Difference between revisions of "S22: Road Runner"

(→CAN Communication) |

(→CAN Communication) |

||

| Line 275: | Line 275: | ||

More technical details to fill in.. | More technical details to fill in.. | ||

| − | [[File:Core_CAN-draw.png| | + | [[File:Core_CAN-draw.png|500px|center]] |

=== Hardware Design === | === Hardware Design === | ||

Revision as of 20:48, 19 April 2022

Contents

Road Runner

Abstract

Road Runner is a self navigating car built with the ability to drive to a specified geo-location within its battery range, while avoiding any physical obstacles that come on its way and successfully reaching its destination, with no human intervention apart from commanding the destination location . The car’s infrastructure has four important nodes (Driver, Sensor and Bridge, Geo and Motor) communicating within themselves over internal CAN Bus and with the end user over a mobile application. The car always strives to stay on and maintain its path to the destination by periodically sensing and processing all the relevant information from the nodes to arrive at an informed decision. It is built on top of a hobby grade RC car chassis with all the necessary adjustments and components to achieve its intended objective of self navigating and object avoidance, one of the basic requirements and functionality of an autonomous vehicle.

Introduction

The project was divided into 5 modules:

- Bridge and Sensor Controller

- Motor Controller

- Geo Controller

- Driver / LCD Controller

- Android app interface

Team Members & Responsibilities

<Team Picture>

Road Runner Firmware: GitLab Repo

Team Members:

- Dhruv Choksi

- Jonathan Doctolero

- Tudor Donca

- Hisaam Hashim

- Saicharan Kadari

- Kyle Kwong

Project Subteams:

- Bridge and Sensor Controller:

- Tudor Donca

- Saicharan Kadari

- Motor Controller:

- Dhruv Choksi

- Hisaam Hashim

- Geological Controller:

- Kyle Kwong

- Jonathan Doctolero

- Saicharan Kadari

- Driver and LCD Controller:

- Hisaam Hashim

- Kyle Kwong

- Android Application:

- Jonathan Doctolero

- Tudor Donca

- Integration and System Testing:

- Tudor Donca

- Dhruv Choksi

- Hisaam Hashim

- Saicharan Kadari

- Kyle Kwong

- Jonathan Doctolero

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 03/06/2022 | 03/12/2022 |

|

|

| 2 | 03/13/2022 | 03/19/2022 |

|

|

| 3 | 03/20/2022 | 03/26/2022 |

|

|

| 4 | 03/27/2022 | 04/02/2022 |

|

|

| 5 | 04/03/2022 | 04/09/2022 |

|

|

| 6 | 04/10/2022 | 04/16/2022 |

|

In Progress |

| 7 | 04/17/2022 | 04/23/2022 |

|

|

| 8 | 04/24/2022 | 04/30/2022 |

|

|

| 9 | 05/01/2022 | 05/07/2022 |

|

|

| 10 | 05/08/2022 | 05/15/2022 |

|

Parts List & Cost

| Item# | Part Description | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Redcat [1] | 1 | $153.00 |

| 2 | CAN Transceivers | Various | 6 | $55 |

| 3 | Ultrasonic Sensors | Max Botix[2] | 3 | $134.00 |

| 4 | Adafruit Bluetooth UART Tranceiver | Adafruit[3] | 1 | $33.90 |

| 5 | GPS Module and Antenna | Adafruit[4][5] | 1 | $59.50 |

| 6 | Compass Module | Adafruit[6] | 1 | $29.00 |

| 7 | Wheel Speed RPM Encoder | 1 | ||

| 8 | Discrete Electronic Components | Generic[7] | 1 | $ |

Printed Circuit Board

<Picture and information, including links to your PCB>

CAN Communication

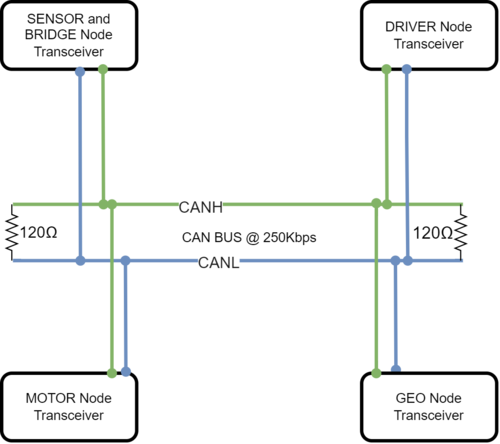

We used CAN Communication setup between all the nodes of the RoadRunner setup. This CAN Bus is terminated with the use of two 120 ohm resistors at both the ends of the Bus. Message IDs were chosen based upon an agreed priority scheme and Bus arbitration scheme. We assigned high priority IDs to messages that controlled the motor, thereby controlling the actual physical movement of the car, followed by sensor and GEO messages, and lowest priority messages were for debug and status messages from the respective nodes . More technical details to fill in..

