Difference between revisions of "F15: Doorknock over Bluetooth"

Proj user20 (talk | contribs) (→Software Design) |

Proj user20 (talk | contribs) (→Project Source Code) |

||

| Line 274: | Line 274: | ||

=== Project Source Code === | === Project Source Code === | ||

| − | * [https://sourceforge.net/projects/ | + | * [https://sourceforge.net/projects/cmpe146-f15-doorknock/files/?source=navbar Sourceforge Source Code Link] |

== References == | == References == | ||

Revision as of 22:34, 13 December 2015

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

Doorknock over Bluetooth

Abstract

This project is to build a door knock sensor that is mounted on a user's door. Using a vibration sensor, the device will alert the user when someone knocks at their door by sending a notification over Bluetooth to the user's mobile android application, that will be developed to pair with the device.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

- Andrew Herbst

- Sensor interface and UART communication

- Banks Lin

- Android developer and bluetooth communication

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

| Week# | Date | Task | Status |

|---|---|---|---|

| 1 | 10/23 | Complete Abstract | Completed |

| 2 | 10/30 | Further develop wiki page and purchase/receive components | Completed |

| 3 | 11/6 | Complete bluetooth and Android communication | Completed |

| 4 | 11/13 | Have basic response from the sensor | Completed |

| 5 | 11/20 | Actual communication with bluetooth module | Completed |

| 6 | 11/27 | Debugging on Android side | Completed |

| 7 | 12/4 | Finish last debugging and construct hardware | Completed |

Parts List & Cost

Give a simple list of the cost of your project broken down by components. Do not write long stories here.

- Piezo Element (vibration sensor): $1.50

- JBtek HC-06 Bluetooth Module: $8

- LPC1758 SJ One Board: $80

- Motorola Nexus 6: $600

Total Cost: $689.50

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

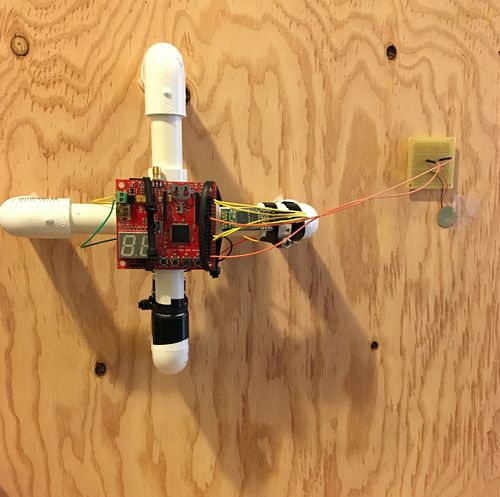

Discuss your hardware design here. Show detailed schematics, and the interface here.

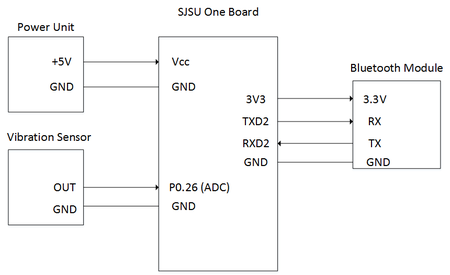

For the Bluetooth module, UART communication was used to send data to the mobile application, alerting the user of a knock on the door.

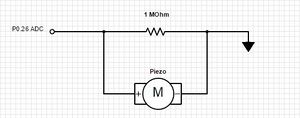

As shown in Figure 1, the ADC input pin (P0.26) of the SJSU One Board was used to collect the analog signal transmitted by the Piezo vibration sensor. Once the analog signal is collected, it would be converted to a digital value using analog-to-digital conversion methods built into the board. This value would then be measured to determine if the vibration was significant enough to be a knock on the door.

The RXD2 and TXD2 pins on the CPU were used for UART communication with the Bluetooth module. Once a knock was detected by the vibration sensor, a single data byte would be transmitted from the controller to the HC-06 which would be able to transmit the data over Bluetooth to the paired mobile device.

In summary, the pin functionality is briefly described below:

- P0.26 was configured to be the ADC input from the vibration sensor.

- TXD2 was used to send data using the UART2 communication bus to the Bluetooth module.

- RXD2 was used to receive data using the UART2 communication bus from the Bluetooth module.

- 3V3 was used to power the HC-06 by a 3.3V output voltage.

