F19: Tower Defense in Space

Contents

ABSTRACT

My abstract goes here.

INTRODUCTION AND OBJECTIVES

|

RC CAR OBJECTIVES | ||||

|---|---|---|---|---|

|

| ||||

|

TEAM OBJECTIVES | ||||

|---|---|---|---|---|

|

| ||||

|

CORE MODULES OF TOWER DEFENSE | ||||

|---|---|---|---|---|

| ||||

|

PROJECT MANAGEMENT ADMINISTRATION ROLES | ||||

|---|---|---|---|---|

| ||||

|

TEAM MEMBERS & RESPONSIBILITIES | ||||

|---|---|---|---|---|

|

Team Members |

Administrative Roles |

Technical Roles | ||

|

|

| ||

|

| |||

|

|

| ||

|

| |||

SCHEDULE

|

TEAM MEETING DATES & DELIVERABLES | ||||

|---|---|---|---|---|

|

Week# |

Date Assigned |

Deliverables |

Status | |

| 1 | 10/15/19 |

|

| |

| 2 | 10/22/19 |

|

| |

| 3 | 10/29/19 |

|

| |

| 4 | 11/5/19 |

|

| |

| 5 | 11/12/19 |

|

| |

| 6 | 11/19/19 |

|

| |

| 7 | 11/26/19 |

|

| |

| 8 | 12/3/19 |

|

| |

| 9 | 12/10/19 |

|

| |

BILL OF MATERIALS (GENERAL PARTS)

|

MICRO-CONTROLLERS | ||||

|---|---|---|---|---|

|

PART NAME |

PART MODEL & SOURCE |

QUANTITY |

COST PER UNIT (USD) | |

|

|

| ||

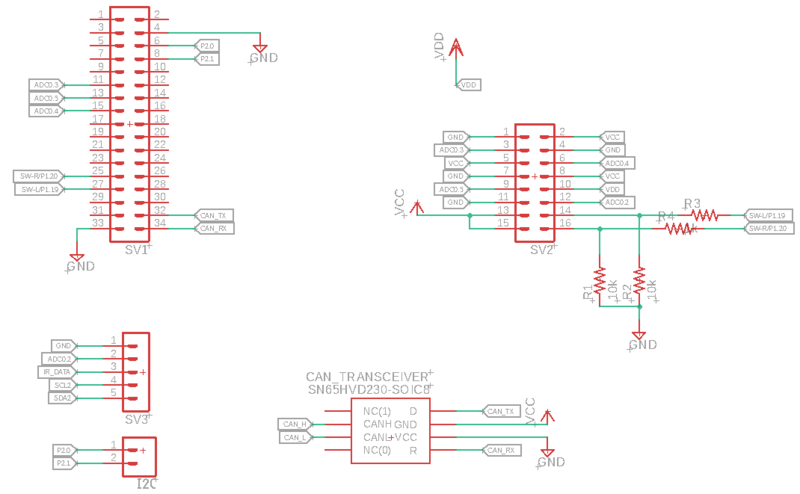

HARDWARE INTEGRATION PCB

Hardware Design

The hardware integration PCB was designed with two goals:

1. Minimize the footprint of the onboard electronics

2. Minimize the chances of wires disconnecting, during drives

To accomplish these goals,

The board consisted of n layers:

layer name

Technical Challenges

Design

- Balancing priorities between HW design and getting a working prototype

Assembly

- Wireless antenna connector on master board not accounted for in footprint, it may have to be removed to avoid interference with one connector.

Bill Of Materials

|

HARDWARE INTEGRATION PCB | ||||

|---|---|---|---|---|

|

PART NAME |

PART MODEL |

QUANTITY |

COST PER UNIT (USD) | |

TEST

In order

Hardware Design

During

We used

MOTOR CONTROLLER

Hardware Design

The motor board

1 pin

1 pin f

1 pin

The ESC was included with the RC we purchased and it was interfaced with 3 pins:

1 pin fo

Manag

Managing wheel spin was a more complicated process. The ESC also requires a PWM signal in order to operate, but is not as simple as the servo's operation.

