F18: Spartan Warrior

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

SPARTAN WARRIOR

Abstract

This project involves creating a shooting game, with increasing levels of difficulty, as the user progresses. The point of the game will be to shoot all of the enemies on the LED screen and avoid getting shot by them. If all enemies are shot within the allotted time, then the user will progress to a higher level, where there will be more enemies. The user will be given 3 lives. After 3 deaths, the user will have to start a new game, in order to play again.

Objectives & Introduction

Team Members & Responsibilities

- Alisha Jean Patrao

- Game Design and Firmware, PCB

- Andrew Kwon

- Soundtrack, LED Matrix Driver Development and LPC1758 Integration

- Samir C. Mohammed

- Wiki Management, PCB, LED Matrix Driver Development and LPC1758 Integration, Game Design and Firmware

- Sanjana Gowda

- Game Design and Firmware, PCB

- Tanmay Chandavarkar

- Controller Design and Integration, Soundtrack

Headline text

Schedule

| Week# | Date | Deliverables | Status |

|---|---|---|---|

| 1 | 10/8 |

|

|

| Week# | Date | Deliverables | Status |

| 2 | 10/16 |

|

|

| Week# | Date | Deliverables | Status |

| 3 | 10/23 |

|

|

| Week# | Date | Deliverables | Status |

| 4 | 10/30 |

|

|

| Week# | Date | Deliverables | Status |

| 5 | 11/06 |

|

|

| Week# | Date | Deliverables | Status |

| 6 | 11/13 |

|

|

| Week# | Date | Deliverables | Status |

| 7 | 11/20 |

|

|

| Week# | Date | Deliverables | Status |

| 8 | 11/27 |

|

|

| Week# | Date | Deliverables | Status |

| 9 | 12/4 |

|

|

| Week# | Date | Deliverables | Status |

| 10 | 12/11 |

|

|

| Week# | Date | Deliverables | Status |

| 11 | 12/19 |

|

|

Parts List & Cost

| Part | # | Cost | Source |

|---|---|---|---|

| LPC 1758 Development Board | 2 | $160.00 | Preet |

| Adafruit 32 x 32 LED Matrix | 1 | $39.95 | https://www.adafruit.com/product/1484 |

| PCB | 1 | $5.00 | https://www.pcbway.com/ |

| eBoot Mini MP1584EN DC-DC Buck Converter | 1 | $7.99 (6 pack) | https://www.amazon.com/gp/product/B01MQGMOKI/ref=oh_aui_detailpage_o00_s00?ie=UTF8&psc=1 |

| 5V/4A Power Supply US plug | 1 | $15.95 | https://www.amazon.com/gp/product/B0749668H2/ref=oh_aui_detailpage_o01_s00?ie=UTF8&psc=1 |

| 2.1mm Female Barrel Jack | 1 | $5.79 (2 pack) | https://www.frys.com/product/7726878?site=sr:SEARCH:MAIN_RSLT_PG |

| VS1053 Codec + MicroSD Breakout - v4 | 1 | $24.95 | https://www.adafruit.com/product/1381 |

Design & Implementation

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

MP3 Decoder...

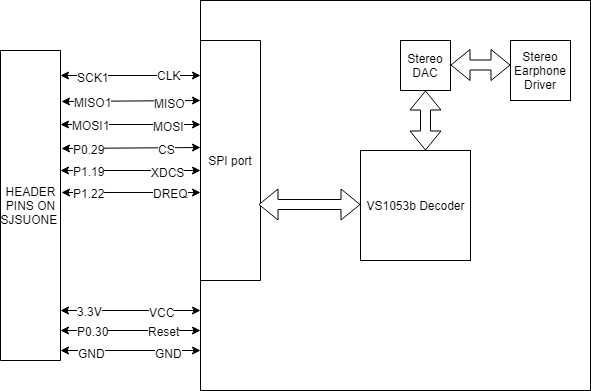

The SDCS pin on the VS1053b decoder is not used, because transfer of Mp3 file data is done using the SD card on the LPC 1758 micro-controller.

