S19: Tech Savy

Contents

- 1 Tech Savy RC Car

- 2 Abstract

- 3 Introduction & Objectives

- 4 Team Members & Technical Responsibilities

- 5 Administrative Responsibilities

- 6 Team Deliverables Schedule

- 7 BILL OF MATERIALS (GENERAL PARTS)

- 8 Printed Circuit Board

- 9 CAN Communication

- 10 Hardware Design

- 11 DBC File

- 12 Sensor Node

- 13 Motor Controller

- 14 Geographical Controller

- 15 Bridge Controller Communication

- 16 Master Module

- 17 Mobile Application

- 18 Design & Implementation

- 19 Testing & Technical Challenges

- 20 Conclusion

- 21 References

- 22 Grading Criteria

Tech Savy RC Car

Abstract

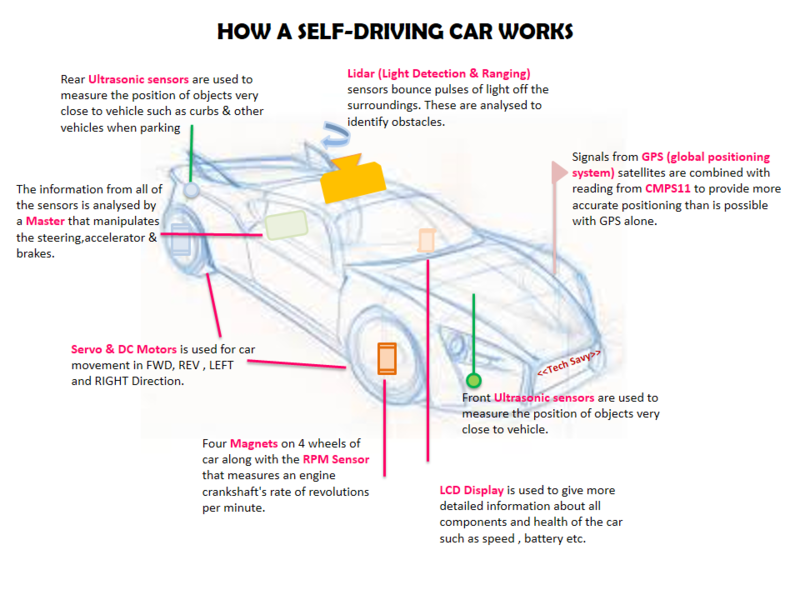

In this project our main aim to build a Self-Navigating Car named Tech Savy, that navigates from a source location to a selected destination by avoiding obstacles in its path using sensors and motors.

Introduction & Objectives

The key features support by the system are

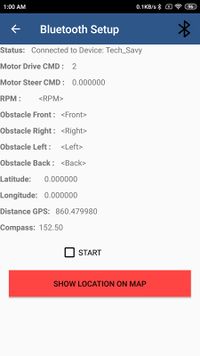

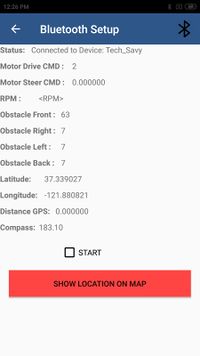

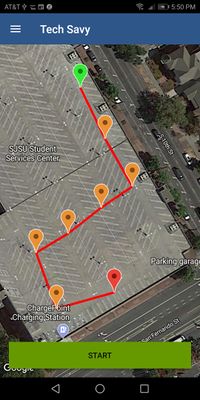

1. A Google-map based Android application is developed which will update the live location of RC car given by GPS to Bridge over Bluetooth.Android app is used to get information from all the Modules and will show live data of MOTOR, SENSORS, GPS and COMPASS and we can set the final destination so that car can drive to the destination.

2. The car will be integrated with the GPS, Compass, Bluetooth, multiple sensors such as Ultrasonic sensors and RPM sensors to fulfill the purpose of navigation, obstacle detection, and avoidance

3. LIDAR and Ultrasonic Sensor is used for obstacle detection and avoidance in all the angles in the view of 360 degrees.

4. Motor drives the car by Route Calculation done on GPS using the shortest distance path algorithm between current location and destination and connects to the self-driving RC car via Bluetooth to send the GPS Coordinates and Maneuvering to the selected destination and Self- Adjusting the speed of the car on Ramp.

5. LEDs and LED Display are used for debugging and to get all relevant information about the status of the car, in real time and LCD Display is used to give more detailed information related to the car.

