Difference between revisions of "S17: CamBot"

Proj user16 (talk | contribs) (→Bluetooth Module) |

Proj user16 (talk | contribs) (→Android App Implementation) |

||

| Line 654: | Line 654: | ||

The android application to control our CamBot is a simple one screen application. The screenshot showing the button layout (UI) is given on the right. The table with the button descriptions is given below. Any button press will result in sending of the command byte via Bluetooth to board module which will be received via UART. The Bluetooth task and android app communication will receive all and any message sent. The motor task will decide what to do with the received commands and whether it is valid or not, with respect to the software flow. | The android application to control our CamBot is a simple one screen application. The screenshot showing the button layout (UI) is given on the right. The table with the button descriptions is given below. Any button press will result in sending of the command byte via Bluetooth to board module which will be received via UART. The Bluetooth task and android app communication will receive all and any message sent. The motor task will decide what to do with the received commands and whether it is valid or not, with respect to the software flow. | ||

| + | |||

| + | The android code starts in the MainActivity.java where an UUID is initialized for the bluetooth adapter objects created in the MainActivity class. After this, a bluetooth socket is created using the above mentioned UUID. A list is created which is initialized with the paired devices of the Application host. Clicking on any of these would start a connection with the device ID via the socket object. After connection is established, any command sent would be done so via this created socket object. The next function call would be based on what button is pressed. There are onClickListeners for all these buttons which would send the respective commands on button press. | ||

{| class="wikitable" | {| class="wikitable" | ||

Revision as of 21:30, 25 May 2017

Contents

CamBot

Abstract

The project aims to build a motorized camera holding bot that helps the photographers to create moving time-lapses across a landscape.The photographers can program the bot to move in a sequence of desired directions and capture the time-lapse. CamBot can slowly move over time to capture the time-lapse and also slowly change angles.

Objectives & Introduction

The main objective of the project is to learn the precise stepper and DC motor control, android application development and PCB design in order to create a platform for photographers to create an effective time-lapse photography. The project explores the PWM, GPIO and UART drivers in LPC1758 platform. CamBot is driven with the help of DC Motors whose PWM Signals are given by LPC1758. Since stepper motor moves in precise repeatable steps, it is best suited for applications requiring precise positioning. Precise increments of movement also allow for excellent control of rotational speed for process automation and robotics. Normal DC motors do not have much torque at low speeds. The sequence of directions for the CamBot is provided by a Bluetooth Application which sends the commands for specific movements.

