Difference between revisions of "S24: Team Zero"

(→Hardware Design) |

(→Hardware Design) |

||

| Line 382: | Line 382: | ||

{| | {| | ||

| − | |[[File:top_view_left_tz|300px|center|thumb|Top View of Vehicle (Left Side)]] || [[File:top_view_left_tz|300px|center|thumb|Top View of Vehicle (Right Side)]] | + | |[[File:top_view_left_tz.jpeg|300px|center|thumb|Top View of Vehicle (Left Side)]] || [[File:top_view_left_tz.jpeg|300px|center|thumb|Top View of Vehicle (Right Side)]] |

| | | | ||

|} | |} | ||

Revision as of 07:44, 25 May 2024

Contents

Project Title

TEAM ZERO

Abstract

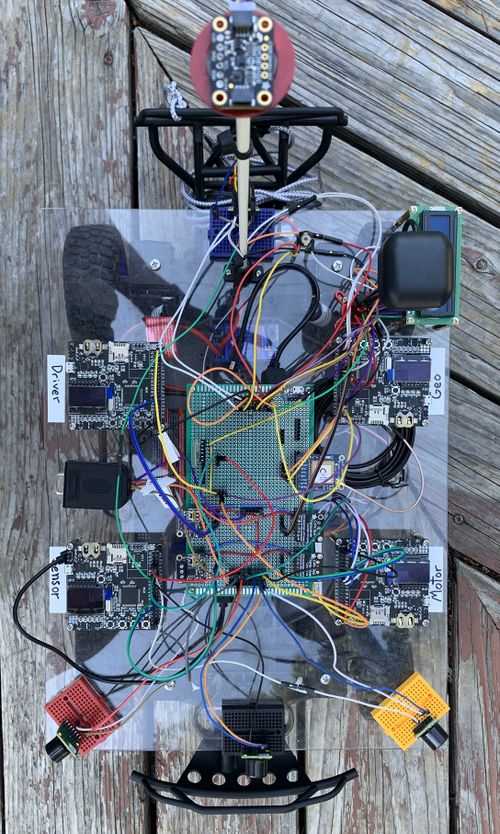

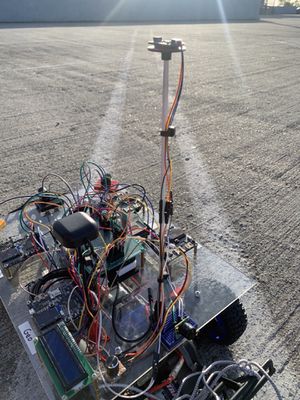

Team Zero's Self driving RC car, as the name states, is an autonomous vehicle designed to navigate to a given specified destination successfully, avoiding obstacles along its way. The car's infrastructure is built upon four key components: the Driver, Sensor-Bridge, Geo, and Motor nodes, which communicate internally via a CAN Bus and with the user via a mobile app. The vehicle continuously senses and processes all the information from these nodes to make decisions to ensure it stays on course and reaches its destination. It is built on a hobby-grade RC car chassis, modified with the necessary components and adjustments to fulfill its primary objectives of autonomous navigation and obstacle avoidance.

Introduction

The project was divided into N modules:

- Geographical Controller and LCD

- Motor Controller

- Sensor-Bridge Controller

- Driver Controller

- Mobile Application

Team Members & Responsibilities

Gitlab Project Link - [1]

Cody Ourique [2]

- Geo controller

- Compass,GPS and LCD interfacing

- Hardware design, development and mounting

- LCD modules

- Unit Testing

Anusha Arunnandi [3]

- Sensor-Bridge controller

- Ultrasonic range finder and bluetooth interfacing

- Web application

- Unit Testing

Chaitanya Battula [4]

- Driver controller

- Motor controller

- RPM sensor, ESC, and servo motor interfacing

- Unit Testing

Rohit Duvvuru [5]

- Unit Testing

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 03/03/2024 | 03/09/2024 |

|

Completed |

| 2 | 03/10/2024 | 03/16/2024 |

|

Completed |

| 3 | 03/17/2024 | 03/23/2024 |

|

Completed |

| 4 | 03/24/2024 | 03/30/2024 |

|

Completed |

| 5 | 03/31/2024 | 04/06/2024 |

|

Completed |

| 6 | 04/07/2024 | 04/13/2024 |

|

Completed |

| 7 | 04/14/2024 | 04/20/2024 |

|

Completed |

| 8 | 04/21/2024 | 04/27/2024 |

|

Completed |

| 9 | 04/28/2024 | 05/04/2024 |

|

Completed |

| 10 | 05/05/2024 | 05/11/2024 |

|

Completed |

| 11 | 05/12/2024 | 05/18/2024 |

|

Completed |

| 12 | 05/19/2024 | 05/25/2024 |

|

Completed |

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC car | Traxxas [6] | 1 | $239.95 |