In or

S

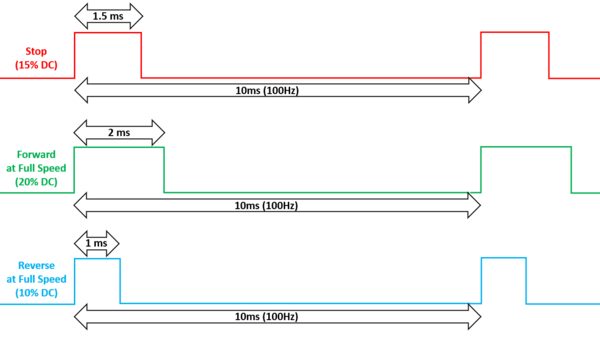

Speed Control Timing Diagrams

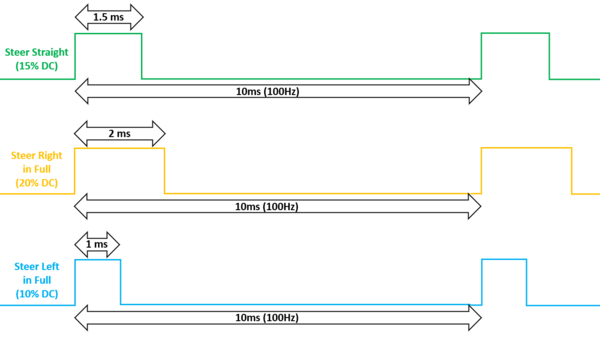

Steering Control Timing Diagrams

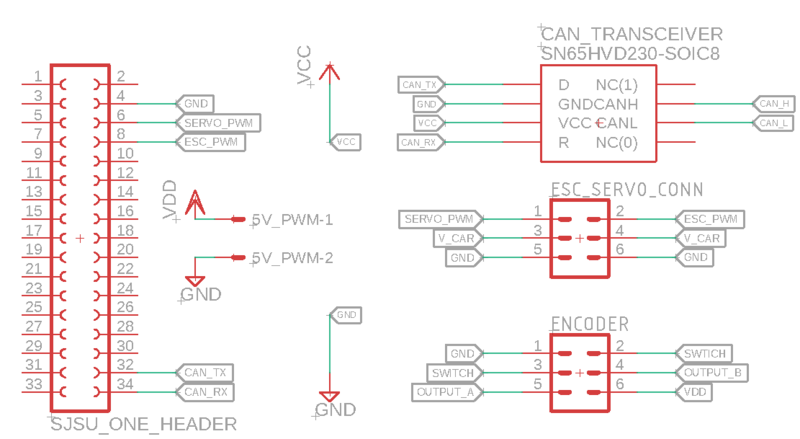

Motor Controller Schematic

Software Design

Periodic Callback: Init (beginning of program)

Periodic Callback: 1Hz (every 1sec)

- Che

Periodic Callback: 10Hz (every 100ms)

