S18: Smart Rock Paper Scissors

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

Hand gesture controlled rock paper scissors game.

Abstract

This project recreates the classic Rock,Paper, Scissors game using a LED Matrix to display and keep track of scoring, and wireless gloves to record the user input. The LED Matrix helps users to know what round they are on, what the score is, as well as provide prompts of when to give the Rock, Paper or Scissors signal. The Smart aspect of the system also allows users to play against a computer player. The wireless gloves utilize Bluetooth modules and flex sensors to detect the player input and feed that input into the game logic and game controller.

Objectives & Introduction

- Create LED display to guide players through the game

- Create wireless gloves to allow players to give input

- Create feedback to the gloves to enhance the game experience

- Make the game platform modular, so other games could be easily built with the system

Team Members & Responsibilities

- Josh Skow

- System Integration

- PCB

- Kaustubh Jawalekar

- Bluetooth

- Glove, Sensors

- Kevin Gadek

- LED Display

- Akinfemi Aluko

- Bluetooth

- Glove, Sensors

- Sarvpreet Singh

- LED Display

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 03/20 | Submit Project Proposal | Completed.

Had to modify project proposal from original submission. |

| 2 | 03/27 | Determine project architecture | Completed. |

| 3 | 04/03 | Order Parts | Completed. |

| 4 | 04/10 | Begin work on Display, Bluetooth

Begin work on PCB. Begin testing glove sensors. |

Completed. |

| 5 | 04/17 | Write multiple lines on Display Successfully

Set Bluetooth device to master mode Read valid data from flex sensor |

Completed.

Had to purchase a Bluetooth module that supports master mode. |

| 6 | 04/24 | Draw full image on Display.

Complete Bluetooth logic. Begin working on game logic and game state machine. Begin assembling glove and sensors to mount on wrist. Finish PCB, and submit PCB layout to fab. |

Game logic completed. Bluetooth logic working, and basic gloves put together. |

| 7 | 05/01 | Finalize glove design, and wrist mounting.

Finish Display logic. Finalize game logic. Receive PCB from fab, populate and test PCB. |

Completed.

PCB received. Glove drivers working and glove is physically put together. |

| 8 | 05/08 | Test for edge cases with game logic.

Fine tune display images for game. Add game features if time permits. Re-work PCB as needed based on testing. |

Completed? Problems Encountered? |

| 9 | 05/15 | Complete final project documentation.

Prepare project for demo. |

Completed? Problems Encountered? |

| 10 | 05/22 | Finish debugging project for demo. | Completed? Problems Encountered? |

Parts List & Cost

| Part Name | Description | Link | Quantity | Cost |

|---|---|---|---|---|

| 32x32 RGB LED Matrix | 32x32 Matrix to display game | Link | 1 | $44.95 |

| Bluetooth HC-05 Module | Bluetooth module with master mode capability | Link | 2 | $29.90 |

| XBee Bluetooth HC-06 Module | Gikfun HC-06 Bluetooth Bee V2.0 Slave Module | Link | 2 | $23.96 |

| SJOne Boards | Microcontrollers | N/A | 4 | $320 |

| Flex Sensors | Flex sensors to measure finger flex | Link | 4 | $26 |

| Parallax 28821 Vibration motors | Feedback motors | Link | 2 | $11 |

| Gloves | Gloves to record gestures | Link | 2 | $20 |

| PCB | PCB to route power | Link | 3 | $140 |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

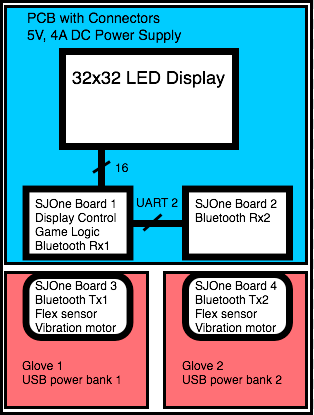

Smart Rock Paper Scissors used a 32x32 LED Display, four Bluetooth modules, and four SJOne boards as the primary hardware devices in the system. Two SJOne boards were used as Bluetooth receivers, and two SJOne boards were used as Bluetooth transmitters. One Bluetooth receiver board was also responsible for driving the LED Display and handling the Rock, Paper, Scissors logic.

A PCB was created in order to route power from a 5V, 4A AC/DC power supply to the LED display, and both Bluetooth receiver SJOne boards. The SJOne boards attached to the glove controllers each use USB power banks to power the board.

Figure 1: Block diagram of the Smart Rock, Paper, Scissors hardware components.