| 2 | RPM sensor | Traxxas [7] | 1 | $12.00 |

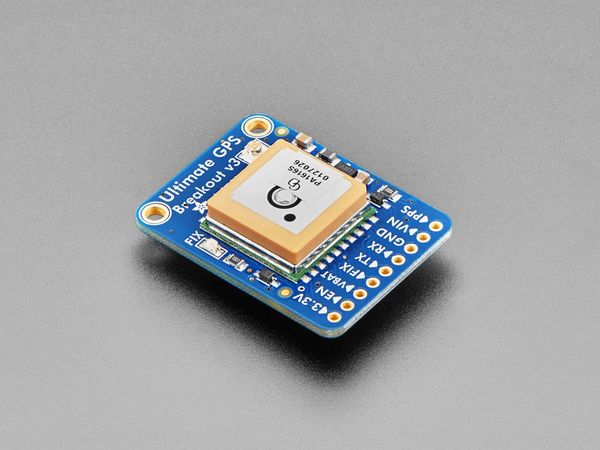

| 3 | GPS Breakout Board | Adafruit [8] | 1 | $54.95 |

| 4 | PCB prototype circuit board | A1 Cables N PCBs [9] | 1 | $8.57 |

| 5 | Plexiglass | Lesnlok [10] | 1 | $9.98 |

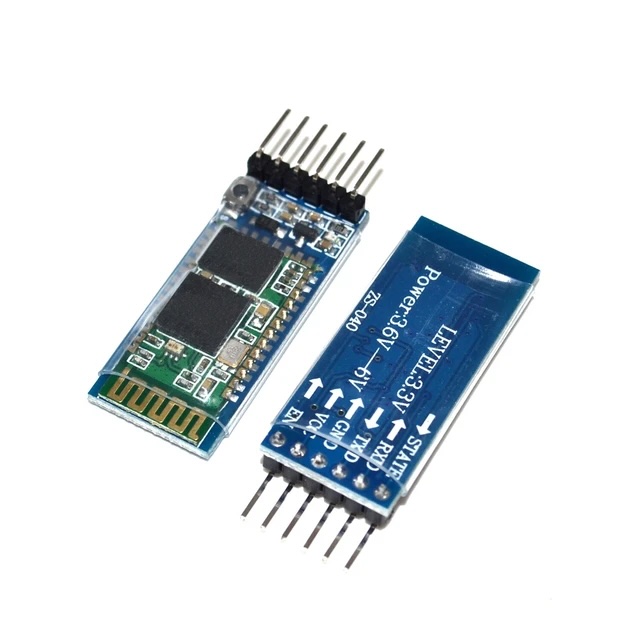

| 6 | Wireless bluetooth RF transceiver | HiLetgo [11] | 1 | $9.95 |

| 7 | Compass | Adafruit [12] | 1 | $5.95 |

| 8 | Ultrasonic range finder | Adafruit [13] | 4 | $114.00 |

| 8 | Potentiometer | Amazon [14] | 1 | $9.99 |

| 8 | 2 Pack 15000mAh power bank | Amazon [15] | 1 | $19.99 |

| 8 | GPS Antenna Mount | Honbay [16] | 2 | $7.29 |

| 8 | I2C Qwiic Cable Kit | Amazon [17] | 1 | $9.99 |

| 8 | Black Foam Padding | Amazon [18] | 1 | $11.99 |

| 8 | Traxxas 6537 Wire Retainers | Amazon [19] | 1 | $6.95 |

| 8 | USB Micro-B Breakout Board | Adafruit [20] | 1 | $4.88 |

| 8 | 24 awg Wire Solid Core | Amazon [21] | 1 | $14.99 |

| 8 | ELEGOO 6PCS 170 tie-Points Mini Breadboard | Amazon [22] | 1 | $6.98 |

| 8 | GPS Antenna | Amazon [23] | 1 | $10.99 |

| 8 | Standoffs | Amazon [24] | 1 | $22.96 |

| 8 | Breadboard Wires | Amazon [25] | 1 | $5.97 |

| 8 | 3/16 inch fiberglass rod | TAP plastics | 1 | $5.11 |

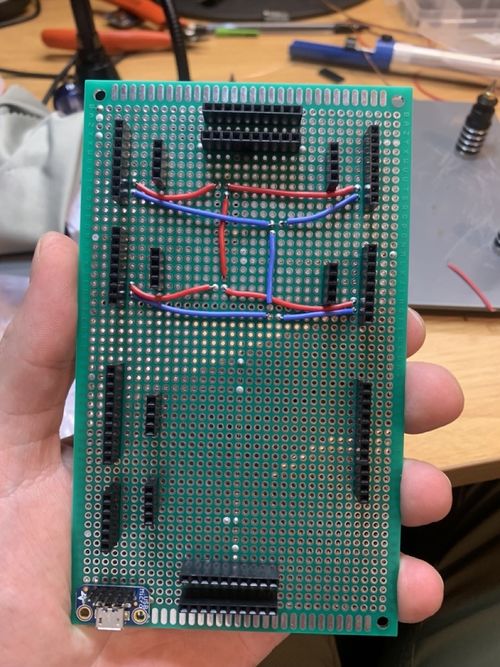

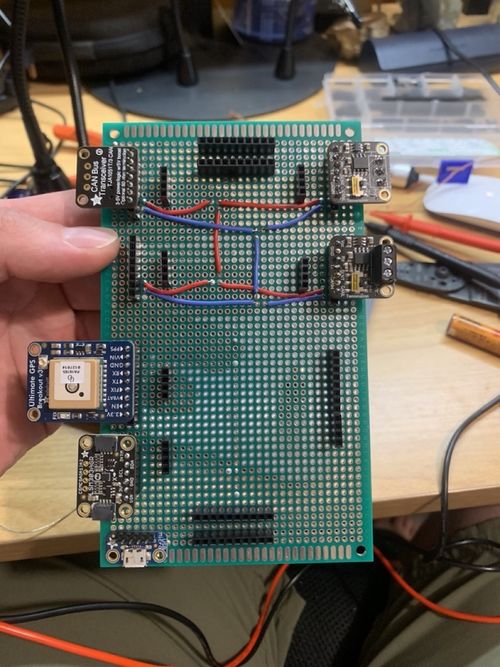

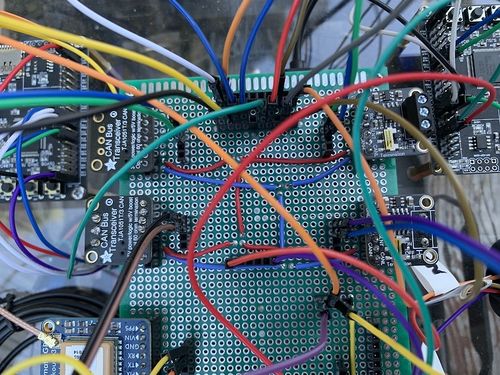

Prototype Circuit Board