Hardware Design

<Show your CAN bus hardware design>

DBC File

Gitlab link to the RoadRunner DBC file

VERSION "" NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_ BS_: BU_: DBG DRIVER MOTOR SENSOR_BRIDGE GEOLOGICAL BO_ 100 MOTOR_CMD: 4 DRIVER SG_ MOTOR_steer_degrees : 0|9@1- (1,-45) [-45|45] "degrees" MOTOR SG_ MOTOR_speed_kph : 9|20@1- (0.1,-40.5) [-40.5|40.5] "kph" MOTOR BO_ 101 MOTOR_STATUS: 4 MOTOR SG_ MOTOR_STATUS_steer_degrees : 0|9@1- (1,-45) [-45|45] "degrees" DRIVER SG_ MOTOR_STATUS_speed_kph : 9|20@1- (0.1,-40.5) [-40.5|40.5] "kph" DRIVER BO_ 200 SENSOR_SONARS: 8 SENSOR_BRIDGE SG_ SENSOR_SONARS_left : 0|10@1+ (1,0) [0|500] "cm" DRIVER SG_ SENSOR_SONARS_right : 10|10@1+ (1,0) [0|500] "cm" DRIVER SG_ SENSOR_SONARS_middle : 20|10@1+ (1,0) [0|500] "cm" DRIVER SG_ SENSOR_SONARS_back : 30|10@1+ (1,0) [0|500] "cm" DRIVER BO_ 201 GPS_DESTINATION: 8 SENSOR_BRIDGE SG_ GPS_DESTINATION_latitude : 0|28@1- (0.000001,-90.000000) [-90|90] "Degrees" GEOLOGICAL SG_ GPS_DESTINATION_longitude : 28|28@1- (0.000001,-180.000000) [-180|180] "Degrees" GEOLOGICAL BO_ 350 GEO_STATUS: 8 GEOLOGICAL SG_ GEO_STATUS_COMPASS_HEADING : 0|12@1+ (1,0) [0|359] "Degrees" DRIVER,SENSOR_BRIDGE SG_ GEO_STATUS_COMPASS_BEARING : 12|12@1+ (1,0) [0|359] "Degrees" DRIVER,SENSOR_BRIDGE SG_ GEO_STATUS_DISTANCE_TO_DESTINATION : 24|24@1+ (1,0) [0|0] "Meters" DRIVER,SENSOR_BRIDGE BO_ 360 GEO_CURRENT_POSITION: 8 GEOLOGICAL SG_ GEO_CURRENT_POSITION_latitude : 0|28@1- (0.000001,-90.000000) [-90|90] "Degrees" DRIVER,SENSOR_BRIDGE SG_ GEO_CURRENT_POSITION_longitude : 28|28@1- (0.000001,-180.000000) [-180|180] "Degrees" DRIVER,SENSOR_BRIDGE BO_ 500 DEBUG_SENSOR_BRIDGE: 8 SENSOR_BRIDGE SG_ sensor_left_raw_value : 0|12@1+ (1,0) [0|0] "" DBG SG_ sensor_right_raw_value : 12|12@1+ (1,0) [0|0] "" DBG SG_ sensor_middle_raw_value : 24|12@1+ (1,0) [0|0] "" DBG SG_ sensor_back_raw_value : 36|12@1+ (1,0) [0|0] "" DBG BO_ 510 DEBUG_DRIVER: 8 DRIVER SG_ driver_intention : 0|8@1+ (1,0) [0|0] "" DBG SG_ driver_steer_direction : 8|8@1+ (1,0) [0|0] "" DBG SG_ driver_drive_direction : 16|8@1+ (1,0) [0|0] "" DBG CM_ BU_ DRIVER "The driver controller driving the car"; CM_ BU_ MOTOR "The motor controller of the car"; CM_ BU_ SENSOR_BRIDGE "The sensor and bluetooth bridge controller of the car"; CM_ BU_ GEOLOGICAL "The GPS and compass controller of the car"; CM_ BO_ 100 "Sync message used to synchronize the controllers"; BA_DEF_ "BusType" STRING ; BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; BA_DEF_ SG_ "FieldType" STRING ; BA_DEF_DEF_ "BusType" "CAN"; BA_DEF_DEF_ "FieldType" ""; BA_DEF_DEF_ "GenMsgCycleTime" 0; BA_ "GenMsgCycleTime" BO_ 100 1000; BA_ "GenMsgCycleTime" BO_ 200 50; BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd"; VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ; BA_ "FieldType" SG_ 510 driver_intention "driver_intention"; VAL_ 510 driver_intention 1 "DESTINATION_HEADING" 0 "OBSTACLE_AVOIDANCE"; BA_ "FieldType" SG_ 510 driver_steer_direction "driver_steer_direction"; VAL_ 510 driver_steer_direction 2 "TURN_RIGHT" 1 "TURN_LEFT" 0 "STRAIGHT"; BA_ "FieldType" SG_ 510 driver_drive_direction "driver_drive_direction"; VAL_ 510 driver_drive_direction 2 "BACKWARDS" 1 "FORWARDS" 0 "STOPPED";

