S22: TBD

Contents

Project Title

THE BEST DRIVER

Abstract

Our goal for this project is to use knowledge we gathered from lectures to design, implement, and test a self-driving RC car using a Controller Area Network (CAN) bus for controller communication. The project involves FreeRTOS and utilizes periodic tasks (running at 1Hz, 10Hz, and 100Hz) to gather, process, and display data from various embedded modules.

Introduction

The project was divided into 5 modules:

- Sensor/Bridge Controller

- Motor Controller

- Geo Controller

- Driver/LCD Controller

- Web Application

Team Members & Responsibilities

From Left to Right: Jasdip Sekhon, Brian Ho, Justin Stokes, Billy Lai, Isaac Wahhab, William Hernandez

- Sensor

- Jasdip Sekhon

- Brian Ho

- Justin Stokes

- Motor

- Justin Stokes

- Isaac Wahhab

- Geographical

- Brian Ho

- William Hernandez

- Jasdip Sekhon

- Driver Logic & LCD & LED Ring

- William Hernandez

- Billy Lai

- Isaac Wahhab

- Web Application & Communication Bridge Controller

- Isaac Wahhab

- Billy Lai

- Testing Team

- The Best Driver Team

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 02/15/2022 | 02/21/2022 |

|

Completed |

| 2 | 02/22/2022 | 02/28/2022 |

|

Completed |

| 3 | 03/01/2022 | 03/07/2022 |

|

Completed |

| 4 | 03/08/2022 | 03/14/2022 |

|

Completed |

| 5 | 03/15/2022 | 03/21/2022 |

|

Completed |

| 6 | 03/22/2022 | 03/28/2022 |

|

Completed |

| 7 | 03/29/2022 | 04/04/2022 |

|

Completed |

| 8 | 04/05/2022 | 04/11/2022 |

|

Completed |

| 9 | 04/12/2022 | 04/18/2022 |

|

Completed |

| 10 | 04/19/2022 | 04/25/2022 |

|

Completed |

| 11 | 04/26/2022 | 05/02/2022 |

|

Completed |

| 12 | 05/03/2022 | 05/09/2022 |

|

Completed |

| 13 | 05/10/2022 | 05/16/2022 |

|

Completed |

| 14 | 05/17/2022 | 05/25/2022 |

|

Completed |

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Redcat Racing | 1 | $139.00 |

| 2 | SJTwo Boards | SJTwo Boards On Amazon | 4 | $200.00 |

| 3 | CAN Transceivers (SN65HVD230) | Waveshare | 4 | $40.00 |

| 4 | LSM303 Triple-Axis Accelerometer and Magnetometer | Adafruit | 1 | $15.00 |

| 5 | Venus GPS with SMA Connector | SparkFun | 1 | |

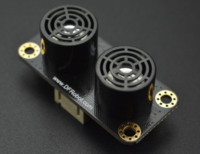

| 6 | URM09 Ultrasonic Sensors | DFRobot Gravity | 4 | $52.00 |

| 7 | PCB | JLCPCB | 1 | $5.00 |

| 8 | Plexiglass | 1 | ||

| 9 | LCD Display | SunFounder LCD Display | 1 | $12.99 |

| 10 | APA102 Ring LED | Sparkfun | 1 | $11.50 |

| 11 | LEDs for obstacle detection, GPS lock status, and web app lock status | 6 | ||

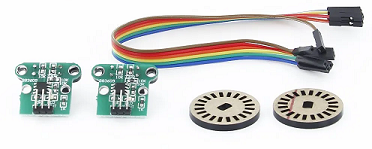

| 12 | Rotary Encoder & Wheel Set | Tinkersphere | 2 | $10.99 |

| 13 | Set of Headlights and taillights | eBay | 1 | $3.99 |

| 14 | Logic Level Converters | Sparkfun | 1 | $3.50 |

| 15 | Buck Converters | 1 | ||

| 16 | Standoffs for mounting SJTwo boards, PCB, and raising compass | 40 |

Printed Circuit Board

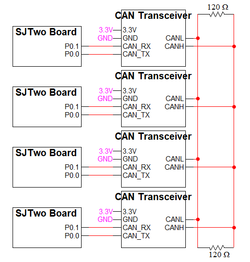

We designed and implemented two PCBs: CAN Bus PCB and RC Car PCB.

