Difference between revisions of "S19: Tech Savy"

Proj user22 (talk | contribs) (→3D printing models) |

Proj user22 (talk | contribs) (→3D printing models) |

||

| Line 934: | Line 934: | ||

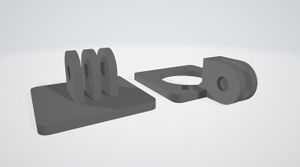

We used a 3D mount model to mount the ultrasonic sensor and compass. After testing the ultrasonic sensor at different angles we noticed that best results are when sensors are mounted at 70 degrees with respect to the ground. Most important thing to consider was the mount should be able to adjust tilt of the sensors since we were receiving lot of reflection from the ground. So in order to satisfy that requirement mount is constructed from two parts, the stand and part that holds the sensor what gave us freedom to test sensors positioning. We used the 3D mount design from Thingiverse. | We used a 3D mount model to mount the ultrasonic sensor and compass. After testing the ultrasonic sensor at different angles we noticed that best results are when sensors are mounted at 70 degrees with respect to the ground. Most important thing to consider was the mount should be able to adjust tilt of the sensors since we were receiving lot of reflection from the ground. So in order to satisfy that requirement mount is constructed from two parts, the stand and part that holds the sensor what gave us freedom to test sensors positioning. We used the 3D mount design from Thingiverse. | ||

| − | + | | | |

|[[File:Ultrasonic_mount.jpg|300px|thumb|left|Ultrasonic Sensor Mount]] | |[[File:Ultrasonic_mount.jpg|300px|thumb|left|Ultrasonic Sensor Mount]] | ||

|[[File:Compass_mount.JPG|300px|thumb|center|Compass Mount]] | |[[File:Compass_mount.JPG|300px|thumb|center|Compass Mount]] | ||

|[[File:Compass_mount.JPG|300px|thumb|center|Compass Mount]] | |[[File:Compass_mount.JPG|300px|thumb|center|Compass Mount]] | ||

| − | | | + | | |

Since we needed to keep the Compass sensor away from DC Motor's interference, we decided to keep the compass at certain height above the PCB. So we used 3D printing to print the support plate with the mounting holes of same dimension as M3X10 screw standoffs. | Since we needed to keep the Compass sensor away from DC Motor's interference, we decided to keep the compass at certain height above the PCB. So we used 3D printing to print the support plate with the mounting holes of same dimension as M3X10 screw standoffs. | ||

Revision as of 00:04, 24 May 2019

Contents

- 1 Tech Savy RC Car

- 2 Abstract

- 3 Introduction & Objectives

- 4 Team Members & Technical Responsibilities

- 5 Administrative Responsibilities

- 6 Team Deliverables Schedule

- 7 BILL OF MATERIALS (GENERAL PARTS)

- 8 Printed Circuit Board

- 9 CAN Communication

- 10 Hardware Design

- 11 LED Functionality in PCB

- 12 DBC File

- 13 3D printing models

- 14 Sensor Node

- 15 Motor Controller

- 16 LCD Screens

- 17 Flow charts

- 18 Geographical Controller

- 19 Bridge Controller Communication

- 20 Master Module

- 21 Mobile Application

- 22 Suggestions for Future Students

- 23 Conclusion

- 24 References

Tech Savy RC Car

Abstract

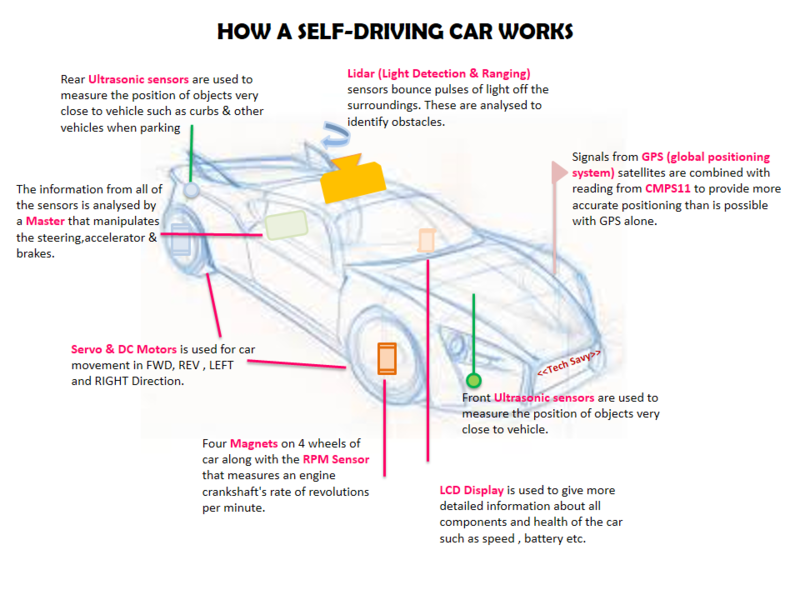

In this project our main aim to build a Self-Navigating Car named Tech Savy, that navigates from a source location to a selected destination by avoiding obstacles in its path using sensors and motors.

Introduction & Objectives

The key features support by the system are

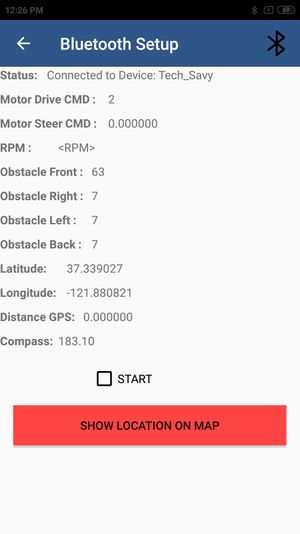

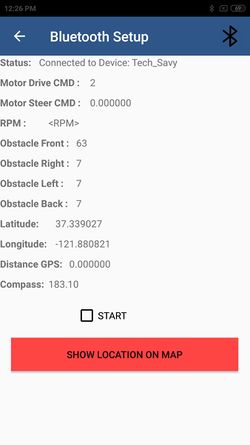

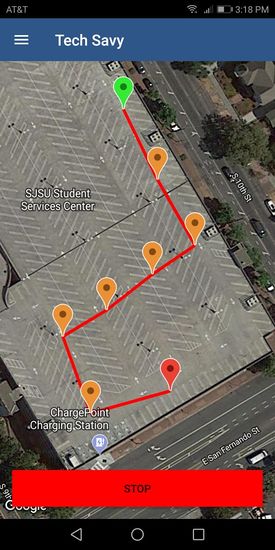

1. A Google-map based Android application is developed which will update the live location of RC car given by GPS to Bridge over Bluetooth.Android app is used to get information from all the Modules and will show live data of MOTOR, SENSORS, GPS and COMPASS and we can set the final destination so that car can drive to the destination.

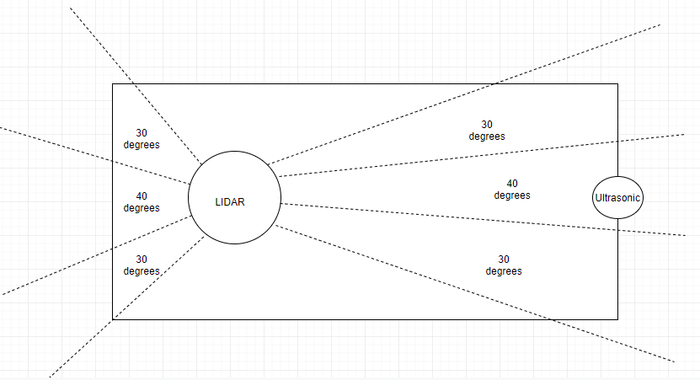

2. The car will be integrated with the GPS, Compass, Bluetooth, multiple sensors such as Ultrasonic sensors and RPM sensors to fulfill the purpose of navigation, obstacle detection, and avoidance

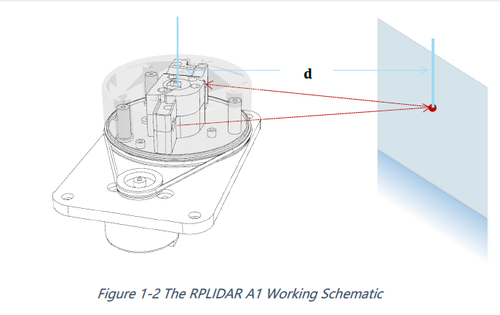

3. LIDAR and Ultrasonic Sensor is used for obstacle detection and avoidance in all the angles in the view of 360 degrees.