This prototype circuit board was carefully designed so that it could power all the microcontrollers, compass module, GPS module, bluetooth module, ultrasonic sensors and the LCD. In addition, the board has 4 slots for CAN tranceivers and an integrated CAN bus line. The board has a common ground line for all connected devices and has a total of 20 available sockets. Also, the board has 3.3V power and has 20 open sockets. Additionally, the board has 5V power with 4 available sockets delivered via micro USB.

CAN Communication

The microcontrollers communicate using the CAN bus. Each controller is sending or receiving CAN messages through periodic callback functions. All CAN bus messages are transmitted every 10Hz.

Geographical Controller CAN Messages:

- GEO_READINGS: The geo readings message responsibility is to send the heading, bearing and distance to destination information to the driver and sensor-bridge nodes. The driver node uses the geo readings to determine which direction it should go and when the vehicle should stop. In addition, the sensor-bridge needs the data to display it to the user on the mobile application.

- GEO_DATA_TO_DRIVER_AND_BRIDGE: This message's responsibility was to send current coordinates to the driver and sensor-bridge nodes so that the data could be properly displayed over the mobile application. The MIA threshold for this message is 100 and if this message goes into MIA its values will be set to 0.

- GEO_DEBUG_MESSAGE: The purpose of the debug message was to send a signal to the driver that the GPS has acquired a fix on the current location and another value to indicate the number of periodic callbacks needed to acquire the lock.