Team Members & Responsibilities

- Spoorthi Mysore Shivakumar

- Goutam Madhukeshwar Hegde

- PCB Design

- Component soldering and mounting

- Chethan Palangotu Keshava

- Andriod app developemnt

- Aajna Karki

Schedule

Team Schedule

| SI No. | Start Date | End Date | Task | Status | Actual Completion Date |

|---|---|---|---|---|---|

| 1 | 03/14/2017 | 03/21/2017 |

|

Completed | 03/21/2017 |

| 2 | 03/21/2017 | 03/28/2017 |

|

Completed | 03/28/2017 |

| 3 | 03/29/2017 | 04/04/2017 |

|

Completed | 04/04/2017 |

| 4 | 04/05/2017 | 04/12/2017 |

|

Completed | 04/12/2017 |

| 5 | 04/13/2017 | 04/18/2017 |

|

Completed | 04/18/2017 |

| 6 | 04/19/2017 | 04/25/2017 |

|

Completed | 04/25/2017 |

| 7 | 04/26/2017 | 05/02/2017 |

|

Completed | 05/02/2017 |

| 8 | 05/03/2017 | 05/09/2017 |

|

Completed | 05/09/2017 |

| 9 | 05/10/2017 | 05/15/2017 |

|

Completed | 05/25/2017 |

Parts List & Cost

| Item# | Part Name | Vendor | Cost $ |

|---|---|---|---|

| 1 | SJOne Board | From Preet | 80$ |

| 2 | PCB Fabrication | 4PCB | 66$ |

| 3 | Bluetooth Module | Sparkfun | 25$ |

| 4 | Chassis | Amazon | 15$ |

| 5 | Battery - 1000mAh | Amazon | 14$ |

| 6 | Motor Wheel Couplers | Amazon | 10$ |

| 7 | Corner Braces | Amazon | 6$ |

| 8 | Lipo Battery Charger | Amazon | 12$ |

| 9 | Motor Drive Shield | Amazon | 5.5$ |

| 10 | Stepper motor | Amazon | 13$ |

| 11 | IR Reflective Sensor | Amazon | 7$ |

Design & Implementation

Hardware Design

This section includes schematics and hardware interface of the components used in the project.

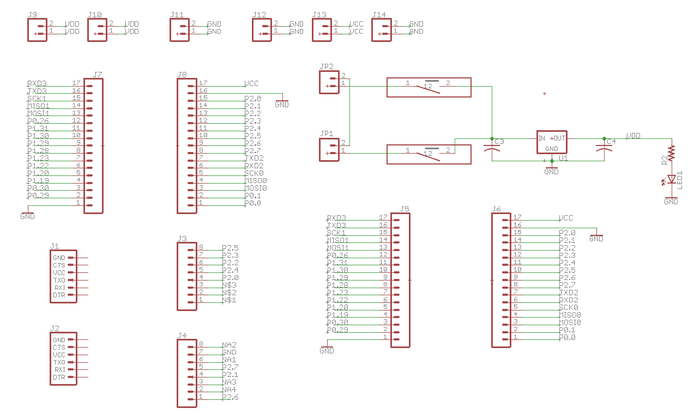

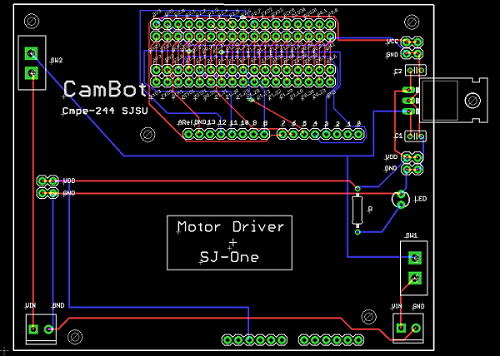

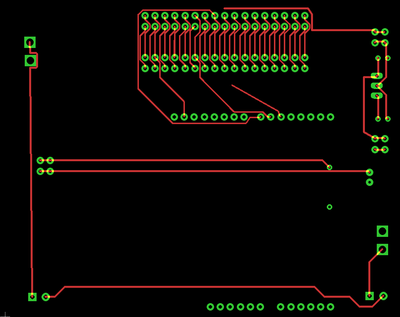

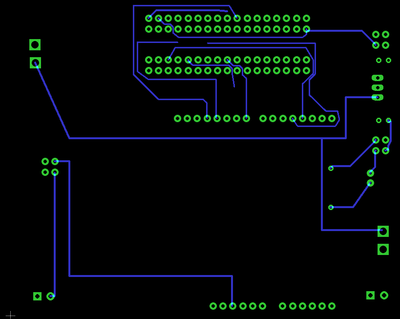

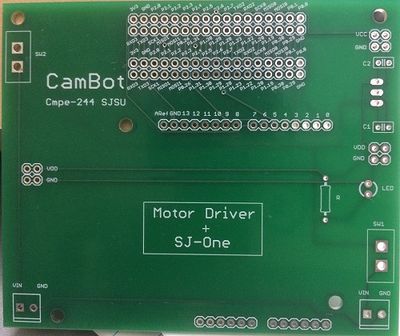

PCB Design

Eagle 8.1.0 software is used for PCB design.We created a 2 layer PCB of size 10cm x 8cm.

The steps involved in the PCB design process are discussed below.