- Sen

Technical Challenges

SJOne PWM

W

Encoder

The

Bill Of Materials

|

MOTOR CONTROLLER | ||||

|---|---|---|---|---|

|

PART NAME |

PART MODEL |

QUANTITY |

COST PER UNIT (USD) | |

|

|

| ||

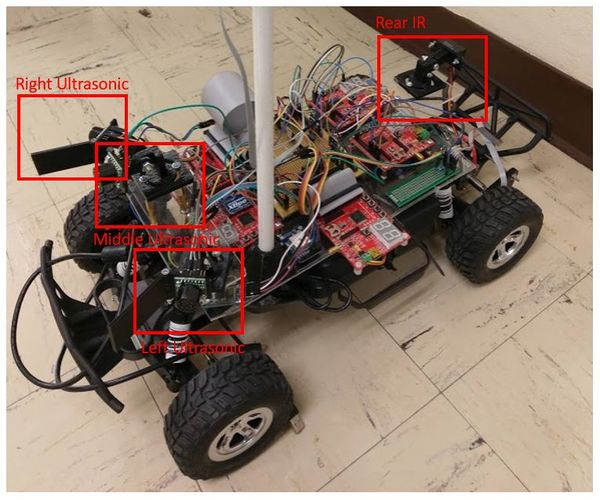

SENSOR CONTROLLER

Hardware Design

Sen

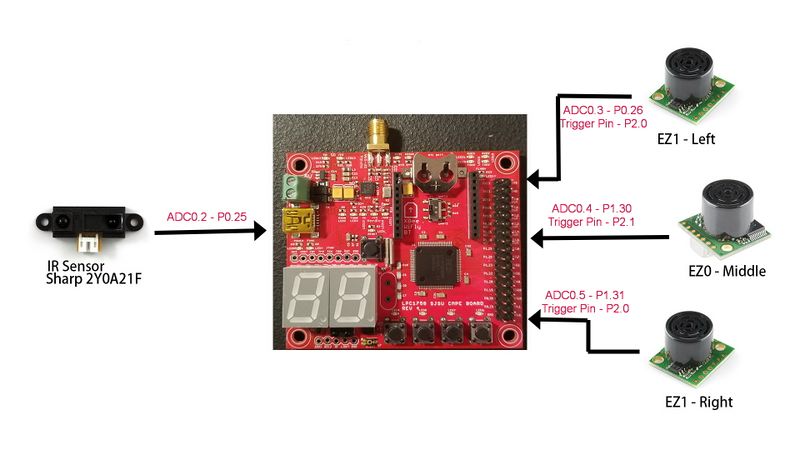

Sensor Controller Schematic

CAD Design

We g

Placement for the Ultrasonic Sensors

We r

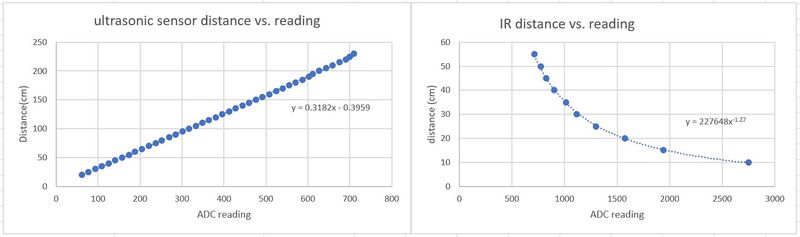

Sensor Value Conversion

In or

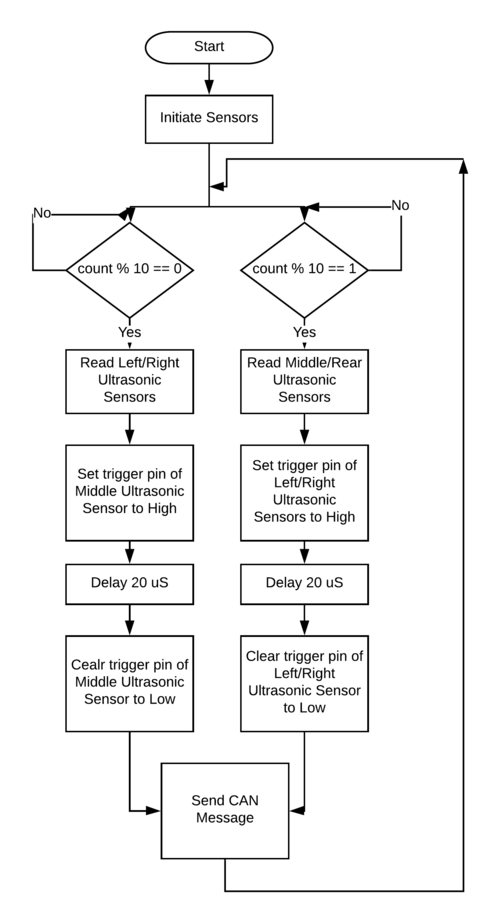

Software Design

Flowchart

The f

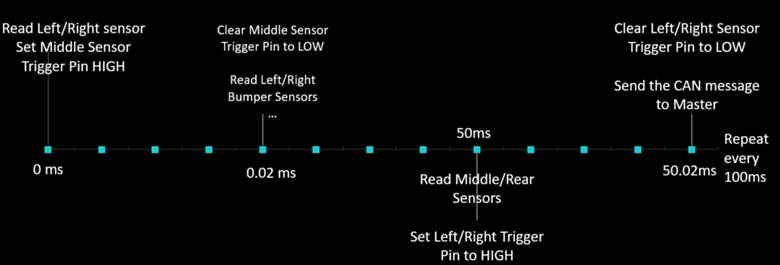

Timing Diagram

Technical Challenges

Sensor Interference

We saw :

- Higher

- Instead of l

Power Deficiency

At first

Unstable HR-04 Readings

At fi

ADC Supply Voltage

The mid

Slow car response to obstacle due to large queue size (running average)

During

Bill Of Materials

|

SENSOR CONTROLLER | ||||

|---|---|---|---|---|

|

PART NAME |

PART MODEL |

QUANTITY |

COST PER UNIT (USD) | |

|

|

| ||

|

|

| ||

|

|

| ||

CONCLUSION

This pr

Project Video

Project Source Code

Advice for Future Students

- FORM YOUR TEAM AS EARLY AS POSSIBLE AND START WORKING ON THE PROJECT AS EARLY AS POSSIBLE (WEEK 1 IF POSSIBLE)

- If you are