F18: Catch me if you can

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

Catch Me If You Can

Abstract

"Catch me if you can" is a fun game where the user must be attentive and agile enough to catch the randomly dropping eggs from above into a basket with increasing difficulty levels for an intriguing experience. This is all displayed in the LED matrix acting as the screen. The system will consist of two SJ1 boards, one used as a game console with which user will try to catch the eggs by moving it in the required orientation. The other board will control the display module that displays the graphics of eggs falling and also the basket movement. The display module shall communicate with the game console via RF Nordic transceiver. There will be game sounds produced by the display module board for various events during the game like entering a new level.

Objectives & Introduction

Objective

To develop an Embedded system in the form of a 2D game involving a Matrix LED display acting as the Human Machine Interface to guide the player along the way while playing the game. This project aims at integrating micro-controller peripheral drivers and the application software in a meaningful way, where the accelerometer data is sent out from a node via wireless Nordic transceiver to control slider movement on the other node to control the game according to player's performance.

Introduction

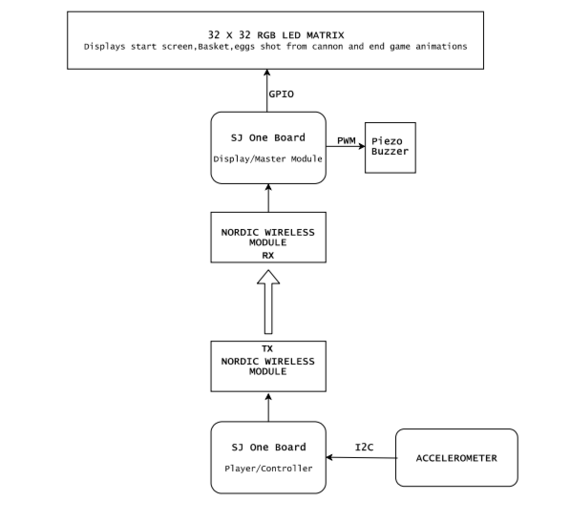

The Project consists of three main modules:

Console Module: It consists of accelerometer on SJ one board. Calibrated board orientation and switch pressed status is sent to the Display Module via Wireless Module.

Display Module: It is responsible for controlling 32*32 LED Matrix and Piezo buzzer interfaced to SJ One Board.

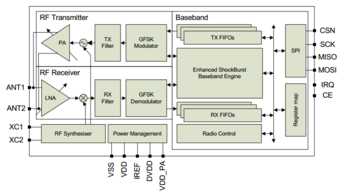

Wireless Module: This establishes communication between Display and Console module.

About the game

- Player should collect the eggs into the basket which are shot from the canon.

- Press switch on the console (SJOne board) to start the game.

- Tilt the console left or right to move the basket.

- Collect the eggs.

- Avoid red objects, if caught Game Over, else continue to collect eggs till the end of level.

Team Members & Responsibilities

- Aquib Abduljabbar Mulani

- Wireless chip TX driver/application and calibrating accelerometer.

- Kailash Kumar Chakravarty

- RGB LED 32x32 matrix driver and game application code.

- Nandini Mandya Shankaraiah

- Audio output and Wireless chip RX driver/application.

- Rishabh Sheth

- PCB design.

- Swanand Sapre

- Console and Game design and application code.

