Difference between revisions of "S21: (RC)^2"

Proj user10 (talk | contribs) (→Software Design) |

Proj user10 (talk | contribs) (→Software Design) |

||

| Line 506: | Line 506: | ||

:*;''motors__steering_handler()'' | :*;''motors__steering_handler()'' | ||

::This private function controls the RC Car's steering angle. | ::This private function controls the RC Car's steering angle. | ||

| − | The steering driver works in a similar way to how the motor driver works in the sense that it makes use of a digital to analog converter (DAC) to send signals to the motor transceiver to tell the car how much to steer. First, the motor node receives a CAN message through the CAN bus that contains a float value from within the range of -2.1 (full lock to the left) to 2.1 (full lock to the right). The steering driver then converts this float to an integer number used to write to the 12-bit DAC through I2C communication. Essentially, the range [-2.1, 2.1] which has 42 steps, is mapped to the range of [0, 4096] using the equation: (input + 2.1) * 10 * 4096 / 42. | + | ::The steering driver works in a similar way to how the motor driver works in the sense that it makes use of a digital to analog converter (DAC) to send signals to the motor transceiver to tell the car how much to steer. First, the motor node receives a CAN message through the CAN bus that contains a float value from within the range of -2.1 (full lock to the left) to 2.1 (full lock to the right). The steering driver then converts this float to an integer number used to write to the 12-bit DAC through I2C communication. Essentially, the range [-2.1, 2.1] which has 42 steps, is mapped to the range of [0, 4096] using the equation: (input + 2.1) * 10 * 4096 / 42. |

| + | |||

3. '''void motors__set_speed_and_steering_values(dbc_MOTOR_VALUES_s *motor_values)''' | 3. '''void motors__set_speed_and_steering_values(dbc_MOTOR_VALUES_s *motor_values)''' | ||

:This function is used by the '''CAN Bus Message Handler to set the desired speed and steering angle'''. When the CAN Bus Message Handler module receives a CAN package, it will decode the motor values and call this function. This function is also used by the MIA handler as well to stop the RC Car if it doesn't receive any CAN messages from the driver node ten times in a 10Hz periodic callback. | :This function is used by the '''CAN Bus Message Handler to set the desired speed and steering angle'''. When the CAN Bus Message Handler module receives a CAN package, it will decode the motor values and call this function. This function is also used by the MIA handler as well to stop the RC Car if it doesn't receive any CAN messages from the driver node ten times in a 10Hz periodic callback. | ||

| + | |||

4. '''dbc_MOTOR_VALUES_TO_DRIVER_s motors__get_motor_values(void)''' | 4. '''dbc_MOTOR_VALUES_TO_DRIVER_s motors__get_motor_values(void)''' | ||

:This function is used by the '''CAN Bus Message Handler to transmit the current speed''' of the car. | :This function is used by the '''CAN Bus Message Handler to transmit the current speed''' of the car. | ||

Revision as of 20:22, 23 May 2021

Contents

(RC)2

(RC)2

Abstract

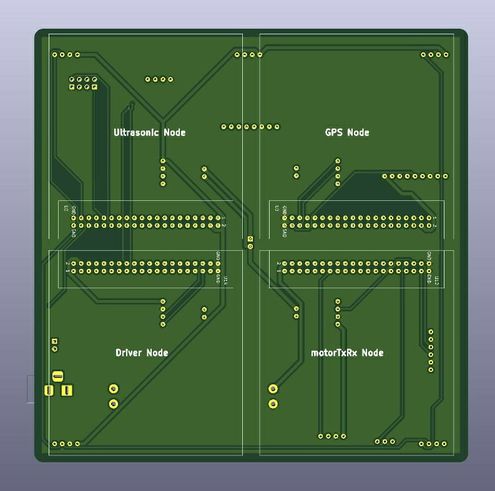

Team (RC)^2 built an RC car capable of navigating to a destination controlled by an Android application while avoiding obstacles that may be in its path. The RC car is composed of various nodes that each have a specific task such as reading sensor data, controlling the motor, and attaining compass values. These individual nodes communicate and share pertinent information regarding the car’s operation with each other over a CAN bus.