4. Motor drives the car by Route Calculation done on GPS using the shortest distance path algorithm between current location and destination and connects to the self-driving RC car via Bluetooth to send the GPS Coordinates and Maneuvering to the selected destination and Self- Adjusting the speed of the car on Ramp.

5. LEDs and LED Display are used for debugging and to get all relevant information about the status of the car, in real time and LCD Display is used to give more detailed information related to the car.

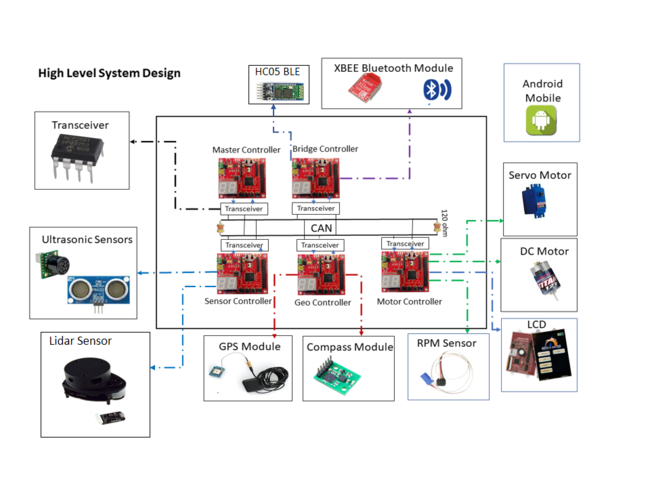

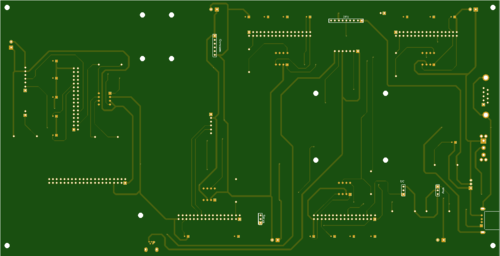

The system is built on FreeRTOS running on LPC1758 SJOne controller and Android application. The main building blocks of Tech Savy are the five controllers communicating through High Speed CAN network designed to handle dedicated tasks. The controllers integrate various sensors that are used for navigation of the car.

CAR Objectives

1. Master Controller - Handles the Route Manuevering,Path Planning and Obstacle Avoidance

2. Sensor Controller - Detects the surrounding objects

3. Geo Controller - Provides current location in the form of coordinates and navigate car using CMPS11

4. Motor Controller - controls the movement of the Car.

5. Bridge controller - Interfaces the system using Bluetooth to an Android application.

Team Objectives

1. Learn each and every module as much as possible, in order to develop an industrial product.

2. Achieve 100% code coverage, during unit testing.

3. Document and track all the bugs encountered during development, unit testing, and field testing.

Team Members & Technical Responsibilities

- Git Project Link: Tech Savy

- Master Controller

- Motor Controller

- Geographical Controller

- Sensor Controller

- Communication Bridge Controller

- Android Application

- LCD Interfacing & UI Designing

- Hardware PCB Integration

- Testing

Administrative Responsibilities

| Administrative Roles | ||||

|---|---|---|---|---|

|

Aakash Chitroda | |||

|

Halak Vyas | |||

|

Vatsal Makani | |||

|

Vidushi Jain | |||

|

Jay Parsana | |||

Team Deliverables Schedule

| WEEK |

START DATE |

END DATE |

TASK DETAILS |

STATUS |

|---|---|---|---|---|

| 1 | 26 Feb 2019 | 4 March 2019 |

|

Completed Completed Completed Completed |

| 2 | 05 March 2019 | 12 March 2019 |

|

Completed Completed Completed |

| 3 | 13 March 2019 | 19 March 2019 |

|

Completed Completed Completed Completed Completed Completed |

| 4 | 20 March 2019 | 26 March 2019 |

|

Completed Completed Completed Completed Completed Completed |

| 5 | 27 March 2019 | 09 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed |

| 6 | 10 April 2019 | 16 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed |

| 7 | 17 April 2019 | 23 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed In Progress Completed Completed |

| 8 | 24 April 2019 | 30 April 2019 |

|

Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed Completed |

| 9 | 1 May 2019 | 7 May 2019 |

|

Completed Completed Completed Completed Completed Completed Completed |

| 10 | 8 May 2019 | 21 May 2019 |

|

Completed Completed Completed Completed Completed |

| 11 | 22 May 2019 |

|

Completed Completed |

BILL OF MATERIALS (GENERAL PARTS)

| PART NAME |

PART MODEL & SOURCE |

QUANTITY |

COST PER UNIT (USD) |

|---|---|---|---|

|

|

|

|

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

|

|

|

|

|

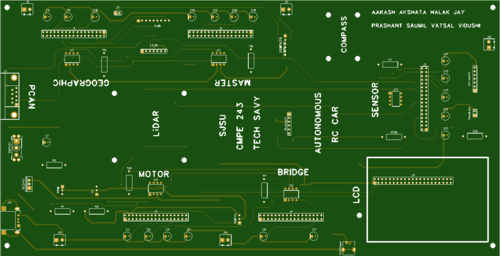

Printed Circuit Board

Design And Architecture

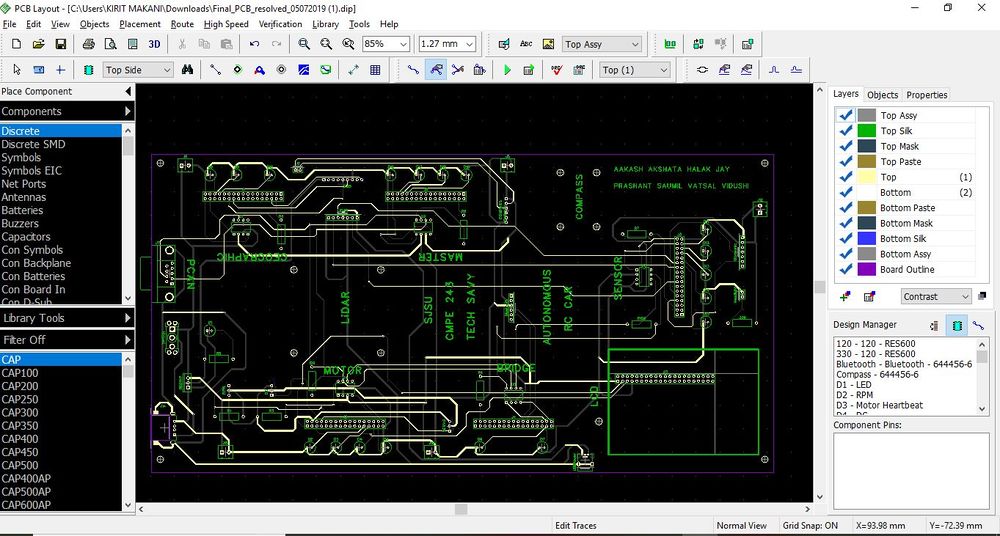

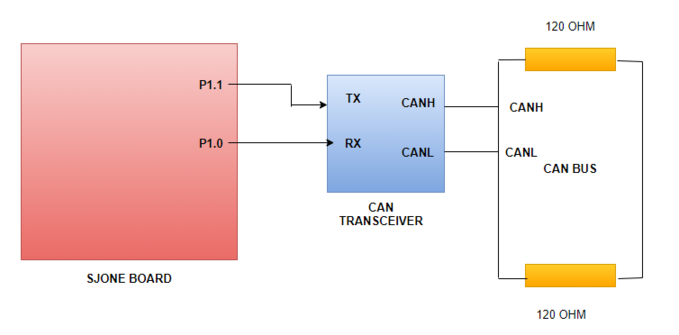

We designed the custom PCB using DipTrace Software in which we implemented connections for all the controller modules(SJOne Board LPC1758) all communicating/sending data via CAN bus. The data is sent by individual sensors to the respective controllers. GPS and Compass are connected to Geographical Controller. RPM sensor, DC and Servo Motors are connected to Motor Controller. Ultrasonic and Lidar are connected to Sensor Controller. LCD is connected to Motor Controller. Bluetooth is connected to Bridge Controller. CAN Bus is implemented using CAN Transceivers MCP2551 terminated by 120Ohms; with PCAN for monitoring CAN Debug Messages and Data.

