DBC Format

DBC file is a proprietary format that describes the data over a CAN bus.

Contents

DBC File Format

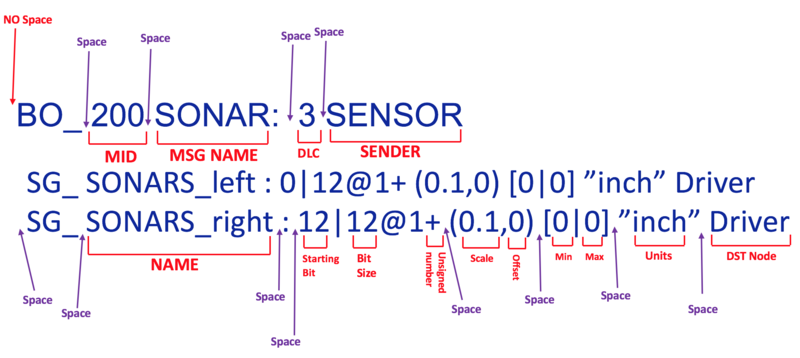

First, let's understand what the DBC file's format looks like.

VERSION ""

NS_ :

NS_DESC_

CM_

BA_DEF_

BA_

VAL_

CAT_DEF_

CAT_

FILTER

BA_DEF_DEF_

EV_DATA_

ENVVAR_DATA_

SGTYPE_

SGTYPE_VAL_

BA_DEF_SGTYPE_

BA_SGTYPE_

SIG_TYPE_REF_

VAL_TABLE_

SIG_GROUP_

SIG_VALTYPE_

SIGTYPE_VALTYPE_

BO_TX_BU_

BA_DEF_REL_

BA_REL_

BA_DEF_DEF_REL_

BU_SG_REL_

BU_EV_REL_

BU_BO_REL_

SG_MUL_VAL_

BS_:

BU_: NOONE SENSOR DRIVER MOTOR IO

BO_ 100 HEARTBEAT: 1 DRIVER

SG_ DRIVER_HEARTBEAT_cmd : 0|8@1+ (1,0) [0|0] "" SENSOR,MOTOR

BO_ 200 SONARS: 6 SENSOR

SG_ SENSOR_SONARS_mux M : 0|4@1+ (1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_s1_fault : 4|1@1+ (1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_s2_fault : 5|1@1+ (1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_s3_fault : 6|1@1+ (1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_s4_fault : 7|1@1+ (1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_left m0 : 8|12@1+ (0.1,0) [0|400] "" DRIVER,IO

SG_ SENSOR_SONARS_middle m0 : 20|12@1+ (0.1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_right m0 : 32|12@1+ (0.1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_rear m0 : 44|12@1+ (0.1,0) [0|0] "" DRIVER,IO

SG_ SENSOR_SONARS_no_filt_left m1 : 8|12@1+ (0.1,0) [0|400] "" NOONE

SG_ SENSOR_SONARS_no_filt_middle m1 : 20|12@1+ (0.1,0) [0|400] "" NOONE

SG_ SENSOR_SONARS_no_filt_right m1 : 32|12@1+ (0.1,0) [0|400] "" NOONE

SG_ SENSOR_SONARS_no_filt_rear m1 : 44|12@1+ (0.1,0) [0|400] "" NOONE

BO_ 300 MOTOR_CMD: 1 DRIVER

SG_ MOTOR_CMD_steer : 0|4@1- (1,-5) [-5|5] "" MOTOR

SG_ MOTOR_CMD_drive : 4|4@1+ (1,0) [0|9] "" MOTOR

BO_ 400 MOTOR_STATUS: 3 MOTOR

SG_ MOTOR_STATUS_wheel_error : 0|1@1+ (1,0) [0|0] "" DRIVER

SG_ MOTOR_STATUS_speed : 8|16@1+ (0.001,0) [0|0] "kph" DRIVER

CM_ BU_ NOONE "No node, used to indicate if it's a debug message going to no one";

CM_ BU_ DRIVER "The driver controller driving the car";

CM_ BU_ SENSOR "The sensor controller of the car";

CM_ BU_ MOTOR "The motor controller of the car";

CM_ BO_ 100 "Sync message used to synchronize the controllers";

BA_DEF_ "BusType" STRING ;

BA_DEF_ SG_ "FieldType" STRING ;

BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0;

BA_DEF_DEF_ "BusType" "CAN";

BA_DEF_DEF_ "FieldType" "";

BA_ "GenMsgCycleTime" BO_ 100 1000;

BA_ "GenMsgCycleTime" BO_ 200 100;

BA_ "GenMsgCycleTime" BO_ 300 100;

BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd";

VAL_ 100 DRIVER_HEARTBEAT_cmd 0 "DRIVER_HEARTBEAT_cmd_NOOP" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 2 "DRIVER_HEARTBEAT_cmd_REBOOT";

CAN Communication Handling in C

I created auto-generation tool that operates on the DBC file that produces Auto-Generated-Code that we will refer to as AGC in this article. AGC contains useful artifacts such as:

- C structures that store data variables as described in the DBC message

- Each signal that your controller is a recipient of will occupy a member variable of the struct

- If your controller is the sender of the message, then all signals of the DBC message will appear in the structs

- Receive handling to convert a CAN message to the C structure

- Transmission handling to convert the C structure into the CAN message's data bytes

The AGC essentially removes the burden of encoding and decoding the CAN message data. For example, you don't have to parse fields individually by doing something such as "bit 5 of byte 6 means foo", and instead, you will simply have a C structure where the CAN message data can be parsed and stored upon.

MIA Handling

MIA means "Missing in Action", and the objective is that if a periodic message is not received as expected, then the contents of the parsed message can be defaulted to the data of your choice. For example, if a temperature sensor reading is not received, then we can tell the AGC to default the sensor reading value to 68 degrees Fahrenheit. This reduces code clutter because each time you use the temperature sensor's value, you don't have to check if the corresponding CAN data was received in the last few seconds.

CAN RX

To handling the messages that are to be received, we must have "glue code" that pieces together the data of a received messages to the target structure. Unfortunately the AGC cannot generate the glue code because it is decoupled from the CAN driver and furthermore, it leaves it up the application to provide the destination structure to convert the CAN data onto.

TODO

CAN TX

The transmission side is simpler than receive because you simply provide an 8-byte data storage for the CAN message, and the encode_ functions convert the C structure onto the 8-bytes that you can send out as part of the CAN message. The encode_ functions also return the message ID and the length of the CAN message and this was done in an effort to decouple the CAN driver from the AGC.

TODO

Full Example on Periodic Scheduler

TODO