Introduction

The project was divided into five main components that were important to the RC car as a whole:

- Sensor Node

- Motor Node

- Geographic Controller

- Communication Bridge/OLED

- Driver Node

Team Members & Responsibilities

<Team Picture>

Gitlab Project Link - https://gitlab.com/rc-2/sjtwo-c

- Sensor

- Huy - https://gitlab.com/vyhuy2004

- Prabjyot - https://gitlab.com/PrabjyotObhi

- Motor

- Jesse - https://gitlab.com/JessePhams

- Michael - https://gitlab.com/mwmichaelwang

- Geographical

- Brian - https://gitlab.com/Brian1234132

- Arun - https://gitlab.com/arunhiremath92

- Communication Bridge Controller & LCD

- Prabjyot - https://gitlab.com/PrabjyotObhi

- Arun - https://gitlab.com/arunhiremath92

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 03/01/2021 | 03/07/2021 |

|

Complete |

| 2 | 03/08/2021 | 03/14/2021 |

|

Complete |

| 3 | 03/15/2021 | 03/21/2021 |

|

Complete |

| 4 | 03/22/2021 | 03/28/2021 |

|

Complete |

| 5 | 03/29/2021 | 04/04/2021 |

|

Complete |

| 6 | 04/05/2021 | 04/11/2021 |

|

Complete |

| 7 | 04/12/2021 | 04/18/2021 |

|

Complete |

| 8 | 04/19/2021 | 04/25/2021 |

|

Complete |

| 9 | 04/26/2021 | 05/02/2021 |

|

Complete |

| 10 | 05/03/2021 | 05/09/2021 |

|

To-do |

| 11 | 05/10/2021 | 05/16/2021 |

|

To-do |

| 12 | 05/17/2021 | 05/23/2021 |

|

To-do |

| 13 | 05/24/2021 | 05/26/2021 |

|

To-do |

Parts List & Cost

TODO: Check Drive and add to this table

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Traxxas | 1 | $129.99 |

| 2 | CAN Transceivers MCP2551-I/P | Microchip [2] | 8 | Free Samples |

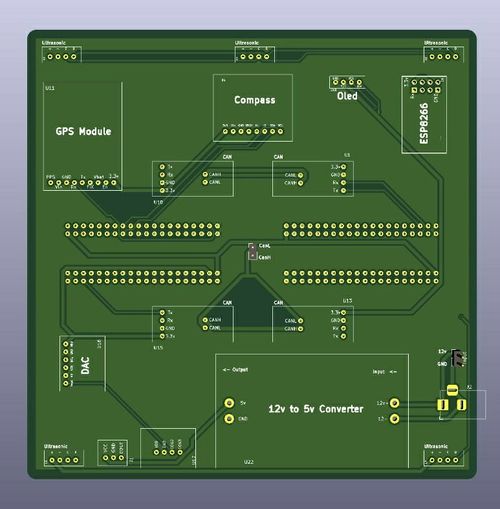

| 3 | GPS Module | Adafruit [3] | 1 | $59.99 |

| 4 | Compass | Adafruit [4] | 1 | $14.95 |

| 5 | ESP8266 (WiFi) | DIYmall [5] | 1 | $14.95 |

| 6 | HC-020K (Wheel Encoder) | Hilitchi [6] | 1 | $8.99 |

| 7 | URM09 Ultrasonic Sensor (I²C) | DFRobot [7] | 4 | $12.90 |

| 8 | SJ2 Board Microcontroller | SCE [8] | 5 | $250.00 |

| 9 | Male/Female Headers | DEPEPE [9] | 1 | $5.00 |

| 10 | Screw Terminal Block Connectors | DZGGI [10] | 1 | $7.99 |

| 11 | CR1220 Lithium Battery | Energizer [11] | 1 | $5.90 |

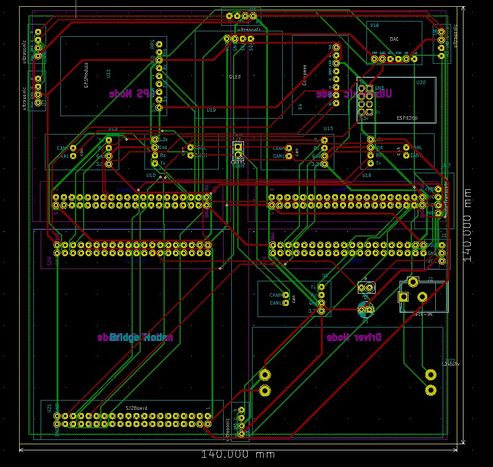

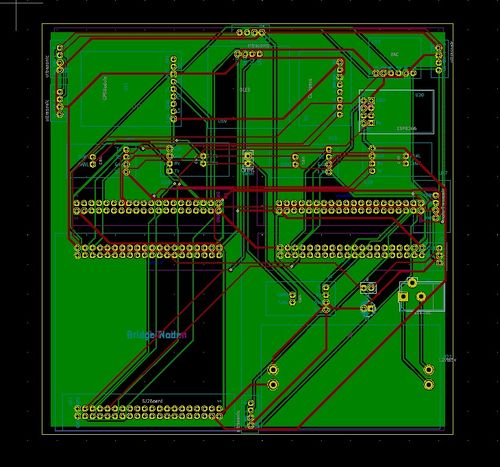

Printed Circuit Board

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management etc.>

Hardware Design

<Show your CAN bus hardware design>

DBC File