1. PCB Schematic Design:

In the first step, we need to design a circuit using components available in Eagle library.Here two important things to keep in mind are:

- The Electrical Characteristics: Based on our requirement of voltage or current rating, we select the components which are suitable for our board.For example, if we want to connect a switch to conduct 5A current, we should not select a switch with 2A current rating from the library because the copper width for 2A switch will not be able to conduct 5A current.

- Components Selection: We need to carefully select the components here because each component has specific dimension as defined in their library.So once we convert this schematic into board layout, the size of the pads printed on the board depends on the component selection.We can't change the size if we select the library components.But there is a way we create our custom components with required electrical characteristics and dimensions.For our design, we used most of the parts from the Sparkfun library as it is very reliable and some of the parts which are not available in the library are created manually using Eagle.

EAGLE Components Used:

| Parts# | Part Name | DEVICE | LIBRARY | PACKAGE | Quantity |

|---|---|---|---|---|---|

| 1 | LED | LED3MM | SparkFun | LED_3MM | 1 |

| 2 | Toggle Switch | TOGGLE_SWITCH | toggle_switch(Custom library) | TOGGLE_SWITCH(Custom Package) | 2 |

| 3 | Famale Connectors | CONN_08" | SparkFun-Connectors | 1X08 | 2 |

| 4 | Female Connectors | 6_PIN_SERIAL_TARGET | SparkFun-Connectors | 1X06 | 2 |

| 5 | Male Connectors | CONN_17 | SparkFun-Connectors | 1X17 | 4 |

| 6 | Male Connectors | CONN_02 | SparkFun-Connectors | 1X02 | 6 |

| 7 | Terminal headers | M023.5MM | SparkFun | SCREWTERMINAL-3.5MM-2 | 2 |

| 8 | Capacitors | C-US025-025X050 | rcl | C025-025X050 | 2 |

| 9 | Resistors | R-US_0207/10 | rcl | 0207/10 | 1 |

| 10 | Voltage Regulator | V_REG_78XX-TO-220 | SparkFun-IC-Power | TO-220-ALT | 1 |

2. PCB Board Layout:

PCB board layout involves mainly placing components in the layout and routing them together.we can do manual routing or auto routing to connect components together with copper lines.But sometimes auto routing does not work or it will not be able to route all the connectors in an efficient manner.So manual routing is the best way where we will be able to plan and do the routing. In our project, the main challenges faced while PCB design is placing connectors and components in the appropriate place.Since we used a motor driver shield, which has 14 pin male connectors on the one side and 12 pin male connectors on the other side, it was very important that we measure proper dimension to fit this board on female connectors placed on PCB.We used dimension tool of the eagle to fix the accurate placement of connectors. The other challenge involved in the PCB design is routing the 34 pin connector for connecting SJ-one board to PCB.We decided to leave out extra 34 pin connector corresponding to SJ-one board because it can be used for any additional features added to our project.

In this process, we used Eagles add-on features to check for any error in our design.It is important that we follow all the strict PCB design guidelines before generating Gerber files for PCB manufacturing.

The features of PCB:

- Power supply circuit with 12V,5V and 3.3V connectors.

- Switch to control power to SJ-One board and Switch to control power to Motor driver shield.

- Female connectors to place Adafruit Motor Driver shield.

- 34 pin male connectors to connect SJ-one board to PCB.

- Extra 34 pin male connectors covering all 34 pins of SJ-one board for future use or if any extra features added.

Overall PCB design was a great learning experience and we would like to offer following tips to readers who are new to PCB:

1. Follow Sparkfun Eagle tutorial or a similar one to learn the guidelines and rules for PCB design. 2. Try to select components from standard libraries like Sparkfun to make sure that we get the proper components according to the PCB specification. 3. It is better to select Through Hole components because it is easy to solder and is easily available in the market. 4. Give careful attention to components ratings and size because it will the determine pads size for this components. 5. Carefully select the thickness of copper wire for routing.Because for high current lines like supply line we need thicker one and for GPIO's and all we need thinner one. 6. Use the dimension tool properly to place the components in the desired place. 7. Also if it is a two layer PCB, please make sure that there are fewer copper wires passing near component pads.It will make the soldering process easy without any damage to PCB. 8. Before giving PCB to manufacturing please check with the guidelines provided by vendors to make sure we meet all the PCB design rules.