Sensor_Bridge Controller CAN Messages:

- SENSOR_ULTRA_SONIC

- SENSOR_BATTERY

- BRIDGE_DATA_TRANSFER

Motor Controller CAN Messages:

- MOTOR_READINGS

Driver Controller CAN Messages:

- DRIVER_HEARTBEAT

- MOTOR_CMD

Hardware Design

DBC File

VERSION "" NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_ BS_: BU_: DBG DRIVER MOTOR SENSOR_BRIDGE GEO BO_ 100 DRIVER_HEARTBEAT: 1 DRIVER SG_ DRIVER_HEARTBEAT_cmd : 0|8@1+ (1,0) [0|0] "" SENSOR_BRIDGE,MOTOR BO_ 101 MOTOR_CMD: 1 DRIVER SG_ MOTOR_CMD_steer : 0|4@1- (1,0) [-5|5] "steering direction" MOTOR SG_ MOTOR_CMD_drive : 4|4@1+ (0.1,-5) [-5|5] "kph" MOTOR BO_ 102 MOTOR_READINGS: 4 MOTOR SG_ MOTOR_READINGS_steer_degrees : 0|4@1- (1,0) [-5|5] "steer direction" DRIVER SG_ MOTOR_READINGS_speed : 4|4@1+ (0.1,-5) [-5|5] "kph" DRIVER BO_ 200 SENSOR_ULTRA_SONIC: 8 SENSOR_BRIDGE SG_ SENSOR_ULTRA_SONIC_left : 0|10@1+ (1,0) [0|500] "cm" DRIVER SG_ SENSOR_ULTRA_SONIC_right : 10|10@1+ (1,0) [0|500] "cm" DRIVER SG_ SENSOR_ULTRA_SONIC_middle : 20|10@1+ (1,0) [0|500] "cm" DRIVER SG_ SENSOR_ULTRA_SONIC_back : 30|10@1+ (1,0) [0|500] "cm" DRIVER BO_ 202 SENSOR_BATTERY: 1 SENSOR_BRIDGE SG_ SENSOR_BATTERY_voltage : 0|8@1+ (1,0) [0|0] "V" DRIVER BO_ 300 BRIDGE_DATA_TRANSFER: 8 SENSOR_BRIDGE SG_ GPS_DESTINATION_send_latitude : 0|32@1+ (0.000001,0) [0|0] "Degrees" GEO SG_ GPS_DESTINATION_send_longitude : 32|32@1+ (0.000001,0) [0|0] "Degrees" GEO BO_ 301 GEO_READINGS: 8 GEO SG_ GEO_READINGS_COMPASS_HEADING : 0|12@1+ (1,0) [0|359] "Degrees" DRIVER, SENSOR_BRIDGE SG_ GEO_READINGS_COMPASS_BEARING : 12|12@1+ (1,0) [0|359] "Degrees" DRIVER, SENSOR_BRIDGE SG_ GEO_READINGS_DISTANCE_TO_DESTINATION : 24|24@1+ (1,0) [0|0] "Meters" DRIVER, SENSOR_BRIDGE BO_ 302 GEO_DATA_TO_DRIVER_AND_BRIDGE: 8 GEO SG_ GEO_DATA_TO_DRIVER_AND_BRIDGE_latitude : 0|32@1+ (0.000001,0) [0|0] "Degrees" DRIVER, SENSOR_BRIDGE SG_ GEO_DATA_TO_DRIVER_AND_BRIDGE_longitude : 32|32@1+ (0.000001,0) [0|0] "Degrees" DRIVER, SENSOR_BRIDGE BO_ 304 GEO_DEBUG_MESSAGE: 2 GEO SG_ GEO_DEBUG_MESSAGE_LOCK : 0|8@1+ (1,0) [0|0] "Boolean" DRIVER SG_ GEO_DEBUG_MESSAGE_LOCK_TIME : 8|8@1+ (0.1,0) [0|0] "Seconds" DRIVER CM_ BU_ GEO "The gps contoller"; CM_ BU_ SENSOR_BRIDGE "The bridge controller"; CM_ BU_ DRIVER "The driver controller driving the car"; CM_ BU_ MOTOR "The motor controller of the car"; CM_ BO_ 100 "Sync message used to synchronize the controllers"; CM_ SG_ 100 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver"; BA_DEF_ "BusType" STRING ; BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; BA_DEF_ SG_ "FieldType" STRING ; BA_DEF_DEF_ "BusType" "CAN"; BA_DEF_DEF_ "FieldType" ""; BA_DEF_DEF_ "GenMsgCycleTime" 0; BA_ "GenMsgCycleTime" BO_ 100 1000; BA_ "GenMsgCycleTime" BO_ 200 50; BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd"; VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ;

Sensor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Motor ECU

Motor - https://gitlab.com/Ouriquco/cmpe_243_team_zero/-/tree/NodeMotor/projects/MotorNode?ref_type=heads

The motor is controlled by an Electronic Speed Controller (ESC), which serves as an interface between the motor and the power source (e.g., battery). The ESC receives input signals, typically from a microcontroller or remote control receiver, to adjust the motor's speed, direction, and sometimes braking. The motor node sends PWM signals to the ESC, which decodes these signals and converts them into the appropriate power levels for the motor. The motor node's role is to receive commands from the driver node, which processes obstacle avoidance and geolocation algorithms over the CAN bus. Understanding the various PWM values corresponding to different motor operations is critical for precise control and efficient performance.

