F15: Minion

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

Abstract

This section should be a couple lines to describe what your project does.

Objectives & Introduction

Show list of your objectives. This section includes the high level details of your project. You can write about the various sensors or peripherals you used to get your project completed.

Team Members & Responsibilities

Sensor Controller:-

Motor & I/0 Controller:-

- Sudheer Doddapaneni

- Keerthanaa Alagudurai

Communication Bridge & Android Controller:-

- Akshay Kanchar

- Asmita Deshpande

Geographical Controller:-

- Amit Pachore

- Sindhuja Gopalakrishnan Elango

Master Controller:-

- Gaurao Chaudhari

- Akshay Dabholkar

- Asmita Deshpande

Tester:-

Treasurer:-

- Keerthanaa Alagudurai

Hardware:-

- Sudheer Doddapaneni

Release:-

- Akshay Kanchar

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

Common Schedule

| Sl. No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 9/22/2015 | 9/28/2015 | RC Car and important component buying | ||

| 2 | 9/29/2015 | 10/6/2015 | 1) Algorithm and architecture 2) Setup of car and decision on CAN Id's |

||

| 3 | 10/7/2015 | 10/13/2015 | 1) Coding and final set-up of car 2) Successful communication of CAN bus. 3) Car in running position. |

||

| 4 | 10/14/2015 | 10/20/2015 | Sensor Data gathering and movement according to sensors. | ||

| 5 | 10/21/2015 | 10/27/2015 | 1) LCD Display working and finalizing the data to be displayed on LCD module. 2) GEO data gathering and controlling of car using Android module. |

||

| 6 | 10/28/2015 | 11/3/2015 | Integration of all the modules into one. | ||

| 7 | 11/4/2015 | 11/10/2015 | Inclusion of new features in the car. | ||

| 8 | 11/11/2015 | 11/17/2015 | Testing depending upon the newly added features. | ||

| 9 | 11/18/2015 | 11/24/2015 | Testing of Car and testing the self driving capability | ||

| 10 | 11/25/2015 | 12/1/2015 | Testing of Car |

Sensor Controller Schedule

| Sl. No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 9/20/2015 | 10/5/2015 | Study available sensors and place order | Completed | 10/4/2015 |

| 2 | 10/6/2015 | 10/13/2015 | Collaborate with the other sub teams to finish the CAN bus communication | Completed | 10/13/2015 |

| 3 | 10/13/2015 | 10/20/2015 | Develop simple test code for the sensors | Completed | 10/18/2015 |

| 4 | 10/21/2015 | 10/30/2015 | Interface all sensors and develop code for reading all sensors and implement filter for the same | ||

| 5 | 10/30/2015 | 11/2/2015 | Positioning of sensors and identifying dead band if any | ||

| 6 | 11/2/2015 | 11/5/2015 | Work on light and battery sensor (optional) | ||

| 7 | 11/06/2015 | 12/17/2015 | Final testing and debugging |

Motor & I/0 Controller Schedule

| Sl. No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 9/21/2015 | 9/25/2015 | Order LCD Display | Completed | 9/25/2015 |

| 2 | 9/28/2015 | 10/3/2015 | Going through the motor concepts and PWM | Completed | 10/2/2015 |

| 3 | 10/4/2015 | 10/9/2015 | Intreface the DC and SERVO Motors with SJONE board | Completed | 10/8/2015 |

| 4 | 10/10/2015 | 10/13/2015 | Establishing basic CAN communication with other modules | Completed | 10/13/2015 |

| 5 | 10/11/2015 | 10/16/2015 | Getting the car to run with the PWM signals from Motor controller | Completed | 10/15/2015 |

| 6 | 10/17/2015 | 10/23/2015 | Research on Speed cotrol method and sensor for the same interface LCD display with LPC1758 via UART | ||

| 7 | 10/23/2015 | 11/4/2015 | Establishing reliable CAN communication for IO & Motor with others | ||

| 8 | 11/5/2015 | 11/12/2015 | Integrate Speed sensor and get feedback. Start working on start,stop buttons and headlight | ||

| 9 | 11/13/2015 | 11/20/2015 | Testing substantial self driving capability of the car | ||

