Difference between revisions of "F18: Wireless sensor network"

Proj user22 (talk | contribs) (→Wireless Rx Implementation) |

Proj user22 (talk | contribs) (→References Used) |

||

| (69 intermediate revisions by the same user not shown) | |||

| Line 2: | Line 2: | ||

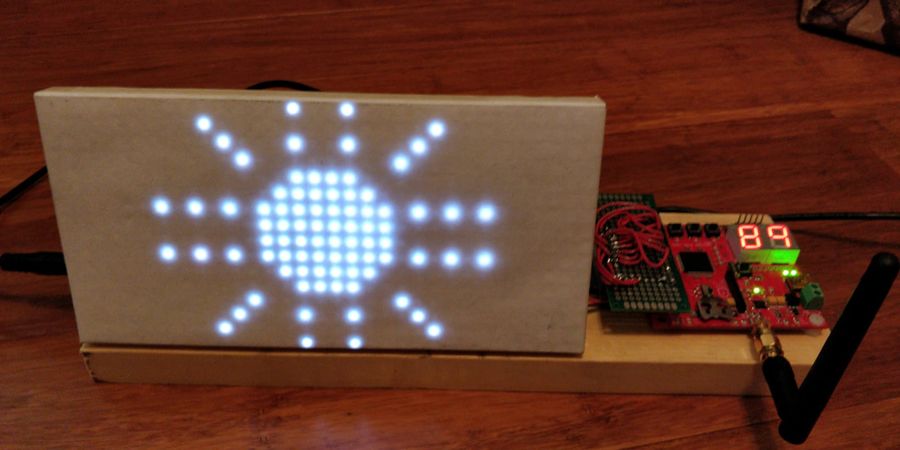

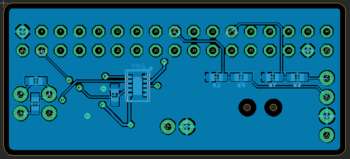

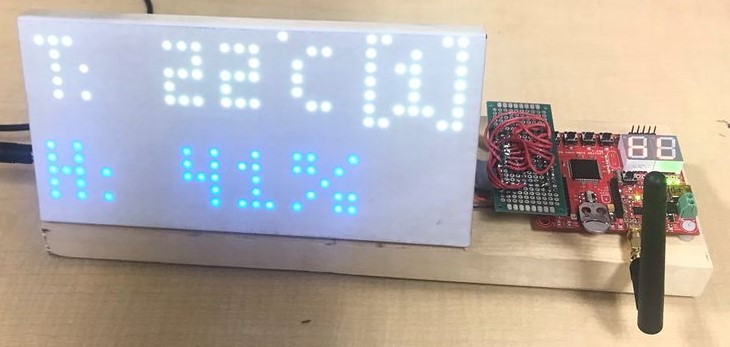

[[File:SensorNetwork MasterAssy front.jpeg|900px|thumb|center]] | [[File:SensorNetwork MasterAssy front.jpeg|900px|thumb|center]] | ||

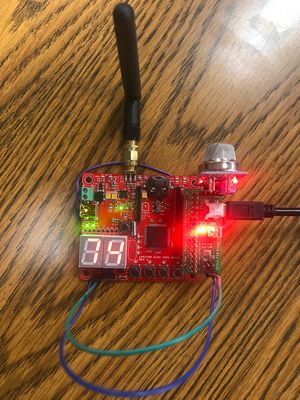

| − | Wireless Sensor | + | Wireless Sensor Network project displays data received from various nodes on a 16*32 LED Matrix which is connected with the Master node (SJOne Board).<br> |

| − | Each node | + | Each node measures various environmental parameters from its surrounding and send those data to master in form of packets. |

== Abstract == | == Abstract == | ||

| − | A wireless sensor network (WSN) consists of collection of sensor nodes. Each individual node consists of MCU with on-board sensors and Nordic wireless | + | A wireless sensor network (WSN) consists of collection of sensor nodes. Each individual node consists of MCU with on-board sensors and Nordic wireless for communication, which are distributed to monitor physical or environmental conditions, such as temperature, ambient light, humidity, air pressure and air quality. The SJ-One board contains an onboard light intensity sensor, and a custom PCB for the project has a combined Temperature, Pressure, and Humidity sensor and an air quality sensor. These sensor data are transmitted to a network coordinator which controls the wireless network. The coordinator board collates the data from all nodes, and displays it on a 16x32 LED matrix. |