VERSION "" NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_ BS_: BU_: DBG DRIVER IO MOTOR SENSOR GEO BRIDGE BO_ 101 DRIVE_STOP: 1 BRIDGE SG_ DRIVE_STOP : 0|8@1+ (1,0) [0|0] "" DRIVER BO_ 102 DRIVE_START: 1 BRIDGE SG_ DRIVE_START : 0|8@1+ (1,0) [0|0] "" DRIVER BO_ 121 GPS_DESTINATION_LOCATION: 8 BRIDGE SG_ DEST_LATITUDE : 0|28@1+ (0.000001,-90.000000) [-90|90] "deg" GEO SG_ DEST_LONGITUDE : 28|29@1+ (0.000001,-180.000000) [-180|180] "deg" GEO BO_ 131 SONAR_VALUES: 8 SENSOR SG_ SONAR_VALUES_left : 0|8@1+ (1,0) [0|150] "cm" DRIVER SG_ SONAR_VALUES_right : 8|8@1+ (1,0) [0|150] "cm" DRIVER SG_ SONAR_VALUES_front : 16|8@1+ (1,0) [0|150] "cm" DRIVER SG_ SONAR_VALUES_back : 24|8@1+ (1,0) [0|150] "cm" DRIVER BO_ 141 COMPASS_HEADING_DISTANCE: 8 GEO SG_ HEADING : 0|12@1+ (0.1,0) [0|359.9] "deg" DRIVER,BRIDGE SG_ BEARING : 12|12@1+ (0.1,0) [0|359.9] "deg" DRIVER,BRIDGE SG_ DISTANCE : 24|17@1+ (0.01,0) [0|0] "m" DRIVER,BRIDGE BO_ 151 MOTOR_VALUES: 3 DRIVER SG_ MOTOR_VALUES_speed : 0|8@1+ (1,-25) [-25|25] "kph" MOTOR SG_ MOTOR_VALUES_steering : 8|6@1+ (0.1,-2.1) [-2.1|2.1] "deg" MOTOR BO_ 161 MOTOR_VALUES_TO_DRIVER: 3 MOTOR SG_ MOTOR_VALUES_TO_DRIVER_speed : 0|8@1+ (1,-25) [-25|25] "kph" DRIVER BO_ 171 GPS_DESTINATION_REACHED: 1 GEO SG_ DESTINATION_REACHED : 0|1@1+ (1,0) [0|1] "bool" DRIVER,BRIDGE BO_ 181 GPS_RAW_DATA: 8 GEO SG_ CURR_LATITUDE : 0|28@1+ (0.000001,-90.000000) [-90|90] "deg" BRIDGE SG_ CURR_LONGITUDE : 28|29@1+ (0.000001,-180.000000) [-180|180] "deg" BRIDGE SG_ GPS_QUALITY : 57|2@1+ (1,0) [0|2] "val" BRIDGE BO_ 182 COMPASS_ACCEL_RAW_DATA: 6 GEO SG_ ACCEL_X : 0|16@1+ (0.01,-162.01) [-162.01|162.01] "ms^2" BRIDGE SG_ ACCEL_Y : 16|16@1+ (0.01,-162.01) [-162.01|162.01] "ms^2" BRIDGE SG_ ACCEL_Z : 32|16@1+ (0.01,-162.01) [-162.01|162.01] "ms^2" BRIDGE BO_ 183 COMPASS_MAG_RAW_DATA: 6 GEO SG_ MAG_X : 0|16@1+ (0.01,-162.01) [-162.01|162.01] "mT" BRIDGE SG_ MAG_Y : 16|16@1+ (0.01,-162.01) [-162.01|162.01] "mT" BRIDGE SG_ MAG_Z : 32|16@1+ (0.01,-162.01) [-162.01|162.01] "mT" BRIDGE BO_ 191 DRIVER_HEARTBEAT: 1 DRIVER SG_ DRIVER_HEARTBEAT_cmd : 0|8@1+ (1,0) [0|0] "" SENSOR, MOTOR, GEO CM_ BU_ DRIVER "The driver controller driving the car"; CM_ BU_ MOTOR "The motor controller of the car"; CM_ BU_ SENSOR "The sensor controller of the car"; CM_ BO_ 191 "Sync message used to synchronize the controllers"; CM_ SG_ 191 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver"; BA_DEF_ "BusType" STRING ; BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; BA_DEF_ SG_ "FieldType" STRING ; BA_DEF_DEF_ "BusType" "CAN"; BA_DEF_DEF_ "FieldType" ""; BA_DEF_DEF_ "GenMsgCycleTime" 0; BA_ "GenMsgCycleTime" BO_ 100 1000; BA_ "GenMsgCycleTime" BO_ 200 50; BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd"; VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ;