| 10 | 11/21/2015 | 11/30/2015 | Complete integration, Debugging and Fine tuning | ||

| 11 | 12/1/2015 | 12/5/2015 | Final Validation |

Geographical Controller Schedule

| Sl. No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 09/27/2015 | 10/07/2015 | Ordering Parts and understanding each module | Completed | 10/11/2015 |

| 2 | 10/07/2015 | 10/13/2015 | CAN Communication with other boards and understanding each module | ||

| 3 | 10/07/2015 | 10/30/2015 | Algorithm for distance and heading calculation and coding | ||

| 4 | 10/14/2015 | 10/20/2015 | Interfacing of compass(I2C) and GPS (UART) with SJONE board | ||

| 5 | 10/20/2015 | 10/30/2015 | Compass,GPS Calibration and Coding | ||

| 5 | 10/25/2015 | 11/15/2015 | Individual unit testing | ||

| 6 | 10/30/2015 | 11/30/2015 | Interfacing with Android, Master and IO controllers | ||

| 7 | 10/30/2015 | 11/30/2015 | Integration Testing,On Car Calibration |

Master Controller Schedule

| Sl. No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 09/30/2015 | 10/6/2015 | a) Design of Algorithm and Architecture for Master Module. b) Setup of CAN communication between two controllers. |

||

| 2 | 10/7/2015 | 10/13/2015 | a) Development of CAN message system for Android, Sensor and GPS, I/O reception. b) Decide about periodic function frequencies that’ll be handling different modules. |

||

| 3 | 10/14/2015 | 10/20/2015 | a) Development of driving,stopping and obstruction avoidance algorithm for motor. b) Implementation of LED Display to display number of messages on CAN bus. c) Implementation of turning algorithm as per the data received from the Geo Controller. |

||

| 4 | 10/21/2015 | 10/27/2015 | a) Designing of Kill switch with the help of Motor, I/O and Android. b) Design the system to restore the last known configuration. c) Implementation to reset modules if the CAN bus reaches BUS off state. |

||

| 5 | 10/28/2015 | 11/3/2015 | a) Design of Head Light functionality with the help of Sensor module. b) Implementation of log files saving to SD card. |

||

| 6 | 11/4/2015 | 11/10/2015 | a) Integration of all the modules with Master module and check it after combining everything. b) Probable implementation of additional features. |

||

| 7 | 11/11/2015 | 11/17/2015 | a) Refine the work done earlier.Change areas that need a change. b) Test the Master module while all the modules are integrated together and list down modifications and additions to be done. |

||

| 8 | 11/18/2015 | 11/24/2015 | Testing of system and specially making sure that last week’s shortcomings are taken care of. | ||

| 9 | 11/25/2015 | 12/1/2015 | a) Final testing of individual modules. b) Testing the self-driving capability of the car. |

||

| 10 | 12/2/2015 | 12/8/2015 | Final working on the shortcomings in the previous week. | ||

| 11 | 12/9/2015 | 12/15/2015 | Final Testing of Car. |

Communication Bridge & Android Controller Schedule

| Sl. No | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 9/29/2015 | 10/06/2015 | Ordering bluetooth module and setting up android dev enviornment | Completed | 10/06/2015 |

| 2 | 10/06/2015 | 10/13/2015 | Implementing basic UI with Start and Stop buttons and testing bluetooth module | Completed | 10/12/2015 |

| 3 | 10/13/2015 | 10/27/2015 | Integrating android app with bluetooth module and SJ One board | Ongoing | |

| 4 | 10/27/2015 | 11/03/2015 | Establishing communication with other modules using CAN and testing Prototype | ||

| 5 | 11/03/2015 | 11/17/2015 | Enhancing UI features with Google Maps and display of sensor data from different modules | ||

| 6 | 11/17/2015 | 12/01/2015 | Setting up Communication with GPS and Master and prototype testing | ||

| 7 | 12/01/2015 | 12/08/2015 | Final app testing |

Parts List & Cost

Give a simple list of the cost of your project broken down by components. Do not write long stories here.