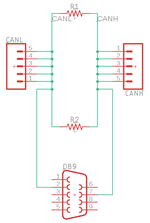

CAN Bus PCB Schematic

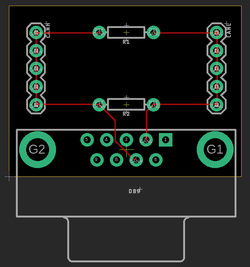

CAN Bus PCB Board

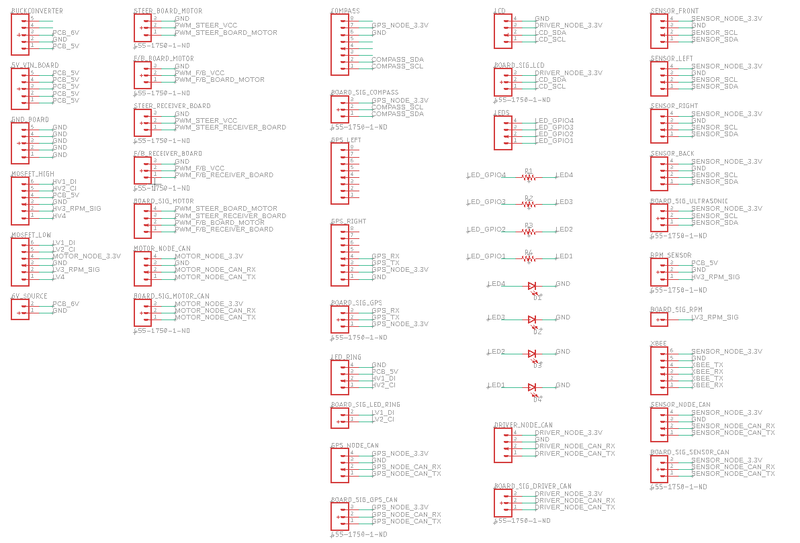

RC Car PCB Schematic

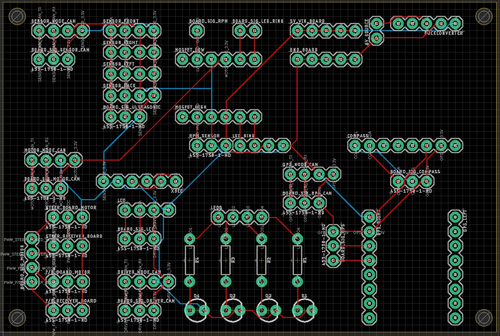

RC Car PCB Board

CAN Communication

Our message IDs are arranged with priority given to the nodes in the following order: DRIVER, SENSOR, GEO, MOTOR. The following critical messages are transmitted at 100Hz:

- SENSOR_TO_DRIVER_SONARS

- GPS_DESTINATION_LOCATION

- SENSOR_TO_DRIVER_WHEEL_ENCODER_MSG

- GEO_STATUS

- DRIVER_TO_MOTOR_CMD

The remaining debug messages are transmitted at 10Hz or 1Hz.

We decided to give 32 message IDs to each node and to separate the nodes' message IDs accordingly.

| Node | Message ID Range | |

|---|---|---|

| 1 | DRIVER | 32 - 63 |

| 2 | SENSOR | 63 - 95 |

| 3 | GEO | 96 - 127 |

| 4 | MOTOR | 128 - 159 |

Hardware Design

DBC File

Gitlab link to our master branch's DBC file

Our DBC file includes the SENSOR, DRIVER, MOTOR, and GEO nodes.

