Difference between revisions of "S15: Swarm Robots"

Proj user5 (talk | contribs) (→Hardware Interface) |

Proj user5 (talk | contribs) (→Hardware Interface) |

||

| Line 174: | Line 174: | ||

: 3. ADC pins are used to read the value from IR sensor. | : 3. ADC pins are used to read the value from IR sensor. | ||

'''Pin connections''' | '''Pin connections''' | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! scope="col"| Serial No. | ||

| + | ! scope="col"| Port and Pin number | ||

| + | ! scope="col"| Pin Type | ||

| + | ! scope="col"| Purpose | ||

| + | |- | ||

| + | ! scope="row"| 1 | ||

| + | | P0.1, P0.0, P0.29, P0.30 | ||

| + | | GPIO output | ||

| + | | DC motors | ||

| + | |- | ||

| + | ! scope="row"| 2 | ||

| + | | P2.0, P2.1 | ||

| + | | PWM | ||

| + | | DC motors | ||

| + | |- | ||

| + | ! scope="row"| 3 | ||

| + | | P2.2 | ||

| + | | PWM | ||

| + | | Servo motors | ||

| + | |- | ||

| + | ! scope="row"| 4 | ||

| + | | P1.19, P2.7 | ||

| + | | GPIO | ||

| + | | Ultrasonic sensors | ||

| + | |- | ||

| + | ! scope="row"| 5 | ||

| + | | P0.26, P1.30 | ||

| + | | ADC | ||

| + | | IR sensors | ||

| + | |- | ||

| + | ! scope="row"| 6 | ||

| + | | P4.28, P4.29 | ||

| + | | UART3 | ||

| + | | Communication between openCV and SJone board | ||

| + | |- | ||

| + | } | ||

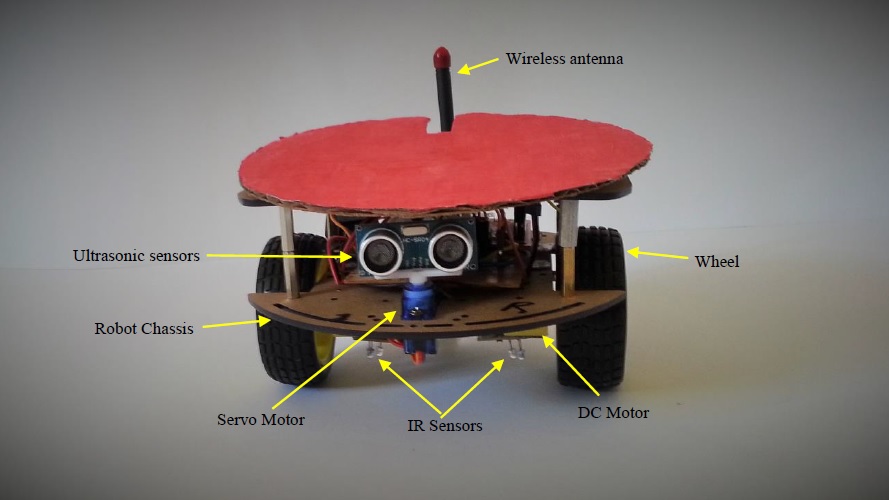

[[File:S15_244_grp12_Robot_Hardware.jpg|center|Robot]] | [[File:S15_244_grp12_Robot_Hardware.jpg|center|Robot]] | ||

