Difference between revisions of "F17: Viserion"

Proj user7 (talk | contribs) (→Hardware Design) |

Proj user7 (talk | contribs) (→3D Printing Design) |

||

| Line 333: | Line 333: | ||

==== 3D Printing Design ==== | ==== 3D Printing Design ==== | ||

| − | After testing sensors on different heights from the ground and different angles we noticed that best results are when sensors are mounted as closer to the ground as possible, so we came out with our own design for sensors mount. | + | After testing sensors on different heights from the ground and different angles we noticed that best results are when sensors are mounted as closer to the ground as possible, so we came out with our own design for sensors mount. Most important thing to consider when making design was to be able to adjust tilt of the sensors since we were receiving lot of reflection from the ground with temporarly mounts we used until we got the final printed version. So in order to satisfy that requirement mount is constructed from two parts, the stand and part that holds the sensor. |

=== Hardware Interface === | === Hardware Interface === | ||

Revision as of 07:21, 16 December 2017

Contents

Viserion Team RC Car

Abstract

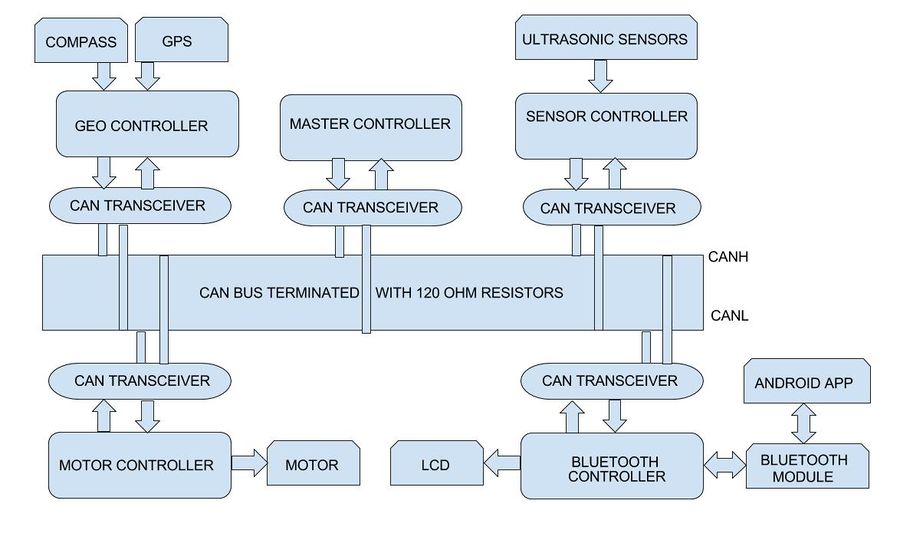

Aim of this project is to build a self-navigating car. The car is divided into five modules. Each module consists of SJ One board as the main controller. The different modules in the car are master, sensors, geo, motor and bluetooth module. The car uses CAN communication protocol for communication between the modules.

The five modules of the car are :

Sensor Controller: This module detects obstacles in the driving path with the help of ultrasonic sensors.

Motor Controller: This controller drives the DC motor and Servo in the car.

Geographical Controller: This module assists the car in navigating to a destination with the help of location details provided by GPS and the orientation(bearing and heading angle) provided by the compass.

Bluetooth Controller: The controller uses Bluetooth to communicate with an Android application. Destination coordinates are provided by this module. The bluetooth module also displays important data like sensor readings, GPS coordinates and speed.

Master Controller: This module will collect data from all modules and direct the motor towards the destination.

Objectives & Introduction

Objectives

The objectives are as follows:

1.To detect and avoid obstacles encountered in the path.

2.To move at an appropriate speed depending upon the path requirement.

3.To use Bluetooth module to start/stop the car and display important data on the LCD.

4.To integrate gps and compass to make sure that the car navigates from source to destination.

5.To efficiently establish communication between all the modules using CAN protocol.

6.To reach a destination given by the Bluetooth module autonomously for a valid path.

