, Light Sensor, PWM software

- Design and Build Planter

- Eduardo Lemus

- LCD Interface

- Source Code Task and Timing Cleanup

- David Chiu

- Moisture Sensor Interface

- Power Regulator Circuit

- Design and Build Planter

Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/24 | Research best lighting, temperature, moisture conditions | Completed |

| 2 | 10/30 | Purchase necessary equipment, and begin testing equipment (sensors) | Completed |

| 3 | 11/06 | Interface Sensors | Completed |

| 4 | 11/13 | Interface LEDs and Water Pump | Completed |

| 5 | 11/20 | Begin Building Planter | Completed |

| 6 | 11/27 | Finish Building Planter & Begin RT Code | Completed |

| 7 | 12/2 | Functionality Testing and Prototype Verification | Completed |

| 8 | 12/9 | Plant Flower and Field Test | In Progress |

Parts List & Cost

| Part Name | Cost | |

|---|---|---|

| Water Pump | $6.99 | http://www.amazon.com/gp/product/B00MP4Q6K2?psc=1&redirect=true&ref_=ox_sc_act_title_1&smid=AAOUP5IQ82N49 |

| Soil Hygrometer | $6.11 | http://www.amazon.com/gp/product/B00KKQYW76?psc=1&redirect=true&ref_=ox_sc_act_title_1&smid=AIOZ1JWV33B58 |

| 1/2 gallon Water Reservoir | $7.00 | Auto Zone |

| Faux-Ceramic Planting Pot | $5.00 | Home Depot |

| Baby Mums (Flowers) | $2.00 | Trader Joes |

| SJone Board | $80.00 | SJSU |

| Soil | $10.00 | Home Depot |

| 12V Power Adapter | $6.00 | Anchor Electronics |

| LCD Screen | $13.90 | http://www.seeedstudio.com/depot/grove-lcd-rgb-backlight-p-1643.html |

| 7805 Voltage Regulator | $0.50 | Anchor Electronics |

| Total | $136.6 |

Design & Implementation

Hardware Design

The hardware design for this projects will be split into the different sections of our project. The different hardware components include a power circuit and water pump/LED drivers. The

Hardware design will then be followed by the design of the Plant Pot and finally the Hardware interfacing components.

Power Circuit

Due to the low power outputs of the LPC1758. in order to drive the LED and the the water pump,

an external power source strong enough to do so is necessary.

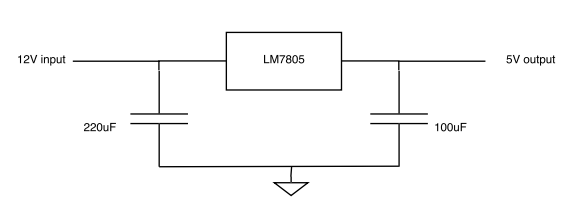

Figure 1. Power Regulator Circuit (12V-5V)

In figure 1, the power circuit uses 2 capacitors (100uF and 220 uF) to maintain stability of the regulator. The LM7805 is used to convert 12V to 5V as needed to power the LCD screen, drive the LED, and the motor. A switch was added at the 5V node in order to be able to switch on and off the 5V.

Water Pump/LED Driver

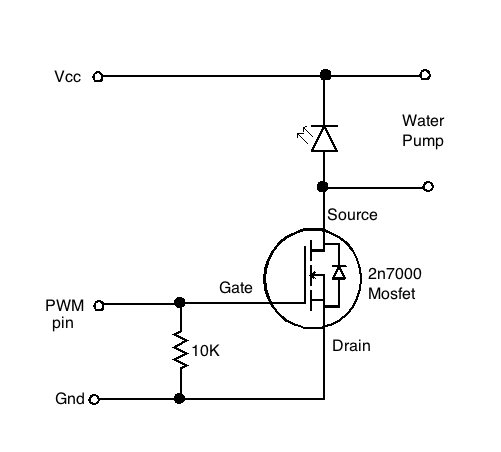

FIgure 2. PWM Mosfet Driver for water pump

The figure above (Figure 2) displays the circuit design used in our plant control system for driving the water pump via PWM. The PWM input from the LPC1758 enters the gate of the 2n7000 mosfet which allows the Source-to-Drain circuit completion. When the Source-to-Drain circuit is complete, the current will flow though the water pump and thus pump water into the dry soil when needed. The LED in the circuit is used to polarize the current so that it only flows in one direction disallowing the pump to receive current in a reverse direction. The circuit for driving the plant lighting LED is similar to the water pump driving circuit other than that the leads to the water pump are connected to a 5V LED. The plant lighting LED is connected in parallel to the forward current directing diode. A 10K Resistor connected from the Gate to the Drain in order to ensure gate is grounded if drive is ever disconnected.

Plant Casing

The Plant casing was designed to look like a classic ceramic/adobe plant pot. A water reservoir was connected to the back of the plant pot and the water pump was placed inside of the water reservoir. A hose was connected to the water pump and connected to go around the plant pot to drip water around the pot whenever a signal is received from the soil moisture sensor. An LED was mounted to the top of the plant pot in order to provide light whenever the light is in a dark environment. A figure showing the mounting is shown below.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

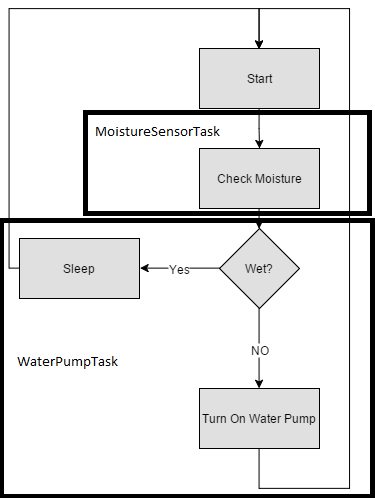

Below are flow charts for the software algorithm combining the tasks that are performing the reading and the tasks that are enabling/disabling the IO devices.

Figure 3. Water Pump Flow Chart

In the figure above, we have two tasks that control the water pump. The first task (MoistureSensorTask) reads the sensors and the second task (WaterPumpTask) determines whether to turn on the water pump or not.

Figure 4. LED Flow Chart

In the figure above, we have two tasks that control the LED. The first task (LightSensorTask) reads the sensors and the second task (LightPWMConsumerTask) determines whether to turn on the LED or not.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

We would like to thank both Preetpal Kang and Dr. Haluk Ozemek, for their limitless support and encouragement throughout the semester.

The knowledge and skills gained in CMPE146 were paramount to the completion of this project.

References Used

Soil Hygrometer

LCD RGB Backlight

2N7000 Transistor

Voltage Regulator

Appendix

You can list the references you used.