Revision as of 00:45, 25 May 2015

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Swarm Robots

Abstract

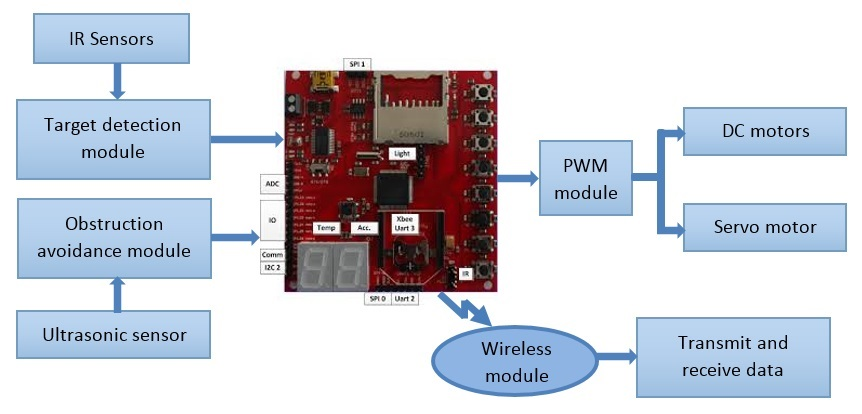

Swarm robots deals with coordination of multiple robots. The collective behavior of the robot swarm emerges from interaction with each other and surroundings. All the Robots can communicate with each other. The position of each robot is determined and monitored by an overlooking camera. Large number of simple robots can perform complex tasks in a more efficient way than a single robot, giving robustness and flexibility to the group.

Objectives & Introduction

- Initially all robots will go in search of the target, as and when the target is located, the bot which is near the target sends out a message about its present location to all other bots.

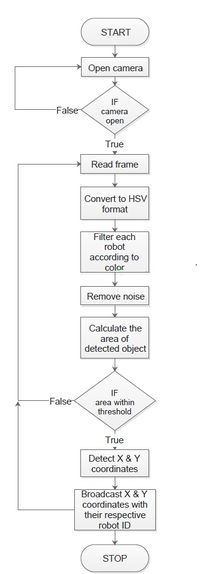

- Overhead camera serves the purpose of determining the location of individual bots.

- Once the message regarding the target position is received by other bots, each of them will move towards the target.

Team Members & Responsibilities

- Team Member 1

- Abhishek Gurudutt - IR sensor circuit and interface, OpenCV (Image detection and co-ordinate mapping).

- Team Member 2

- Bhargava Sreekantappa Gayithri - Robot assembly, Motor driver circuit, interfacing ultrasonic sensors and Motors

- Team Member 3

- Chinmayi Divakara - Wireless communication and synchronization

- Team Member 4

- Praveen Prabhakaran - OpenCV co-ordinate mapping. OpenCV and SJone board communication.

- Team Member 5

- Tejeshwar Chandra Kamaal - Robot assembly, Motor driver circuit, interfacing ultrasonic sensors and Motors

Schedule

| Week# | Date | Task | Actual | Status |

|---|---|---|---|---|

| 1 | 4/14/2015 |

1) Hardware - Design of Motor Controller,

Robot assembly

2) Software - OpenCV environment setup,

Basic video processing

|

1) Hardware, OpenCV setup - Completed

Problems Encountered - Hardware Bug discovered in version 0.1

of motor controller circuit after testing.

2) Software - Problems during filtering video for certain colors.

|

Completed |

| 2 | 4/21/2015 |

1) Communication between OpenCV to SJone board

using DB9 connector and UART3

2) PWM and Ultrasonic sensor drivers

3) Object detection and mapping

4) Wireless communication between two nodes

|

1) Modification of RS232 header file to support windows 7 file API.

Was not able to communicate between OpenCV and SJone board using UART0

2) Unable to receive the echo signal and was not able to use

ultrasonic sensor without interrupt.

3) HSV values had to be detected to recognize particular color.

Had difficulties to find the HSV values for a color.

This was solved by writing a program to print the

HSV value of the color that is pointed in the video.

4) Packet sending and recieving failure. System crash while

transmitting and recieving packets

|

Completed |

| 3 | 4/28/2015 |

1) PID Controller Design

2) Co-ordinates communication between nodes

and boundary mapping

3) Inter board communication and

communicating the Co-ordinates

|

1) Point to point travel using PID control loop. Code written PID tuning in progress. 2) Object detection completed. Co-ordinates mapping in progress. 3) Inter board communication completed. |

