F13: Remote Control Car

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Remote Control Car

Using two SJSU development board to control a Remote Control Car.

Abstract

IN-WORK: This section should be a couple lines to describe what your project does.

Objectives & Introduction

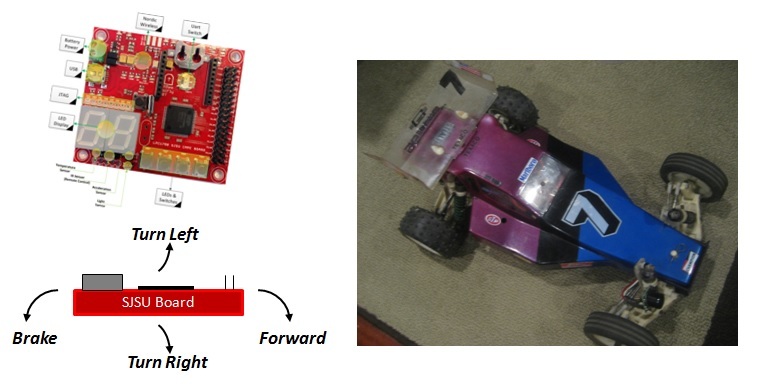

RX Board Overview

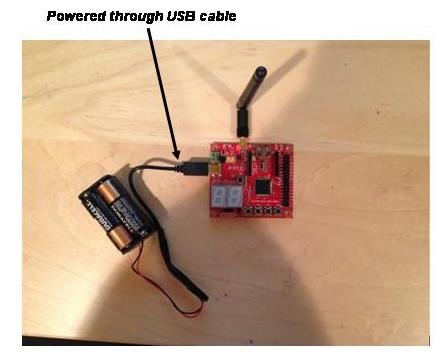

TX Board Overview

Team Members & Responsibilities

- Alan Wang

- TX Board software development including:

- Develop driver for Acceleration Sensor (throttle and steering)

- Develop Wireless message protocol between boards

- Develop TX board software to transmit commands

- TX Board software development including:

- Curtis Woodworth

- RX Board software/hardware development including:

- Integrate hardware onto R/C Car (board, power, cable)

- Develop RX board software to control RC car

- Develop front proximity sensor detection software

- RX Board software/hardware development including:

IN-WORK: Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Schedule

| Week# | Date | Task | Completion

Date |

|---|---|---|---|

| 1 | 10/8 | Identify R/C Car usage and ensure operation

Identify & Order parts needed Complete Project Proposal document |

10/8 |

| 2 | 10/15 | Setup & build R/C Car

Test R/C operation with nominal controller Develop pin list for I/O use & types |