Schedule

| Week# | Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|

| 1 | 10/16/2018 |

|

Completed | 10/25/2018 |

| 2 | 10/30/2018 |

|

Completed | 11/05/2018 |

| 3 | 11/06/2018 |

|

Completed | 11/13/2018 |

| 4 | 11/13/2018 |

|

Completed | 11/16/2018 |

| 5 | 11/20/2018 |

|

Completed | 11/22/2018 |

| 6 | 11/27/2018 |

|

Completed | 12/1/2018 |

| 7 | 11/30/2018 |

|

Completed | 12/06/2018 |

| 8 | 12/04/2018 |

|

Completed | 12/11/2018 |

| 9 | 12/11/2018 |

|

Completed | 18/11/2018 |

Parts List & Cost

| Sl No | Parts | Seller | Quantity | Price |

|---|---|---|---|---|

| 1 | SJOne LPC1758 Microcontroller Board | Preetpal Kang | 2 | $160 |

| 2 | RGB LED Matrix Panel - 32x32 | Sparkfun | 1 | $55.6 |

| 3 | Piezo Buzzer | Amazon | 2 | $1.5 |

| 4 | Accelerometer | On board | 1 | NA |

| 5 | Switches | On board | 4 | NA |

| 6 | Portable Power Supply | Local seller | 1 | $5 |

| 7 | RF Nordic | On board | 1 | NA |

| 8 | BOM / PCB components | Moser | - | $20 |

Design & Implementation

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

PCB Design

PCB is an important part of the embedded system, it is certainly true for this project as it reduced wire complexity and gave independent power to our circuit. There are many softwares available for PCB design, among them Eagle and KiCAD are more popular and both software are free for students. We chose KiCAD (v5.10.0) for PCB design over Eagle because, it is opensource so we din't have to worry about the license and it offers free usage for students for an year. The second reason was that, all of our team members was new to PCB design so the learning curve was same for both software but we found a good tutorial series for KiCAD on youtube ( KiCAD tutorials ). KiCAD has its own issues which are discussed in the issue section of this wiki.

The steps involved in the PCB design process are described in the next section.

Schematic Design:

Our project can be divided into two main circuits, first is game display circuit and second is a console circuit. We decided to design separate PCB for both circuits as doing so can make wiring easy and improve the user experience.

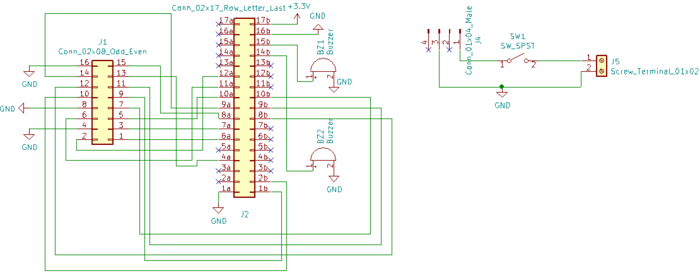

Display PCB schematic:

Display PCB has two independent circuits. One circuit is to connect SJOne board to LED panel connector and with two piezo buzzers. While another circuit is to connect one unused power cable of LED panel to SJOne board so that we don't have to power SJOne board from PC while we are playing the game. Our preliminary idea was to make this PCB, a Arduino kind of shield but for SJOne board.

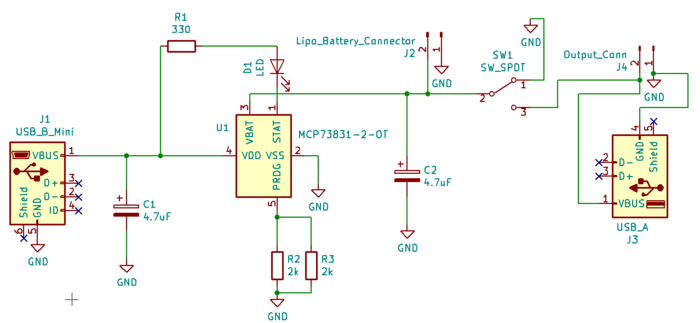

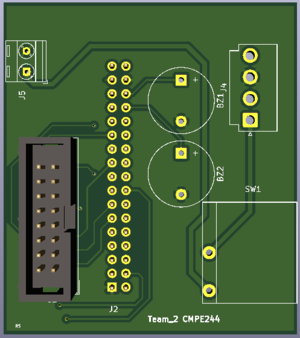

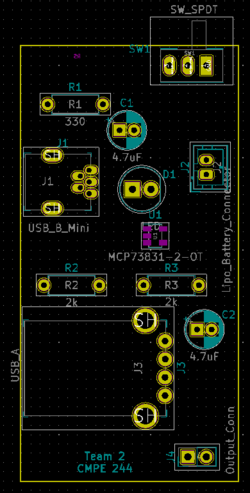

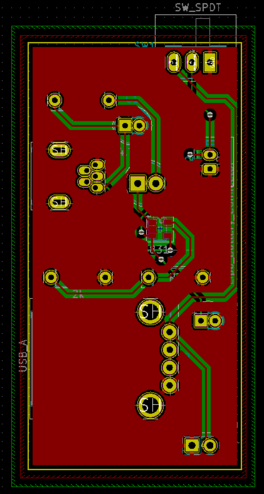

Console PCB schematic:

In this game, console is used to move the basket to catch fast falling eggs and if there were any wires attached to console then it is very inconvenient for the user to play. so, we decided to make PCB which can charge battery and power the console while the user is playing. As shown in figure, the heart of the circuit is microchip's MCP73831 LiPo battery charging management IC. One LED is connected to it's Status Pin which glows when the battery is charging. A mini USB B port is used to connect to power resource (PC or any 5V mobile charger)via USB cable to charge the battery. while playing the game, the user must connect USB A port to SJOne Board's mini USB B port. To use the console on battery power user must turn on/off switch.