Below are the messages defined in the file:

BO_ 32 DRIVER_TO_MOTOR_CMD: 3 DRIVER SG_ DRIVER_TO_MOTOR_steer : 0|9@1+ (1,-180) [-180|179] "" MOTOR SG_ DRIVER_TO_MOTOR_speed : 9|5@1+ (1,0) [0|31] "RPM" MOTOR SG_ DRIVER_TO_MOTOR_current_rpm : 14|10@1+ (1,0) [0|1023] "RPM" MOTOR

BO_ 33 DRIVER_DEBUG_MSG: 1 DRIVER SG_ DRIVER_DEBUG_MSG_sensor_mia : 0|1@1+ (1,0) [0|0] "" DBG SG_ DRIVER_DEBUG_MSG_geo_mia : 1|1@1+ (1,0) [0|0] "" DBG

BO_ 64 SENSOR_TO_DRIVER_SONARS: 4 SENSOR SG_ SENSOR_TO_DRIVER_SONARS_front_left : 0|8@1+ (1,0) [0|0] "" DRIVER SG_ SENSOR_TO_DRIVER_SONARS_front_middle : 8|8@1+ (1,0) [0|0] "" DRIVER SG_ SENSOR_TO_DRIVER_SONARS_front_right : 16|8@1+ (1,0) [0|0] "" DRIVER SG_ SENSOR_TO_DRIVER_SONARS_back : 24|8@1+ (1,0) [0|0] "" DRIVER

BO_ 65 GPS_DESTINATION_LOCATION: 7 SENSOR SG_ GPS_DESTINATION_LOCATION_latitude : 0|28@1+ (0.000001,-134.217727) [-134.217727|134.217728] "" GEO,DRIVER SG_ GPS_DESTINATION_LOCATION_longitude : 28|28@1+ (0.000001,-134.217727) [-134.217728|134.217728] "" GEO,DRIVER

BO_ 66 SENSOR_TO_DRIVER_WHEEL_ENCODER_MSG: 2 SENSOR SG_ SENSOR_TO_DRIVER_WHEEL_ENCODER_MSG_rpm : 0|10@1+ (1,0) [0|0] "RPM" DRIVER,DBG

BO_ 67 SENSOR_TO_DRIVER_APP_CONNECTION_MSG: 1 SENSOR SG_ SENSOR_TO_DRIVER_APP_CONNECTION_MSG_app_connected : 0|1@1+ (1,0) [0|0] "" DRIVER

BO_ 96 GEO_STATUS: 5 GEO SG_ GEO_STATUS_compass_heading : 0|9@1+ (1,0) [0|359] "Degrees" SENSOR,DRIVER SG_ GEO_STATUS_destination_heading : 9|9@1+ (1,0) [0|359] "Degrees" SENSOR,DRIVER SG_ GEO_STATUS_distance_to_destination : 18|16@1+ (0.1,0) [0|0] "Meters" SENSOR,DRIVER

BO_ 97 GEO_DEBUG_MSG: 1 GEO SG_ GEO_DEBUG_MSG_lock_status : 0|1@1+ (1,0) [0|0] "" DRIVER,DBG SG_ GEO_DEBUG_MSG_num_satellites : 1|4@1+ (1,0) [0|15] "" DRIVER,DBG

BO_ 98 GEO_CURRENT_LOCATION_DEBUG: 7 GEO SG_ GEO_CURRENT_LOCATION_DEBUG_latitude : 0|28@1+ (0.000001,-134.217727) [-134.217727|134.217728] "" DRIVER,DBG SG_ GEO_CURRENT_LOCATION_DEBUG_longitude : 28|28@1+ (0.000001,-134.217727) [-134.217728|134.217728] "" DRIVER,DBG

BO_ 99 GEO_CURRENT_DESTINATION_LOCATION_DEBUG: 7 GEO SG_ GEO_CURRENT_DESTINATION_LOCATION_DEBUG_latitude : 0|28@1+ (0.000001,-134.217727) [-134.217727|134.217728] "" SENSOR,DBG SG_ GEO_CURRENT_DESTINATION_LOCATION_DEBUG_longitude : 28|28@1+ (0.000001,-134.217727) [-134.217728|134.217728] "" SENSOR,DBG

BO_ 128 MOTOR_DEBUG_MSG: 3 MOTOR SG_ MOTOR_DEBUG_MSG_echo_steer : 0|3@1+ (1,-2) [-2|2] "" DBG SG_ MOTOR_DEBUG_MSG_echo_speed : 3|5@1+ (1,0) [0|31] "RPM" DBG SG_ MOTOR_DEBUG_MSG_echo_rpm : 8|10@1+ (1,0) [0|1023] "RPM" DBG

MIA Management

Since the DRIVER node is our main controller, we conducted MIA management in the driver_logic code module.