A total of 9 pins are used, in order to implement communication between the Mp3 decoder and the micro-controller; 6 Pins for SPI transfer(SCLK, MISO, MOSI, XDCS, CS, DREQ) and 3 pins for VCC, GND, and Reset. The CS pin is used to read and write to registers on the Mp3 decoder.

The XDCS pin is used to transfer data directly to the decoder, in order to output sound.

Another significant pin, is the DREQ pin. DREQ is the only input signal to the LPC 1758 micro-controller from the Mp3 decoder. The purpose of this signal is to alert the decoder and signal that 32 bytes of the Mp3 file are ready to be decoded. When DREQ is low, an SPI transfer to the decoder should not take place. This may be because the previous SPI transfer has not finished.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

MP3 Decoder

The MP3 file is located on an SD card on the SJSUOne Board. Using the Storage object provided in the SJSUDev environment, 4k bytes of a mp3 file are read and transferred to a queue. When data in the queue is available, 32 bytes of the mp3 file are sent through SPI to the decoder that translates that information and outputs sounds.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Developing a driver for the LED matrix...

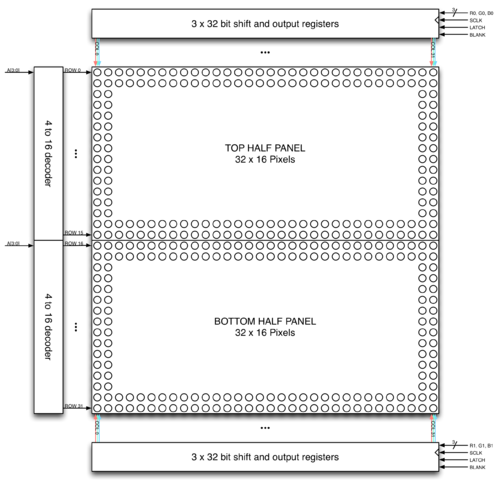

The biggest technical challenge that we faced was interfacing the LPC 1758 micro-controller, with the Adafruit 32 x 32 LED matrix.

Adafruit (the 32 x 32 LED matrix's manufacturer) provides a basic tutorial on their website, in order to help with interfacing the LED matrix to a micro-controller. The tutorial briefly describes the functions of the pins on the board's input and output connector ports. It also describes how to connect jumper wires to the ribbon cable (which comes packaged with the board), which connects to the matrix's input and output connector ports. It assumes that the user will utilize an Arduino-type micro-controller to drive the matrix's RGB LED's.

Because we used the LPC 1758 to drive the LED matrix, our choices were to either adapt a third party driver library designed for an Arduino, or develop a new driver. We chose the latter option, as the third party Arduino-focused API's were difficult to fully understand. We also felt that developing our own driver would allow us to gain a strong understanding of all aspects of micro-controller to LED matrix integration. This proved useful both for firmware development and debugging.

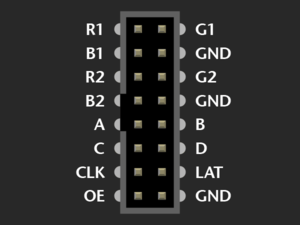

The first part of developing the LED matrix driver, was learning how each of the 16 input pins affected the matrix display.

The LED matrix's input socket looked as follows:

GND...

The 3 GND pins were the easiest to understand. They provided a ground signal reference for the matrix's RGB LED's. The GND pins on the LED matrix were connected to GND on the LPC 1758, through a ground plane on the PCB, allowing the micro-controller and LED matrix to share the same signal reference.

A B C D...