Hardware Interface

The hardware components used in this project include:

- Motor Shield

- Stepper Motor

- DC Motor

- Bluetooth module.

Motor Shield

The Adafruit motor shield is used in this project.

Why use a motor shield?

- Stepper motor requires huge current. The micro-controller does not cater to this requirement. Motor shield IC is capable of handling such high currents.

- Since the stator coils behave as an inductor, a change in the direction of current results in huge spikes. This can damage the microcontroller. The H bridge can proetct the microcontroller in such a case.

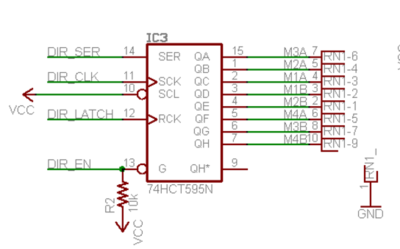

The Adafruit motor shield comprises of two L293D dual H-bridge motor driver ICs. It has four digital inputs which are in pairs. Each pair controls a motor. The motor shield has a shift register which facilitates the host controller to send data in serial manner which saves some of the pins of controller. The operation can be explained with an example. If pin 7 is set low and pin 2 is set high, motor 1 is turned on. Reversing the inputs will reverse the motor.

In order to conserve pins, the motor driver IC pins are wired to the outputs of 74HCT595N IC which is an 8-bit shift register. The data is fed in serially into this IC which then outputs the data in the parallel form.

The inputs to the shift register consisting of:

- DIR_EN: Enable Input (Active Low)

- DIR_SER: Data Input

- DIR_CLK: Rising edge results in shifting in of the input data bit

- DIR_LATCH: Rising edge results in internal bits to be moved out as parallel data

Motor Shield and SJOne Interface

| Motor Shield Pin | SJOne Pin |

|---|---|

| 4 (CLK) | P2.4 |

| 7 (EN) | P2.5 |

| 8 (DATA) | P2.6 |

| 12 (LATCH) | P2.7 |

Stepper Motor

Stepper motor is used to obtain the rotation of the phone for capturing a time-lapse.

Stepper motors consist of a rotor and stationary electromagnets around the rotor. The movement of the rotor is controlled by energizing the electromagnets in a particular sequence as required. The movement of the rotor occurs as the rotor is attracted towards the electromagnets.

In this project, we use the NEMA 17 stepper motor which has a precision of 200 steps per revolution. Based on the angle required, the stepper motor can be configured to take the required number of steps in the provided direction.

NEMA 17 is a bipolar stepper motor. In the case of bipolar stepper motor, in order to reverse the polarity of stator poles, the current needs to be reversed. It is a 2-phase stepper motor and has one winding per phase. It has four leads. Each pair of leads is connected to one winding.

Testing the leads

Each pair corresponds to one winding.

- If the resistance measured between one pair is infinite, the two wires in the pair belong to different windings.

- If the resistance measured between one pair is a definite value, the two wires in the pair belong to the same winding.

Each pair of these leads is connected to the motor input pins of the Motor Shield.

Stepper Motor and Motor Shield Interface

| Stepper Motor | Motor Shield |

|---|---|

| 2A and 2B | M2 |

| 3A and 3B | M3 |

SJOne PWM for Stepper Motor

| Stepper Motor | SJOne Pins |

|---|---|

| 2A and 2B | P2.0 (PWM1) |

| 3A and 3B | P2.3 (PWM4) |

DC Motor

DC motor is used in this project to move the robot forward and backward. Two DC motors are used each connected to a wheel.

The DC motor converts electrical energy to mechanical energy. It consists of a current carrying conductor placed in an electromagnetic field. When current is passed through the conductor, a mechanical force is generated due to the electromagnetic effect.