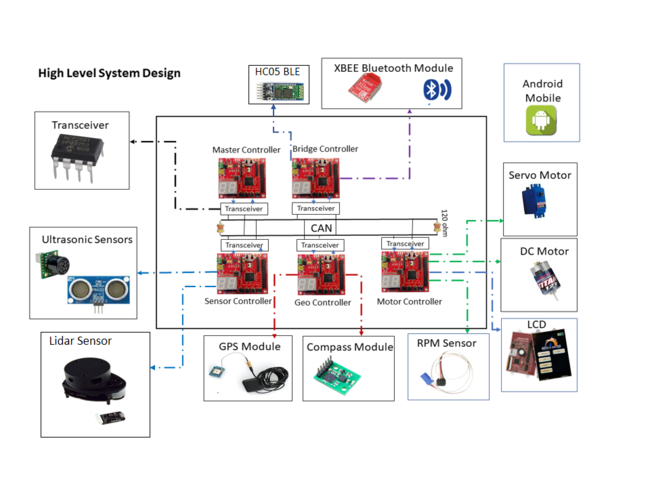

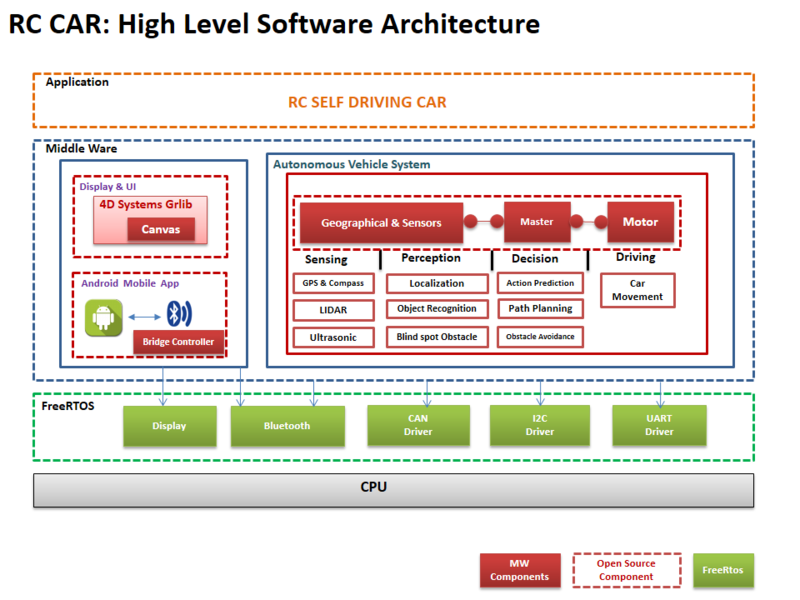

The system is built on FreeRTOS running on LPC1758 SJOne controller and Android application. The main building blocks of Tech Savy are the five controllers communicating through High Speed CAN network designed to handle dedicated tasks. The controllers integrate various sensors that are used for navigation of the car.

CAR Objectives

1. Master Controller - Handles the Route Manuevering,Path Planning and Obstacle Avoidance

2. Sensor Controller - Detects the surrounding objects

3. Geo Controller - Provides current location in the form of coordinates and navigate car using CMPS11

4. Motor Controller - controls the movement of the Car.

5. Bridge controller - Interfaces the system using Bluetooth to an Android application.

Team Objectives

1. Learn each and every module as much as possible, in order to develop an industrial product.

2. Achieve 100% code coverage, during unit testing.

3. Document and track all the bugs encountered during development, unit testing, and field testing.

File:CmpE243 TechSavy Application.png Android Application |

Team Members & Technical Responsibilities

- Git Project Link: Tech Savy

- Master Controller

- Motor Controller

- Geographical Controller

- Sensor Controller

- Communication Bridge Controller

- Android Application

- LCD Interfacing & UI Designing

- Hardware PCB Integration

Administrative Responsibilities

| Administrative Roles | ||||

|---|---|---|---|---|

|

Aakash Chitroda | |||

|

Halak Vyas | |||

|

Vatsal Makani | |||

|

Vidushi Jain | |||

|

Jay Parsana | |||

Team Deliverables Schedule

| WEEK |

START DATE |

END DATE |

TASK DETAILS |

STATUS |

|---|---|---|---|---|

| 1 | 26 Feb 2019 | 4 March 2019 |

|

Completed Completed Completed Completed |

| 2 | 05 March 2019 | 12 March 2019 |

|

Completed Completed Completed |

| 3 | 13 March 2019 | 19 March 2019 |

|

Completed Completed Completed Completed Completed Completed |

| 4 | 20 March 2019 | 26 March 2019 |

|

Completed Completed Completed Completed Completed Completed |

| 5 | 27 March 2019 | 09 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed |

| 6 | 10 April 2019 | 16 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed |

| 7 | 17 April 2019 | 23 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed In Progress Completed Completed |

| 8 | 24 April 2019 | 30 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed |

| 9 | 1 May 2019 | 7 May 2019 |

|

Completed Completed Completed Completed Completed Completed Completed |

| 10 | 8 May 2019 | 21 May 2019 |

|

In Progress |

| 11 | 22 May 2019 |

|

In Progress |

BILL OF MATERIALS (GENERAL PARTS)