== Objectives & Introduction == | == Objectives & Introduction == | ||

| − | This project was a culmination of a semester of learning about FreeRTOS and embedded software. Our objectives were to apply what we had learned, while also using our critical thinking and problem solving to figure out how to implement parts of our project that we didn't yet know how to do, such as interfacing with an LED Matrix display. | + | This project was a culmination of a semester of learning about FreeRTOS and embedded software. Our objectives were to apply what we had learned, while also using our critical thinking and problem solving to figure out how to implement parts of our project that we didn't yet know how to do, such as interfacing with an LED Matrix display and wireless communication. In this project we have created wireless network which includes one master node(SJ-One board), 4 slave nodes(SJ-One board) and LED matrix on which we will display data. Purpose of these network is to measure pressure, temperature, humidity and air quality of surrounding atmosphere. We are using MQ135 for air quality sensor and BME280 sensor for pressure, temperature, humidity. These network will work as follow. |

| + | |||

| + | *4 slave nodes have sensors on them which will sense atmospheric parameters and do some process on them to convert them into human readable data.<br> | ||

| + | *Slave will send these data to master node.<br> | ||

| + | *master node will transfer these data to LED matrix.<br> | ||

| + | *LED matrix will show us data one of the slave node which we have selected from master node.(Select node using on board switches on master node)<br> | ||

== Team Members & Responsibilities == | == Team Members & Responsibilities == | ||

| Line 227: | Line 232: | ||

* Project Demo and Review day | * Project Demo and Review day | ||

| Everyone | | Everyone | ||

| − | * | + | * Entire sensor network is functional and project is executed successfully |

|} | |} | ||

| Line 425: | Line 430: | ||

== Design & Implementation == | == Design & Implementation == | ||

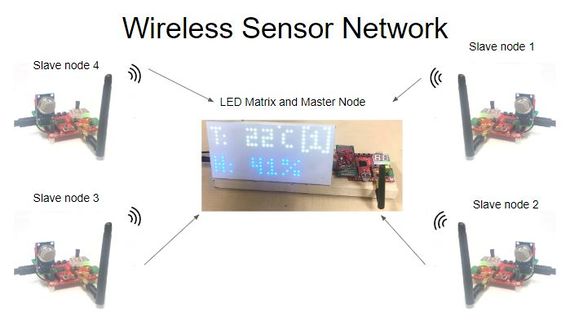

[[File:Wsn.jpg|570px|thumb|center|Wireless Sensor Network]] | [[File:Wsn.jpg|570px|thumb|center|Wireless Sensor Network]] | ||

| − | + | ||

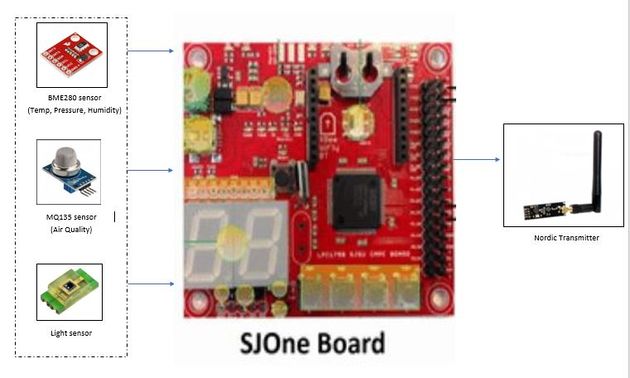

=== Hardware Design === | === Hardware Design === | ||

| − | The project is based around the SJ one board, which uses an LPC1758 Arm | + | The project is based around the SJ one board, which uses an LPC1758 Arm Cortex M3 microcontroller. The system design consists of two main devices: a wireless master with a display and a wireless sensor node (of which there are several). |

==== Wireless Master ==== | ==== Wireless Master ==== | ||

| Line 438: | Line 443: | ||

|[[File:MatrixInterfaceBoard bottom.jpg|300px|thumb|center|LED Matrix connector board]] | |[[File:MatrixInterfaceBoard bottom.jpg|300px|thumb|center|LED Matrix connector board]] | ||

|} | |} | ||

| + | <br> | ||

==== Wireless Slave Node ==== | ==== Wireless Slave Node ==== | ||

| Line 481: | Line 487: | ||

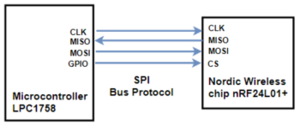

[[File:350px-Wireless_Chip_Interface.png|300px|thumb|right|Nordic SPI Hardware Interface]] | [[File:350px-Wireless_Chip_Interface.png|300px|thumb|right|Nordic SPI Hardware Interface]] | ||

| − | The Nordic nRF24L01+ wireless sensor is a highly integrated, ultra low power (ULP) 2Mbps RF transceiver IC for the 2.4GHz ISM (Industrial, Scientific and Medical) band. The nRF24L01+ is designed for operation in the frequency band of 2.400 - 2.483GHz. The high air data rate combined with two power saving modes make the nRF24L01+ very suitable for ultra-low power designs. This chip is interfaced with LPC1758 microcontroller of SJOne Board using SPI pins (MOSI, MISO, CLK, CS). It is | + | The Nordic nRF24L01+ wireless sensor is a highly integrated, ultra low power (ULP) 2Mbps RF transceiver IC for the 2.4GHz ISM (Industrial, Scientific and Medical) band. The nRF24L01+ is designed for operation in the frequency band of 2.400 - 2.483GHz. The high air data rate combined with two power saving modes make the nRF24L01+ very suitable for ultra-low power designs. This chip is interfaced with LPC1758 microcontroller of SJOne Board using SPI pins (MOSI, MISO, CLK, CS). It is an on-board chip on the SJOne Board, so no breakout board connections are required for this project. We had to attach an RP-SMA Adapter as well as antenna to communicate between the multiple nodes and the master board. |