Our MIA management is serviced at 10Hz and ensures that the expected messages are received within a time limit set by threshold values.

If a message goes "missing" past set threshold times, a default replacement value is used.

The MIA threshold values and replacement structures are found in the can_mia_configurations.c file.

SENSOR_TO_DRIVER_SONARS

- Default value in the DRIVER node is to set the sensor values to 0. This will result in the driver_logic simulating obstacles detected at 0cm in the front and back, and the car will not move.

GPS_DESTINATION_LOCATION

- Default value in the GEO node is to set the current coordinates and destination coordinates to 0. This will result in a 0 distance_to_destination calculation, and the DRIVER node will subsequently send an IDLE speed to the MOTOR node.

GEO_STATUS

- Default value in the DRIVER node is to set compass heading, destination heading, and distance to destination to 0. This will result in the ring LED not lighting up (to show an invalid state) and the DRIVER will send an IDLE speed to the MOTOR node.

DRIVER_TO_MOTOR_CMD

- Default value in the MOTOR node is to set the motor speed and steering to IDLE and 0, respectively. Without updated driver to motor commands, the RC car should not move.

Sensor Controller

Hardware Design

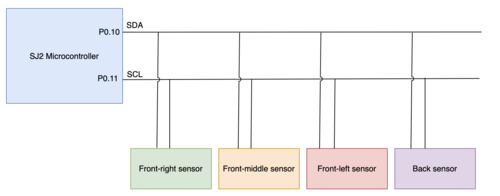

We used 4 Gravity DFRobot URM09 ultrasonic sensors. These ultrasonic sensors are used by the RC car for the purpose of obstacle avoidance. Three sensors were placed on the front side of the RC car and one on the back. They use I2C communication to send distance data to the SJ2 microcontroller. On the SJ2 microcontroller, P0.10 was used for SDA, and P0.11 was used for SCL. The measurement range is 300cm. It takes in 3.3V supply voltage. Using the I2C driver, the registers on the ultrasonic sensors were configured and the distance was read from the specified registers in the datasheet.

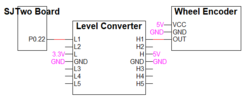

The wheel encoder is interfaced using 3 pins: VCC, GND, and OUT. The voltage input requires 4.5-5.5V and the data pin outputs 5V. The 5V output is converted to 3.3V using a level converter, and then used as a GPIO input to P0.22 on the SENSOR node.

The rotary wheel has 20 slits spaced evenly. An infrared beam and sensor is used to detect when the beam is blocked. When the beam is blocked, the data OUT pin outputs 0V. When the beam is unblocked, the data OUT pin outputs 5V.

Software Design

The ultrasonic sensors use the I2C driver available in the project. The implementation is done in the 100Hz periodic callback function. After writing to the control register address of the ultrasonic sensors, the distance values are read from the appropriate distance. Each sensor periodically sends sound waves according to the callback_count variable. To prevent signal interference, only one sensor sends pulses for each iteration of the periodic_callback. After the distance values were read, they were sent to the driver for obstacle avoidance. The following are the functions used to configure the ultrasonic sensor by writing to the register and then reading from the register specified in the sensor datasheet over I2C:

static const uint8_t distance_low_bits_register = 0x04;

void ultrasonic__passive_measurement_mode(uint8_t slave_address) {

const uint8_t passive_measurement_mode = 0x00;

const uint8_t control_register = 0x07;

i2c__write_single(I2C__2, slave_address, control_register, passive_measurement_mode);

}

uint8_t ultrasonic__single_sensor_read(uint8_t slave_address) {

return i2c__read_single(I2C__2, slave_address, distance_low_bits_register);

}

Wheel Encoder

The wheel encoder uses a GPIO pin (P0.22). To measure the speed of rotation, we enabled GPIO interrupts by adding a gpio_isr module to dispatch GPIO interrupts to associated handler methods. On rising edges, a GPIO interrupt service routine (ISR) increments a wheel encoder rising edge counter. In the 100Hz periodic callback, the wheel encoder counter is used to calculate the measured rotations per minute (RPM). This RPM value is sent from the SENSOR node and is relayed through the DRIVER node to the MOTOR node. After sending out the RPM value, the wheel encoder rising edge counter is reset.