Power Section

We implemented separate power modules for LIDAR and remaining modules of the PCB. The micro USB mini B supplies 5V to LIDAR Motor and Scanner (max current rating estimated @ 1A). Another power is supplied through USB 2.0 Type A connector with a rating of 5V@2A. Since GPS requires 3.3V, we have used a linear regulator REG1117-3.3. All the parts are through-hole components.

Fabrication

PCB was sent to fabrication to JLCPCB China which provided PCB with MOQ of 5 with the lead time of 1 week. We implemented 2 layers of PCB with most of the parts in top layer. We implemented rectangular header connector for SJOne boards, RPM sensor, DC & Servo Motor and GPS modules on the bottom layer.

Challenges

There were 2 iterations of this board. The first one was designed without validation and had problems with orientation of the SJOne board header & pin connections. We also need to change the header for LCD since it was having different pitch.This design lacked several necessary power connections and was limited by functionality. These problems were fixed in the 2nd iteration.

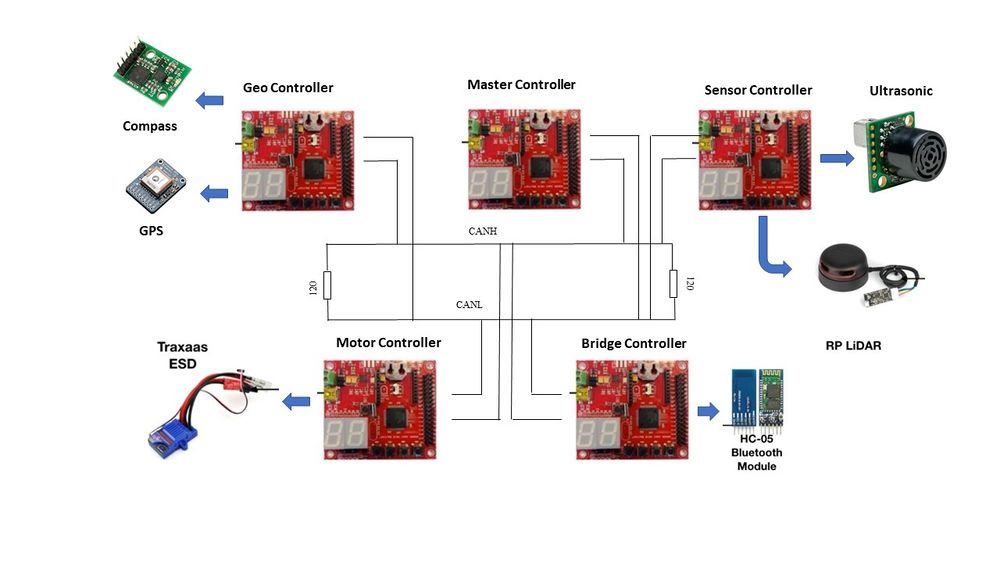

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management, etc.>

Hardware Design

The CAN bus hardware implementation between all the controller module for this project is shown below. It is necessary to terminate the CAN bus at 120 Ohms to prevent any signal reflections.

We have implemented some LEDs for indicating the heartbeat signals sent by the master, sensor readings and motor movements. Below is the table explaining the LEDs in PCBs along with the color, pin and signal description

|

LED DESIGNATION |

GPIO PINS |

DESCRIPTION |

COLOR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

VCC and GND | POWER | RED | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P2.5 and VCC | RPM | RED | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Motor Heartbeat | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | DC Motor | Blue | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Servo Motor | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Bridge Heartbeat | Red | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | DC Motor | BLUE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | Geographical FIX | BLUE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Geographical Heartbeat | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Compass Data | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Sensor Heartbeat | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | Left Obstacle | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Right Obstacle | Blue | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.20 | Front Obstacle | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Right Obstacle | Blue | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Sensor Heartbeat | Red | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | Motor Heartbeat | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Bridge Heartbeat | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.20 | Geographical Heartbeat | Blue |

|

LED DESIGNATION |

GPIO PINS |

DESCRIPTION |

COLOR | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

VCC and GND | POWER | RED | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P2.5 and VCC | RPM | RED | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Motor Heartbeat | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | DC Motor | Blue | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Servo Motor | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Bridge Heartbeat | Red | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | DC Motor | BLUE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | Geographical FIX | BLUE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Geographical Heartbeat | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Compass Data | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Sensor Heartbeat | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | Left Obstacle | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Right Obstacle | Blue | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.20 | Front Obstacle | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Right Obstacle | Blue | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.29 | Sensor Heartbeat | Red | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P0.30 | Motor Heartbeat | Green | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.19 | Bridge Heartbeat | Yellow | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

P1.20 | Geographical Heartbeat | Blue | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Since we needed to keep the Compass sensor away from DC Motor's interference, we decided to keep the compass at certain height above the PCB. So we used 3D printing to print the support plate with the mounting holes of same dimension as M3X10 screw standoffs. Sensor NodeWe used 2 sensor modules to achieve accurate and reliable obstacle avoidance system.

2. Ultrasonic Sensor (Maxbotix LV-MaxSonar-EZ0) - One Ultrasonic sensor with a maximum range of 600 cm was used to detect very small objects at the front that Lidar might miss because of it's leveled placement.

Sensor Node CodeHardware Design

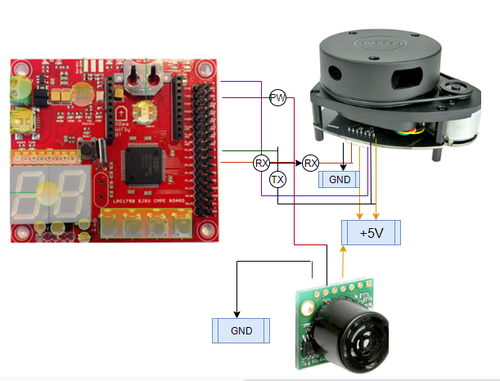

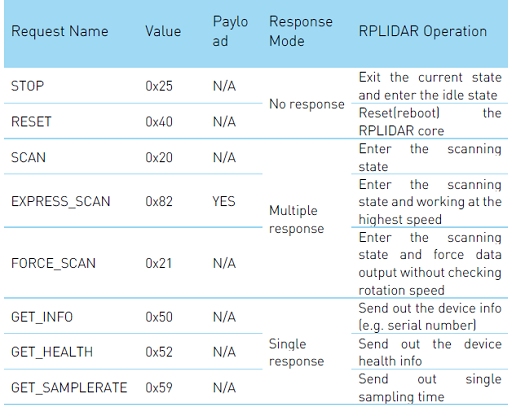

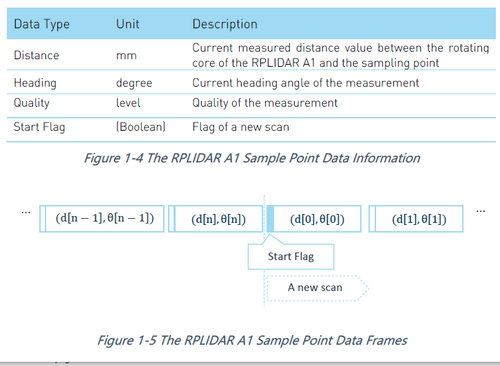

ImplementationUltrasonicLV Maxsonar ultrasonic sensor is used at the very front of the RC car to provide wide range sonar detection ranging from 0 to 645 cm. It supports LiDAR sensor to detect very small obstacles like stone that can hinder car from moving forward. so we have purposefully mounted it at a lower level than LiDAR. LiDARRPLidar works on UART. We have used UART 2 of SJOne Board to establish communication between them.

