Difference between revisions of "S22: TBD"

(→Printed Circuit Board) |

(→Hardware Design) |

||

| Line 443: | Line 443: | ||

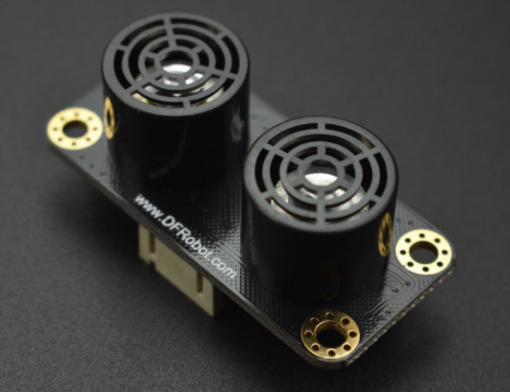

We used 4 Gravity DFRobot URM09 ultrasonic sensors. These ultrasonic sensors are used by the RC car for the purpose of obstacle avoidance. They use I2C communication to send distance data to the SJ2 microcontroller. The measurement range is 300cm. It takes in 3.3V supply voltage. Using the I2C driver the registers on the ultrasonic sensors were configured and the distance was read from the specified registers in the datasheet. | We used 4 Gravity DFRobot URM09 ultrasonic sensors. These ultrasonic sensors are used by the RC car for the purpose of obstacle avoidance. They use I2C communication to send distance data to the SJ2 microcontroller. The measurement range is 300cm. It takes in 3.3V supply voltage. Using the I2C driver the registers on the ultrasonic sensors were configured and the distance was read from the specified registers in the datasheet. | ||

| + | [[File:sensor_conection.png]] | ||

<br> | <br> | ||

Revision as of 06:10, 11 May 2022

Contents

Project Title

<TBD>

Abstract

<2-3 sentence abstract>

Introduction

The project was divided into 5 modules:

- Sensor

- Motor

- Geo Controller

- Driver/LCD Controller

- Web application

Team Members & Responsibilities

<Team Picture>

Gitlab Project Link - [1]

<Provide ECU names and members responsible> <One member may participate in more than one ECU>

- Sensor

- Brian Ho

- Jasdip Sekhon

- Motor

- Billy Lai

- Link to Gitlab user2

- Geographical

- Justin Stokes

- Link to Gitlab user2

- Communication Bridge Controller & LCD

- Isaac Wahhab

- Link to Gitlab user2

- Android Application

- Link to Gitlab user1

- Link to Gitlab user2

- Testing Team

- Billy Lai

- Link to Gitlab user2

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 02/15/2022 | 02/21/2022 |

|

Completed |

| 2 | 02/22/2022 | 02/28/2022 |

|

Completed |

| 3 | 03/01/2022 | 03/07/2022 |

|

Completed |

| 4 | 03/08/2022 | 03/14/2022 |

|

Completed |

| 5 | 03/15/2022 | 03/21/2022 |

|

Completed |

| 6 | 03/22/2022 | 03/28/2022 |

|

Completed |

| 7 | 03/29/2022 | 04/04/2022 |

|

Completed |

| 8 | 04/05/2022 | 04/11/2022 |

|

Completed |

| 9 | 04/12/2022 | 04/18/2022 |

|

Completed |

| 10 | 04/19/2022 | 04/25/2022 |

|

Completed |

| 11 | 04/26/2022 | 05/02/2022 |

|

Completed |

| 12 | 05/03/2022 | 05/09/2022 |

|

In Progress |

| 13 | 05/10/2022 | 05/16/2022 |

|

Incomplete |

| 14 | 05/17/2022 | 05/25/2022 |

|

Incomplete |

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Redcat Racing [2] | 1 | $139.00 |

| 2 | SJTwo Boards | SJTwo Boards On Amazon [3] | 1 | $139.00 |

| 3 | CAN Transceivers (SN65HVD230) | Waveshare [4] | 4 | $40.00 |

| 4 | LSM303 Triple-Axis Accelerometer and Magnetometer | Adafruit [5] | 1 | $15.00 |