Technical Challenges

1. Ultrasonic sensor interference

- Since we had 3 ultrasonic sensors on the front side sending sound waves, there was interference between them. As a result, the values being read from the sensors were incorrect. Also, when testing the car in a narrow hallway, the sensors would detect obstacles when there were none due to the sound waves interfering with each other. To resolve this issue, instead of sending sound waves at once from all the front sensors in the periodic callbacks function, we decided to send them at different times. We also began testing outdoors.

2. Ultrasonic sensor wiring not secure

- One of the issues we faced was that the sensors would not be connected properly because the RC car was constantly being moved around. A solution was to clean up the wiring and use a PCB. Also, we would use CAN Busmaster to check which sensors were not connected.

3. Wheel Encoder Data Output Debouncing

- We realized that the GPIO ISR was triggered multiple times when the wheel is moving slowly, causing our RPM values to be inaccurate. This problem had a minimal impact when the wheel is moving at higher speeds.

Motor Controller

Hardware Design

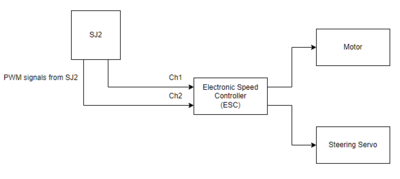

The hardware design for the motor controller was determined by the hardware of the car. We knew that the cars motors were controller through an electronic speed controller(ESC) and just had to interface the SJ2 with this. The top of the receiver revealed 12 pins, in 4 rows of 3. Each row had the following according the the sticker: GND, VCC, and signal. The signal pin would be hooked up to the pins which are firmware configured to output PWM.

Software Design

Controlling the motors was done through firmware generating PWM signals. We decided to begin by hooking up the car's receiver to a Saleae Logic Analyzer to see the waveforms generated when using the remote control that came with the car. This was helpful in many ways. First, we were able to see which channel was used for the steering servo, and which was used for the actual motor. Second, we were able to see the maximum, minimum, and neutral PWM duty cycles required and the period period of the waveform. Lastly, we were able to visually see the different sequences necessary to run the motors.

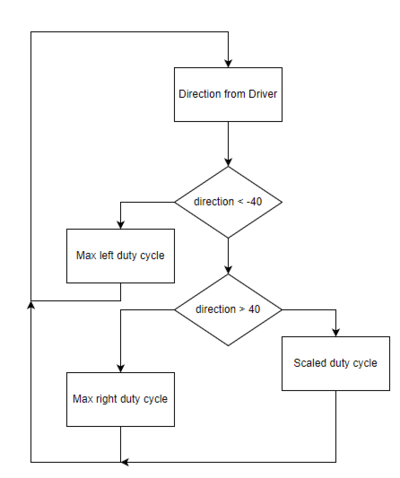

Steering Algorithm

A simple algorithm was used to determine the PWM signal sent to the steering servos. We decide to have the driver node send a direction between the values of -180 to 179. After some quick testing with the values, we found the range to be much larger than then we required to get the steering to be a fluid motion. To solve this, we had our firmware treat any signal above 40 and below -40 to be max right and left respectively. We then had to scale the values within that range using the algorithm in the flow chart above.

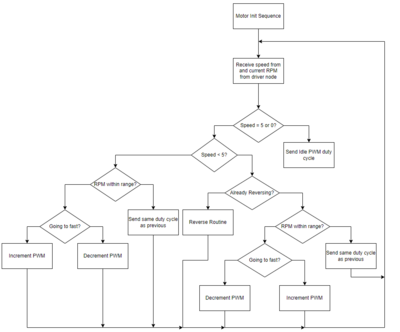

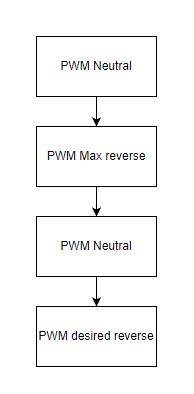

Forward Backward Algorithm

The motor speed control algorithm was more complicated due to the ESC having built in firmware to prevent the user from repeated sending forward and reverse signals and frying the motor. A specific routine was needed to allow the motor to correctly receive a reverse signal. This routine is depicted in the flow chart below. Other than that we used a fairly straight forward algorithm based on the neutral, max forward, and max reverse duty cycles read from the Saleae analyzer mentioned earlier. The driver would send a drive_speed from 0 - 31 and a current_rpm based on sensor readings. The 0 - 31 values were broken down as such:

- 0 and 5 were mapped to 'neutral' or 'idle' pwm cycles.

