F12: Smart Bulb

Contents

SmartBulb: The Intelligent Lighting System

Problem Statement

Conventional lighting systems do not provide flexibility or automatically adapt to users’ needs. While there has been a push for smarter light bulbs, the equipment which has been released to the market incorporates no intelligence, and the functionality is superficial at best.

Our Solution

A lighting system which adapts to occupant needs and produces optimal light output. SmartBulb automatically recognizes ambient light and the presence of occupants, incorporates the diurnal cycle into its decisions, and enables supervisory devices to request changes to the system configuration.

Abstract

Conventional lighting systems, such as those used in commercial workplaces and residences, are antiquated, primarily because these systems provide minimal flexibility and do not automatically adapt to user’s needs. While there has been a push for “smarter lightbulbs”, the equipment which has been released to the market (such as color configurable LED bulbs) incorporates no intelligence, and the functionality is superficial at best. Being able to change your living room’s color to hot pink via your smartphone only allows a user to amuse him/herself. In comparison, we are interested in having the lighting system adapt to occupant needs automatically, recognizing ambient light and occupant presence, incorporating the diurnal cycle into its decisions, and enabling supervisory devices to request changes to the system’s current configuration.

For instance, each of the bulbs (nodes) within our intelligent lighting system is able to sample the current ambient light within the room without visible interruption to its own light output. We accomplish this by producing a light with a 120 Hz flicker, utilizing 60 Hz AC power as a ground-truth available to all bulbs. Since all bulbs are connected to the same 60 Hz AC power source, they all flicker at the same time. This allows us to sample the ambient light using our color sensors, without the light output from the bulb or the adjacent bulbs impacting our measurements. From our samplings, we can determine the intensity of light in the room, along with the color composition of the light. This information is shared amongst all bulbs within the same room via a shared intelligence network facilitated by the Digimesh protocol, which utilizes XBee radios. From this information, a consistent lighting color / temperature is created in the room, and light output can be limited when plenty of ambient light (such as sunlight) is available. When ambient light is limited, the system will utilize the current time-of-day and the diurnal cycle to determine optimal light output. By utilizing the diurnal cycle to make lighting decisions, we can ensure that occupant fatigue due to lighting is minimized, improving occupant comfort.

This project extends the work currently being performed within our senior projects.

Objectives & Introduction

System will be able to detect and adapt to changing ambient light conditions

- If the room is dark and occupants are detected, the system should utilize the time-of-day combined with the diurnal cycle to output the preferred light temperature and brightness

- If the room has ambient light, the system should attempt to match the color of the ambient light and should lower its light output to meet the room’s desired number of lumens. * For instance, if a warm colored ambient light is visible to the system, it should produce a warm colored output. If a cool color light is visible to the system, it should produce a cool colored output. Extreme cases can also be demonstrated

- Lights should not need to turn on / off (from occupant perspective) during ambient light measurements

- System will be able to respond to supervisory commands via Digimesh network

- Web interface will be connected to Digimesh network via Raspberry Pi or via ConnectPort X2. User will be able to control the current output (intensity, color) of each bulb, and modify other configuration settings (amount time on when occupant detected, relative location to other bulbs, etc.)

- Supervisory commands intended to show that other systems (including home automation) can be tied into this system.

Team Members & Responsibilities

- Phil Cyr

- Hardware architect, electronics, sensors, software

- Stephanie Fung

- Electronics, sensors, software, wiki-updater

- Brandon Schlinker

- Embedded systems architect, software, network

Schedule

| Week Number | Planned Items | Actual |

|---|---|---|

| 1 |

|

|

| 2 |

|

|

| 3 |

|

|

| 4 |

|

|

| 5 |

|

|

| 6 |

|

|

| 7 |

|

|

| Week Number | Scheduled Items | Items Completed |

Parts List & Cost

| Part | Quantity | Unit Cost |

|---|---|---|

| Parallax PIR Motion Sensor | 12.99 | |

| TAOS TCS3414FN Color Sensor | 3.68 | |

| LedEngin LZC-A3MD00 40W RGBW LED Module | 37.70 | |

| LM3404MA High Power LED Driver Chip | 3.28 | |

| LPC1769 Cortex M3 Processor | 9.01 | |

| j-link EDU | 60 | |

| Xbee-PRO DigiMesh 2.4GHz Module | 34 | |

| RN-SMA-S-RP 1" Antenna for Xbee PRO | 5.95 | |

| LS35-5 5V 7A Switching Power Supply | 19 | |

| 36V DC 9.7A 350W Regulated Switching Power Supply | 35.49 | |

| Aavid Heat Sinks 2.25 X 3.0 X 2.996 | 17.25 | |

| Arctic Silver Thermal Cooling Compound | 16.33 |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