Bluetooth Gloves

|

Flex Sensors Flex sensors are used to detect the hand gesture of the user. Two flex sensors are used on fingers 2 and 4, if paper both are not bent, if scissors one is bent and if rock both are bent.

|

[[File:|100px|left|frame|Glove Picture]] |

LED Matrix

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Bluetooth Gloves

The hardware interface to the Flex sensors uses ADC for input and ground to complete connection. Vibration motor uses GPIO. Bluetooth HC-05 uses UART connection to the SJOne board.

| SJ One Board Pin | Description |

|---|---|

| P0.0 | Vibration motor Vcc |

| P0.1 | Flex Sensor1 Vcc |

| P2.7 | Flex Sensor2 Vcc |

| P0.26 | Flex Sensor1 ADCin |

| P1.31 | Flex Sensor2 ADCin |

| P RxD2 | Bluetooth HC05 Tx |

| P TxD2 | Bluetooth HC05 Rx |

| PTxD2 | Bluetooth HC05 Vcc |

| P GND | Common to Flex sensors |

| P GND | Bluetooth HC05 GND |

| P GND | Vibration motor GND |

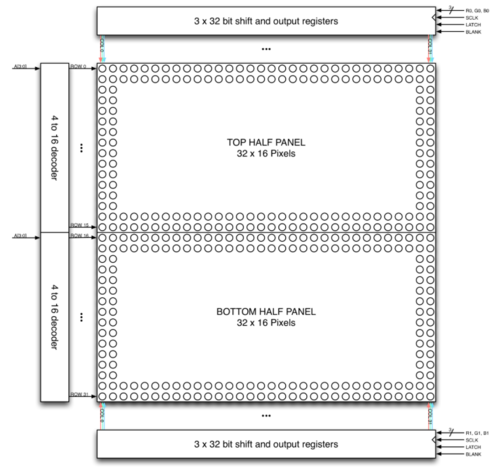

LED Matrix

The hardware interface to the LED Matrix uses GPIO for all data and control lines. A GPIO clock is toggled to shift in data sitting at the Matrix's 6 data ports.

| SJ One Board Pin | Description |

|---|---|

| P0.0 | addrA |

| P0.1 | addrB |

| P2.6 | addrC |

| P2.7 | addrD |

| P1.29 | Latch |

| P1.19 | Clock |

| P1.22 | R1 |

| P0.26 | G1 |

| P1.23 | B1 |

| P1.30 | R2 |

| P1.31 | G2 |

| P2.5 | B2 |

Printed Circuit Board (PCB) Design

The PCB is used to distribute power between the SJOnes an the LED display from the DC Power Jack. The PCB also routes the LED control and data signals to the SJOne.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Game Control Logic

Smart Rock Paper Scissors was designed using classes to support a generic game flow. Rock, Paper, Scissors is a type of game, and each game has up to two players and one display. Each player has a score and a controller. The display and controller classes use initialization methods in order to create tasks to handle the display and controller drivers.

The game parent class creates a task that handles the flow of each game in stages. A game is started by calling "start_game" on an instance of the game you wish to start. Start game will create a task for the game logic, and then launch the task scheduler.

The game task operates on a private "stage" variable, where each stage is an abstraction of levels for different types of games. The game task will continually call the virtual function get_stage(). get_stage() must be defined by the subclass game, in this case Rock, Paper, Scissors. The Rock, Paper, Scissors get_stage() will determine which stage to call based on the current stage value, and will handle switching between stages as makes sense in the flow of the game. The game task will run forever unless the developer implements logic for the "stop" variable. The game class maintains this "stop" variable in case the developer wants to quit the current game type.

The game class also has "start", "mode" and "reset" variables that help to control the flow of the game. For Rock, Paper, Scissors, the start variable corresponds to an external start switch. When the start switch is pressed, the game "start" is set to high and the Rock, Paper, Scissors will begin the rounds of the game.

Bluetooth Gloves

LED Matrix

An LEDMatrixGPIO class was built for the purposes of providing a common singleton instance to allow our state machine to easily draw images on our LED Matrix. A uint32_t 2-D array object called frameBuffer stored as a private member of this class is used to store the current 'image frame' that should be displayed on the matrix. The 32-bit pixel data for each row and each color is stored within this singular frameBuffer. The class provides API functions that will be used by our state machine such as drawStartScreen(), drawScoreboard(), drawRoundEnd(), drawGameOver(), and updateDisplay() are described in detail below.

updateDisplay()

The core of the LED Matrix drawing algorithm is an updateDisplay function that is called by a Repetitive Interrupt Timer at a rate of 30-50 MHz. This essentially acts as our refresh clock frequency. The updateDisplay code fragment is shown below.