Algorithm to establish communication through UART

Software DesignUltrasonic

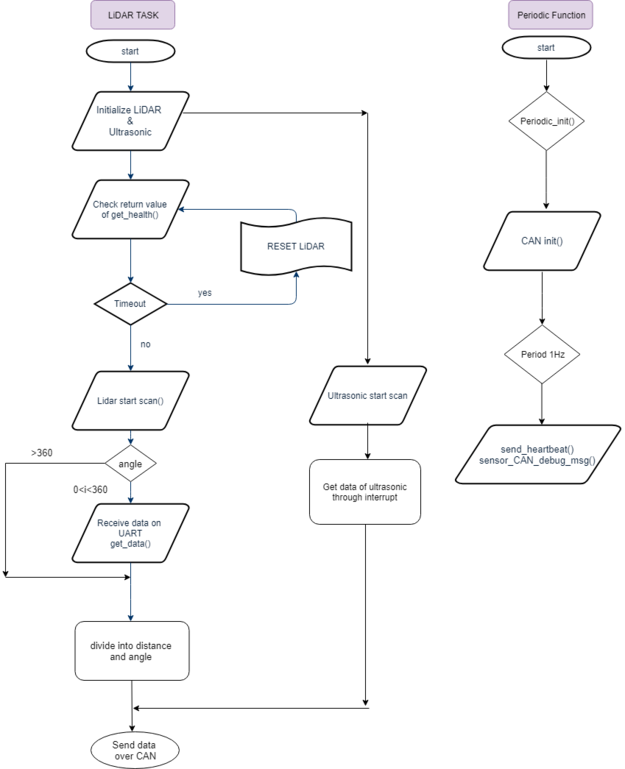

LiDARBelow diagram shows the code flow of sensor module. A separate task was used to send sensor data over CAN, which continuously sends data in while(1) loop. CAN DBC Messages Send from SensorBO_ 105 SENSOR_NODE: 5 SENSOR SG_ SENSOR_FRONT_cm : 0|10@1+ (1,0) [0|645] "cm" MASTER,MOTOR,BRIDGE SG_ LIDAR_Obstacle_FRONT : 10|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE SG_ LIDAR_Obstacle_RIGHT : 13|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE SG_ LIDAR_Obstacle_LEFT : 16|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE SG_ LIDAR_Obstacle_BACK : 19|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE SG_ LIDAR_Obstacle_BACK_RIGHT : 22|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE SG_ LIDAR_Obstacle_BACK_LEFT : 25|3@1+ (1,0) [0|0] "" MASTER,MOTOR,BRIDGE LED Blinking signals for SENSOR CONTROLLER ON CAR* RED LED ON: MASTER HEARTBEAT STATUS on CAR * BLUE LED ON: Obstacle detected at front of CAR * Rightmost GREEN LED ON: Obstacle detected at right of CAR * YELLOW LED ON: Obstacle detected at back of CAR * Leftmost GREEN LED ON: Obstacle detected at left of CAR. Technical ChallengesUltrasonic

LiDAR

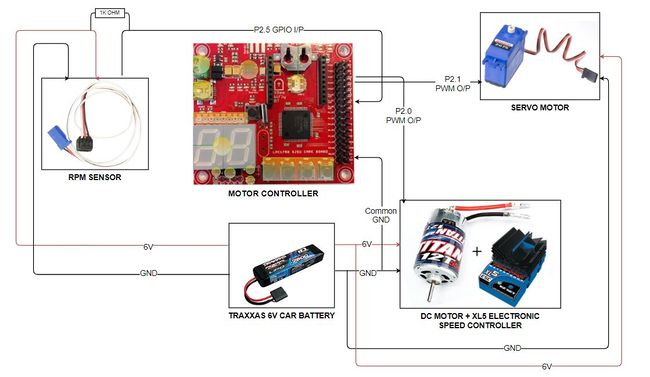

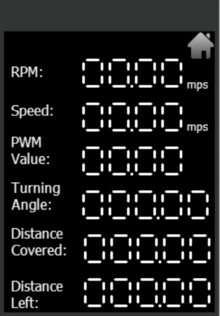

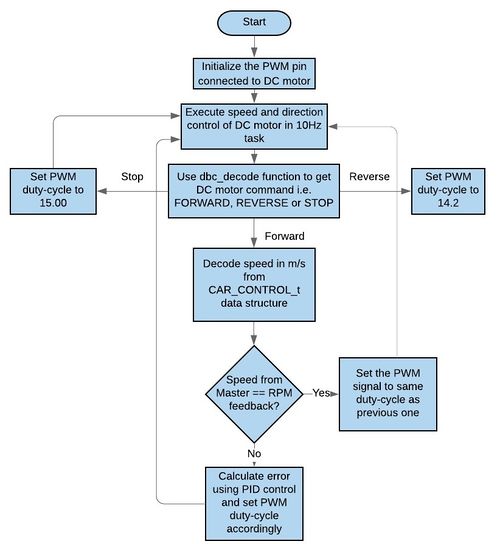

Motor ControllerMotor Controller is responsible to control the DC and Servo Motor, RPM Sensor measurements and LCD control. The motor control logic controls the steering and the speed of the vehicle using a servo and DC motor respectively based on the CAR_CONTROL_t CAN message from the master. It takes input from RPM sensor as a feedback for maintaining a constant speed and based on the RPM sensor reading, a PID loop calculates duty-cycle for PWM signal which are then given to DC motor. Based on other can messages from the sensor controller, geo controller and bridge controller, motor controller processes and communicates the information to the LCD by refreshing the data periodically in 10Hz function. Hardware DesignThe hardware interface details of MOTOR Module with SJOne board are given below: Hardware InterfaceElectronic Speed Controller (ESC)We made use of the Traxxas ESC XL-05 which comes with the RC car. ESC stands for Electronic Speed Control. It is used to control the DC motor using PWM signals from the controller. It powers up when we connect a LiPo or NiMH battery of 7.4v. The ESC has a dc-to-dc converter which converts 7.4v to 6v and provides it to DC motor. It can provide high current to the power hungry DC motors running at faster speeds. It has an LED and a button which is used for calibration and setting different modes for the car.

DC MotorThe DC motor is controlled using the ESC which get PWM pulses for controlling it. A PWM signal wire is connected to the microcontroller and the required current is provided by the LiPo battery and the ESC.

The DC motor is controlled using PWM at 100Hz.

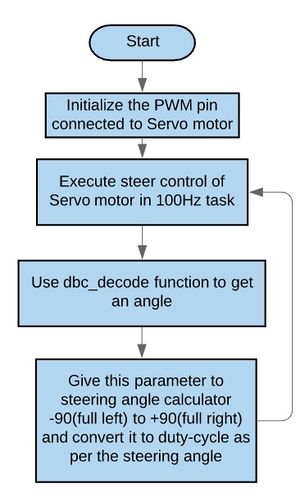

Servo MotorThe direction the vehicle's front wheels turn is dependent on the servo motor in the vehicle. Based on various PWM signals, the servo steers the front wheels of the vehicle in the left and right direction. The servo has 3 wires of which one is for the PWM input signal whereas the other two are to power up the servo. We powered our servo motor using the 6v power supply from the battery elimination circuit present in the ESC so that a single switch to turn on and off both the servo and DC motor. PWM signals to control the servo is provided by the motor controller. Based on the PWM signal from the SJOne board, the shaft shall be rotated to a certain degree left or right

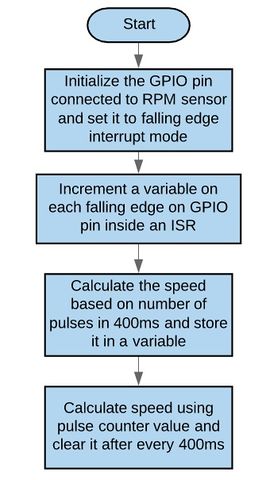

RPM SensorRPM sensor is used as a feedback element in the PID to maintain a constant speed of the vehicle. The RPM sensor mounts on the rear DC motor shaft compartment with a special assembly also provided by Traxxas. We make use of one magnet and we get one pulse on one wheel rotation The sensor works on the hall effect principle where it provides a current across its terminal when placed in a magnet's field. These pulses are read by the SJOne board and fed to the speed control algorithm. The RPM sensor has 3 wires, the white where are the output wire that provides the pulses to the SJone board and the other wires power the sensor. Implementation1. The idea is that every time the motor completes 1 whole revolution, it reaches very close to the sensor. And when the sensor detects the magnet nearby, it sends out a high pulse until the magnet moves away from it. Therefore, upon detecting the X number of a rising edge in Y seconds we can say that rpm was X revolutions/Y seconds.