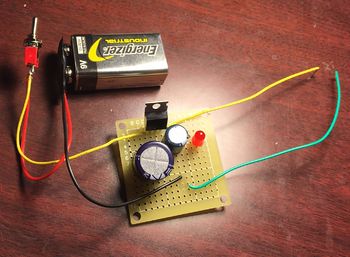

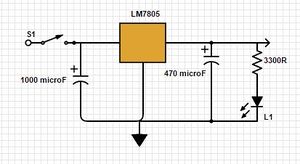

Power Unit:

A 9V battery was used to power the device. However, we could not supply a 9V supply to the LPC1758, as it would damage the baord. Thus, a voltage regulator was designed to supply a 5V output to the SJSU One board. Using two capacitors, a switch, and and LED to indicate power on, as shown in Figure 2, the regulator output a steady 5 volts. The design was completed by soldering the components to perf board and the wire leads were attached to the input ports on the SJSU One board to power the device.

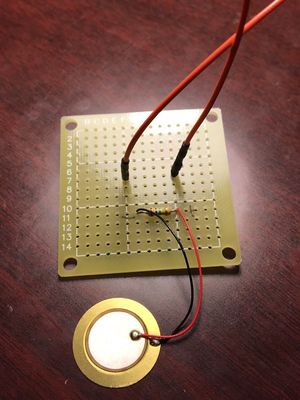

Vibration Sensor: The device was equipped with a Piezo Vibration sensor to detect the knock. The Piezo sensor operates using the piezoelectric effect, which essentially generates a voltage when the disc on the sensor is touched. This generated voltage can be extremely high, which is why a 1 MOhm resistor was used as a voltage divider so that the output would reach the microcontroller at a safe level. When a vibration is detected, an analog signal is sent to the microcontroller through one of the ADC inputs. The resultant value collected by the microcontroller is 0-4096, as the ADC resolution is 12-bits.

Bluetooth Module:

The JBtek HC-06 Bluetooth module was chosen for this device because it is a widely-used and high-quality device, is compatible with the Android Phone, and has low power-consumption. The device acts as a Bluetooth serial interface module to send data over a wireless connection to the paired mobile application. The device has a built-in 2.4GHz transceiver, enabling it to be paired with nearly any Bluetooth device.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

The communication between the vibration sensor and the SJSU One board takes place through the GPIO pin P0.26, which is configured during initialization to operate as an analog-to-digital converter (ADC). The analog signal is sent over a wire to the board, which then converts the value to a scaled digital value.

//Vibration Sensor interface LPC_SC->PCONP |= (1 << 12); // enables power to ADC LPC_ADC->ADCR |= (1 << 21); // enables ADC pin LPC_SC->PCLKSEL0 &= ~(3 << 24); // clears [25:24] LPC_SC->PCLKSEL0 |= (1 << 24); // enables PCLK_ADC / 1 LPC_PINCON->PINSEL1 &= ~(3 << 20); // clears [21:20] LPC_PINCON->PINSEL1 |= (1 << 20); // ADC-3 is on P0.26, select this as ADC0.3 LPC_GPIO0->FIODIR &= ~(1 << 26); // enables pin as an input

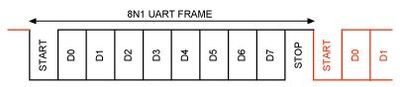

The Bluetooth module acted as a relay between the microcontroller and the user's mobile application. Once a knock was detected, the microcontroller would send a byte of data to the HC-06 using the UART2 bus. One main change made during initialization was to synchronize the baud rate between the board and the Bluetooth module. The HC-06 has a default baud rate of 9600 bps, so the board's baud rate had to be adjusted accordingly. Also, the UART bus was configured to send an 8-bit transfer per data transaction. Each data frame begins with a start bit, indicated by a high-to-low transition, and ends with a stop bit, which is a low-to-high transition. When no activity is occurring on the UART bus, the line is held high. The data frame transaction is illustrated in the figure below.

//Bluetooth module driver LPC_SC->PCONP |= (1 << 24); // enables power to UART2 LPC_SC->PCLKSEL1 &= ~(3 << 16); // clears [17:16] LPC_SC->PCLKSEL1 |= (1 << 16); // enables PCLK_UART2 / 1 LPC_PINCON->PINSEL4 &= ~(3 << 16); LPC_PINCON->PINSEL4 &= ~(3 << 18); LPC_PINCON->PINSEL4 |= (2 << 16); // enables Rx/Tx for UART2 LPC_PINCON->PINSEL4 |= (2 << 18); LPC_UART2->LCR |= (1 << 7); // DLAB = 1 (table 279) //calculate baud rate LPC_UART2->DLM = 0; uint16_t DLMDLL = 0; DLMDLL = sys_get_cpu_clock() / (16 * 9600); LPC_UART2->DLM = (DLMDLL >> 8); // top 8 bits LPC_UART2->DLL = (DLMDLL & 0xFF); // bottom 8 bits