Pins A, B, C and D, were used as control bits for the LED matrix's row multiplexer. The 32 x 32 matrix is made up of two individual 16 x 32 LED panels. Each panel contains 16 rows and 32 columns. The binary values of the multiplexer signals, A, B, C and D, are used to determine which row of LED's is being driven. Each panel drives the same row of LED's at a time, based on these values. For example, if A, B, C and D are set to 0000, then the LED's in the first row of each panel can be driven. If A, B, C and D are set to 0001, then the LED's in the second row of each panel can be driven. This pattern continues until A, B, C and D are set to 1111, which corresponds to sixteenth (bottom) row of each panel. We set our row iterating value, as i = (i + 1) % 16, so that A, B, C and D, would be set to 0000, after finishing latching data into the sixteenth row. This allowed the multiplexer to continuously loop through each row in each panel, from top to bottom. We applied a delay of 1ms after each row iteration, thereby setting the overall scan rate to 62Hz. This scan rate was too fast for the human eye to detect, which allowed the LED matrix to display objects steadily, without annoying flickering compromising the image quality.

R1 B1 G1

R2 G2 B2...

Pins R1, B1, G1 and R2, B2, G2, were the 6 control signals used to drive the matrix's RGB LEDs, different combinations of red, blue and green (depending on their binary values). R1, B1 and G1, controlled indiidual LED colors on the top panel (panel 1), while R2, B2 and G2, controlled individual LED colors on the bottom panel (panel 2). The way these color combinations manifested on the board, were as follows:

| R | B | G | COLOR |

| 0 | 0 | 0 | OFF |

| 0 | 0 | 1 | GREEN |

| 0 | 1 | 0 | BLUE |

| 0 | 1 | 1 | CYAN |

| 1 | 0 | 0 | RED |

| 1 | 0 | 1 | YELLOW |

| 1 | 1 | 0 | PURPLE |

| 1 | 1 | 1 | WHITE |

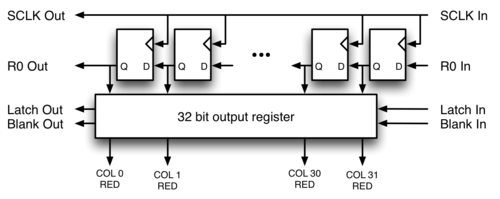

In order to understand how these signals drive individual LEDs on the matrix, one must understand the hardware that they control. The matrix's RGB LEDs are driven by 6 column drivers, each having 32 outputs. Each panel has 3 column drivers. Each column driver can drive 32 LED's in each panel, either red, green or blue (because each of the 3 column drivers controls one of these 3 colors). As a result, the 6 column drivers can drive up to 192 individual red, green and blue LED's (each RGB LED consists of 3 individual red, green and blue LED's) at a time.

CLK LAT OE...

Each column driver is composed of a serial data input, a blanking input, a shift register, and a parallel output register. Data bits are passed into the shift register on the rising edge of each clock cycle. The clock is controlled using the signal CLK. Because there are 32 RGB LED's per row, 32 clock cycles must occur, in order to drive all LED's in a row. After 32 bits of data are passed into the shift register, the LATCH signal (which is set low before shifting in data bits to the shift register) must be asserted, in order to transfer the data bits from the shift register to the parallel output register. Output enable (OE) is pulled low at this point, in order to enable the column driver. It is pulled high again, when transitioning to a new row.

We designed our driver to operate on 32 bit, bit strings (of type uint32_t), in order to utilize all 32 LEDs in each row of the matrix. Each 32 bit string, was stored in a 32 element array of type, uint32_t. We assigned the base memory address of the array to a pointer, and used integer offset values to pass the different bit strings, stored in the array, into the matrix driver function. This method allowed us to pass 32 unique bit strings into all 32 rows of the LED matrix. The integer offsets corresponded to row numbers. For example an offset of 4, would increment the pointer, pointing at the memory address of row 0, by 4 memory addresses. Dereferencing the pointer with this offset (4), would give access to data bits governing the output of row 4 of the LED matrix (the fifth row).

For each row, we used a for loop (which iterated from 0 to 31) in order to shift all 192 data bits into the shift registers. We latched the data bits into the parallel output register, after shifting was completed, which allowed us to illuminate different individual LED's in each row. This allowed us to use 32 bit, bit strings, to create data structures and graphics.