10/15 |

| 3 | 10/22 | Develop Accelerometer software driver

Develop Server control software driver |

10/15 |

| 4 | 10/29 | Develop Transmitter data protocol

Develop Transmitter software driver Develop LED control software driver |

10/15 |

| 5 | 11/5 | Integrate accelerometer and transmitter drivers program

Integrate servo and LED control drivers into program |

10/29 |

| 6 | 11/12 | Integrate TX and RX development boards communications

Integrate & Test system with simulated R/C Car |

10/29 |

| 7 | 11/19 | Integrate & Test system with actual R/C Car | 11/18 |

| 8 | 12/3 | Demo Project

Finish report |

12/3 |

IN-WORK: Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

Parts List & Cost

| Part Number | Description | Price ($) | Qty |

|---|---|---|---|

| SJSUONE | SJSU-One Development Board | 75.00 | 2 |

| - | AA Battery Pack | 6.00 | 1 |

| RC10 | Associated RC10 Car | 305.00 | 1 |

| 410-MXc | Novak Electronic Speed Control | 90.00 | 1 |

| Stock | Pocket Rocket Motor | 25.00 | 1 |

| - | Sanyo 1400mA 7.2V Battery | 20.00 | 1 |

| S9302 | Futaba HS Steering Servo | 40.00 | 1 |

| MB1010 | LV-MaxSonar EZ1 | 30.00 | 1 |

| - | Misc Hardware | 8.00 | 1 |

| Total | 674.00 |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

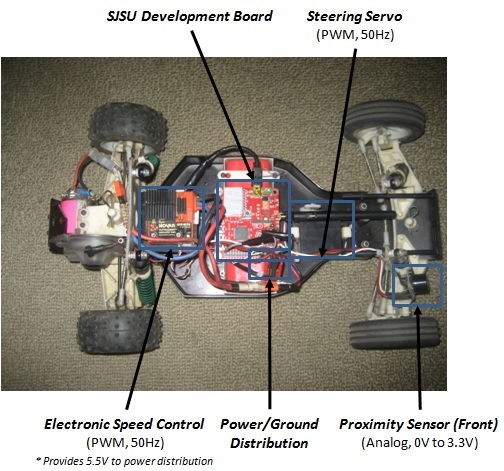

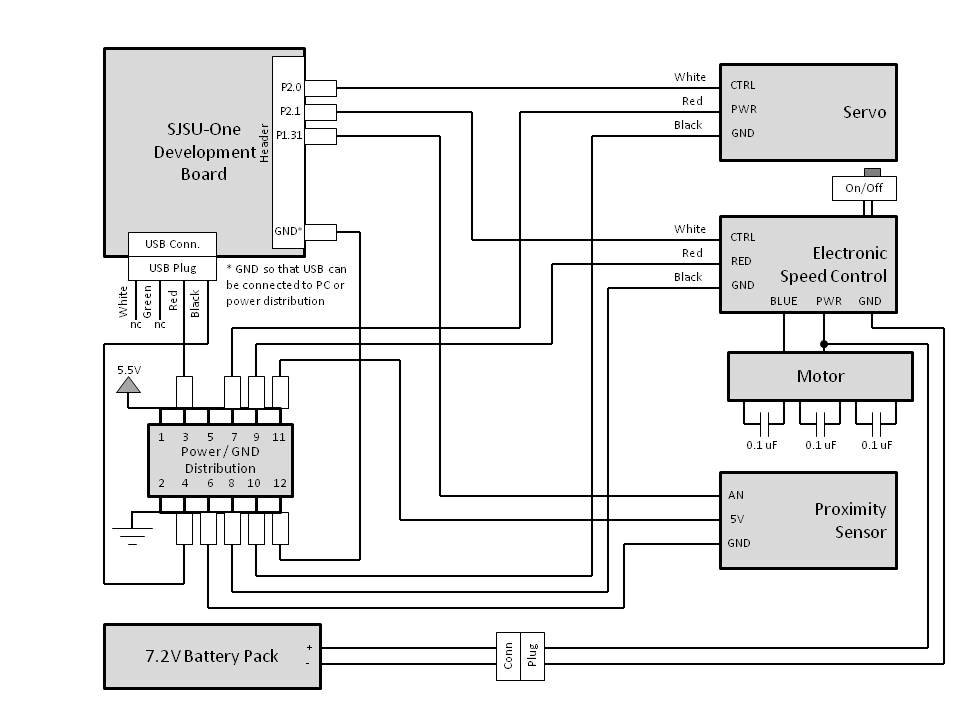

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

The TX board used the following interfaces:

- Accelerometer sensor for steering and throttle control (I2C Bus)

- Nordic wireless interface for transmitting control packets (SPI Bus)

- Switches for Enable/Disable of Control and Sensor (GPIO)

- LED number display for throttle position

The RX board used the following interfaces:

- PWM interface to steering servo (50Hz)

- PWM interface to electronic speed control (50Hz)