The System

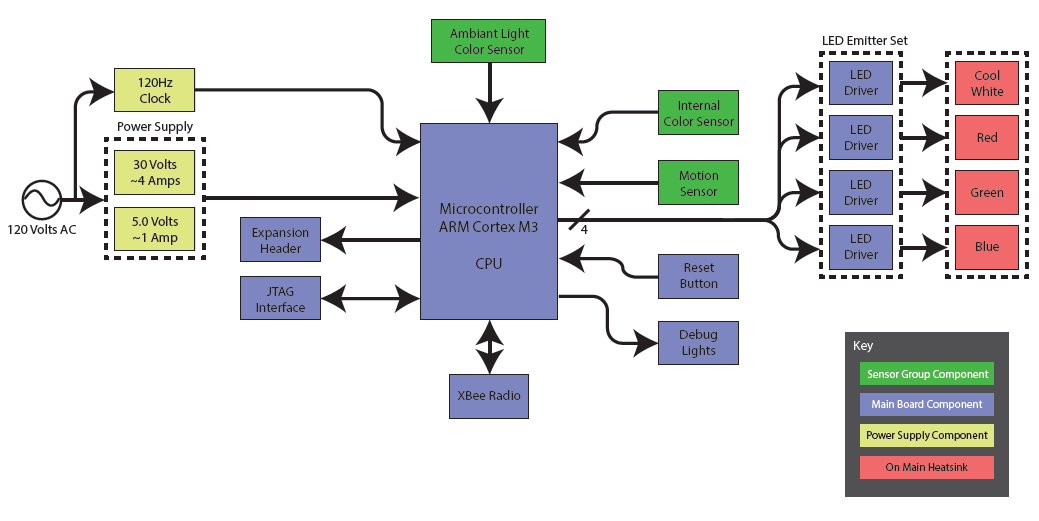

As seen in the main system diagram below, there are four key elements of our system.

Sensor Group Components

The sensors consist of two color sensors and one motion sensor. The techniques for interfacing each individual sensing component is described further into this section. The internal color sensor is soldered directly on the PCB. The other two sensors have extension headers from their respective traces.

Main Board Components

The main board components revolve around our microcontroller. The JTAG interface allows us to flash our microcontoller and debug our code. The debug lights and reset button offer us simple debug tools directly on the PCB. The XBee radio utilizes DigiMesh protocol so that the system can communicate to other light nodes. Furthermore, there are several expansion headers which connect to the microcontroller which allow for expanding the unit to utilize new modules.

Power Supply Components

Switching power supply units supply the two main power types used on the board. The 30 volts PSU is utilized by the LED drivers, while the 5 volt power supply supplies the rest of the power.

The LEDs

Our LEDs are driven by the LED drivers which are controlled via pulse-width modulation (PWM). The PWM is software controlled, and the signals are generated by the microcontroller.

Motion Sensing

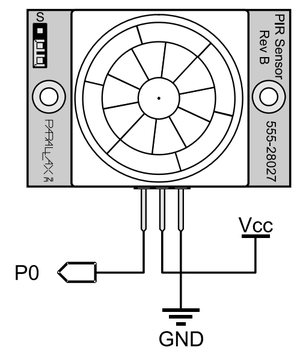

Motion sensing is the key element for the occupancy sensing of the system. This is achieved by using a Parallax PIR motion sensor. There are three pins on the motion sensor: power, ground, and output. The motion sensor is active high, so it will go HIGH (Vcc) when movement is sensed. The approximate distance range for the sensor is 30 feet. By having a motion sensor module on each of lighting fixture, we are able to sense movement to a fine resolution.

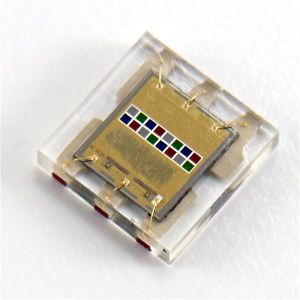

Color Sensing

Color sensing on the system consists of two elements: sensing the hue or color, and sensing the brightness or intensity of the light. The main component used to achieve this is the TCS3414, which can sense the intensity of red, green, and blue (RGB) colored light. This color sensor is an I2C device, several photodiodes with corresponding RGB color filters result in different sensor values depending on how much light of each color is sensed on their respective color channels.