The column driver also allowed us to give the illusion of motion, by turning different LED's on and off in adjacent rows.

Integrating an acceleration sensor to move an avatar...

Another significant technical challenge that we faced, was integrating the LPC 1758's acceleration sensor with a virtual avatar (the player sprite). We used feedback from the acceleration sensor's Y-axis tilt output, to govern the player sprite's lateral movement. In this day, the play had one dimension of control over the sprite, by adjusting the Y-axis tilt of the LPC 1758.

While the task using acceleration sensor feedback to control movement was fairly trivial, it induced a bug in the game. The player sprite flickered one column to the left or one column to the right intermittently, when moving. When the LPC 1758 was completely still, flickering did not occur.

We tried sampling the acceleration sensor 10 times and averaging the integer result, before scaling it by our chosen step value (83), in order to apply the appropriate bit shift to the player sprite. This did not resolve the flickering.

We also tried processing the acceleration Y-axis feedback in a separate task from where we drew the sprite. We included a 1ms delay for each task, as we were concerned that there may have been overlap of calculating acceleration sensor feedback and applying the bit shift to the player sprite.

A few modifications to our move_player_sprite() function led to a significant improvement in performance. We increased the acceleration sensor step size (which is used to scale the Y-axis feedback integer value into a bit shift offset) and implemented our software interpretation of bandpass filter. We also stored the difference between the previous acceleration sensor Y-axis feedback value and the current value in a variable. We used the absolute value of this difference to determine if the acceleration sensor had registered significant enough movement to justify changing the current sprite position offset value. We also increased the move_player_sprite() function's block time to 100ms, which allowed it to more accurately track real-time movement (as human hands don't move fast enough to justify a 1ms delay). These modifications significantly reduced player sprite flickering.

<Bug/issue name>

Using the acceleration sensor to control player sprite movement resulted in the sprite flickering...

The player sprite flickered one column to the left or one column to the right intermittently, when moving. When the LPC 1758 was completely still, flickering did not occur.

We tried sampling the acceleration sensor 10 times and averaging the integer result, before scaling it by our chosen step value (83), in order to apply the appropriate bit shift to the player sprite. This did not resolve the flickering.

We also tried processing the acceleration Y-axis feedback in a separate task from where we drew the sprite. We included a 1ms delay for each task, as we were concerned that there may have been overlap of calculating acceleration sensor feedback and applying the bit shift to the player sprite. (12/7/18)

A few modifications to our move_player_sprite() function led to a significant improvement in performance. We increased the acceleration sensor step size (which is used to scale the Y-axis feedback integer value into a bit shift offset) and implemented our software interpretation of bandpass filter. We also stored the difference between the previous acceleration sensor Y-axis feedback value and the current value in a variable. We used the absolute value of this difference to determine if the acceleration sensor had registered significant enough movement to justify changing the current sprite position offset value. We also increased the move_player_sprite() function's block time to 100ms, which allowed it to more accurately track real-time movement (as human hands don't move fast enough to justify a 1ms delay). These modifications significantly reduced player sprite flickering. (12/10/18)

Writing to registers on the MP3 decoder...

When attempting to read the contents of reset values on the VS1053b registers, we were always receiving high impedance. This is the default value for the MISO line in SPI protocol. We changed the master clock speed to a slower value 12Mhz and finally we could read the contents of the reset values. Another important modification in our code was to reset the MP3 decoder through the reset pin before writing to the registers.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

- https://bikerglen.com/projects/lighting/led-panel-1up/

- https://www.sparkfun.com/sparkx/blog/2650

- https://learn.adafruit.com/32x16-32x32-rgb-led-matrix/

- https://learn.adafruit.com/adafruit-vs1053-mp3-aac-ogg-midi-wav-play-and-record-codec-tutorial/assembly

Appendix

You can list the references you used.