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Car Framework and Components

The RC car, Traxxas Stampede, in its raw form consists of a Titan 12T 550 Brushed DC motor, a Servo motor, an XL-5 ESC (Electronic Speed Control) unit, battery and a pre-programmed wireless receiver and controller. The Battery used in the RC car is an 8.4 V, 3000 NiMH from Traxxas. The wireless receiver gets commands from the remote control and drives the motors accordingly, but the DC motor can be controlled only through ESC.

The ESC (Electronic Speed Control) unit is an electronic module, which receives PWM signals from the controller and varies speed and direction of the DC motor and also acts as dynamic brakes. ESCs are often used in RC models. The ESC has the capability to provide dynamic braking depending on the mode in which it is being operated.

Motor and I/O Controller

Motor Module

The motor module comprises of a servo motor for the direction control and a DC motor for speed control. The servo motor helps the car in turning left and right where as the DC motor on the other hand helps the car move forward and backward. The motor used in the project is a brushed motor. Conventionally, brushless motors are faster and more efficient than brushed motors. But, the reason for selecting a brushed motor over a brushless motor is that we employ a dedicated battery for the motor such that we do not have any issues with power and efficiency. Moreover, we need not operate the car at high speeds.

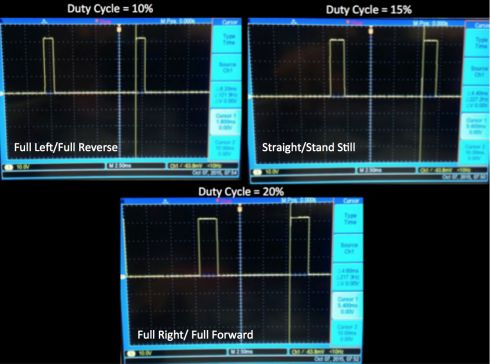

The initial task in the motor module is to find the operating ranges of the motor so that we get to know the output signal range and frequency from the SJONE board which would be replacing the pre-programmed controller. The simplest way to find the operating ranges of the motor is to tap and analyze PWM signal that is being supplied to the motor over an oscilloscope. The results as shown in the below pictures indicate that the operating duty cycle of both the motors lie between 10% to 20% and the frequencies at which the motors operate is 100Hz.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

CAN Communication [Empty spaces will be filled as the project progresses]

| Sr. No | Message ID | Message function | Message Data | To | From |

|---|---|---|---|---|---|

| High | |||||

| 1 | 0x220 | Motor Control | a.speed b.Direction |

||

| 2 | 0x010 | Kill Message | Master | Android | |

| 3 | 0x020 | Kill Message-Broadcast | All | Master | |

| 4 | 0x030 | Stop | Just a message and nothing else. | Master | Android |

| 5 | 0x040 | Stop | Motor | Master | |

| 6 | 0x210 | Sensor Data | a.Forward Distance Byte[0] Distance in cms. b.Left Distance Byte[1] Distance in cms. c.Right Distance Byte[2] Distance in cms. d.Back Distance Byte[3] Distance in cms. |

Master/Motor-IO | Sensor |

| 7 | 0x230 | Request Checkpoints | Android | Geo | |

| 8 | 0x240 | Send Checkpoints | Geo | Android | |

| 9 | 0x250 | Distance | a.Final remaining Distance b.Next checkpoint distance |

Master | Geo |

| 10 | 0x260 | Heading and Bearing | a.Heading b.Bearing |

Master | Geo |

| 11 | 0x270 | Run Command | Master | Android | |

| Medium | |||||

| 12 | 0x410 | Destination reached. Functions-a.Stop the motor. |

All | Master | |

| 13 | 0x420 | Battery Status | Master/IO | Sensor | |

| Low | |||||

| 14 | 0x610 | Boot Request | All | Master | |

| 15 | 0x620 | Boot Reply | Master | Motor-IO | |

| 16 | 0x621 | Boot Reply | Master | Sensor | |

| 17 | 0x622 | Boot Reply | Master | Geo | |

| 18 | 0x630 | Boot Status – This message will enable the map and run button in Android | Motor-IO/Android | Master | |

| 19 | 0x640 | System Start | All | Android | |

| 20 | 0x650 | Source Co-ordinates | Android | Geo | |

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

Appendix

You can list the references you used.