- 1 - 4 were varying speeds of reverse with 1 being fastest, and 4 being slowest reverse speed.

- 6 - 31 were varying speeds of forward with 6 being slowest, 31 being fastest.

The current_rpm was used to decided whether or not the car was moving at an expected speed based on a mapping which we allocated statically. From there the algorithm designed was pretty straight forward. Based on the speed and current rpm received from driver, we followed the above flow chart incrementing or decrementing the previously set PWM duty cycle as necessary. This algorithm could definitely have been improved using some basic control theory such as a PID controller, but we found that we were able to get a consistent and smooth ride speed without one.

Technical Challenges

- Initial run through of the algorithm to control speed ended up 'sling-shotting' the car. This due to the PWM duty cycles being set would over shoot the desired RPM values by a large margin. To solve this, we changed the the value we scale up or down the PWM to 0.005f. Since our motor commands were being processed so quickly, a small value was needed to prevent the car from the 'sling-shotting' behavior of ramping up and down the motor to quickly.

- The reverse routine and start up routines of the motor may vary depending on the firmware that comes along with the ESC. For Traxxas, a specific routine was needed to start and reverse the motors. Without a logic analyzer or oscilloscope to visualize the routine, deciphering it would have been near impossible.

- Start off slow and then ramp up after. It really does not take much higher than the neutral duty cycle to make the cars move at a decent pace. Early on, we capped our speed to 300rpm and this would have been plenty fast enough to even get through the demo.

Geographical Controller

Code for GEO Node

Code for LSM303 Compass

Compass and Accelerometer

Hardware Design

LSM303DLHC Magnetometer

For the compass heading we used the lsm303DLHC compass + accelerometer from Adafruit. The compass was interfaced using I2C with a speed of 100KHz. The data output rate was set to 220HZ. The gain was left as the default +-1.3 gauss. The operation mode was switch to continuous conversion mode. The compass was placed at a safe distance above all of the other hardware components to minimize the magnetic disturbance.

Software Design

Compass Implementation and Calibration

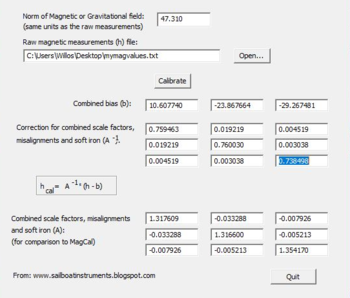

Once the required registers have been initialized, the compass will return uncalibrated x, y, and z values. For its calibration we used the software Magneto v1.2. Magneto requires a txt file of raw magnetometer values and our locations magnetic field. Magneto will then provide the bias and scaling factor matrix needed for calibration. Those values are then plug into the equation Matrix^-1((raw/gain*100)-bias), where gain is 1100 gauss for the x and y values and 980 gauss for the z value. Those calibrated x and y values are used to find the radians of the compass heading. The radians are then converted and returned as degrees. By flipping the compass upside down, the compass was able to reduced tilt factor to provide accurate readings.