//designed to loop through frameBuffer and shift data for paired rows

void updateDisplay()

{

//only need to iterate up to 16 because we're doing 2 rows at a time

for(int i = 0; i < 16; i++)

{

setEn(true); //turn off currently displayed row

setLatch(false); //about to shift in data so make sure that data isn't latched until whole row is shifted in

selRow(i); //will select i and i+16 rows at same time, this function sets 4 address lines to select correct rows

//this inner loop will shift MSB of frameBuffer[i] first into corresponding shift register

for(int j = 31; j >= 0; j--)

{

((frameBuffer[i][0] >> j) & 1) ? r1->setHigh() : r1->setLow(); //shift in r1 data with msb getting shifted in first

((frameBuffer[i][1] >> j) & 1) ? g1->setHigh() : g1->setLow(); //g1 data

((frameBuffer[i][2] >> j) & 1) ? b1->setHigh() : b1->setLow(); //b1 data

//bottom half for corresponding row; rows 0/16, 1/17 etc

((frameBuffer[i + 16][0] >> j) & 1) ? r2->setHigh() : r2->setLow(); //r2

((frameBuffer[i + 16][1] >> j) & 1) ? g2->setHigh() : g2->setLow(); //g2

((frameBuffer[i + 16][2] >> j) & 1) ? b2->setHigh() : b2->setLow(); //b2

clk->setHigh(); clk->setLow(); //shift in all 6 bits at once

}

//at this point, all 3 shift registers should be filled with corresponding row data in frameBuffer

setLatch(true); //latch shift register contents down to parallel output register

setEn(false); //turn on two rows i and i+16

delay_us(250); //very small delay to reduce flickering

}

}With this updateDisplay running in the background, drawing images simply entails updating a frameBuffer object with the 'bitmap' images and letting updateDisplay handle the overhead of toggling control signals such as latch and output enable. For each 'image' that we're using, such as words, numbers and graphics, the bitmap representations had to be painstakingly obtained so that information about which pixels are lit could be procured for each row and each color.

drawStartScreen()

drawScoreboard()

drawGameOver()

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Bluetooth Gloves

Steps to acquire data from gloves and send it via Bluetooth to controller

- Initialize ADC for 2 channels

- Initialize UART2

- Read ADC input and write it to UART2

- If the data is read successfully and received feedback from the controller, vibrate the indicator motor

- Repeat this process for every round

LED Matrix

Steps to write to LED Matrix:

- Set output enable HIGH to disable LED output for selected row

- Set latch LOW to block shift register from pushing to parallel data output register

- Shift in 32 bits of data for R1, G1, B1, R2, G2, B2 for rows 0/16

- Set addr lines A, B, C, D to select rows 0/16

- Set latch HIGH to move shift register data into parallel data output register

- Set output enable LOW to display currently selected row

- Repeat this process for the other rows 100 to 200 times per second

Testing & Technical Challenges

//Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? //Make a smooth transition to testing section and described what it took to test your project.

Bluetooth Gloves

Bluetooth pairing

LED Matrix

The RGB LED Matrix presented several challenges from both a hardware and software standpoint.

Several of these problems are described below:

SPI vs GPIO

The LED Matrix works by shifting in data available at its six data ports: R1, G1, B1, R2, G2, B2. Early experimentation with an SPI interface involved testing data transfer through a MOSI to B1 and SPI_CLK to SCLK connection. While this worked fine for top half control with one color, more thought had to go into being able to transfer data to the 2 other top-half color ports as well as the bottom half ports. An approach that was tried was connecting MOSI0 to one of the three top-half data ports and MOSI1 to one of the three bottom-half ports. Because the matrix takes in a single SCLK input to shift in data for both halves, a high-speed multiplexer was connected to let the SJOne board select the SPI clock that would be shifting in data depending on which half would be receiving data. In addition,

With GPIO, the issue of having to write data to 6 data lines with only two MOSI lines was solved by just using 6 GPIO ports and a GPIO clock. Multiplexers to switch between two clocks and other data lines were no longer needed.

Sensitivity

The LED Matrix proves to be extremely sensitive to input and other factors. In order to get an accurate image with minimal flickering and visual glitches, both the data lines from the SJOne board to the IDC ribbon cable as well as the power cable itself have to be positioned a specific way. Without fiddling with the position of the wires, glitches such as mislit rows and off colors are prone to happen. This problem was initially thought to be a timing issue in software when trying to shift in data through SPI or GPIO with delays placed in between important parts of the transfer sequence like row selection and latch toggling. However, the problem was eventually traced to hardware. Replacing the power supply eliminated virtually all flickering and visual glitches.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

Flex Sensor guide

Bluetooth HC 05 guide

RGB LED Matrix Guide

Appendix

You can list the references you used.