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

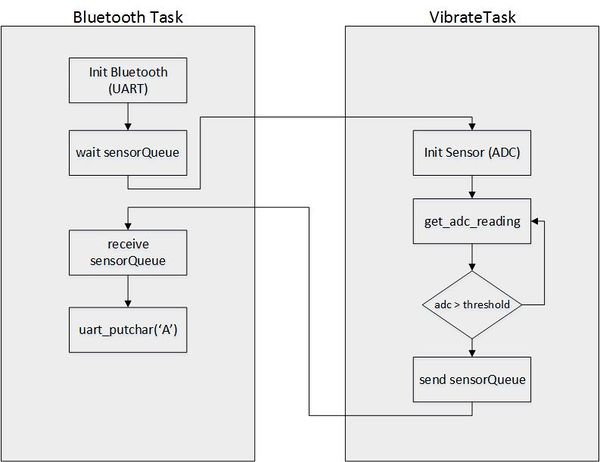

For this project, the team used FreeRTOS tasks to design and execute the main drivers of the device. The software for the Android application will be discussed in a later section. The flowchart below depicts the basic operation of our device's software.

As shown, after initialization of the peripherals, the Bluetooth task waits using a queue for an incoming signal from the vibration sensor task. The vibration sensor polls the ADC input until a voltage is detected above the minimum threshold, indicating a knock on the door. At this point, an item is placed on the queue and the higher priority Bluetooth task receives the item and resumes execution.

Bluetooth Task

pseudocode:

initialize Bluetooth peripherals (UART2);

if(QueueReceive(SensorQueue, portMaxDelay)) // waits until data is in queue

{

UART2 putchar(); // sends data byte over UART2 to Bluetooth serial interace

}

Sensor Task

pseudocode:

initialize vibration sensor;

set minimum threshold value;

adc_get_reading();

if( adc > threshold )

{

QueueSend(SensorQueue, portMaxDelay);

}

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Vibration Sensor:

The main implementation issue encountered with the Piezo sensor was to configure the correct minimum threshold value. Because the sensor is fairly sensitive, an appropriate value for the minimum threshold had to be properly chosen in order to signal if a vibration was significant enough to be considered a knock on the door. As the sensor task receives each ADC reading, it checks it against the threshold value, and if it is greater than, a context switch occurs to the Bluetooth task.

Bluetooth Serial Interface:

As mentioned earlier, the Bluetooth serial interface uses the UART2 bus for communication, sending one byte per data frame transaction. This transaction takes place using a custom-built put_char function. Essentially, the function first places the parameterized character on the THR transmitting register and then begins to wait. Then, once the data is consumed by the receiving device, in this case the Android application, the register is set, at which point the function completes and returns.

void u2_putchar(char c)

{

LPC_UART2->THR = c; // start sending data

while ( !(LPC_UART2->LSR & (1 << 5)) ); // waits for THR to be empty

return;

}

Android Application

The other half of this project is to develop an Android application (app) that can receive a signal from the bluetooth module whenever the vibration sensor picks up a knock. Developing an Android app is something that we have never done before, therefore there was a huge learning curve that came with working on this project. Throughout the app development process, the majority of the time spent during the first couple of weeks was a learning how to utilize Android Studio. After the initial learning process of how to develop an Android app, everything else came together much quicker.

The DoorKnock app is designed to have a single home screen that initially displays a list of MAC addresses of the bluetooth devices within reach, a send and clear button, an input line to send signal, and an open space which displays text whenever it receives signal. The app is designed to give a notification to the user whenever it receives a signal from the bluetooth module that is connected to the SJSUOne board. The notification would display a short message to the user in the notification bar as well as alerting the user with a sound.

Android Application Development

Testing the Android Application

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

Issue #1: Piezo Sensor Sensitivity

Discuss the issue and resolution.

We used several different types of Piezo vibration sensors before deciding to use this particular Piezo Element model. The other sensors seemed to generate a lot of noise and provided inconsistent resulting voltage values. It took thorough testing in real-time to decide on an appropriate minimum threshold value to use. If the threshold was too low, false positives would occur through ambient vibrations or noise in the readings. Yet, a threshold that is too high would not trigger the sensor during a knock, in some cases. Eventually, through trial and error, an appropriate threshold value was decided on.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

HC-06 Datasheet: https://www.olimex.com/Products/Components/RF/BLUETOOTH-SERIAL-HC-06/resources/hc06.pdf

Piezo Element Datasheet: https://www.sparkfun.com/datasheets/Sensors/Flex/p37e.pdf

Appendix

You can list the references you used.