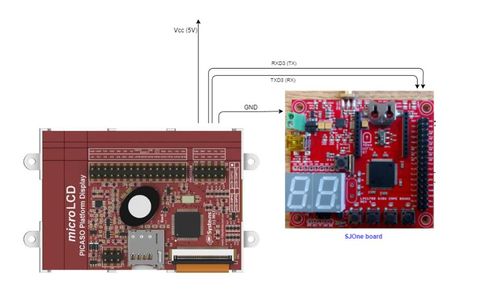

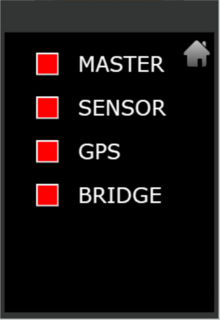

uLCD32-PTUuLCD32-PTU by 4D systems has a 3.2" TFT LCD Display module. The module comes with a display resolution of 240x320 pixels. 4D Systems provides a programming cable based on UART for burning the LCD code to the module. The project is burnt to a uSD card which is used for display during booting of the LCD. It is recommended that we use the programming adapter provided by 4D systems as it has a special reset button that can be used to download the built project to the LCD display.Once the LCD display was configured with different widgets and screens, the motor module was coded to display information in LCD through UART. Workshop4 IDE was used to program the GUI, and data was transmitted from the SJOne board through UART communication. The LCD displays the main menu screen with options of all the modules: Sensor, Motor, Bridge, GPS, Compass and MIA information. These modules represent the page numbers of the display whose information can be found from the pre-processed data format of the LCD.This data format contains the following fields:

The following figure shows the programming cable and the pins used for uLCD32-PTU.

Software DesignThe dc motor and servo motor operation is fundamentally based on PWM (Pulse Width Modulation). We set the PWM frequency to 100Hz for both dc and servo motor. Pseudo code for initializing PWM to 100Hz. PWM *motor_control; //pointer object defined globally

PWM *servo_control;

void init_pwm(long unsigned int freq) {

motor_control = new PWM(PWM::pwm1, freq); // using PWM constructor to initialize the PWM 2.0 pin to desired frequency

servo_control = new PWM(PWM::pwm2, freq);

}

DC MotorThe DC motor is connected to pin P2.0 on SJONE board. The DC motor is commanded every 100ms to change or maintain its speed or direction(FORWARD, REVERSE and STOP). A switch case is used to check the command that we are receiving over CAN bus from master. Pseudo code for dc motor and speed control float speed = get_speed(); float _error = calculate_error_PID(drive_forward->MOTOR_mps, speed, &dc_motor); *PWM_percent += _error set_pwm_value(motor_1, *PWM_percent); Servo MotorThe Servo motor is connected to pin P2.1 on SJONE board. The servo motor is commanded every 10ms to change or maintain its angle between 0 and 180 degrees. We receive angle in the range of -90(full left), 0(neutral) and +90(full right) from master. The calculate PWM_duty_cycle_servo function maps the angle received from master to PWM signal and rotates the servo motor accordingly. Pseudo code for servo motor and angle calculation on_time = 10 + ((servo->MOTOR_STEER_cmd + 90) * (10/180)); set_pwm_value(servo_2, on_time); RPM SensorThe RPM sensor is connected to pin P2.6 of SJONE board. When the wheel rotates once we get one pulse. We make use of interrupt to register these pulses in a 400ms time frame and then calculate the speed in m/s based on the formula: speed_m_per_sec = (circumference * rotation_per_sec) / (constant); After every 400ms we reset the pulse counter. We have an ISR which increments these pulses. void eint3_handler(void){

pulse++;

}

LED Blinking signals for MOTOR CONTROLLER

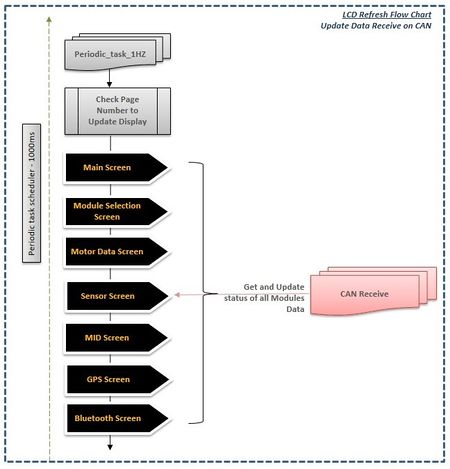

LCD Software Flow ChartProgramming SJONE Board for LCD Display

Creating a project using Workshop 4 IDE and programming the LCD display

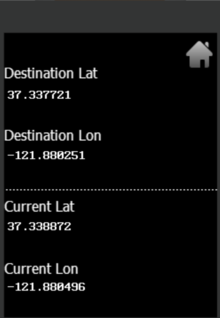

The steps taken for interfacing the LCD display with the SJONE board is shown on the right: Each of the reading is considered as a object with the object type ID and object number. Below are the list of objects used for lcd. #define GPS_DEST_LATITUDE_OBJ 0 #define GPS_DEST_LONGITUDE_OBJ 1 #define GPS_CURRENT_LATITUDE_OBJ 2 #define GPS_CURRENT_LONGITUDE_OBJ 3 #define GPS_HEADING_OBJ 13 #define GPS_BEARING_OBJ 14 #define GPS_DISTANCE_OBJ 3 #define MOTOR_SPEED_MS_OBJ 8 #define MOTOR_PWM_OBJ 12 #define MOTOR_RPM_OBJ 4 #define MOTOR_TURNING_ANGLE_OBJ 9 #define MOTOR_DISTANCE_COVERED_OBJ 10 #define MOTOR_DISTANCE_LEFT_OBJ 11 So our approach was to send a LCDquery at 1Hz task using the below function. void lcd_screen_query(void)

{

char comm[] = {0, 0x0a, 0, 0x0a};

for (int i = 0; i < (int)sizeof(comm); i++)

{

uart3_put_char(comm[i], 0);

}

}

This query sends a a array of character to LCD and LCD acknowledges it and sends the pre-formated data to the controller using lcd_receive() called at every 10Hz. The receive() will contain the page number(lcd_screen) based on the screen it is currently into and prints the data corresponding to that screen i.e. GPS screen will call GPS_print function to print the GPS values. void lcd_print()

{

switch (lcd_screen)

{

case menu:

lcd_print_menu_screen();

break;

case bridge:

lcd_print_bridge_screen();

break;

case gps:

lcd_print_gps_screen();

break;

case sensor:

lcd_print_sensor_screen();

break;

case motor:

lcd_print_motor_screen();

break;

case home:

lcd_print_home_screen();

break;

case mia:

lcd_print_mia_screen();

break;

case compass:

lcd_print_compass_screen();

break;

default:

break;

}

}

LCD Screens

Flow charts

DC motor speed and direction control using RPM sensor, Servo motor control and Speed calculator flow-chart

Technical ChallengesPWM frequency setting problem

PWM motor_control(PWM::pwm1, freq); PWM servo_control(PWM::pwm2, freq);

PWM *motor_control; //pointer object defined globally

PWM *servo_control;

void init_pwm(long unsigned int freq) {

motor_control = new PWM(PWM::pwm1, freq); // using PWM constructor to initialize the PWM 2.0 pin to desired frequency

servo_control = new PWM(PWM::pwm2, freq);

}

DC motor shooting randomly

PID Calibration for uphill and downhill

LCD Refreshing

char msb,lsb = 0; int local_heading = gps_bearing * 100; lsb = (char)((char) local_heading & 0xff); msb = (char)((char) (local_heading >> 8) & 0xff); lcd_put_comm(WRITE_OBJ, LED_DIGITS, GPS_HEADING_OBJ, msb, lsb);