| PART NAME |

PART MODEL & SOURCE |

QUANTITY |

COST PER UNIT (USD) |

|---|---|---|---|

|

|

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

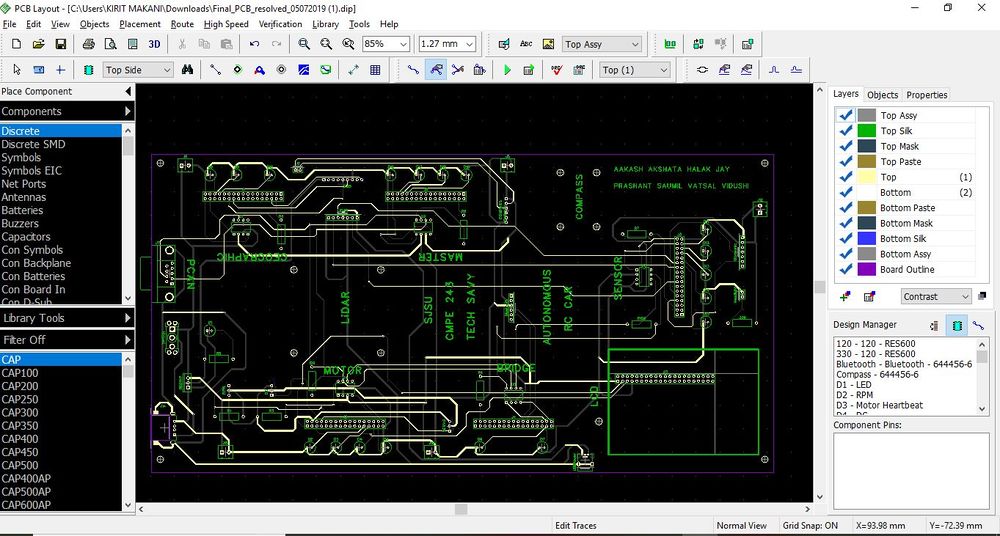

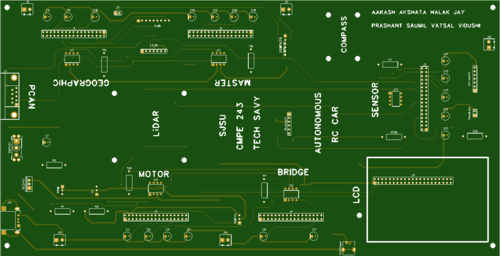

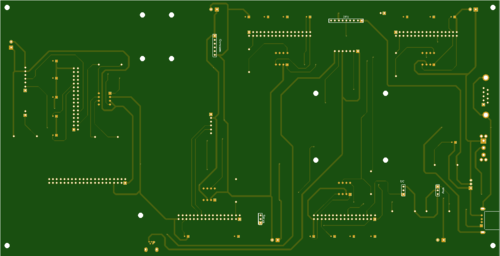

Printed Circuit Board

Design And Architecture

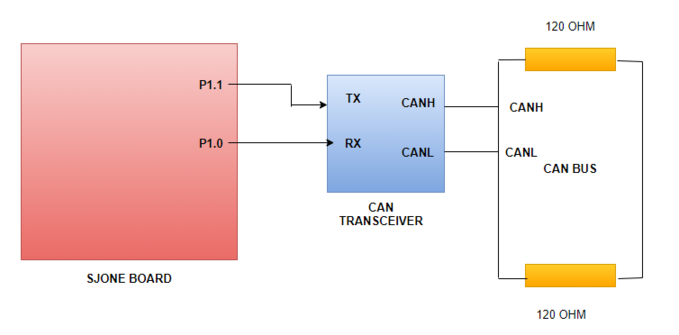

We designed the custom PCB using DipTrace Software in which we implemented connections for all the controller modules(SJOne Board LPC1758) all communicating/sending data via CAN bus. The data is sent by individual sensors to the respective controllers. GPS and Compass are connected to Geographical Controller. RPM sensor, DC and Servo Motors are connected to Motor Controller. Ultrasonic and Lidar are connected to Sensor Controller. LCD is connected to Motor Controller. Bluetooth is connected to Bridge Controller. CAN Bus is implemented using CAN Transceivers MCP2551 terminated by 120Ohms; with PCAN for monitoring CAN Debug Messages and Data.

Power Section

We implemented separate power modules for LIDAR and remaining modules of the PCB. The micro USB mini B supplies 5V to LIDAR Motor and Scanner (max current rating estimated @ 1A). Another power is supplied through USB 2.0 Type A connector with a rating of 5V@2A. Since GPS requires 3.3V, we have used a linear regulator REG1117-3.3. All the parts are through-hole components.

Fabrication

PCB was sent to fabrication to JLCPCB China which provided PCB with MOQ of 5 with the lead time of 1 week. We implemented 2 layers of PCB with most of the parts in top layer. We implemented rectangular header connector for SJOne boards, RPM sensor, DC & Servo Motor and GPS modules on the bottom layer.

Challenges

There were 2 iterations of this board. The first one was designed without validation and had problems with orientation of the SJOne board header & pin connections. We also need to change the header for LCD since it was having different pitch.This design lacked several necessary power connections and was limited by functionality. These problems were fixed in the 2nd iteration.

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management, etc.>

Hardware Design

<Show your CAN bus hardware design>

DBC File

A Link to the DBC file that defines the CAN communication of the system is as follows:

DBC link on GitLab

DBC is a format that enables fewer hassles while developing code to either interpret data received or send data over the CAN bus. This project used DBC effectively.

Shown below is the DBC implementation for this project.

VERSION ""

NS_ :

BA_

BA_DEF_

BA_DEF_DEF_

BA_DEF_DEF_REL_

BA_DEF_REL_

BA_DEF_SGTYPE_

BA_REL_

BA_SGTYPE_

BO_TX_BU_

BU_BO_REL_

BU_EV_REL_

BU_SG_REL_

CAT_

CAT_DEF_

CM_

ENVVAR_DATA_

EV_DATA_

FILTER

NS_DESC_

SGTYPE_

SGTYPE_VAL_

SG_MUL_VAL_

SIGTYPE_VALTYPE_

SIG_GROUP_

SIG_TYPE_REF_

SIG_VALTYPE_

VAL_

VAL_TABLE_

BS_:

BU_: MASTER BRIDGE MOTOR SENSOR GPS DBG

BO_ 103 BRIDGE_NODE: 1 BRIDGE

SG_ BRIDGE_START_cmd : 0|1@1+ (1,0) [0|1] "" MASTER,MOTOR

BO_ 104 CAR_CONTROL: 4 MASTER

SG_ MOTOR_DRIVE_cmd : 0|2@1+ (1,0) [0|0] "" MOTOR,BRIDGE

SG_ MOTOR_STEER_cmd : 2|15@1+ (0.1,-90.0) [-90|90] "" MOTOR,BRIDGE

SG_ MOTOR_kph : 17|12@1+ (0.01,0) [0.00|20.00] "kph" MOTOR,BRIDGE

BO_ 105 SENSOR_NODE: 5 SENSOR

SG_ SENSOR_FRONT_cm : 0|10@1+ (1,0) [0|645] "cm" MASTER,MOTOR,BRIDGE

SG_ LIDAR_Obstacle_FRONT : 10|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE

SG_ LIDAR_Obstacle_RIGHT : 13|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE

SG_ LIDAR_Obstacle_LEFT : 16|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE

SG_ LIDAR_Obstacle_BACK : 19|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE

SG_ LIDAR_Obstacle_BACK_RIGHT : 22|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE

SG_ LIDAR_Obstacle_BACK_LEFT : 25|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE

BO_ 106 MOTOR_NODE: 2 MOTOR

SG_ MOTOR_SPEED_kph : 0|12@1+ (0.01,0) [0.00|20.00] "kph" MASTER,BRIDGE

BO_ 107 BRIDGE_CHECKPOINTS: 8 BRIDGE

SG_ CHECKPOINT_LAT_deg : 0|28@1+ (0.000001,-90.000000) [-90|90] "Degrees" MASTER,GPS,MOTOR

SG_ CHECKPOINT_LONG_deg : 28|29@1+ (0.000001,-180.000000) [-180|180] "Degrees" MASTER,GPS,MOTOR

BO_ 108 GPS_LOCATION: 8 GPS

SG_ CURRENT_LAT_deg : 0|28@1+ (0.000001,-90.000000) [-90|90] "Degrees" MASTER,BRIDGE,MOTOR

SG_ CURRENT_LONG_deg : 28|29@1+ (0.000001,-180.000000) [-180|180] "Degrees" MASTER,BRIDGE,MOTOR

BO_ 109 COMPASS: 8 GPS

SG_ CMP_HEADING_deg : 0|12@1+ (0.1,0) [0|359.9] "Degrees" MASTER,BRIDGE,MOTOR

SG_ CMP_BEARING_deg : 12|12@1+ (0.1,0) [0|359.9] "Degrees" MASTER,BRIDGE,MOTOR

SG_ CMP_DISTANCE_meters : 24|17@1+ (0.01,0) [0|0] "Meters" MASTER,MOTOR,BRIDGE

BO_ 110 MASTER_HEARTBEAT: 1 MASTER

SG_ MASTER_hbt : 0|1@1+ (1,0) [0|1] "" SENSOR,MOTOR,BRIDGE,GPS

BO_ 111 SENSOR_HEARTBEAT: 1 SENSOR

SG_ SENSOR_hbt : 0|1@1+ (1,0) [0|1] "" MASTER

BO_ 112 MOTOR_HEARTBEAT: 1 MOTOR

SG_ MOTOR_hbt : 0|1@1+ (1,0) [0|1] "" MASTER

BO_ 113 GPS_HEARTBEAT: 1 GPS

SG_ GPS_hbt : 0|1@1+ (1,0) [0|1] "" MASTER

BO_ 114 BRIDGE_HEARTBEAT: 1 BRIDGE

SG_ BRIDGE_hbt : 0|1@1+ (1,0) [0|1] "" MASTER

BO_ 115 SENSOR_DEBUG: 1 SENSOR

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_sensor_init : 1|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_CAN_TX : 2|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_bus_off : 3|1@1+ (1,0) [0|0] "" DBG

BO_ 116 MOTOR_DEBUG: 2 MOTOR

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_bus_off : 1|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_RPM_kph : 2|12@1+ (0.01,0) [0.00|20.00] "kph" DBG

BO_ 117 MASTER_DEBUG: 1 MASTER

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_bus_off : 1|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_drive_mode : 2|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_HBT_FROM_ALL_CONTR : 3|1@1+ (1,0) [0|0] "" DBG

BO_ 118 GPS_DEBUG: 1 GPS

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_HBT_Transmit : 1|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_bus_off : 2|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_GPS_rx : 3|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_GPS_Fix : 4|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_Compass_Rx : 5|1@1+ (1,0) [0|0] "" DBG

BO_ 119 BRIDGE_DEBUG: 1 BRIDGE

SG_ IO_DEBUG_CAN_init : 0|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_HBT_Transmit : 1|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_bus_off : 2|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_Connected : 3|1@1+ (1,0) [0|0] "" DBG

SG_ IO_DEBUG_Bridge_rx : 4|1@1+ (1,0) [0|0] "" DBG

CM_ BU_ MASTER "The master controller driving the car";

CM_ BU_ MOTOR "The motor controller of the car";

CM_ BU_ SENSOR "The sensor controller of the car";

CM_ BU_ BRIDGE "The bridge controller of the car";

CM_ BU_ GPS "The gps controller of the car";

CM_ BU_ DBG "The debug node of the car";

CM_ BO_ 100 "Sync message used to synchronize the controllers";

BA_DEF_ "BusType" STRING ;

BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0;

BA_DEF_ SG_ "FieldType" STRING ;

BA_DEF_DEF_ "BusType" "CAN";

BA_DEF_DEF_ "FieldType" "";

BA_DEF_DEF_ "GenMsgCycleTime" 0;

BA_ "GenMsgCycleTime" BO_ 103 100;

BA_ "GenMsgCycleTime" BO_ 104 100;

BA_ "GenMsgCycleTime" BO_ 105 100;

BA_ "GenMsgCycleTime" BO_ 106 100;

BA_ "GenMsgCycleTime" BO_ 107 100;

BA_ "GenMsgCycleTime" BO_ 108 100;

BA_ "GenMsgCycleTime" BO_ 109 100;

BA_ "GenMsgCycleTime" BO_ 110 100;

BA_ "GenMsgCycleTime" BO_ 111 100;

BA_ "GenMsgCycleTime" BO_ 112 100;

BA_ "GenMsgCycleTime" BO_ 113 100;

BA_ "GenMsgCycleTime" BO_ 114 100;

BA_ "GenMsgCycleTime" BO_ 115 100;

BA_ "GenMsgCycleTime" BO_ 116 100;

BA_ "GenMsgCycleTime" BO_ 117 100;

BA_ "FieldType" SG_ 104 MOTOR_DRIVE_cmd "MOTOR_DRIVE_cmd";

VAL_ 104 MOTOR_DRIVE_cmd 2 "MOTOR_STOP" 1 "MOTOR_REV" 0 "MOTOR_FORWARD" ;