DC Motor and Motor Shield Interface

| DC Motor | Motor Shield |

|---|---|

| DC Motor 1 | M1 |

| DC Motor 2 | M4 |

SJOne PWM for DC Motor

| DC Motor | SJOne Pins |

|---|---|

| DC Motor 1 | P2.1 (PWM2) |

| DC Motor 2 | P2.2 (PWM3) |

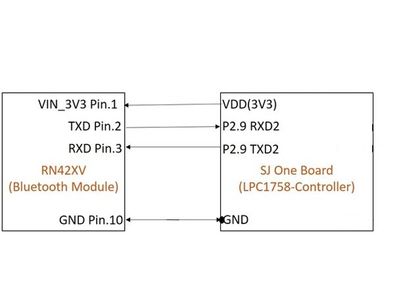

==== Bluetooth Module ====

RN42XV is built around Microchip's RN42 low power Bluetooth module. Some features of this module are as follows

- Based on the popular 2 x 10 (2mm) socket footprint.

- Voltage range: (3-3.6)Volts

- Current range: 26 μA sleep, 3 mA connected, 30 mA transmit.

- UART data connection interface.

- Sustained data rates: 240 Kbps (slave), 300 Kbps (master)

- Transmission range up to 60 feet (20 m) distance, +4 dBm output transmitter, -80 dBm typical receive sensitivity.

- FHSS/GFSK modulation, 79 channels at 1-MHz intervals.

The Bluetooth module uses simple UART communication protocol for sending/receiving data from the Micro-controller board. we are using UART2 to communicate with the Bluetooth module.

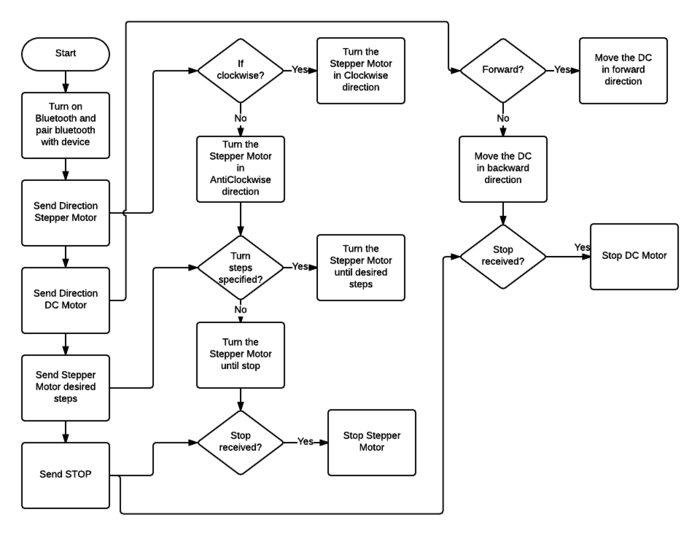

Software Design

The software design consists of 3 tasks:

- Bluetooth Task

- Stepper Motor Task

- DC Motor Task

The Bluetooth task is of high priority since the user data needs to be received and acted upon. The Stepper Motor and the DC Motor tasks are run with medium priority.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Motor Shield Software Implementation

The shift register in the motor shield requires 4 inputs. They are configured using SJOne GPIOs as below:

GPIO MOTORLATCH(P2_7); GPIO MOTORDATA(P2_6); GPIO MOTORCLK(P2_4); GPIO MOTORENABLE(P2_5); MOTORLATCH.setAsOutput(); MOTORENABLE.setAsOutput(); MOTORDATA.setAsOutput(); MOTORCLK.setAsOutput();

Latch enabling is required every time a data is set since it controls the data moving into the shift register and the parallel data being sent out of the motor shield. This functionality of latching motor state data is implemented as follows:

for(i=0; i<8; i++)

{

setMotorClockLow();

if(latch_state & (1 << (7-i))

{

setMotorDataHigh();

}

else

{

setMotorDataLow();

}

setMotorClkHigh();

}

setMotorLatchHigh();

Stepper Motor Task Implementation

PWM Initialization:

PWMs 1 and 4 are used for Stepper Motor.