| 5 | GPS with SMA Connector | SparkFun [6] | 1 | |

| 6 | Ultrasonic Sensors | DFRobot Gravity [7] | 4 | $52.00 |

| 7 | PCB | JLCPCB [8] | 1 | $5.00 |

| 8 | Plexiglass | 1 | ||

| 9 | Ring LED | Sparkfun [9] | 1 | $11.50 |

| 9 | Wheel Encoder | 1 |

Printed Circuit Board

<Picture and information, including links to your PCB>

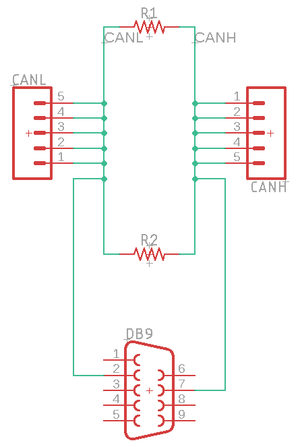

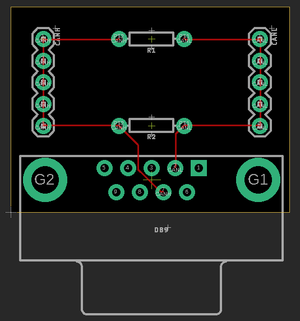

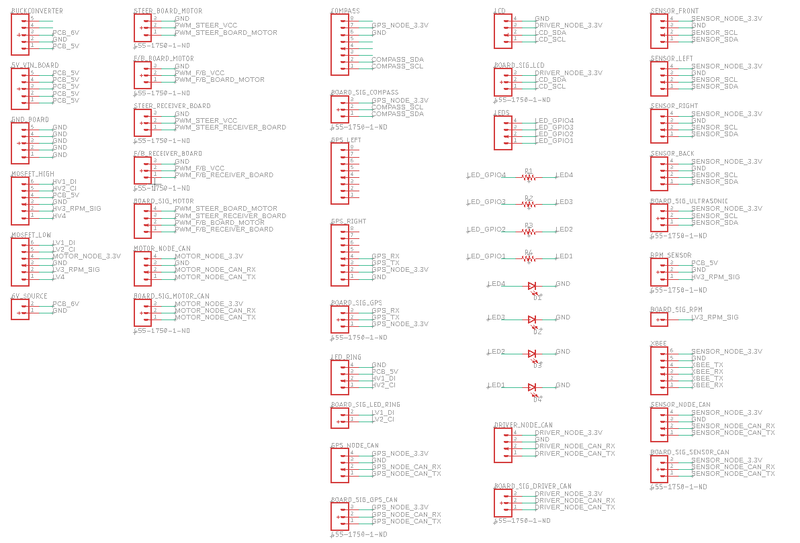

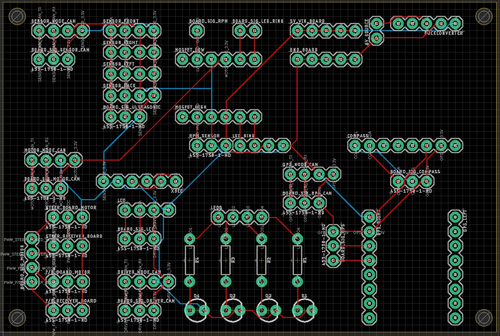

We designed and implemented two PCBs: CAN Bus PCB and RC Car PCB.

CAN Bus PCB Schematic

CAN Bus PCB Board

RC Car PCB Schematic

RC Car PCB Board

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management etc.>

Our message IDs are arranged with priority given to the nodes in the following order: DRIVER, SENSOR, GEO, MOTOR.

We decided to give 32 message IDs to each node and to separate the nodes' message IDs accordingly.

| Node | Message ID Range | |

|---|---|---|

| 1 | DRIVER | 32 - 63 |

| 2 | SENSOR | 63 - 95 |

| 3 | GEO | 96 - 127 |

| 4 | MOTOR | 128 - 159 |

Hardware Design

<Show your CAN bus hardware design>

DBC File

Gitlab link to our master branch's DBC file

Our DBC file includes the SENSOR, DRIVER, MOTOR, and GEO nodes.

Below are the messages defined in the file:

BO_ 32 DRIVER_TO_MOTOR_CMD: 1 DRIVER

SG_ DRIVER_TO_MOTOR_steer : 0|3@1+ (1,-2) [-2|2] "" MOTOR SG_ DRIVER_TO_MOTOR_speed : 3|5@1+ (1,0) [0|31] "RPM" MOTOR

BO_ 64 SENSOR_TO_DRIVER_SONARS: 3 SENSOR

SG_ SENSOR_TO_DRIVER_SONARS_front_left : 0|8@1+ (1,0) [0|0] "" DRIVER SG_ SENSOR_TO_DRIVER_SONARS_front_middle : 8|8@1+ (1,0) [0|0] "" DRIVER SG_ SENSOR_TO_DRIVER_SONARS_front_right : 16|8@1+ (1,0) [0|0] "" DRIVER

BO_ 65 GPS_DESTINATION_LOCATION: 8 SENSOR

SG_ GPS_DESTINATION_LOCATION_latitude : 0|28@1+ (0.000001,-90.000000) [-90|90] "Degrees" GEO SG_ GPS_DESTINATION_LOCATION_longitude : 28|29@1+ (0.000001,-180.000000) [-180|180] "Degrees" GEO

BO_ 96 GEO_STATUS: 5 GEO

SG_ GEO_STATUS_compass_direction : 0|9@1+ (1,0) [0|359] "Degrees" SENSOR,DRIVER SG_ GEO_STATUS_destination_direction : 9|9@1+ (1,0) [0|359] "Degrees" SENSOR,DRIVER SG_ GEO_STATUS_distance_to_destination : 18|16@1+ (0.1,0) [0|0] "Meters" SENSOR,DRIVER

BO_ 128 MOTOR_DEBUG_MSG: 1 MOTOR

SG_ MOTOR_DEBUG_MSG_echo_steer : 0|3@1+ (1,-2) [-2|2] "" DBG SG_ MOTOR_DEBUG_MSG_echo_speed : 3|5@1+ (1,0) [0|31] "RPM" DBG

Sensor ECU

Hardware Design

We used 4 Gravity DFRobot URM09 ultrasonic sensors. These ultrasonic sensors are used by the RC car for the purpose of obstacle avoidance. They use I2C communication to send distance data to the SJ2 microcontroller. The measurement range is 300cm. It takes in 3.3V supply voltage. Using the I2C driver the registers on the ultrasonic sensors were configured and the distance was read from the specified registers in the datasheet.

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Motor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Geographical Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Resources

1. GPGGA Message Definition [10]

2. LSM303DLHC Datasheet [11]

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

Advise for Future Students

<Bullet points and discussion>