Sensor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Motor ECU

Hardware Design

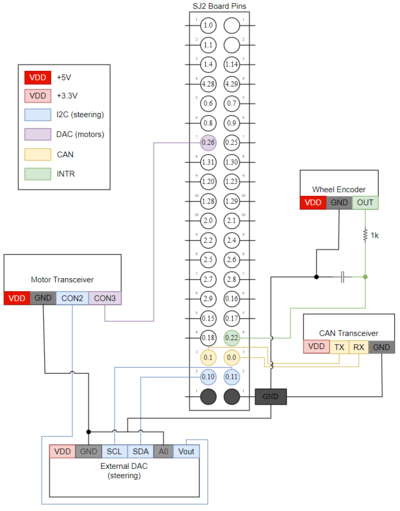

The hardware design for the motor node requires four main components to be connected to the SJ2 Board:

1. CAN Transceiver

- This module will be used to communicate with the Driver Node to receive the desired speed and steering angle through CAN communication protocol. This module will also be used to transmit the car's current speed to the Driver Node. The CAN transceiver will be powered by a +3.3V source with its Transmit Line (Tx) connected to GPIO Pin P0.1 and its Receive Line (Rx) connected to GPIO Pin P0.0.

2. RC Transmit Controller

- Due to the Electronic Speed Controller (ESC) being completely resined into the RC Car's base, there was no direct method of controlling the provided ESC with the SJ2 Board. The team decided to control the ESC using the transmit controller by measuring the internal potentiometer's voltage signal line to the transmit circuit and replicating those voltage values with a Digital-to-Analog Converter (DAC). This transmit controller takes in two input lines to its ports:

- CON2 PORT

- This port takes in one input, which controls the steering angle of the car. The voltage value for the steering to be straight was measured at +2.0V. Lower voltage values steer the car left and higher voltage values steer the car right. The voltage input to this port comes from the External DAC.

- CON3 PORT

- This port takes in one input, which controls the speed of the car. The voltage value for the car to be stationary was measured at approximately +1.5V. Lower voltage values accelerated the car forward and higher voltage values accelerated the car backwards. The voltage input to this port comes from the SJ2 Board's DAC pin P0.26.

3. External DAC

- Since the SJ2 Board has only one DAC pin, which is used to control the motor speed, an additional external DAC is needed to control the car's servo motor for steering.