GPIO PWM1(P2_0); GPIO PWM4(P2_3); PWM1.setAsOutput(); PWM4.setAsOutput();

The Stepper motor coils are energized in the following sequence based on the command received from the application:

Latching for clockwise direction:

latch_state |= (1 << MOTOR3_A) | (1 << MOTOR2_A); latch_state |= (1 << MOTOR2_A) | (1 << MOTOR3_B); latch_state |= (1 << MOTOR3_B) | (1 << MOTOR2_B); latch_state |= (1 << MOTOR2_B) | (1 << MOTOR3_A);

This sequence results in a clockwise rotation. The reverse of this sequence results in an anti-clockwise rotation.

DC Motor Task Implementation

PWM Initialization:

PWMs 2 and 3 are used for DC Motor.

GPIO PWM2(P2_1); GPIO PWM3(P2_2); PWM2.setAsOutput(); PWM3.setAsOutput();

The DC motor is activated based on the command received from the application:

Latching for forward direction:

latch_state |= (1 << MOTOR1_A); latch_state &= ~(1 << MOTOR1_B); latch_state |= (1 << MOTOR4_A); latch_state &= ~(1 << MOTOR4_B);

This sequence results in a forward motion. The reverse of this sequence results in a backward motion.

Control of Stepper and DC Motor

Stepper Motor steps can be controlled based on input from Android Application. To rotate the stepper motor it has to go through phase 1 to 4 to energize the 4 coils in particular sequence based on desired angle and direction. If no angle is set then the stepper motor moves indefinitely. Similarly DC motor is controlled in forward or backward direction.

Structure has all the necessary control variables as below

uint8_t direction; uint8_t fwd_reverse; uint8_t start_stop; uint8_t steps_degree; bool steps_set; int8_t value;

Based on the values sent from application,direction is set to clockwise/anticlockwise, forward/reverse for DC motor, steps_degree for number of desired steps for the given angle etc.

Bluetooth Task Implementation

The bluetooth task initializes UART2 for the communication with Zigbee Bluetooth module with the baud rate of 115200. It waits for a byte from UART2 in its run() function (which is always run in a loop as long as the task is running). The byte it receives can be decoded from the enumeration datatype declared to represent the commands from the app. Below is the definition of the Bluetooth task used along with the enum datatype.

class bluetooth_task : public scheduler_task

{

private:

Uart2 &Bluetooth_uart_2;

static const int Rx_Q_Size = 3;

static const int Tx_Q_Size = 3;

static const int Baud_Rate_Bluetooth_Uart2 = 115200;

char buff;

public:

bluetooth_task(uint8_t priority) :

scheduler_task("Bluetooth Task", 2000, priority),Bluetooth_uart_2(Uart2::getInstance())

{

Bluetooth_uart_2.init(Baud_Rate_Bluetooth_Uart2,Rx_Q_Size,Tx_Q_Size);

buff = 0;

}

bool init(void);

bool run(void *p);

};

enum command

{

init,

start,

stop,

clockwise,

anticlockwise,

angle30,

angle60,

angle90,

angle120,

angle150,

angle180,

forward,

backward,

};

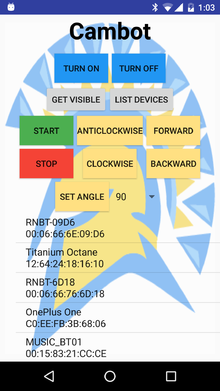

Android App Implementation

The android application to control our CamBot is a simple one screen application. The screenshot showing the button layout (UI) is given on the right. The table with the button descriptions is given below. Any button press will result in sending of the command byte via Bluetooth to board module which will be received via UART. The Bluetooth task and android app communication will receive all and any message sent. The motor task will decide what to do with the received commands and whether it is valid or not, with respect to the software flow.