- Analog to Digital Converter from proximity sensor

- Accelerometer sensor to detect upside or flipping of car

- GPIO to read switch values and output LED status

- LED number display for error codes

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

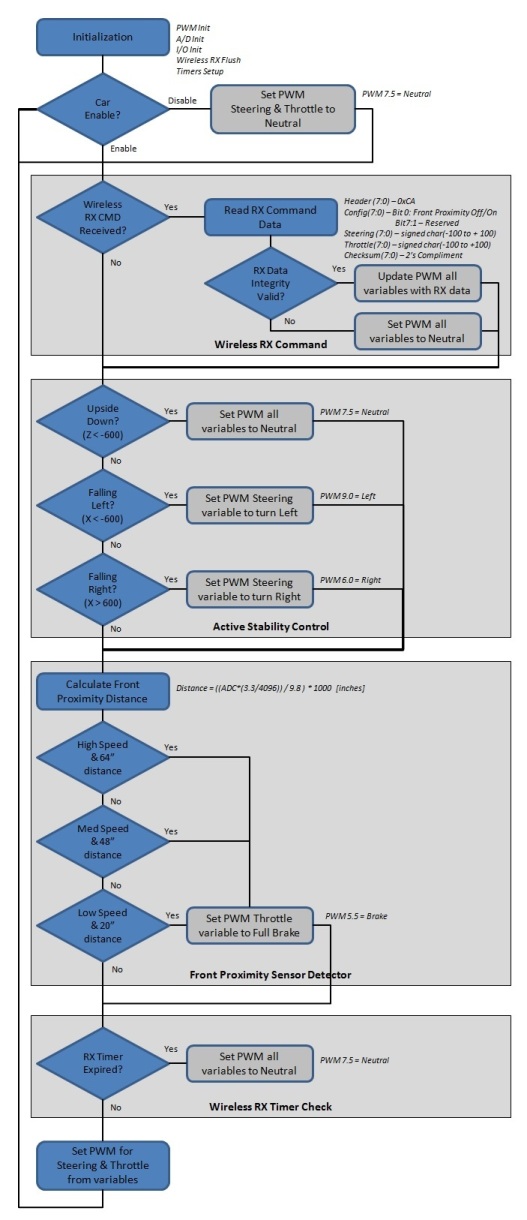

RX Board Software Diagram

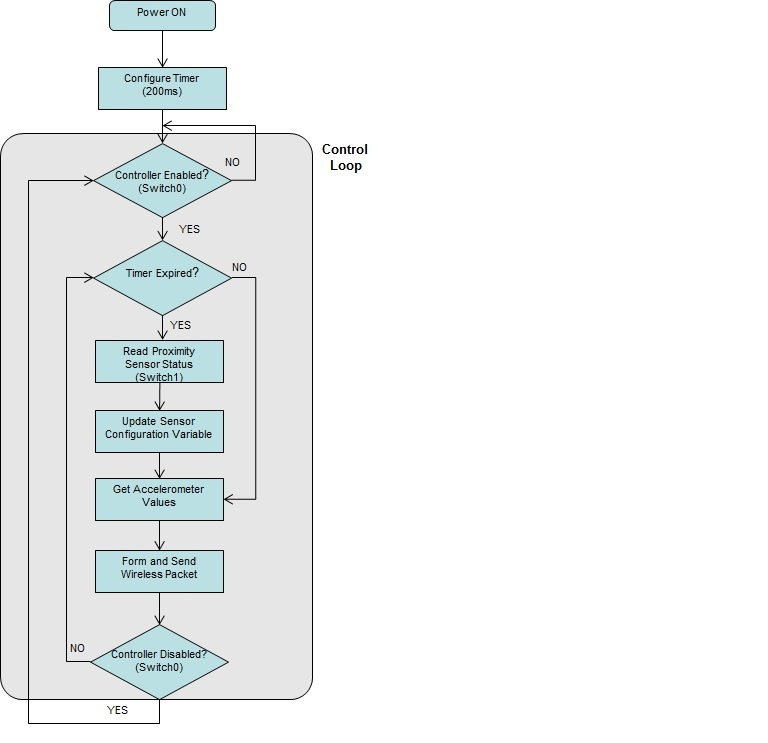

TX Board Software Diagram

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

RX Board

TX Board

Proximity Sensor Configuration

- A 200ms software timer is used to set the sensor configuration variable. At the beginning of the control loop, if the timer has expired then the switch status is read and the configuration is updated. This is to "de-bounce" the switch.

Steering and Throttle Resolution

- The 16-bit value read from the accelerometer is translated to an 8-bit value. The 8-bit value (capped at +/- 100) is then transmitted to the RX Board, to control steering and throttle. 100 steps in each direction provided smoother control and acceleration of the car.

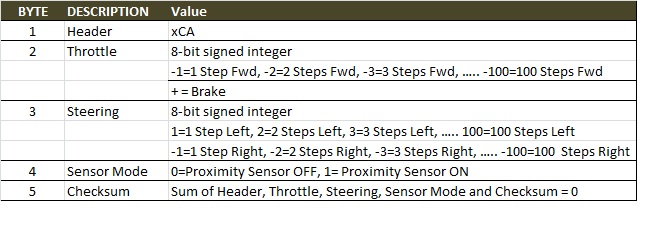

Wireless Command Format

- A header field and checksum was included with the control data to form the command packet. The format is shown below

Technical Challenges

Steering and Throttle Resolution

The initial design used 10 steps in each direction for direction and throttle. As a result, the steering was incredible jittery and acceleration of the car was difficult to control. After testing several settings, we settled on 100 steps. This allowed for smoother control with full range of steering motion.

Proximity Sensor Detection

The proximity sensor was first mounted to the front bumper of the car. When it was disabled, control of the car was normal. When enabled the car became very erratic. We later learned that the field-of-view of the sensor was cone shaped and the ground was most likely in view of the sensor. The sensor also has a minimum range detection of 6". We mounted the sensor higher and farther back on the car which gave us the control expected.

Testing

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

Send me your zipped source code and I will upload this to SourceForge and link it for you.

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.