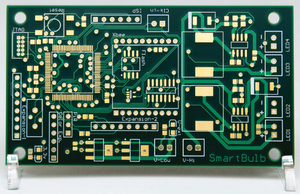

Custom PCB

After testing all the components individually on a breadboard, we soon realized that we would need to create a custom PCB in order to achieve the desired form factor for our project. We used Altium as the PCB CAD software to design our board. We designed two iterations of the circuit board. For the first iteration, our goal was to test our design and connections. For the second iteration, we were able to optimize the size based on lessons learned from the board’s first version.

Hardware Interface

Disclaimer/Note: Always check the datasheet for the sensor module you are using for the voltage characteristics, rating specifications and pin functions. The interface descriptions shown here are specifically for the parts we used, and should be used as a starting point.

Motion Sensor Connection

The figure below shows the pin connections for the minimum working circuit to use the PIR motion sensor module.

There are three pins on this specific module from Parallax. The Vcc pin is the supply voltage for the module, which can be 3 to 6 V. The GND pin is connected to ground. The OUT pin is an active high sensor output, it will output a HIGH signal when motion is sensed, and the sensor dome will light up red. We connected this to a pin on our microprocessor to sense motion.

There is a jumper located on the top right of the module. If the jumper is switched to the “S” mode, it will reduce the sensitivity of the sensor to a 15 feet maximum range instead of the 30 feet maximum. We used the sensor in the “L” mode since our application called for maximum sensitivity. When this sensor initially starts up, it has a warm up time of about 40 seconds where the dome will be red and the OUT pin is HIGH. This warm up time is used to allow the sensor to learn the environment, and the datasheet recommends that during this time, there should be as little motion as possible in the sensor’s field of view. Another notable feature is that after sensing motion, the OUT pin will remain HIGH for about 5 seconds until the sensor will go back to LOW.

Software Design

Describe PWM

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Custom Printed Circuit Board

In order to fulfill our system requirements, we opted to design our own custom printed circuit board (PCB). We ran into several challenges on the path to accomplishing this task:

- Software: We used Altium as our PCB CAD software, it's a sophisticated tool which allowed us to accomplish our task, but we had to put in several hours to learn the intricacies of the tool

- One critical error we ran into for our first iteration of the PCB is we did not know how to run the design rule check, and we had to manually correct them when the PCB arrived

- Altium was not set up to be used with multiple users with files syncing on Dropbox, so we ran into some trouble where changes weren't being executed properly

- Assembly: Due to cost constraints, we had to assemble the boards ourselves including the 100 pin microprocessor chip

- A few of our parts were quite delicate and required extra care to solder onto the board

- We made some mistakes which required de-soldering/rework

- Testing: We had to verify that our boards worked

- During programming some errors would result from shorts on the board

Our solutions:

- Software: We put in many hours to learn Altium, each team member irrespective of their expertise learned how to use Altium to an extent in order to assist with PCB related tasks

- After we ran into the ground errors on our first board, we were vigilant about design rule checking our design to make sure that rules and specifications were followed on our final iteration of the PCB

- In order to make sure our files were not subject to unwanted changes, we made sure to properly close the files and communicated with each other about the status of the project file. We also uploaded major milestone design changes to our repository

- Assembly: We utilized our own soldering expertise, improved our techniques, and learned new techniques to accomplish our board assembly

- For the 100 pin processor chip, Phil skillfully adapted the drag-solder technique, so he was solely in charge of processor chip soldering

- After making mistakes, we would review our work to avoid making the same mistake

- Testing: We would put on the minimum parts needed to test the processor and JTAG connection before moving onto the other parts

- To find shorts, we would use a multimeter to perform a continuity test and verification on the pins. We would also look at the processor chip (it was prone to shorts from the solder drag) under a magnifying glass/microscope

- Board shorting was a particularly difficult challenge we faced, and we would suggest very carefully assembling the board and paying attention to the components which are difficult to solder -- it costed us a lot of time and frustration when a hardware problem was confused with a software issue

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

Due to patent pending the source code is not listed for this project.

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.