4. Wheel Encoder

- This module is used by the motor node to measure the car's speed by keeping track of how many revolutions the rotary revolves around the sensor. The rotary contains twenty hole slits, so a full revolution will "tick" the sensor twenty times.

Software Design

The motor node is designed to receive a desired speed and a desired steering angle from the driver node. These values will be used to adjust the RC Car's motor speed and servo motor angle to align with those requested values.

There are four public functions that are provided in the motor node.

1. void motors__init(void)

- This function is used by the periodic callback to initialize the required peripherals used to control the motor speed as well as the servo motor angle.

2. void motors__run(void)

- This function is used by the periodic callback to set the motor speed and the servo motor angle. This public function will invoke two private functions, motors__speed_handler() which handles the motor speed of the car, and motors__steering_handler() which handles the steering angle of the car.

- motors__speed_handler()

- This private function controls the RC Car's speed, which is calculated by measuring the circumference of the car's wheel and finding out how many times it rotates within a given time frame. Setting the time frame and obtaining the circumference of the wheel is trivial, however, obtaining the amount of rotations required additional effort. We used an HC-020K Wheel Encoder to measure how many times the wheel rotated around its axle and connected the +5V output to one of the SJ2's GPIO pins. This pin was then attached to an interrupt service, which incremented the static variable holding the number of times the wheel has rotated. The sample code to calculate the speed of the car is shown below.

static int8_t motors__private_get_speed_kmh(void) {

int8_t motor_speed = current_speed_kmh;

uint64_t current_time_ms = sys_time__get_uptime_ms();

uint64_t time_elapsed_ms = current_time_ms - wheel_encoder_previous_time_ms;

if (time_elapsed_ms >= 100U) {

wheel_encoder_previous_time_ms = current_time_ms;

if (time_elapsed_ms > 0) {

float number_of_wheel_cycles = (float)wheel_encoder_number_of_ticks / (float)WHEEL_ENCODER_TICKS_PER_CYCLE;

float distance_travelled_cm = (float)(number_of_wheel_cycles * WHEEL_CIRCUMFERENCE_CM);

motor_speed =

(distance_travelled_cm / CENTIMETERS_IN_ONE_KILOMETER) / ((float)time_elapsed_ms / MILLISECONDS_IN_ONE_HOUR);

wheel_encoder_number_of_ticks = 0U;

if (MOTORS__DIRECTION_REVERSE == current_motor_direction) {

motor_speed *= -1;

}

}

}

return motor_speed;

}- motors__steering_handler()

- This private function controls the RC Car's steering angle.

- The steering driver works in a similar way to how the motor driver works in the sense that it makes use of a digital to analog converter (DAC) to send signals to the motor transceiver to tell the car how much to steer. First, the motor node receives a CAN message through the CAN bus that contains a float value from within the range of -2.1 (full lock to the left) to 2.1 (full lock to the right). The steering driver then converts this float to an integer number used to write to the 12-bit DAC through I2C communication. Essentially, the range [-2.1, 2.1] which has 42 steps, is mapped to the range of [0, 4096] using the equation: (input + 2.1) * 10 * 4096 / 42.

3. void motors__set_speed_and_steering_values(dbc_MOTOR_VALUES_s *motor_values)

- This function is used by the CAN Bus Message Handler to set the desired speed and steering angle. When the CAN Bus Message Handler module receives a CAN package, it will decode the motor values and call this function. This function is also used by the MIA handler as well to stop the RC Car if it doesn't receive any CAN messages from the driver node ten times in a 10Hz periodic callback.

4. dbc_MOTOR_VALUES_TO_DRIVER_s motors__get_motor_values(void)

- This function is used by the CAN Bus Message Handler to transmit the current speed of the car.

Technical Challenges

Wheel Encoder Issues

- Wheel Fit in Axle (also talk about where to position the wheel encoder)

- Debounce

- Motor startup sequence (Voltage values must be specifically set before anything else)

- ESC Resined into Platform

Geographical Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

<Organized summary of the project>

<What did you learn?>

- CAN Communication Protocol

- Code modularization

- DBC Files

Project Video

Project Source Code

Advice for Future Students

<Bullet points and discussion>

Acknowledgement

- Arun's roommate?

=== References ===