S13: 2D Plotter

Contents

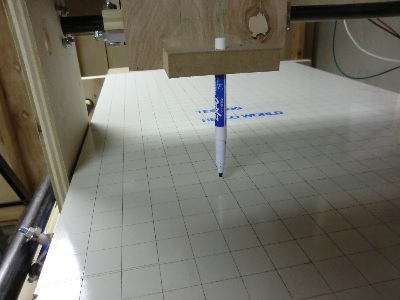

2D Plotter

2D Plotter

Abstract

The following text describes the design, programming, and testing of a simple plotter. A plotter is a computer output device similar to a printer that is designed to print a design based on vectors.

This plotter was developed as the final project for the Embedded Systems class (CmpE146) at San Jose State University, California. It consists of a wooden chassis, two stepper motors to position the print head, a print head using an electromagnet to lift or lower the pen, and an ARM-based controller board running FreeRTOS.

To test the plotter, a set of simple geometric shapes will be printed once the device has been completed.

Objectives & Introduction

The purpose of this project is to design a simple 2D plotter that can then be modified to serve as a CNC router, a laser cutter, or any other vector-based 2D output device. In addition, the design of the plotter is intended as a preliminary step towards the design of a 3D printer. The experience from the design of the plotter will allow us to asses which of our ideas are current ideas can be realized with the hardware and software options available to use at the current time.

One main objective of the design is to reuse as many existing components as possible. For example, belts, gears, and motors from old inkjet printers have been collected to be used in this design.

As far as the operation of the plotter is concerned, the objectives of this project are:

1. Use the ARM-based SJSUONE board to control all necessary hardware through GPIOs.

2. Design a wooden enclosure for the hardware.

3. Create a program that allows control of the hardware to create some useful output.

Team Members & Responsibilities

- Matthias

- Hardware Development

- William

- Driver Development

- Sergey

- Wiki and Documentation

Schedule

| Week | Planned Tasks | Actual Tasks |

|---|---|---|

| 1 |

|

|

| 2 |

|

|

| 3 |

|

|

| 4 |

|

|

| 5 |

|

|

Parts List & Cost

| Parts | Cost |

|---|---|

| 2012 SJ One Board | $65 |

| 3 x Nema 17 Stepper Motors | $33.20 |

| 4 x Steel shapes, round | $14.76 |

| 3 x Stepper Motor Controller | $12.39 |

| Power supply | $10 |

| New wood (various sizes) | $8.94 |

| Breadboard | $7 |

| 6 x Hollow metal tubes | $4.74 |

| 4 to 16 decoder | $3 |

| Old wood | $0 |

| Screws | $0 |

| Old printer gears | $0 |

| Old printer belts | $0 |

| Wires | $0 |

| Glue | $0 |

| Total: | $159.03 |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

Wifi Connection Issues

Many wifi connection issues were encountered. To solve this problem, a dedicated task was created to re-connect to wifi if the connection was ever lost.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

Send me your zipped source code and I will upload this to SourceForge and link it for you.

References

Acknowledgement

None. Preet Kang and Dr. Ozemek did not really help us. They just graded us. If only they spent more time helping us rather than grading us. Just saying.

References Used

3D printing. (2013). Retrieved from http://en.wikipedia.org/wiki/3D_printing

Benchoff, B. (2012). Print huge stuff with the Makerbot Replicator. Retrieved from http://hackaday.com/2012/01/09/print-huge-stuff-with-the-makerbot-replicator/

Chace, Z. (2013). 3-D Printing Is (Kind Of) A Big Deal. Retrieved from http://www.npr.org/blogs/money/2013/01/04/168627298/3-d-printing-is-kind-of-a-big-deal

Deckard, C. (1986). Method and apparatus for producing parts by selective sintering. United States. 4863538. Austin, Texas: Board of Regents, The University of Texas System

Evans, Brian. (2012). The Sciene and Art of 3D Printing. New York, NY: Springer Science + Business Media.

Eveleth, R. (2012). Our three-dimensional future: how 3D printing will shape the global economy. Retrieved from http://www.smartplanet.com/blog/report/our-three-dimensional-future-how-3d-printing-will-shape-the-global-economy/559

Kelly, James F. and Hood-Daniel, P. (2011). Printing in Plastic: Build Your Own 3D Printer. New York, NY: Springer Science + Business Media.

Hartmann, K. et al. (1994). Robot-Assisted Shape Deposition Manufacturing. San Diego, CA: Proceedings of the 1994 IEEE International Conference on Robotics and Automation

Hotz, R. (2012). Printing Evolves: An Inkjet for Living Tissue. Retrieved from http://online.wsj.com/article/SB10000872396390443816804578002101200151098.html

RepRap. (2013). Retrieved from http://www.reprap.org/wiki/Main_Page

RepRap Options. (2013). Retrieved from http://reprap.org/wiki/RepRap_Options

Appendix

You can list the references you used.