System Block Diagram

Team Members & Responsibilities

Master Controller

- Aakash Menon

- Omkar Kale

Geographical Controller

- Ajinkya Mandhre

- Aniket Dali

- Jean Madassery

Sensor Controller

MOTOR & I/O CONTROLLER

- Manoj Ramesh Rao

- Pratap Ramachandran

BLUETOOTH CONTROLLER & ANDROID APP

- Dheemanth Bangalore Vishwanatha

- Pratap Kishore Desai

Schedule

Show a simple table or figures that show your scheduled as planned before you started working on the project. Then in another table column, write down the actual schedule so that readers can see the planned vs. actual goals. The point of the schedule is for readers to assess how to pace themselves if they are doing a similar project.

Legend: Motor & I/O Controller , Master Controller , Communication Bridge Controller, Geographical Controller, Sensor Controller , Team Goal , Team PCB, , Team Android

| Week# | Start Date | End Date | Task | Actual Completion Date / Notes | Status |

|---|---|---|---|---|---|

| 1 | 10/09/2017 | 10/15/2017 |

|

Done | |

| 2 | 10/16/2017 | 10/22/2017 |

|

Done on time except

|

|

| 3 | 10/23/2017 | 29/10/2017 |

|

Done on time except

|

|

| 4 | 10/30/2017 | 11/05/2017 |

|

Done on time | |

| 5 | 11/06/2017 | 11/12/2017 |

|

|

|

| 6 | 11/13/2017 | 11/19/2017 |

|

|

|

| 7 | 11/20/2017 | 11/25/2017 |

|

|

|

| 8 | 11/26/2017 | 12/01/2017 |

|

|

|

| 9 | 12/03/2017 | 12/08/2017 |

|

||

| 10 | 12/10/2017 | 12/12/2017 |

|

||

| 11 | 12/13/2017 | 12/16/2017 |

|

||

| 12 | 12/17/2017 | 12/19/2017 |

|

||

| 13 | 12/20/2017 |

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car - Traxxas 1/10 Slash 2WD | Amazon | 1 | $189.95 |

| 2 | Battery - Traxxas 7600mAh 7.4V 2-Cell 25C LiPo Battery | Amazon | 2 | $143.26 |

| 3 | Charger - Traxxas 2970 EZ-Peak Plus 4-Amp NiMH/LiPo Fast Charger | Amazon | 1 | $49.95 |

| 4 | GPS - Readytosky Ublox NEO-M8N GPS Module | Amazon | 1 | $29.98 |

| 5 | Bluetooth Module HC-05 | Amazon | 1 | $8.99 |

| 6 | IMU SparkFun 9DoF Razor IMU M0 | SparkFun | 1 | $49.95 |

| 7 | LV Maxsonar EZ0 Ultrasonic sensors | Robotshop | 6 | $158.7 |

| 8 | RPM Sensor - Traxxas 6520 RPM Sensor | Amazon | 1 | $10.25 |

| 9 | Jumper Wires | Amazon | 1 | $10 |

| 10 | Acrylic Board MIFFLIN Acrylic Plexiglass 12 x 12 | Amazon | 1 | $11 |

| 11 | CAN tranceivers | Microchip Samples | 30 | Free |

| 12 | SJOne Boards | Provided by Preet | 5 | $400.0 |

Design & Implementation

Sensors Controller

Based on research done on previous projects we decided to use Maxbotix EZ0 Ultrasonic sensors due to its reliability and cost. Four sensors total are used in this project. Three front sensors and one back sensor. They are all of the same type and manufacturer. Since they are triggered at different time, every 50ms, there was no need to use different sensor with different ranging frequency.

Hardware Design

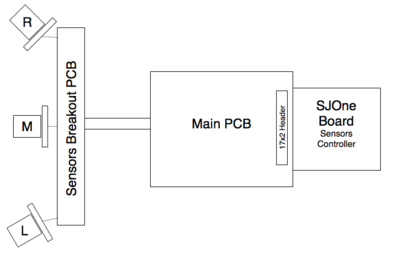

There are two PCBs on car that are involved in wiring sensors, providing them with power and collecting data from them. “Main PCB” which is directly connected to Sensor Controller and “Sensors breakout PCB” which is mounted at the front of the car as close to sensors as possible to reduce wire length that goes through air. Two PCBs are connected with 12-pin ribbon cable. The sensors are powered with 3.3V and since we had only 5V power from power bank, we had to use 3.3V voltage regulator mounted on “Sensors breakout PCB”. Providing stable input voltage for sensors was also required because of unstable reading we were getting from sensors, caused by electrical interference. Our front sensors were interfaced by ADC, so stable input voltage was a must. Back sensor was interfaced by PWM since SJOne board has only three ADC pins.