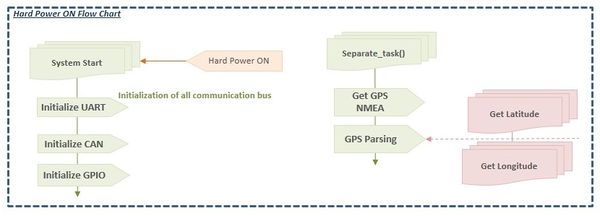

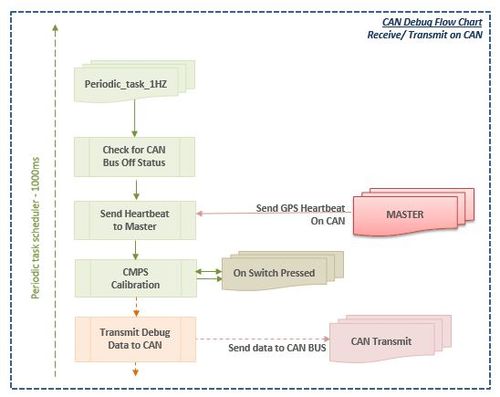

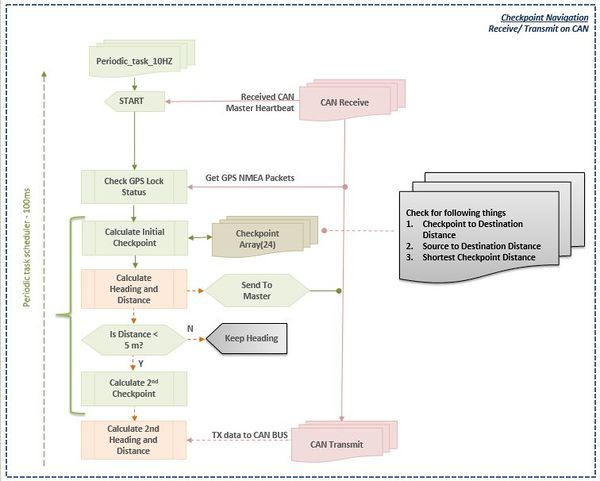

Geographical ControllerGeographical Controller is one the most important controller in the autonomous car which helps it to navigate to its destination. This modules continuously update the position and orientation of the car with respect to geographical north and send the data to Master, Motor and Android controller boards. We are using the Adafruit Ultimate GPS module and CMPS11.

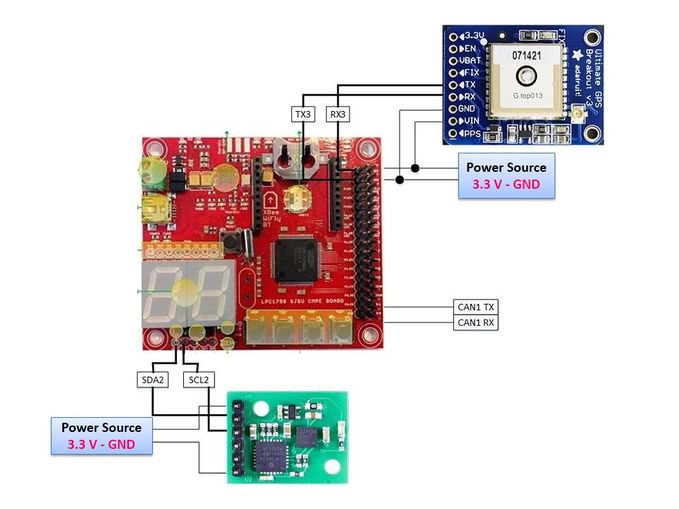

Hardware DesignThe hardware interface details of GPS and Compass Module with SJOne board are given below:

* RED LED ON: MASTER HEARTBEAT STATUS on CAR * BLUE LED ON: Shows GPS FIX STATUS on CAR * GREEN LED ON: COMPASS Data Indication GPS

* VCC: 3.3V Power * GND: Ground * TXD: Serial Transmit pin connected to RXD2 of SJOne board * RXD: Serial Receive pin connected to TXD2 of SJOne board * FIX: States if GPS is fixed not

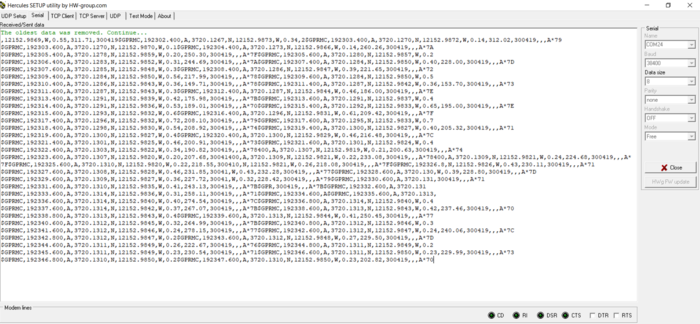

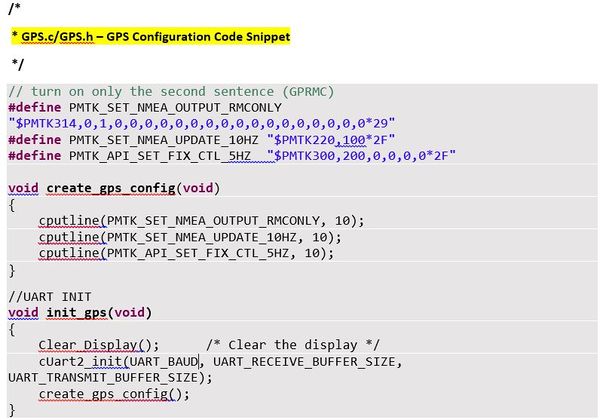

GPS is a global navigation satellite system that provides geolocation and time information to a GPS receiver anywhere on or near the Earth where there is an unobstructed line of sight to four or more GPS satellites. The GPS module used in this project runs on UART communication protocol. Its default baud rate is 9600bps and we are working on the same baud rate to extract GPS data. The GPS module works on NMEA 0183 standards which define the electrical and data specification for communication between the GPS module and its controller. We are using the Recommended minimum specific GPS/Transit data (GPRMC) command. It provides us with three important data which are Fix, Latitude, and Longitude, required for localization and navigation of the car. The update rate of these data from the GPS module is configured at 10Hz and 5Hz for fix control status.

GPS configuration Settings that we have used for the Adafruit GPS module is shown in the following picture. As per Arduino data-sheet, we can use different commands setting to set the different update rate from once a second (1 Hz) to 10 times a second (10 Hz) as per user requirements. Compass

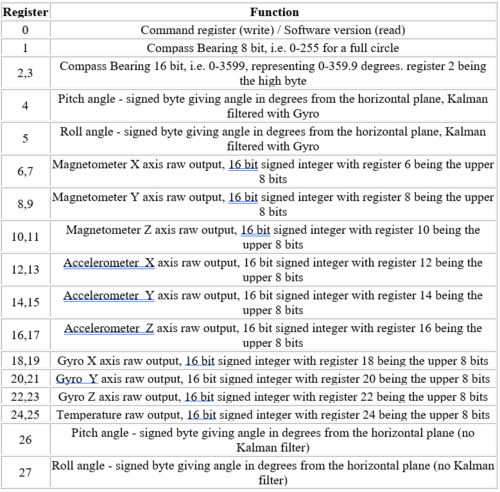

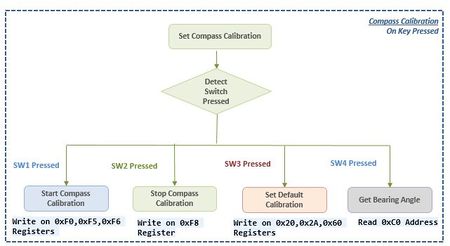

* VCC: 3.3V Power * GND: Ground * SCL: Serial Clock pin connected to SCL of SJOne board * SDA: Serial DATA pin connected to SDA of SJOne board A Compass is an instrument used for navigation and orientation that shows direction relative to the geographic cardinal directions (or points). Compass is communicating over I2C with SJ One board. The register 2 and 3 of the compass provide the compass bearing angle (0- 360 range). Calibrating the compass is an important part. We are calibrating it on ‘horizontal calibration mode’, it works for us because the compass has tilt calibration. We are using the compass in I2C mode of operation. The following table on the left shows the registers and their functions and the software flow chart for getting/setting compass data and calibration on demand and We are using the Compass bearing (16-bit) given by the compass registers 2 and 3 to calculate our car heading.