Hardware Design

The motor is controlled using various PWM signals to move forward, backward, or steer in different directions. The SJ2C board has specific pins designated for PWM signals. Two such pins, P2.0 and P2.1, are dedicated to controlling the motor's speed and servo. The SJ2 board, with its excellent I/O capabilities, allows for precise modulation of output signals to accurately control both the DC and servo motors.

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Geographical Controller & LCD

Gitlab Geographical Controller Source Code - [26]

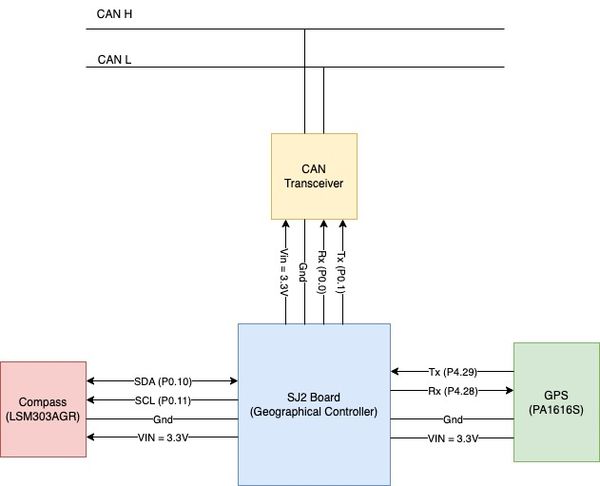

The geographical controllers responsibilities are to ensure that the driver and sensor-bridge controllers receive the most accurate data related to bearing, heading, destination and current coordinates. This information provides the driver controller with the data they need to make logical decisions related to the movement of the vehicle. Also, the information is needed to tell the user why the vehicle may be changing direction. A geographical controller is necessary in any application where location is integrated into the system.

The GPS module has a built in antenna and acquires latitude and longitude in GPGGA format every 10Hz. This module is rated between 3.3V and 5V. In our project we powered this module using 3.3V by integrating it on the prototype board. In addition, we used an external antenna to increase signal strength.

The compass module is a triple axis accelerometer/magnetometer. The accelerometer can tell you which direction is down towards the Earth (by measuring gravity). The magnetometer can sense where the strongest magnetic force is coming from, generally used to detect magnetic north.

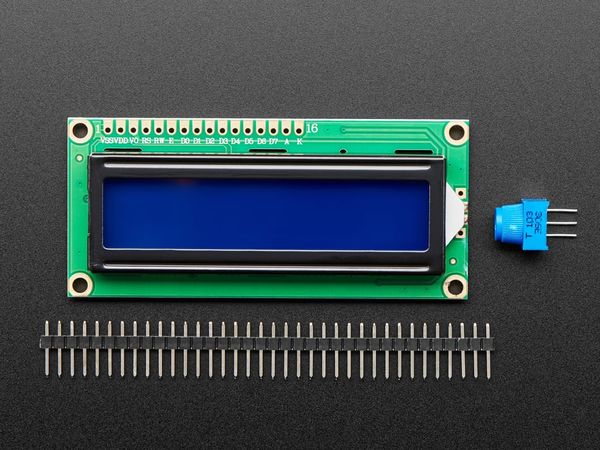

The LCD module has a screen that is can be configured up to 16 characters wide and spans 2 rows. The text is white on blue background and is lit by a single LED.

Hardware Design

The GPS and Compass are both powered by 3.3.V through the prototype board. The GPS uses UART to send and receive GPGGA data. The Compass sends and receives data over I2C. The microcontroller processes this data periodically, every 10 Hz, and sends the data to the CAN transceiver which is connected to the CAN bus line. The compass experienced soft iron and hard iron distortions. Therefore, it was necessary to mount the compass as far away from the car as possible. This goal was accomplished by mounting it approximately 1 ft above the vehicle. In addition, it was difficult for the GPS to acquire a signal fix. To mitigate this issue we mounted an external compass approximately 6 inches above the vehicle.