Completed |

| 4 | 05/05/2015 |

1) Integration, testing and Bug fixing |

- | Scheduled |

Parts List & Cost

| Serial No. | Part Description | Cost |

|---|---|---|

| 1 | Robot chassis and motors | $66.7 |

| 2 | Servo motors | $27.38 |

| 3 | Wireless camera | $26.21 |

| 4 | Ultrasonic sensor | $17.98 |

| 5 | Lipo Batteries and charger | $43.28 |

| 6 | H bridge IC - L293d | $10.91 |

| 7 | Connectors, cables etc | $45 |

| 8 | Antennas for wireless module | $15 |

| 9 | Foam board for arena | $65 |

Design & Implementation

Hardware Design

- All parts of the robot was assembled by the team. Robot assembly started with connecting chassis with dc motor and later on putting the wheels together for the robot. The movement of the motors is controlled by the L293D IC. An ultrasonic sensor is mounted on stepper motor to detect obstacles in the way of robot. The stepper motor helps to rotate the ultrasonic sensor from initial position through 180 degrees.

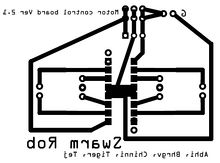

- The schematic was designed by the team and it was embedded on the PCB using the actual process carried on to embed a circuit layout on the PCB. H-bridge image provides the layout information of the motor driver. H-bridge drives the two dc motors of robot which helps in its movement. The dc motor is driven by a rechargeable lipo battery.

- Robot chassis is a circular cardboard material which is strong enough to withstand materials utilized by the robot. These chassis were bought online from https://www.elabpeers.com/smart-car-robot-with-chassis-and-kit-round-black.html

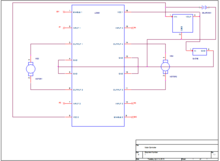

- The L293D circuit along with the LM7805 regulator schematic was drawn using orcad design tool. The aim of the schematic was to achieve proper connections between the motor,L293D IC and 7805. L293D IC is used to drive the two dc motors as shown in the image. The dc motors are driven by supplying a PWM to the enable pin of the L293D. The LM7805 voltage regulator is used to supply power for SJ-One board and its peripherals.

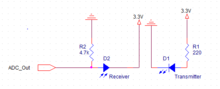

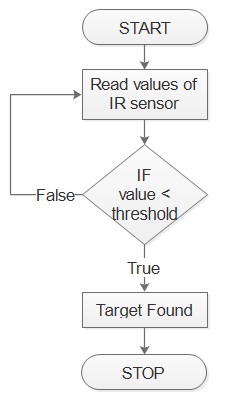

- IR Sensor circuit is used for object detection above the surface. The schematic was drawn using orcad design tool. IR sensor is turned ON by supplying a voltage of 3.3 volt. The transmitter LED sends a light pulse and receiver LED receives the reflected light, depending on the amount of light received by the receiver LED the voltage across the resistor changes. If no light is received by the receiver LED then voltage across the resistor will be very less.

- Servo motors are used for precise rotary movement of ultrasonic sensors. The angle by which the servo motor has to rotate is achieved by providing calculated amount of pulses to PWM pin.

- Ultrasonic sensors are used to detect any obstacle. When ultrasonic sensor is triggered through the trigger pin, ultrasonic sensor transmits sound waves, this hits the object in front and returns back, upon reception the echo pin provides a falling edge. The time taken to receive the sound wave back can be used to calculate the distance of object from the sensor.

Hardware Interface

Design consideration

- 1. Pulses to enable pin of motor driver circuit and to drive the servo motor is given through PWM pin available on SJone board.

- 2. UART3 pin is used to communicate between laptop and SJone board.

- 3. ADC pins are used to read the value from IR sensor.

Pin connections

| Serial No. | Port and Pin number | Pin Type | Purpose |

|---|---|---|---|

| 1 | P0.1, P0.0, P0.29, P0.30 | GPIO output | DC motors |

| 2 | P2.0, P2.1 | PWM | DC motors |

| 3 | P2.2 | PWM | Servo motors |

| 4 | P1.19, P2.7 | GPIO | Ultrasonic sensors |

| 5 | P0.26, P1.30 | ADC | IR sensors |

| 6 | P4.28, P4.29 | UART3 | Communication between openCV and SJone board |