Sensor ECU

<Picture and link to Gitlab>

Hardware Design

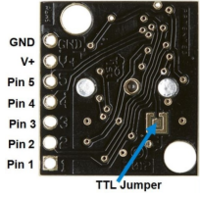

Roadrunner uses three HRLV-MAXSonar-EZ0 MB1003[8] as its eyes and ears on the front and HRLV-MAXSonar-EZ at the rear end . The HRLV-MAXSonar-EZ0 comes in five different models for the ultrasonic sensor. The HRLV-MAXSonar-EZ sensor line is the most cost-effective solution for applications where precision range-finding, low-voltage operation, space-saving, and low-cost are needed. This sensor line features 1mm resolution, target-size and operating-voltage compensation for improved accuracy, superior rejection of outside noise sources, internal speed-of-sound temperature compensation, and optional external speed-of-sound temperature compensation.

These models are the MB1003, MB1013, MB1023, MB1033, and MB1043. The models are based on the beam width of the sensor. It was observed that MB1003 has the optimal beam pattern and was better suited for our objective of object detection. If the beam pattern is too wide given the, there is a greater chance of cross talk between sensors. If the beam pattern is too narrow, there may be blind spots which must be accounted for. Thus, three HRLV-MAXSonar-EZ0 MB1003 sensors were used and the possible unavoidable cross talk is contained by the optimal positioning and software configuration. It will be noted that the SJTWO board is configured to have three ADC channels. Thus to account for a fourth sensor, the DAC was configured to be an ADC channel. Details of this configuration will be discussed in the software design.

Sensor Mounts and Placement

It is decided to place the ultrasonic sensors on mounts and a custom setup to reduce the cross talk and position them to capture the most field of view and possibly avoid any blind spots for the car movement.

Sensor Readings Extraction

To extract range readings from the MB1003, the "AN" pin which represents analog output was utilized. A range reading is commanded by triggering the "RX" pin high for 20us or more. From the details of the sensor datasheet it is observed that the output analog voltage is based on a scaling factor of (Vcc/512) per inch. As in our setup, all four of the sensors were powered from the SJTWO board, thus a 3.3v VCC was supplied to each sensor. According to the HRLV-MaxSonar-EZ datasheet, with 3.3v source, the analog output was expected to be roughly 6.4mV/inch. However, when initially testing the output range readings, the output was inaccurate. We were thankful for the past students' experiences to notice that the ADC channels for the SJTWO are configured at start-up to have an internal pull up resistor. Disabling this pull up resistor will be discussed more in Software Design and this made the range readings more accurate. The readings were tested by having multiple objects placed in front of each sensor and measuring the distance of the object to the sensors physically. Although the range readings accuracy is improved by the pull-up resistor modification, it was found that the range readings did not necessarily follow the expected 6.4mV/inch. Hence, we decided to calibrate the sensors to xx mV/inch. This value was extracted by placing objects around the sensors and checking if the analog output to inch conversion matched to the actual measured distance.

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Motor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Geographical Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

Advise for Future Students

<Bullet points and discussion>

Acknowledgement

=== References ===