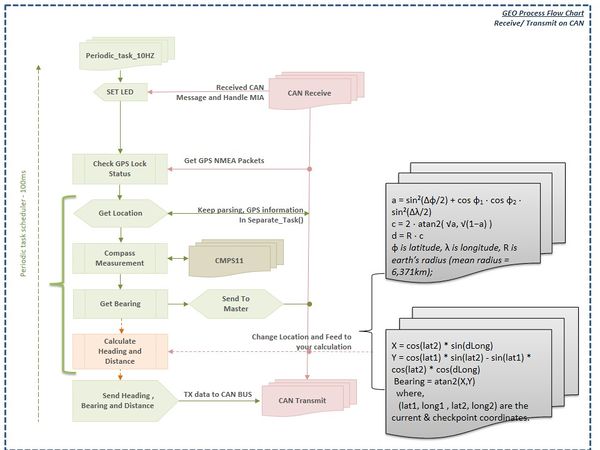

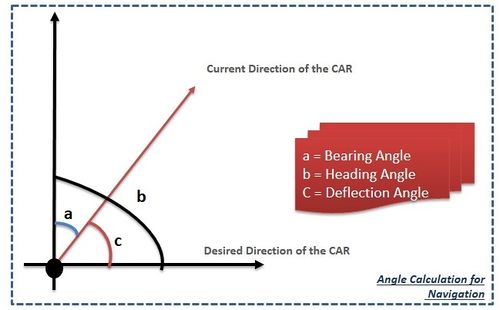

Software Design & ImplementationThe Geographical Controller is in place for navigation purpose. It has two essential parts, namely GPS and compass. It provides direction to the car, by calculating the heading angle and the distance between the coordinates, based on GPS and compass readings. To calculate the heading angle, we need a compass bearing angle and angle between the line joining the two coordinates and the true north(bearing angle for GPS).

Distance between the two coordinates calculationThe distance between the two coordinates can be calculated using the Haversine formula. a = sin²(Δφ/2) + cos φ1 ⋅ cos φ2 ⋅ sin²(Δλ/2)

c = 2 ⋅ atan2(√a, √(1−a))

d = R ⋅ c

where,

φ1 = Latitude of 1st Coordinate

φ2 = Latitude of 2nd Coordinate

λ1 = Longitude of 1st Coordinate

λ2 = Longitude of 2nd Coordinate

Δφ = φ2 - φ1

Δλ = λ2 - λ1

d = distance between the two coordinates

R = earth’s radius (mean radius = 6,371km)

Note: All the angles should be in radians.

GPS Heading angle calculationWith reference to the figure, the Heading angle for GPS is the angle between the line joining the two coordinates and the true north. To calculate it graphically, draw a vector pointing towards the destination coordinates from the start point coordinate and measure the angle between the vector and the true north. Use the below formula to calculate the angle mathematically. Heading angle(α) = atan2(sin Δλ ⋅ cos φ2 , cos φ1 ⋅ sin φ2 − sin φ1 ⋅ cos φ2 ⋅ cos Δλ)

where,

φ1 = Latitude of 1st Coordinate

φ2 = Latitude of 2nd Coordinate

λ1 = Longitude of 1st Coordinate

λ2 = Longitude of 2nd Coordinate

Δλ = λ2 - λ1

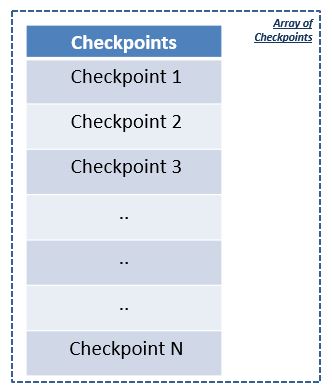

The car reads the value of current coordinates from the GPS module to determine its Euclidean distance from the first checkpoint. It also checks the value on the compass to know which direction it should preferably move in i.e. Heading angle. The sensor readings help it ascertain that there isn't an obstacle to hinder its movement in the determined direction. We have selected 23 checkpoints on the location where the demo is going to takes place and we have filled these coordinates in a Checkpoint Array as shown below.

The Software state machine flow chart for GPS Navigation is shown below: Technical Challenges

Solution - As per recommendation is given in Arduino Data sheet we should use default baud settings of 9600 later we never faced this issue and it was giving a good fix.

Solution - We have followed one of the Arduino Forum in which one of the experts give few tips on how to improve this GPS Fix issue and one of the tips worked for us was the of the Cell battery with the voltage of more than 2.89v. This resolves GPS fix the issue for us.

Solution - Using CMPS11 in default calibration mode helped us to get rid of this problem

Solution - Preet's easy parsing function(using sscanf) and his advice of using separate task using FreeRTOS helped us resolving this problem.

Solution - GPS coordinates require double datatype so, we took coordinates as double and then while sending data on CAN we were typecasting that to float. As we were doing all calculation related to coordinates, distance and checkpoints calculations on GEO Controller itself. So after doing all the calculations in double, we were type casting data to float and we were sending that to MASTER & BRIDGE.