Software Design

Geo controller modules:

- 1. GPS

- 2. Compass

- 3. Waypoints

- 4. Geo logic

- 5. CAN handler

- 6. Line buffer

- 7. LCD

- 1. GPS

gps.h

typedef struct {

float latitude;

float longitude;

} gps_coordinates_t;

void gps__init(void);

void gps__run_once(void);

gps_coordinates_t gps__get_coordinates(void);

}

- 2. Compass

compass.h

typedef struct {

float x;

float y;

float z;

} mag_data_t;

typedef struct {

double latitude;

double longitude;

} Coordinates;

void compass_init();

float get_current_compass_heading();

double calculate_bearing(Coordinates point1, Coordinates point2);

double calculate_distance(Coordinates point1, Coordinates point2);

}

- 3. Waypoints

waypoints.h

gps_coordinates_t waypoints__find_next_waypoint(gps_coordinates_t origin, gps_coordinates_t destination);

double waypoints__calculate_distance(gps_coordinates_t point1, gps_coordinates_t point2);

double waypoints__update_current_bearing(gps_coordinates_t point1, gps_coordinates_t point2);

- 4. Geo logic

geo_logic.h

// Input Data

// Destination coordinates from the bridge controller

static dbc_BRIDGE_DATA_TRANSFER_s data_from_bridge;

// Output Data

// Compass and destination data

dbc_GEO_READINGS_s geo_readings;

// Debug Message Data

dbc_GEO_DEBUG_MESSAGE_s debug_messages;

dbc_GEO_DATA_TO_DRIVER_AND_BRIDGE_s coordinates_to_driver_and_bridge;

void geo_logic__encode_coordinates(can__msg_t *msg);

void geo_logic__encode_geo_readings(can__msg_t *msg);

void geo_logic__decode_bridge_messages(can__msg_t *msg);

gps_coordinates_t geo_logic__get_gps_readings(void);

void geo_logic__print_values(void);

void geo_logic__set_dummy_geo_readings(uint32_t callback_count);

dbc_GEO_DATA_TO_DRIVER_AND_BRIDGE_s geo_logic__get_current_coordinates(void);

dbc_BRIDGE_DATA_TRANSFER_s geo_logic__get_destination_coordinates(void);

dbc_GEO_READINGS_s geo_logic__get_navigation_data(void);

void geo_logic__encode_debug_messages(can__msg_t *msg, uint32_t callback_count);

- 5. CAN handler

can_handlers.h

void can_handler__init(void);

void can_handler__manage_mia_10hz(void);

void can_handler__handle_all_incoming_messages(void);

bool can_handler__transmit_messages_10hz(uint32_t callback_count);

void can_bus_reset_on_is_off(void);

- 6. Line Buffer

line_buffer.h

// Do not access this struct directly in your production code or in unit tests

// These are "internal" details of the code module

typedef struct {

void *memory;

size_t max_size;

size_t write_index;

size_t read_index;

size_t item_count;

} line_buffer_s;

/**

* Initialize *line_buffer_s with the user provided buffer space and size

* Use should initialize the buffer with whatever memory they need

* @code

* char memory[256];

* line_buffer_s line_buffer = { };

* line_buffer__init(&line_buffer, memory, sizeof(memory));

* @endcode

*/

void line_buffer__init(line_buffer_s *buffer, void *memory, size_t size);

// Adds a byte to the buffer, and returns true if the buffer had enough space to add the byte

bool line_buffer__add_byte(line_buffer_s *buffer, char byte);

/**

* If the line buffer has a complete line, it will remove that contents and save it to "char * line"

* Note that the buffer may have multiple lines already in the buffer, so it will require multiple

* calls to this function to empty out those lines

*

* The one corner case is that if the buffer is FULL, and there is no '\n' character, then you should

* empty out the line to the user buffer even though there is no newline character

*

* @param line_max_size This is the max size of 'char * line' memory pointer

*/

bool line_buffer__remove_line(line_buffer_s *buffer, char *line, size_t line_max_size);

- 7. LCD

lcd.h

void lcd__init_pins();

void lcd__init();

void lcd__command(uint8_t cmd);

void lcd__data(uint8_t data);

void lcd__write_string(char *str);

void lcd__print_geo_readings(dbc_GEO_READINGS_s geo_readings, dbc_GEO_DATA_TO_DRIVER_AND_BRIDGE_s current_ccordinates);

void lcd__print_distance_to_destination(dbc_GEO_READINGS_s geo_readings, dbc_BRIDGE_DATA_TRANSFER_s bridge_data);

Technical Challenges

- Issue: There was difficulty acquiring GPS signal during testing.

- Reason: We were testing in a space surrounded by a lot of infrastructure (e.g. buildings).

- Solution: Test in a space that is open and flat.

- Issue: Compass values were varying a lot and seemed arbitrary.

- Reason: This is due to the soft iron and hard iron distortion.

- Solution: Mounting the compass away from ferrous material and electronic currents.

Communication Bridge Controller

The HC-05 Bluetooth module is a widely used and versatile wireless communication module that enables Bluetooth connectivity using its Serial Port Protocol. Key Features HC-05 Bluetooth Module:

Bluetooth Standard:

The HC-05 Bluetooth module operates on Bluetooth version 2.0 + EDR (Enhanced Data Rate), supporting reliable and efficient wireless communication.