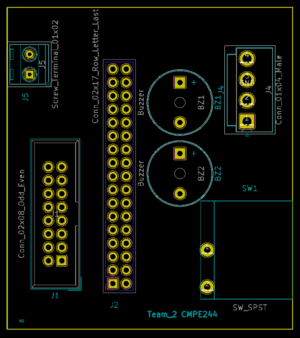

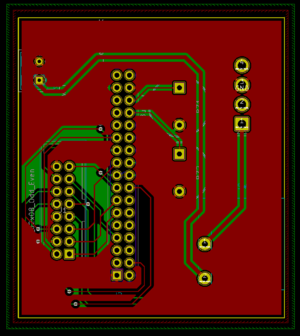

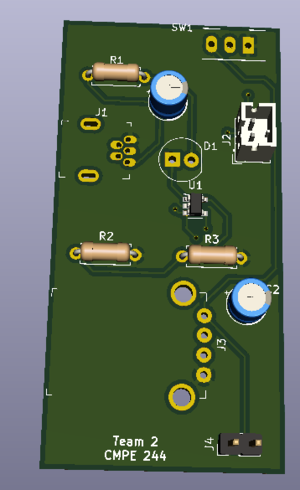

PCB Layout:

After schematic design, the most important step is to connect the PCB layout. In KiCAD components is not automatically associated with it's PCB footprint, so it's user's responsibility to connect right PCB footprint with the right components. In our case, we did not have the footprint of JLC connector and Rocker switch. so, we created it in a different window and saved it. The amazing feature of KiCAD is once we have done with PCB layout we can visualize PCB in 3D by pressing just one button. Below are actual screenshots of both, PCB layout & their 3D model.

Display PCB layout:

Console PCB layout:

PCB manufacturing and soldering:

We chose JLC PCB to manufacture our PCB because, it is the cheapest and convenient option available for any prototype PCB manufacturing. It just cost us $2 for quantity of 10 PCB and $17 for shipment. We received manufactured PCB in just 5 days. We order components from Moser the total BOM cost of both PCB is approx $25 including shipment. Followings are actual photos of manufactured & assembled PCBs.

Hardware Interface

Hardware design diagram above gives an overview of the entire system which consists of the two SJ-One controllers: one board is used as Control Module and other board is used as the Display Module.

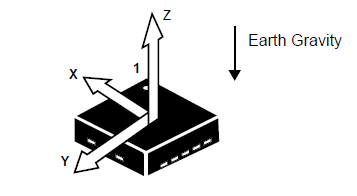

- The Console Module uses the onboard accelerometer on SJ-One which is interfaced via I2C protocol. The calibrated accelerometer values are then used to determine the basket position on the LED Matrix.

- The Display Module SJ-One board is used to control a 32*32 RGB LED Matrix.This matrix displays the basket, eggs shot from the cannon.The movement of the basket is as per the orientation value received from the Control Module, through Wireless Module. It also consists of Peizo buzzer which is controlled via PWM pin.

Software Design and Implementation

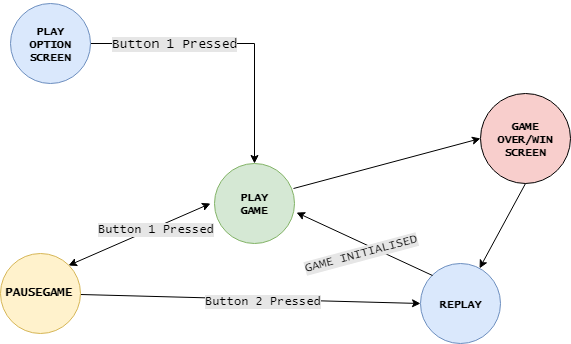

Tasks and Flow Control:

|

File:GameFlowChat.PNG Tasks and Flow Control |

Display Module

RGB LED Matrix:

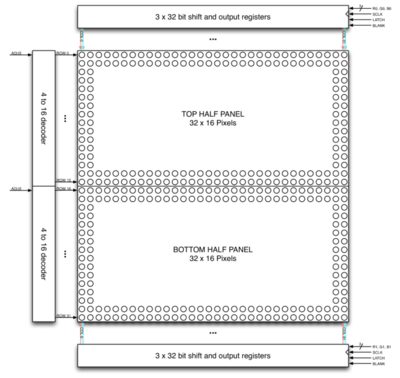

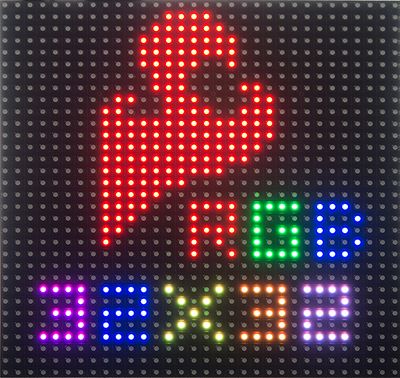

The Human Machine Interface is a display which is composed of 6mm pitch 1024 RGB LEDs arranged in a 32x32 matrix. 32 rows of the matrix is divided into 16 interleaved sections. Here the first section is the 1st and 16th 'row' (32 x 2 = 64 RGB LEDs), the second section is 2nd and 17th 'row' and so on. On the PCB is 12 LED driver chips. These are like 74HC595s but they have 16 outputs and they are constant current. 16 outputs * 12 chips = 192 LEDs that can be controlled at once, and 64 * 3 (R G and B) = 192. So now the design comes together. We can have 192 outputs that can control one line at a time, with each of 192 R, G and B LEDs either on or off. The LPC1758 controller selects which section to currently draw (using A, B, C and D address pins - 4 bits can have 16 values). Once the address is set, the controller clocks out 192 bits of data (24 bytes) and latches it. Then it increments the address and clocks out another 192 bits, etc until it gets to address #15, then it sets the address back to #0. To light up an individual pixel, appropriate row value is loaded on to the address pins A,B,C & D, Clock is set out to traverse the row and when required pixel is reached, the latch is set high to turn ON the LED. The hardware interface to the LED Matrix uses GPIO for all data and control lines. A GPIO clock is toggled to shift in data sitting at the Matrix's 6 data ports.

| SJ One Board Pin | Name | Description |

|---|---|---|

| P0.0 | addrA | Address Input A |

| P0.1 | addrB | Address Input B |

| P2.6 | addrC | Address Input C |

| P2.7 | addrD | Address Input D |

| P1.29 | Latch | Shift in row data/Active High |

| P1.28 | Output Enable | Turn on selected rows/Active Low |

| P1.19 | Clock | Shift clock |

| P1.22 | R1 | Top half red data |

| P0.26 | G1 | Top half green data |

| P1.23 | B1 | Top half blue data |

| P1.30 | R2 | Bottom half red data |

| P1.31 | G2 | Bottom half green data |

| P2.5 | B2 | Bottom half blue data |

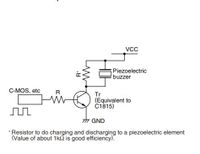

Piezo Buzzer:

Piezo electric buzzer are high performance buzzer that employ piezoelectric elements and are designed for easy incorporation into various circuits. These buzzers are designed for external excitation, the same part can serve as both a musical tone oscillator and a buzzer. In our project we are using this device to create musical tones by varying the operating frequency.The different range of operating frequency are generated from PWM peripheral. Different range of frequencies are maintained as constants ,these constants are fed to PWM,which generates square wave. The output of the PWM is driving the Piezo buzzer.

Code snippet for creating musical tones by varying frequency:

int fire[]=

{

550,/*twice the freq of this and use always tempo as 40 */

404,

315,

494,

182,

260,

455,

387,

340

};

void fire_sound_level(void){

for(int i = 0;i < 8;i++)

{

uint8_t tempo = 40;

while(tempo)

{

pwm.SetFrequency(fire[i]*2);

pwm.SetDutyCycle(pwm.k2_1,50);

pwm.PwmEnableMode(true);

tempo--;

}

}

pwm.PwmEnableMode(false);

}Control Module

Accelerometer:

| In our project,we have calibrated the accelerometer based the values of X,Y and Z co-ordinates corresponding to different orientations of the accelerometer to control the horizontal movement of the Basket to catch the eggs on the screen. This has also helped us decide and control the speed of the basket. |

Code snippet for Accelerometer Calibration:

if (((x_coordiante > px_coordiante + CONSOLE_SENSITIVITY) && (x_coordiante <= CONSOLE_TILT_RANGE) ))

{

boardOrientation=left;

bskObj.speed=BASKET_SPEED;

px_coordiante=x_coordiante;