The android code starts in the MainActivity.java where an UUID is initialized for the bluetooth adapter objects created in the MainActivity class. After this, a bluetooth socket is created using the above mentioned UUID. A list is created which is initialized with the paired devices of the Application host. Clicking on any of these would start a connection with the device ID via the socket object. After connection is established, any command sent would be done so via this created socket object. The next function call would be based on what button is pressed. There are onClickListeners for all these buttons which would send the respective commands on button press.

| Button | Functionality |

|---|---|

| TURN ON | Turn on the Bluetooth on the mobile |

| TURN OFF | Turn off the Bluetooth on the mobile |

| GET VISIBLE | Makes your mobile device visible to other Bluetooth devices |

| LIST DEVICES | Lists all the Bluetooth devices paired with the mobile. You can click on any of the listed devices to connect to it |

| START | After giving appropriate commands and parameters, pressing this button will set the cambot in motion |

| STOP | This stops the motion of the CamBot |

| ANTICLOCKWISE | Press this button to set the direction of rotation of the camera holder stepper motor to anticlockwise direction |

| CLOCKWISE | Press this button to set the direction of rotation of the camera holder stepper motor to clockwise direction |

| FORWARD | Press this button to set the direction of movement of the dc motor to forward direction |

| BACKWARD | Press this button to set the direction of movement of the dc motor to backward direction |

| SET ANGLE | First select appropriate angle for the above discussed stepper motor using the list to the left of this button. Then press this button to set the angle of rotation of the stepper motor |

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

Issue #1

Problem connecting the android app with Zigbee bluetooth module via Bluetooth. The app was initialising connection but was not able to finish the connection process and get connected.

Solution: The RFComm socket was not getting created properly. Even when the RFComm socket gets created, it was not created with the accurate device UUID that needed to be setup. After manually setting up the device UUID and then creating the RFComm socket, you can start the Bluetooth connection with that socket object and then it would successfully connect with the Bluetooth module.

Issue #2

We tried integrating the Sunfounder line follower module that works on I2C interface. We faced an issue where the module was getting discovered but read and write was failing. On further debugging, we observed that the I2C was getting disabled in the software.

Solution: We changed the module to TCRt5000

Issue #3

We faced issue with the mechanical camera mount of the stepper motor. A small mismatch between the coupler used to connect the stepper motor shaft and the camera mount resulted in amplification of the vibration. This caused a lot of vibration on the camera mount when the stepper motor was activated.

Solution

The coupler placement was adjusted for minimal shakiness. Also, the mechanical mount had a lot of distinct moving parts. We replaced it with a camera mount with less moving parts for stability.

Issue #4

We faced problem in choosing a small SPST toggle switch in Eagle library during PCB schematic design.The required specification and dimension was not available in the library.

Solution

We decided to develop our own customized switch using Eagle with the required dimension and specification which fits perfectly with our board.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

https://www.youtube.com/watch?v=Wxr-8NMwPrs

Project Source Code

https://gitlab.com/aajna.karki/cmpe244_CamBot

References

Acknowledgement

We would like to thank Prof. Preetpal Kang for providing a great platform to learn real-time operating systems and implement the concepts with hands-on projects and the continued guidance he provided throughout the semester. We also appreciate our Student Assistants(ISAs) for their guidance and knowledge transfer.

References Used

[1] Preetpal Kang's lecture notes of CMPE 244, Computer Engineering, San Jose State University, Feb-May 2017 [2] https://docs.google.com/document/d/1OdGS0QHKCdbrbAs_x62gmfSx_UdUPFPgZjwZnVDVHDg/preview [3] http://www.vishay.com/docs/83760/tcrt5000.pdf [4] https://developer.android.com/training/basics/firstapp/building-ui.html [5] https://www.tutorialspoint.com/android/android_bluetooth.htm [6] https://learn.sparkfun.com/tutorials/tags/eagle