Magneto1.2v Calibration

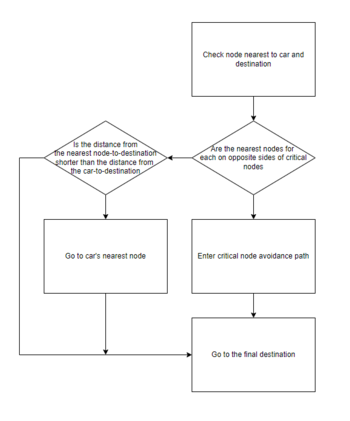

Waypoints Algorithm

Technical Challenges

1. Compass calibration

- Use magnetic field of current position

- Use Magneto software

2. Reliable compass readings

- Flip the compass upside down for more accurate tilt compensation readings

- Place compass at a high enough distance to reduce interference

Driver Controller

Code for Driver Logic Debug Menu State Machine for Menu Navigation

Code for LCD I2C Initialization and Configuration

Code for LED Ring Implementation

Hardware Design

LED Ring

The LED ring we are using is a LuMini LED ring from Sparkfun. It is composed of 20 LEDs and requires a voltage input of 5 volts, a clock signal, and data signal. For communicating with the SJ2, we used the SPI protocol. The led ring works like an array with the first led position at 0 and the last at position 19. The communication protocol requires 32 bits, all set to 0 as the starting frame. Once the starting frame has been set, all the 20 LEDs need to be set to either on or off. Each LED follows the same 32-bit communication format. The first 8 bits are the starting bits plus the brightness. The next 24 bits determine the colors of the LEDs using the RGB color scale. Finally, there is an ending frame of all 32 bits set to 1.

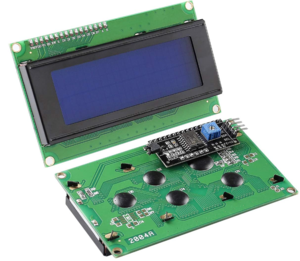

LCD Hardware

For the LCD we are using a 20x4 I2C LCD2004. The LCD uses a separated I2C interface board composed of an 8 bit I/O expander for I2C bus. It required a voltage input of 5v and an I2C slave address 0x4E. The clock speed was set to 100kHZ. The i2c data transferred was different from the usual. There was no sub addressed or registers, instead normal communication will behave as following: slave address, data 1, and data2.

Software Design

Inside periodic_callbacks_DRIVER.c, driver_logic__manage_debug_menu_10hz is periodically called at 10Hz rate. The definition for this method is shown below:

void driver_logic__manage_debug_menu_10hz(uint32_t callback_count) {

display_debug_menu_on_lcd(callback_count);

handle_debug_menu_navigation();

}

This snippet of code is responsible for maintaining the LCD debug menu state machine. It periodically updates the LCD to display menu navigation screens or debug information.

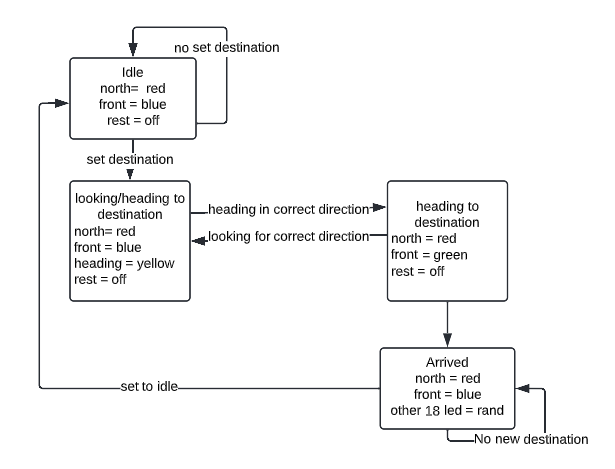

LED Ring State Machine

The LED ring was set for debugging and presentation purposes. At all times it will display the direction of the compass in blue and true north with red. Once a location has been set, a yellow LED will appear to indicate where the car should head. If the car is heading in the correct direction the yellow LED and blue LED will then turn green. Finally, when the car arrives at the set destination or at a waypoint, the led ring will make every light blink with different colors. All major indicators will be on at the same time, even when the car has arrived at its destination. Even when all LEDs are blinking at a final destination, north and front will not change colors and their brightness will increase for better visibility.