3D Printing Design

After testing sensors on different heights from the ground and different angles we noticed that best results are when sensors are mounted as closer to the ground as possible, so we came out with our own design for sensors mount. Most important thing to consider when making design was to be able to adjust tilt of the sensors since we were receiving lot of reflection from the ground with temporarly mounts we used until we got the final printed version. So in order to satisfy that requirement mount is constructed from two parts, the stand and part that holds the sensor.

Hardware Interface

Sensors are interfaced with combination of GPIO, ADC and PWM pins. GPIO pins are used to trigger all sensors. Three ADC pins collect output from front sensors and PWM pin collect output from back sensor. Below you can see pin layout.

| Pin Name | Function |

|---|---|

| P2.6 | Trigger for left sensor |

| P2.7 | Trigger for right sensor |

| P2.8 | Trigger for middle sensor |

| P2.9 | Trigger for back sensor |

| P0.26 | ADC input for left sensor |

| P1_30 | ADC input for right sensor |

| P1_31 | ADC input for middle sensor |

| P2_0 | PWM input for back sensor |

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show pseudocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Motor and I/O Controller

The motor controller is responsible for the steering and controlling the speed of the car. Both direction and speed of the car is controlled using the duty cycle of PWM signal. The speed of the car can be controlled by sending appropriate signals to the ESC connected to the DC motor of the car.

Hardware Design

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high-level workings rather than the inner working of your project.

DC Motor

ESC

Servo

RPM Sensor

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show pseudocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Steering Control

Speed Control

Consistent speed based on feedback

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Master Controller

The master controller is the brain of the car. It communicates over CAN bus with other modules to receive data. It accepts the values of different sensors mounted in front and rear, and takes decision based on this data. It uses heartbeat mechanisms to keep a check on other modules in the system. The entire module has two main algorithms : one for Obstacle Avoidance and another for Navigation.

Hardware Design

This module was interfaced with Microchip CAN transceiver MCP2551 to communicate with other nodes in the bus. No external peripherals were connected to the master controller.

The figure below shows the hardware design of the master.

Software Design

Obstacle Avoidance

Directions And Steering Signals

Testing Challenges

Testing

Technical Challenges

Implementation

Bluetooth Controller And Android Application

Design And Implementation

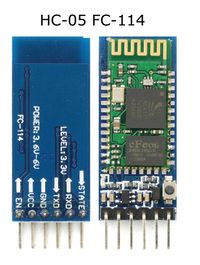

The user selects a destination on the android application which then communicates with the Bluetooth module HC-05 through which car gets to know the route to destination. The user can directly interact with the car using the android application so this is one of the most important modules. The detailed software and hardware design is mentioned in below sub sections.

Hardware Design

This includes

• SJ-One Board

• Bluetooth Module HC-05

• Android Smartphone

• CAN transceiver

Bluetooth Module

Specifications

• Bluetooth protocol: Bluetooth Specification v2.0+EDR

• Frequency: 2.4GHz ISM band

• Speed: Asynchronous: 2.1Mbps(Max) / 160 kbps, Synchronous: 1Mbps/1Mbps

• Profiles: Bluetooth serial port

• Power supply: +3.3VDC 50mA

• Working temperature: -20 ~ +75Centigrade

• Dimension: 26.9mm x 13mm x 2.2 mm

• Modulation: GFSK(Gaussian Frequency Shift Keying)

• Sensitivity: ≤-84dBm at 0.1% BER

• Security: Authentication and encryption

Bluetooth And SJOne Board Connection Diagram

Hardware Interface

The Bluetooth module HC05 is connected to Bluetooth-ECU using UART3. The transmission rate is 9600bps. Bluetooth-ECU communicates with all other ECU's using CAN-Transceiver.The following pins where used for connections.

Bluetooth-ECU

| Function On ECU | Pin NO On ECU | Function On HC05 |

|---|---|---|

| RX | P4_28 | TX |

| TX | P4_29 | RX |

Software Design

Bluetooth Module

Android Application

Implementation

Testing

Technical Challenges

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

<Bug/issue name>

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.