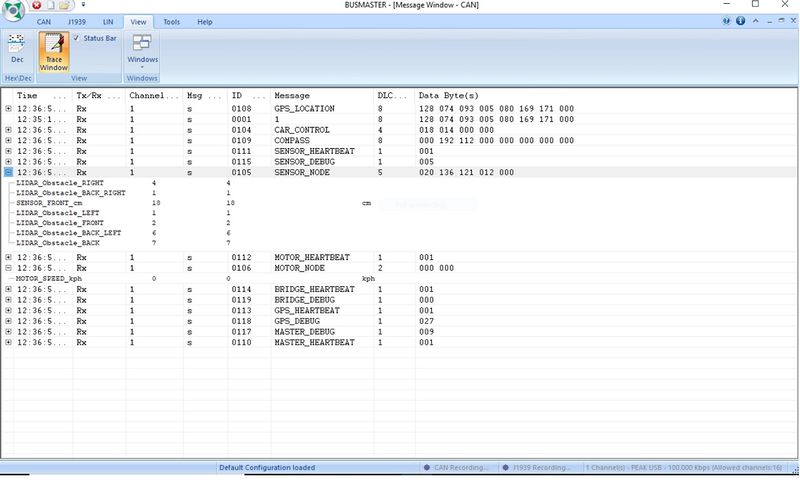

A screenshot of the Bus Master Application is as shown below:

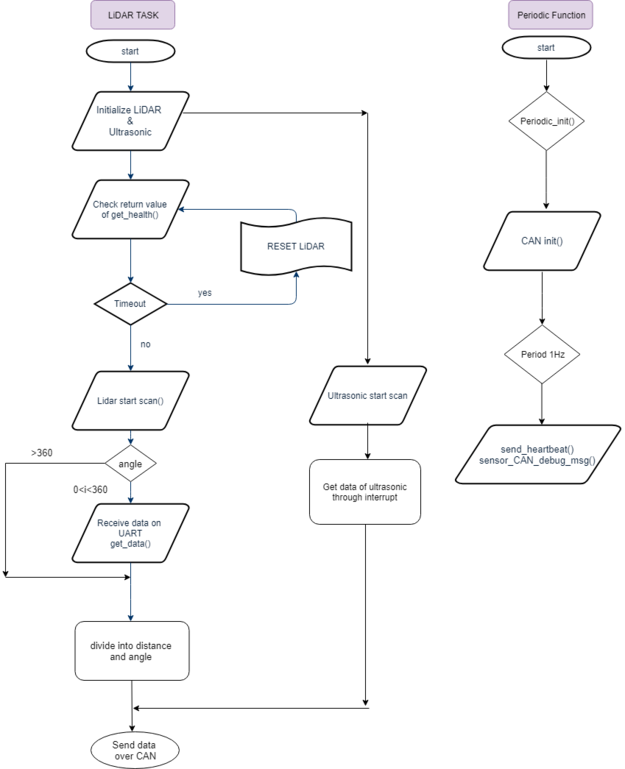

Sensor Node

We used 2 sensor modules to achieve accurate and reliable obstacle avoidance system.

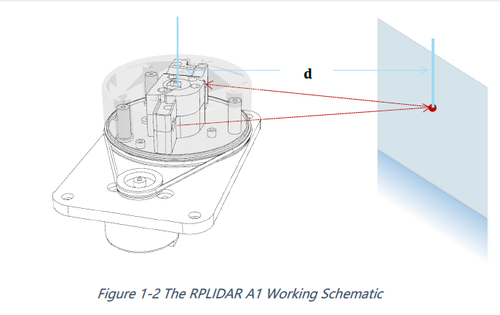

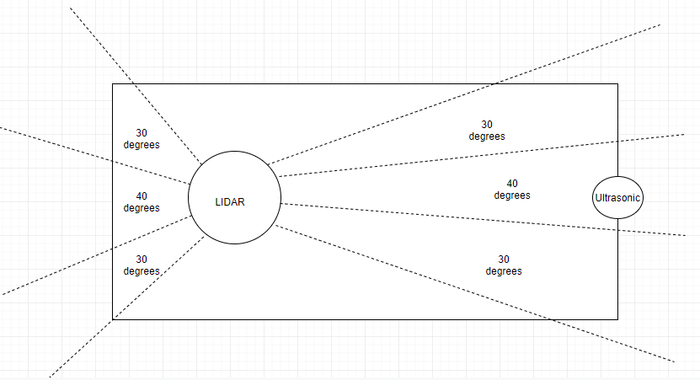

1. Lidar - Main controller to detect obstacle. Giving 360-degree view with a range up to 6 meters in distance.

- RPLidar works on a mechanism known as laser triangulation ranging principle. The system measures distance data in more than 2000 times’ per second and with high-resolution distance output. RPLIDAR emits modulated infrared laser signal and the laser signal is then reflected by the object to be detected. The returning signal is sampled by vision acquisition system in RPLIDAR A1 and the DSP embedded in RPLIDAR starts processing the sample data and output distance value and angle value between object and RPLIDAR A1 through the communication interface.

2. Ultrasonic Sensor (Maxbotix LV-MaxSonar-EZ0) - One Ultrasonic sensor with a maximum range of 600 cm was used to detect very small objects at the front that Lidar might miss because of it's leveled placement.

- Ultrasonic sensor uses a high-frequency beam to detect an object. It first throws light and reads the time taken for light to receive back, depending on the time calculated, it identifies the obstacle. It calibrates after it's first to read cycle, then it can continuously read data of light. The beam depending on the range is shown in figure.