The following are code snippets for the data frames sent to the LED ring. The data frame consists of starting and ending frames and a data frame for setting the color and its intesity:

// starting frame all 32 bits 0

void led_ring_starting_frame(void) {

ssp2__exchange_byte(0x00);

ssp2__exchange_byte(0x00);

ssp2__exchange_byte(0x00);

ssp2__exchange_byte(0x00);

}

// ending frame first 10 bits 0 the rest

void led_ring_ending_frame(void) {

ssp2__exchange_byte(0xFF);

ssp2__exchange_byte(0xFF);

ssp2__exchange_byte(0xFF);

ssp2__exchange_byte(0xFF);

}

void led_ring_all_on(uint8_t brightness, uint8_t blue, uint8_t green, uint8_t red) {

for (int f = 0; f < 20; f++) {

ssp2__exchange_byte(brightness);

ssp2__exchange_byte(blue);

ssp2__exchange_byte(green);

ssp2__exchange_byte(red);

delay__us(10);

}

}LCD Implementation

The LCD needed to be set to 4-bit mode with specific delays, enables and functionality. The LCD data is set in two formats. One is for displaying characters on the screen using ASIIC. The hex ASIIC value is sent 4 times. Each time is sent, the first four bits are based on the ASIIC hex value. For example, 'a' is 0x1C, therefore the first four bits for the first two writes will be 0x1 and the other two will be 0xC. The other four bits are for setting brightness, enable, r/w, and select. The other format is command send, which is for implementation purposes, or location setting. It follows the same methodology as sending ASIIC data, but the select is off for all four transmissions. To write to the display, we would need to send a command to set the location of the message. Then we need to send the actual data as a string. If it is a short string, the rest of the pixels need to be set to empty spaces. This is necessary to display values that are constantly being updated. If not set, the LCD would display old characters. This is call at 100Hz in periodic callbacks.

Technical Challenges

1. LCD display is limited to 4 lines of 20 characters. Having this limit creates a challenge for efficiently using the screen for debugging.

- To resolve this issue, we designed and implemented a finite state machine to update the LCD display according to a debug menu state. This solution is beneficial for its scalability. New debug information can be easily included as additional options in the menu navigation.

2. I2C bus speed was configured too high

- We saw issues with the LCD screen resetting unexpectedly during testing. This was due to our I2C bus speed being configured to run at 400KHz. After reviewing the datasheet, we found that using 100KHz for the I2C bus speed is the correct configuration.

3. Compass heading does not display true north

- After comparing the compass heading with a premade compass, it showed the both compasses rotated in different directions. True north will only be real when compass heading was 0. For all other cases, true north needed to be set at the opposite direction. For example, if compass heading is showing 45 degrees, true north would be 270 degrees.

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

Overall this project taught us many industry relevant topics. We were able to utilize and understand the CAN Bus to create a realistic self-driving RC car which emulated how a real car would function. Different controllers were used for: Obtain geological and position related data, obtain RPM and distance data through various sensors, control steering servo and control forward/ reverse speed, and a singular driver controller to control logic.

<What did you learn?>

Project Video

Youtube Link <-- temporary video, will be updated

Project Source Code

Advice for Future Students

- Add a mobile kill-switch to stop the car

- The car may drive at high speeds and not behave as expected. It is helpful to be able to wirelessly stop the car.

- Add plenty of LED indicators on the RC car

- GPS lock, app connection, obstacle detection, destination reached, etc

- Turn off on-board LEDs for each controller at the end of periodic_callbacks__initialize(). The current base code will light the on-board LEDs in peripherals_init(). By turning off the LEDs after initialization, it will be convenient to use the LEDs to indicate whether the board is resetting unexpectedly

- Stabilize your compass readings

- Calibrate your compass

- Verify tilting the car will not drastically affect magnetometer readings

- Mount the compass module away from metals and any hard/soft iron that may cause the readings to be inaccurate

- Unit test code modules to verify expected behavior

- Once your car can move, test outside on the garage.

- Ultrasonic sensors give incorrect readings at steep angles, making testing in the hallway somewhat difficult.

- Compass readings are also more accurate outside the building where there is less interferance.

Acknowledgement

We would like to acknowledge our instructor, Preet, for encouraging us to gather knowledge and to tackle difficult problems.

References

1. Ultrasonic Sensor Project Wiki

2. GPGGA Message Definition

3. LSM303DLHC Datasheet

4. Calibration Implementaion

5. Venus638FLPx GPS Receiver Datasheet

6. LCD Datasheet

7. LCD Display Initialization and Configuration Example Tutorial

8. LCD Display Implementation and Flowchart Tutorial

9. APA102 Ring LED Datasheet

10. Logic Level Converter Datasheet