Operating Modes:

The module can operate in both Master and Slave modes. In Slave mode, it can pair with other Bluetooth devices, while in Master mode, it can initiate connections.

Communication Range:

The HC-05 is classified as a Class 2 Bluetooth device, providing a communication range of approximately 10 meters (33 feet). This makes it suitable for short to medium-range applications.

Serial Communication:

It communicates with other devices using a serial communication interface, making it compatible with microcontrollers like Arduino. The module typically supports standard baud rates like 9600 bps.

AT Command Configuration:

The HC-05 Bluetooth module can be configured using AT commands, allowing users to customize various parameters such as the device name, pairing code, and operating mode.

Voltage Compatibility:

The module operates within a voltage range of 3.6V to 6V, making it compatible with a variety of power sources.

Security Features:

The HC-05 supports basic security features, including the ability to set a PIN code for pairing and configuring security modes.

LED Indicator:

Many HC-05 modules have an onboard LED indicator that provides visual feedback on the pairing status and communication activity.

Hardware Design

Connected Vcc, GND, Tx and Rx pins. It requires 3.6-6V for functioning. The Tx and Rx pins are used to transmit and recieve the data to and from the application.

Software Design

o begin using serial transmission, you first need to pair the module to your device. During the pairing process, the password request encountered should be expecting one of the default passwords "1234" or "0000". You can change this password using one of the AT commands. We are calling the bluetooth the recieve and transmit functions periodically to send and recieve data in 10Hz periodic callbacks.

Technical Challenges

When we were powering to 3.3V, the LED on the bluetooth was blinking but it was not listing on the mobile phone when we had to connect it. After careful reading of the datasheet, we figured out that we have to power up with 3.6-6V.

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

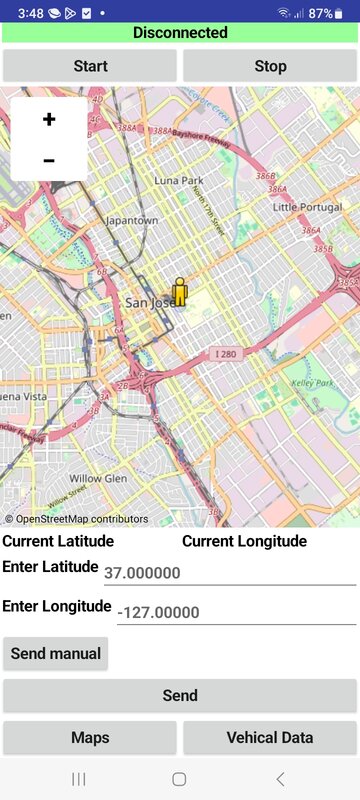

Mobile Application

MIT App Inventor 2 is a free, open-source web application for creating basic Android mobile applications without needing to code in Java or Kotlin. Instead, it uses block-based coding and a graphical user interface (GUI) similar to the Scratch programming language. Users can drag and drop blocks to design the user interface (UI) and employ functional blocks to develop logic, functions, and control flow.

Originally developed by Google and released in 2010, MIT App Inventor for Android was created by a team led by Hal Abelson and Mark Friedman. In the latter half of 2011, Google released the source code, ceased its server operations, and funded the establishment of The MIT Center for Mobile Learning. This center, led by App Inventor creator Hal Abelson and MIT professors Eric Klopfer and Mitchel Resnick, launched the MIT version of App Inventor in March 2012.

The platform includes the MIT AI Companion app, a mobile application that allows users to download a server-cached version of their app in development. This feature facilitates easy and convenient testing of intermediate functions and bug fixes by enabling real-time observation of changes. Once development is complete, users can build and download a ".apk" file, an installable file for the Android OS that allows them to test their app as a standalone application.

The web app features two key sections for mobile app development: the Designer page and the Blocks page.