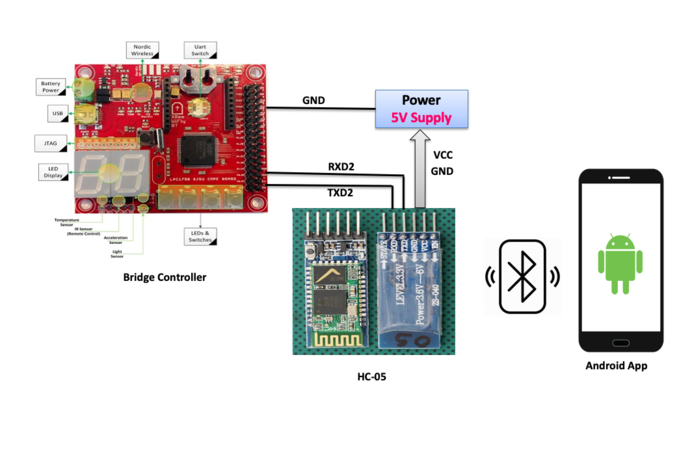

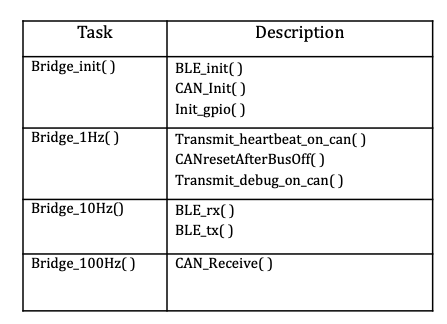

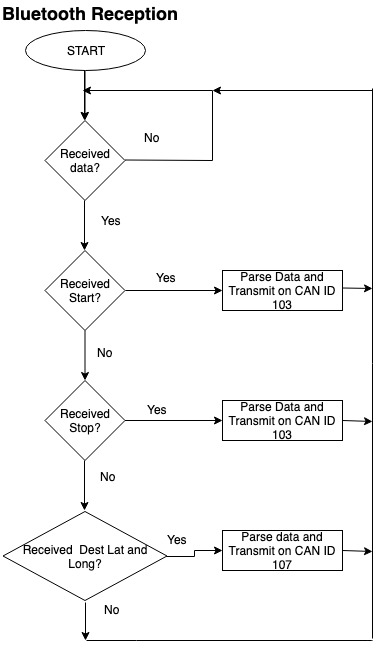

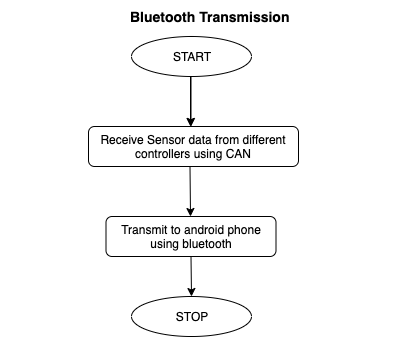

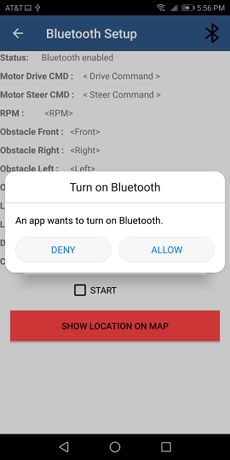

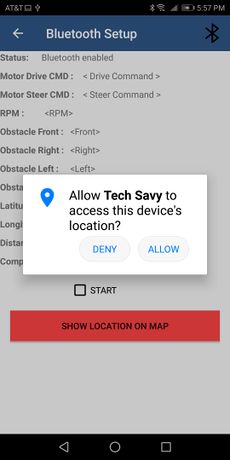

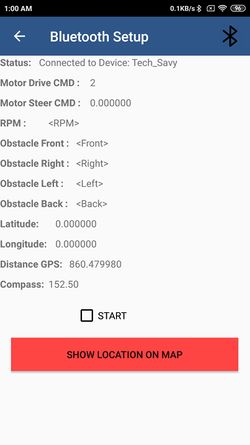

Bridge Controller CommunicationBridge Controller is used for communication between the SJOne board and the android phone using the HC-05 Bluetooth module. The main purpose of the bridge Controller is to receive the start/stop command and destination location from the Android app. Bridge controller will transmit all the sensor information and debug information and this information will be displayed on the android app.

Hardware DesignBluetooth Module Hardware Interfacing: We are using an HC-05 Bluetooth module to send and receive the data from our android application to Controller. The Bridge controller is connected to the Bluetooth module through the Serial interface(UART2) of SjOne board and we have configured HC-05 at 38400 baud rate 8-bit data and 1 stop bit using modules Communication Mode. Bridge Controller is connected to other SJOne Boards using CAN bus. The Bluetooth module communicates with the SJOne board using UART communication at 38400 baud rate.

HC-05 Bluetooth moduleHC-05 Bluetooth Module is used to set up wireless communication between the Car and the Android phone. This module is based on the Cambridge Silicon Radio BC417 2.4 GHz BlueTooth Radio chip. This is a complex chip which uses an external 8 Mbit flash memory It includes the Radio and Memory chips, 26 MHz crystal, antenna, and RF matching network. The right section of the Bluetooth Board has connection pins for power and signals as well as a 5V to 3.3V Regulator, LED, and level shifting.

* EN: In a case brought HIGH before power is applied, forces AT Command Setup Mode * VCC: 5V Power * GND: Ground * TXD: Serial Transmit pin connected to RXD2 of SJOne board * RXD: Serial Receive pin connected to TXD2 of SJOne board * STATE: States if connected or not

* Flashing RED Fast: Ready for Pairing with nearby Bluetooth device available * Flashing RED Slow: Paired and Connected Software DesignTechnical Challenges

Master ModuleHardware DesignDesign and Implementation

Software Design

ImplementationHeartbeat Message of All Modules

bool hbt_sync_from_all_node(void)

{

is_hbt_sync_flag = sensor_hbt_sync & motor_hbt_sync & gps_hbt_sync & bridge_hbt_sync;

return is_hbt_sync_flag;

}

void master_mia_handler(void)

{

if (dbc_handle_mia_SENSOR_HEARTBEAT(&sensor_hbt, 25))

{

sensor_hbt_sync = false;

}

if (dbc_handle_mia_MOTOR_HEARTBEAT(&motor_hbt, 25))

{

motor_hbt_sync = false;

}

if (dbc_handle_mia_GPS_HEARTBEAT(&gps_hbt, 25))

{

gps_hbt_sync = false;

}

if (dbc_handle_mia_BRIDGE_HEARTBEAT(&bridge_hbt, 25))

{

bridge_hbt_sync = false;

}

}

Testing and Technical Challenges

<Bullet or Headings of a module> Improper Unit Testing

Mobile ApplicationSoftware Design1. Enable Bluetooth and Connect to bridge controllerWireless communication with the car takes places with communication over Bluetooth protocol. Android Application is created which provides an interface to exchange data and configure the car parameters. The android app connects to the HC-05 BLE module of the bridge controller. The Bluetooth ask the user for permission to access location and prompts to enable Bluetooth if it's already OFF. Our app is designed to connect to only TechSavy Bluetooth module and no other Bluetooth device to ease the setup of Bluetooth communication. A Bluetooth adapter connects to the HC-05 module and opens a Bluetooth Socket over which read and write messages are sent. A thread runs in the background which checks for available data, reads it and the data can then be processed. Data is written via the same Bluetooth socket. Refer to the following link to get started with Bluetooth on Android app and connection to HC-05 module ([3]). 2. Start/Stop Command and Log Sensor valuesStart and Stop commands are sent to the RC car via the application. When Start/Stop button is pressed 1 or 0 commands are sent to the bridge controller when then transmits it to the CAN Bus for processing. Bluetooth status, Sensor Values, Motor parameters, GPS location, compass heading angle, distance to the checkpoint is displayed for debugging purpose. Sensor, GPS, motor Messages coming from CAN bus are decoded by the bridge controller and sent to the Android application as a string. The android app parses the string and categorizes the data to store it in appropriate variables. The data is then displayed as a text view in Bluetooth activity. To visit the Map Activity for setting destination and checkpoints a button is added. The map Activity opens on pressing the button. 3. Map ActivityThe map activity is used in our app to show the current location of the car and set the destination marker which the car will navigate too. When map loads in the app the cars current location is indicated coming from the GPS as the source location (Red Marker). The desired location on the map can be set as the destination by long clicking on the map (Light Green marker). The destination can be changed as desired by long pressing again. When the start button is pressed command 1 is sent to the CAN bus via Bluetooth to start the car. A thread starts in the background to indicate the current position of the car when the car moves (light blue marker). Also, a polyline is drawn between the source and destination marker to indicate the direction in which the car will move. For adding Google map to app refer the following [4](Refer to Maps and geolocation section) Testing and Technical Challenges1. We faced the problem of adding Bluetooth functionality in the app. There is a lack of tutorials online which shows how to develop an android app with Bluetooth capability and communicating with the HC-05 module. Fortunately, we found this webpage [5] which helped us and Youtube videos of Coding with Mitch. 2. It was difficult to design the UI on the app with little java and Android experience. We designing UI from mainly two resources [6] [7]and searching online for problems faced by us. 3. Initially, we developed the app such that we had to manually connect to a paired device to use Bluetooth functionality. This gave us problems while sending commands to the bridge controller. We solved this problem by fixing the device connection only to our HC-05 module and adding only a single Bluetooth connection button on the app bar for Bluetooth connection. 4. When we received too many sensor values and debug messages from the bridge controller continuously, the app was crashing due to the input buffer overflow. We solved this problem by adding a 1000ms sleep time to limit the input data coming to the app. 5. There was a requirement to continuously update a marker on the map indicating the current location of the car for user feedback. We achieved this using a thread in the background which updated cars position every 1 second.

Suggestions for Future Students

ConclusionIt was a really great working experience for all of us. We were really thrilled from the beginning that we will to work on something that is quite relevant in the industries these days. We worked as a team of 8 which helped us all to know the importance of team-work and co-ordination. We learned many great stuff like CAN bus communication, LIDAR, ultrasonic sensors, PCB designing, GPS, Compass, Android Application development. Unit testing was a great tool and it helped us to get great results in less amount of time. There were a lot of problems while doing this project but it was a steep learning curve. In the end we were able to achieve our objective with really good results. Project VideoProject Source Code

ReferencesAcknowledgementWe would like to express our gratitude to Professor Preetpal Kang for generously sharing his time and knowledge with us and guiding us through the completion of this project. We would also like to thank the Pratap(ISA) for their valuable advice and constructive feedback. References UsedLIDARPID ControlLCDAndroid GUIGoogle MapsDatasheets[1] XL-MaxSonar-EZ4 Ultrasonic Sensor [2] 4D Systems LCD [3] CAN Transceiver [4] GPS Module [5] Compass Module |