Sensor Node Code

Hardware Design

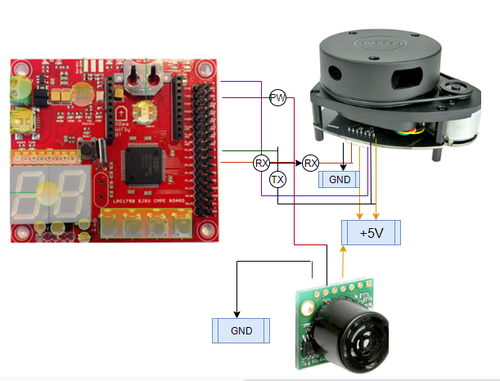

- The Lidar is communicating with SJOne board through UART, we have used UART 2 here as shown in Pin config below.

- Ultrasonic Sensor is simple Interrupt based, hence it connected through GPIO pins of SJOne board as shown in diagram.

Implementation

Ultrasonic

LV Maxsonar ultrasonic sensor is used at the very front of the RC car to provide wide range sonar detection ranging from 0 to 645 cm. It supports LiDAR sensor to detect very small obstacles like stone that can hinder car from moving forward. so we have purposefully mounted it at a lower level than LiDAR.

LiDAR

RPLidar works on UART. We have used UART 2 of SJOne Board to establish communication between them.

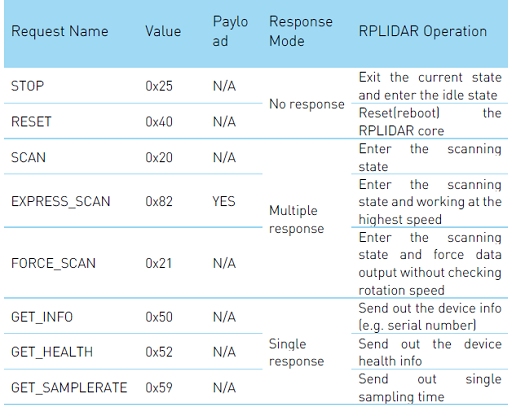

- Figure shows the several operation provided by RPLidar for better performance and reliable data.

Algorithm to establish communication through UART

- In order to start the scanning of Lidar, first send the 0X20 via

uart2.putchar(0x20). Before that, we can check the health status of RPLidar by sending 0x52. It waits for sometime (timeout = 500ms), and if return status is not true throws error indicating Lidar is not initialized properly and hence it gets reset.

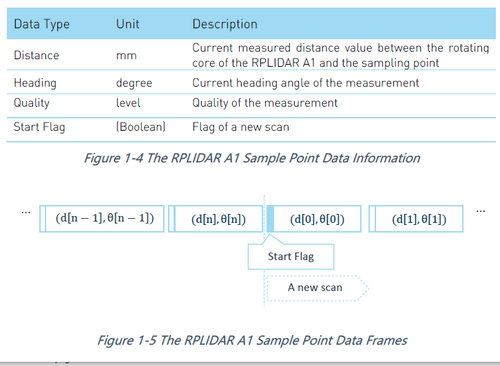

- As soon as correct scan command is received by Lidar, it starts sending data frames continuously on UART. The frame consist of 5 bytes including start bit, Angle, quality and distance, which are useful to identify the exact position of obstacle.

- This data is processed and divided into tracks of 25 cm each.

- By looking at the track, we choose the sector value which depends on angle detected. Below figure shows the division of angle for respective sector value.

- The obstacle information is sent to Master Node through CAN.

Software Design

Ultrasonic

- It works with the help of interrupt.

- After configuring GPIO pins as RX and TX, set RX pin high.

- PW pin gets the input, identify the type of interrupt

- Rising edge interrupt.

- Falling edge interrupt

- Calculate distance to obstacle,

-

ultrasonic_data.distance = (stop_time - start_time)/147;

-

LiDAR

Below diagram shows the code flow of sensor module. A separate task was used to send sensor data over CAN, which continuously sends data in while(1) loop.

Technical Challenges

Ultrasonic

- When mounted initially on CAR, ultrasonic was giving sometimes faulty readings as it was detecting ground as and obstacle.

- We designed a 3D mount for it and adjusted it on such a angle that it gives perfect readings.

- Initialization issue: Sometimes on power-up we noticed that Ultrasonic sensor was giving faulty readings(it was getting stuck on some fixed value).

- After reading the datasheet accurately, I found that it calibrates itself during the first read cycle and so the obstacle should be at least 14 inches far from the sensor.

- Ultrasonic Failure - When the CAR got crashed, Ultrasonic sensor failed and started giving incorrect data.

- We replaced it's wired to get it working.

- We replaced it's wired to get it working.

LiDAR

- Identifying obstacle data and separating it.

- Initially I lost a lot of time in figuring out the data frame as it consists of quality, angle, distance and start bit.

- Dividing the frame bits appropriately and storing it separately in struct variables resolved the issue. Also after that depending on the angle, every 360 times data was fetched in a loop to cover each and every angle value.

- Task overrun because of receiving a large number of data continuously over UART.

- Used a separate task, that receives data continuously in a loop, i.e while(1).

- Instead of receiving whole data in a single frame, took data character by character in a for loop 360 times, to get the value of obstacle at each degree.

- Angle detection problem - When large angles were taken, for example, 30 degrees on the right, it was detecting nearer objects correctly but far objects were getting detected in some other range (for example in front instead of right) of angle because of angle spread. I divided the range into 10 degrees each and store it in the same variable to send it over CAN.

For example, to get 30 degrees in right, 0-10,10-20 & 20-30 values are taken. - Received variable initialization problem.

- I didn't initialize the character variable to get data from UART to 0 and hence it was taking garbage value.

Thanks to Preet, at time of my code review he pointed out this problem and later I checked it with Unit Testing.

- I didn't initialize the character variable to get data from UART to 0 and hence it was taking garbage value.

- Some bugs here and there in the code.

- I identified and resolved a few bugs after Unit testing the code.