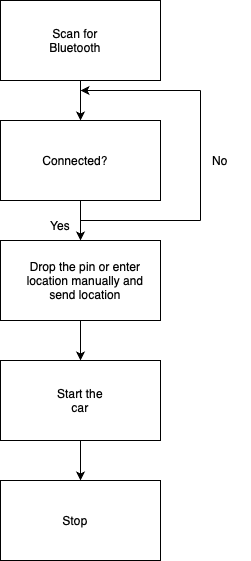

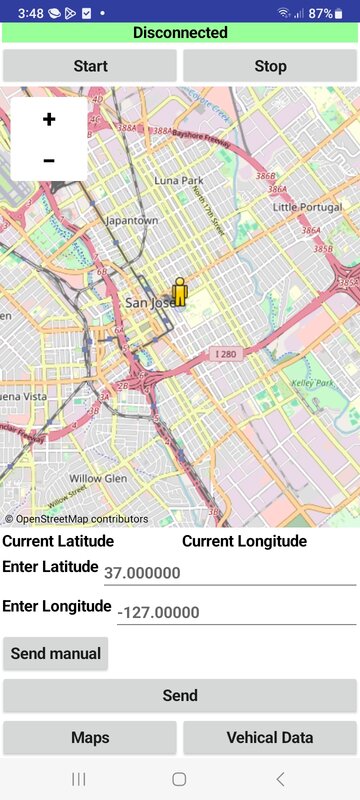

Flow

User Interface

Connects and disconnects the bluetooth and has start and stop buttons. The destination can be given by dropping the pin on the map. It can also be entered manually.

Connects and disconnects the bluetooth. This screen gives the current latitude, longitude, distance to destination, speed of the car and all other details.

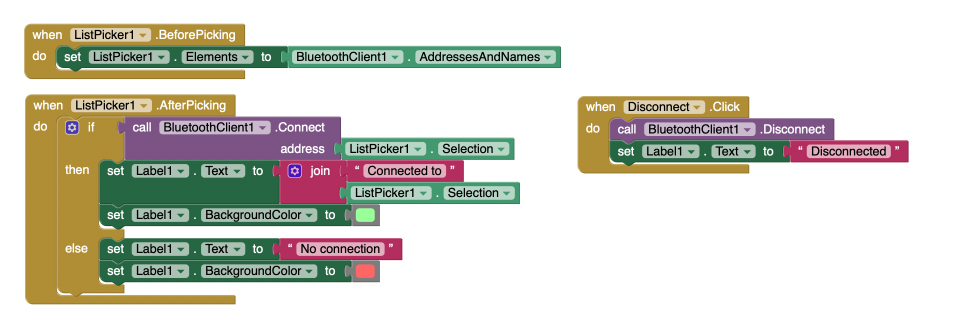

Bluetooth Block

The App uses the bluetooth client block to establish a connection with the HC-05 bluetooth module onboard the car. It is necessary to establish connection and connect to a bluetooth pair to send and receive messages.

Testing and Downloading

MIT App inventor projects can be accessed for testing on the MIT AI companion app or built into a downloadable APK file. It can also be exported as a file to be later imported. The file extension for an app inventor project is “.aia”.

Conclusion

The RC car project provided use with a platform to demonstrate our problem-solving skills and design prowess. It demanded that each team member take charge of their responsibilities to ensure that each controller and modules were operational. Our focus was on crafting clean code, conducting thorough unit testing and building reliable hardware. Together we were able to successfully achieve the main goals from our project and created an autonomous vehicle that can navigate from a starting point to a given destination while avoiding obstacles. Our passion for our commitment to continuous improvement was one of our greatest strengths.

There was many things that we learned during this duration of this project. For example, we learned how to work on a team and manage responsibilities by dividing up work, assigning roles and managing the code repository. Also, having to integrate different hardware components has given us a deeper understanding of the different types of communication that is used in embedded systems such as UART, I2C and CAN. In addition, by creating and utilizing a DBC file, we were able to get a feel for what development may be like in big automotive industries. Another example was during the development of the mobile app we discovered the challenges that are associated with Bluetooth and Wi-Fi connectivity.

Overall this project has been on the most educational and fulfilling experiences for us, offering practical insights which will benefit us in our careers.

Project Video

Link to demo: [27]

Project Source Code

Link to Source Code: [28]

Advise for Future Students

- Start ordering parts as soon as possible. If you wait to order parts it will slow down integration and testing.

- Plan to meet every week for 10+ hours to work on the project with your team.

- Pay attention the power requirements of your sensors and make sure that your prototype board can accommodate them.

- Purchase a CMPS12 compass because it does some of the major calculations on the module itself and will save you time in development.

- Don't take this class if you think it will be easy. It's one of the hardest classes because it is demanding of your time. With that said, it is a very rewarding class which will prepare you for the automotive industry.

Acknowledgement

We give a big shout to Professor Kang for giving us such a rich environment to learn and grow. Also, I will give a shout out to Kyle, our teaching assistant, for always helping us diagnose our problems outside of the classroom especially our CAN bus off problem the day before the demo. Lastly, a shout out to Ninaad, our other teaching assistant for giving us guidance through his own experience as a former CMPE 243 student.

References

Ultrasonic datasheet: [29]

GPS datasheet: [30]

Compass datasheet: [31]

LCD datasheet: [32]