}

//left

else if((x_coordiante<px_coordiante-CONSOLE_SENSITIVITY && x_coordiante>=-CONSOLE_TILT_RANGE))

{

boardOrientation=right;

bskObj.speed=BASKET_SPEED;

px_coordiante=x_coordiante;

}

else if(x_coordiante>CONSOLE_TILT_RANGE ){

boardOrientation=left;

bskObj.speed=BASKET_SPEED;

}

else if(x_coordiante<-CONSOLE_TILT_RANGE ){

boardOrientation=right;

bskObj.speed=BASKET_SPEED;

}

else

{

boardOrientation=invalid;

py_coordiante=y_coordiante;

}Wireless Module:

Code snippet for Wireless Transmitter:

struct pckt

{

int16_t x;

int16_t y;

int16_t z;

int16_t buttonPressed=0;

};

void WirelessTx(void *p)

{

while(1)

{

pckt var;

var.x = AS.getX();/values from accelerometer*/

var.y = AS.getY();

var.z = AS.getZ();

pckt var;

while(1)

{

if(SW.getSwitch(1))

{

var.buttonPressed=1;

vTaskDelay(300);

}

else if(SW.getSwitch(2))

{

var.buttonPressed=2;

vTaskDelay(300);

}

wireless_send(REM, mesh_pkt_nack,(pckt*)&var, 8, 0);

vTaskDelay(50);

}

}

}Code snippet for Wireless Receiver: void wirelessRx(void* p)

{

while(1)

{

mesh_packet_t rcvPkt;

int timeout_ms = 50;

if(wireless_get_rx_pkt(&rcvPkt, timeout_ms)){

iphObj.x_coordiante = (int16_t)(*((uint16_t*)(rcvPkt.data+0)));

iphObj.y_coordiante = (int16_t)(*((uint16_t*)(rcvPkt.data+2)));

iphObj.z_coordiante = (int16_t)(*((uint16_t*)(rcvPkt.data+4)));

iphObj.buttonPressed= (int16_t)(*((uint16_t*)(rcvPkt.data+6)));

if(iphObj.buttonPressed==1 )

{

xSemaphoreGive(playPauseHandler);

}

else if(iphObj.buttonPressed==2 )

{

xSemaphoreGive(resetGameHandler);

}

}

vTaskDelay(50);

}

}

Testing & Technical ChallengesIssue #1Porting Adafruit driver into LPC As we used the existing Adafruit library,we had to map the LPC GPIOs to LED matrix pins.This was challenging because choosing the pins also mattered for PCB design, which we were unaware untill we started to design PCB. We hadto remap the LPC GPIO pins to LED matrix as per PCB wiring convenience. Issue #2In Nordic Wireless, the transmitted data was received only once, despite the transmitter transmitting data continuously. This was because vTaskStartScheduler() API was used by us.The scheduler_start() API was right API to be used for Nordic Wireless to function properly. Once we implemented the queue to collect orientation and switch status,we saw a delay in data reception.This was due to /* to be filled */ Issue #3Determining the range of audio frequencies which would be audible and sensible was challenging.After days of trail and error method we found the range. After finding the range, the problem we encountered was with switching frequencies. Drastically varying frequency of PWM will cause sound produced by Peizo unpleasant.In order to overcome this we had to vary frequency in small steps. Say you want to change frequency from 410 to 510. do it in steps 410,420,430 soon.One more important thing to verify is the whether the frequency generated by PWM peripheral matches your expected frequency, do verify it with logic analyzer once before writing the music tone libraries. Issue #4/*PCB issue to be filled by rishab */ Issue #5Configuring Task Priorities and State Machine was challenge. Game slowed down as the level progress.After Debugging we found out the issue was due to high RIT_Interrupt rate. ConclusionAt the start, project was a jigsaw puzzle. We only had pieces of knowledge and unaware of how to tailor it to solve the puzzle. Well we are successful in implementing our idea of building a game. This project has helped us to gain practical exposure in building a real time embedded system. This project gave us a platform to utilize all LPC drivers and Free RTOS knowledge which we learnt in our course work and what are the key things to consider while building a real time system. We are thankful to Preet, who motivated and guided us through the course work , Project VideoUpload a video of your project and post the link here. Project Source CodeReferencesAcknowledgementAny acknowledgement that you may wish to provide can be included here. References Used[2] [1] [3] Low_Powered_Mesh_Network_stack AppendixYou can list the references you used. |