- Delay in sending data because of large CAN buffer size.

- We were facing this issue with master, motor and sensor communication. The response time was slow as data was getting accumulated before sending because of large buffer size taken.

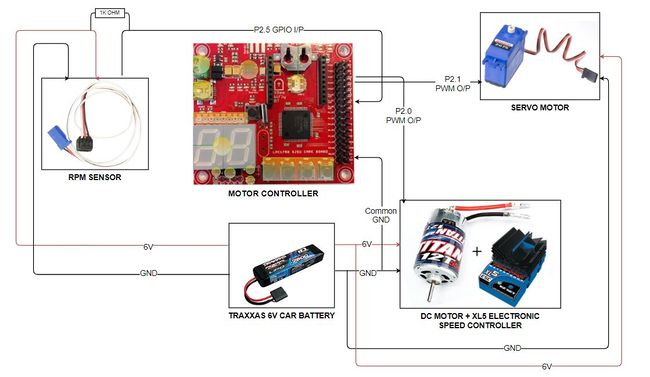

Motor Controller

Hardware Design

The hardware interface details of MOTOR Module with SJOne board are given below:

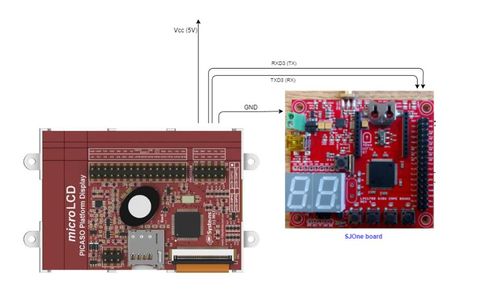

Motor Controller is one of the controllers in the project which is responsible to control the DC and Servo Motor movements, RPM Sensor measurements and LCD control

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Unreliable Servo Motors

<Problem Summary> <Problem Resolution>

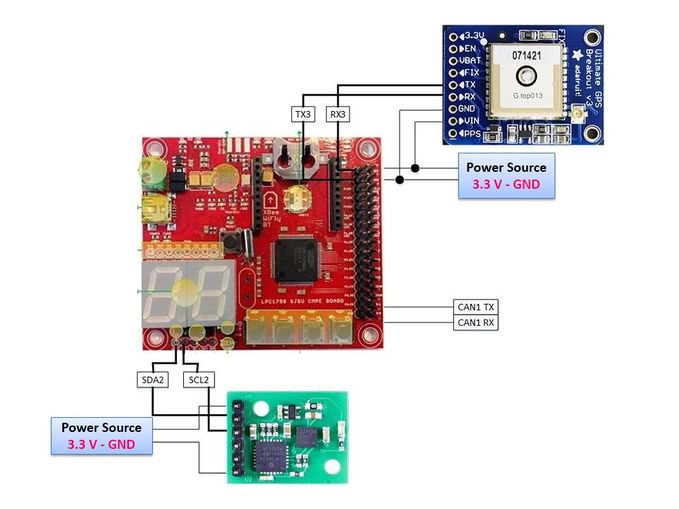

Geographical Controller

- GEO CONTROLLER Git Link: [1]

Hardware Design

The hardware interface details of GPS and Compass Module with SJOne board are given below:

GPS

GPS is a global navigation satellite system that provides geolocation and time information to a GPS receiver anywhere on or near the Earth where there is an unobstructed line of sight to four or more GPS satellites.

Compass

A Compass is an instrument used for navigation and orientation that shows direction relative to the geographic cardinal directions (or points). Compass is communicating over I2C with SJ One board. The register 2 and 3 of the compass provide the compass bearing angle (0- 360 range). Calibrating the compass is an important part. We are calibrating it on ‘horizontal calibration mode’, it works for us because the compass has tilt calibration.

Calibration process: First of all, you need to enter the calibration mode by sending a 3-byte sequence of 0xF0,0xF5 and then 0xF7 to the command register, these MUST be sent in 3 separate I2C frames. There MUST be a minimum of 20ms between each I2C frame.

The LED will then extinguish and the CMPS11 should now be rotated in all directions on a horizontal plane, if a new maximum for any of the sensors is detected then the LED will flash, when you cannot get any further LED flashes in any direction then exit the calibration mode with a command of 0xF8.

Note: Please make sure that the CMPS11 is not located near to ferrous objects as this will distort the magnetic field and induce errors in the reading. While calibrating rotate the compass slowly. Only the X and Y magnetometer axis is calibrated in this mode.

We are sending 3-byte sequence command of 0xF0,0xF5 and then 0xF7 on 4th switch press and 0xF8 command on 2nd switch press of the SJ One board. You can always restore factory calibration mode by sending the 3-byte sequence command of 0x20,0x2A,0x60. We are using switch 3 to restore factory calibration.

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Unreliable GPS lock

<Problem Summary> <Problem Resolution>

Bridge Controller Communication

<Picture and link to Gitlab>

Hardware Design

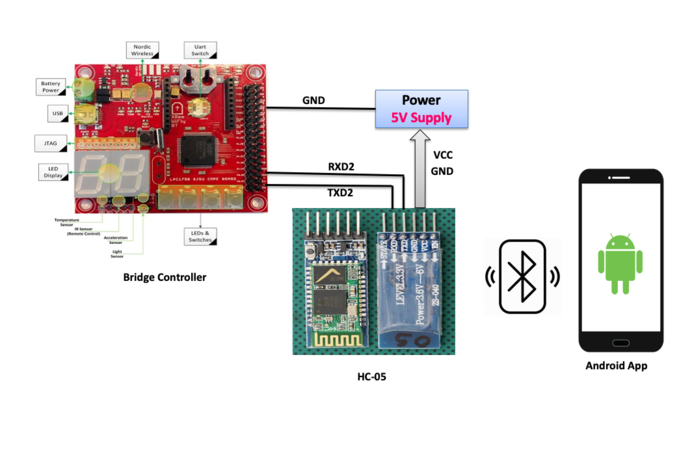

Bluetooth Module Hardware Interfacing:

We are using an HC-05 Bluetooth module to send and receive the data from our android application to Controller. The Bridge controller is connected to the Bluetooth module through the Serial interface(UART2) of SjOne board and we have configured HC-05 at 38400 baud rate 8-bit data and 1 stop bit using modules Communication Mode.

HC-05 Bluetooth module

HC-05 Bluetooth Module is used to set up wireless communication between the Car and the Android phone. This module is based on the Cambridge Silicon Radio BC417 2.4 GHz BlueTooth Radio chip. This is a complex chip which uses an external 8 Mbit flash memory It includes the Radio and Memory chips, 26 MHz crystal, antenna, and RF matching network. The right section of the Bluetooth Board has connection pins for power and signals as well as a 5V to 3.3V Regulator, LED, and level shifting.

- HC-05 PinOut

* EN: In a case brought HIGH before power is applied, forces AT Command Setup Mode * VCC: 5V Power * GND: Ground * TXD: Serial Transmit pin connected to RXD2 of SJOne board * RXD: Serial Receive pin connected to TXD2 of SJOne board * STATE: States if connected or not

- LED Blinking signals

* Flashing RED Fast: Ready for Pairing with nearby Bluetooth device available * Flashing RED Slow: Paired and Connected

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

<Bullet or Headings of a module>

Insane Bug

<Problem Summary> <Problem Resolution>

Master Module

Hardware Design

Design and Implementation

- As name suffice, Master Node acts as the brain of the RC car and gives controlled signals to every other module.

- It manages the communication among all the modules, including Motor, Sensor, Geographical and Bridge Controller.

- Master receives periodically data from CAN bus based on message ID of the sender module.

- Below shows the connection of Master module on CAN bus, connected with CAN Transceiver.

Software Design

- Figure illustrates the bus flow from master to every module.

Technical Challenges

<Bullet or Headings of a module>

Improper Unit Testing

<Problem Summary> <Problem Resolution>

Mobile Application

Hardware Design

Software Design

1. Bluetooth

Wireless communication with the car takes places with communication over Bluetooth protocol. Android Application is created which provides an interface to exchange data and configure the car parameters.

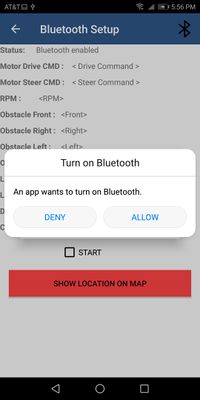

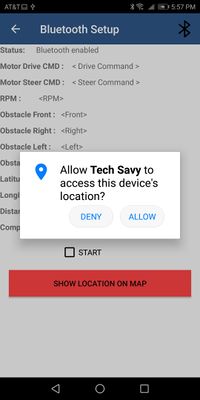

Enable Bluetooth and Connect to bridge controller

The android app connects to the HC-05 BLE module of the bridge controller. The Bluetooth ask the user for permission to access location and prompts to enable Bluetooth if it's already OFF. A Bluetooth adapter connects to the HC-05 module and opens a Bluetooth Socket over which read and write messages are sent. A thread runs in the background which checks for available data, reads it and the data can then be processed. Data is written via the same Bluetooth socket. Refer to the following link to get started with Bluetooth on Android app and connection to HC-05 module ([2]).

2. Start/Stop Command and Log Sensor values

Start and Stop commands are sent to the RC car via the application. When Start/Stop button is pressed 1 or 0 commands are sent to the bridge controller when then transmits it to the CAN Bus for processing. Bluetooth status, Sensor Values, Motor parameters, GPS location, compass heading angle, distance to the checkpoint is displayed for debugging purpose. To visit the Map Activity for setting destination and checkpoints a button is added. The map Activity opens on pressing the button.

3. Map Activity

The map activity is used in our app to show the current location of the car and set the destination marker which the car will navigate too. When map loads in the app the cars current location is indicated coming from the GPS as the source location (Red Marker). The desired location on the map can be set as the destination by long clicking on the map (Light Green marker). The destination can be changed as desired by long pressing again. When the start button is pressed command 1 is sent to the CAN bus via Bluetooth to start the car. A thread starts in the background to indicate the current position of the car when the car moves (light blue marker). Also, a polyline is drawn between the source and destination marker to indicate the direction in which the car will move. For adding Google map to app refer the following [3](Refer to Maps and geolocation section)

Technical Challenges

1. We faced the problem of adding Bluetooth functionality in the app. There is a lack of tutorials online which shows how to develop an android app with Bluetooth capability and communicating with the HC-05 module. Fortunately, we found this webpage [4] which helped us and Youtube videos of Coding with Mitch.

2. It was difficult to design the UI on the app with little java and Android experience. We designing UI from mainly two resources [5] [6]and searching online for problems faced by us.

3. Initially, we developed the app such that we had to manually connect to a paired device to use Bluetooth functionality. This gave us problems while sending commands to the bridge controller. We solved this problem by fixing the device connection only to our HC-05 module and adding only a single Bluetooth connection button on the app bar for Bluetooth connection.

4. When we received too much sensor, GPS data from the bridge controller the app crashes. We solved this problem by adding a 1000ms sleep time to limit the input data coming to the app.

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss your hardware design here. Show detailed schematics and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high-level workings rather than the inner working of your project.

Software Design

Show your software design.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can is started from scratch again? Make a smooth transition to the testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

<Bug/issue name>

Discuss the issue and resolution.

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

- Git Project Link: Tech Savy

Advise for Future Students

<Bullet points and discussion>

Acknowledgement

References

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.