=== Sensors === | === Sensors === | ||

| Line 488: | Line 494: | ||

Light Sensor is an on-board sensor in SJOne Board which interfaces with LPC1758 microcontroller at Port 0, pin 25 analog signal. This sensor shall give the raw value to the controller which will be processed by 12-bit microcontroller ADC. The output of the sensor is shown in a form of 'bulb' indication in LED Matrix | Light Sensor is an on-board sensor in SJOne Board which interfaces with LPC1758 microcontroller at Port 0, pin 25 analog signal. This sensor shall give the raw value to the controller which will be processed by 12-bit microcontroller ADC. The output of the sensor is shown in a form of 'bulb' indication in LED Matrix | ||

| − | ===== Temperature, Pressure | + | ===== Temperature, Pressure and Humidity (BME280)===== |

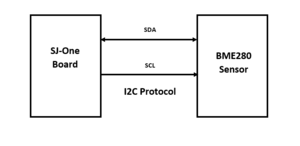

[[File:report2441.png|300px|thumb|right|Temperature, Pressure and Humidity Sensor]] | [[File:report2441.png|300px|thumb|right|Temperature, Pressure and Humidity Sensor]] | ||

| − | BME280 supports both SPI and I2C bus communication. In our wireless | + | BME280 supports both SPI and I2C bus communication. In our wireless project we have used I2C bus over SPI as it can read and write registers very easily compared to SPI. Here we are using BME280 sensor of Bosch which has a facility to measure Temperature, Pressure and Humidity using a single sensor. It only uses 3.6μA of current at 1Hz and requires 3.3V which is provided by SJOne board. |

| − | Operating Range : Temperature (- | + | Operating Range : Temperature (-40°C to +85°C), Pressure (300hPa to 1100hPa), Humidity (0% to 100%) with a tolerance of ±1%. |

| − | The sensor facilitates the user with various modes of operation which can be selected as per preferred environmental conditions. There are basically 3 modes for which range of IIR filter is varied. | + | The sensor facilitates the user with various modes of operation which can be selected as per preferred environmental conditions. There are basically 3 modes for which range of IIR filter is varied. These modes are:<br> |

| + | *Indoor Navigation<br> | ||

| + | *Weather Monitoring<br> | ||

| + | *Gaming Mode<br> | ||

| + | We can switch between any of these modes depending on our requirement. But for our project we are making use of the Indoor mode as our project will be tried and tested in confined spaces. | ||

===== Air Quality Sensor ===== | ===== Air Quality Sensor ===== | ||

| Line 501: | Line 511: | ||

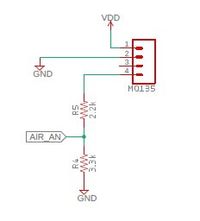

|[[File:report244.jpg|200px|thumb|right|Voltage divider]] | |[[File:report244.jpg|200px|thumb|right|Voltage divider]] | ||

|} | |} | ||

| − | MQ135 is used for air quality | + | MQ135 is used for measuring air quality index in this project. MQ135 is a low cost semiconductor sensor which can detect carbon-dioxide(CO2), benzene, smoke, ammonia(NH3), mono-nitrogen oxide. Sno2 is used for sensing gases as it's conductivity is low in clean air. As the concentration to these gases increases, sensor conductivity also increases. This module can give both analog and digital outputs. For this project we are using analog output. Analog output can go upto 5V, but our SJ-One board can support a max value of 3.3V as input, so we need voltage divider circuit which can convert 5V output from module to 3.3V. |

| − | As we are using analog pin output from module we will configure ADC driver of SJ-One board to read that ADC value and calculate ppm for CO2. Note that in this project we will calibrate our value such that we will get CO2 ppm. | + | As we are using analog pin output from module we will configure ADC driver of SJ-One board to read that ADC value and calculate the air quality index in ppm for CO2. Note that in this project we will calibrate our value such that we will get CO2 in ppm. |

== Software Design == | == Software Design == | ||

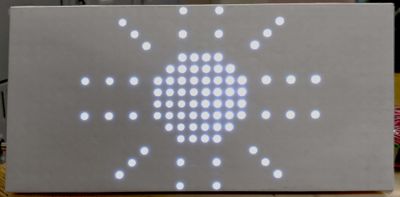

=== Master node with LED Matrix=== | === Master node with LED Matrix=== | ||

[[File:Master.jpeg|750px|thumb|center|Master node with LED Matrix]] | [[File:Master.jpeg|750px|thumb|center|Master node with LED Matrix]] | ||

| − | ==== General Layout ==== | + | ==== General Layout for displaying Data on LED Matrix==== |

We basically made a bit pattern on the matrix for the 4 screens and each of them displays: | We basically made a bit pattern on the matrix for the 4 screens and each of them displays: | ||

| Line 518: | Line 528: | ||

|- | |- | ||

! scope="row"| 1 | ! scope="row"| 1 | ||

| − | | Temperature | + | | Temperature and Node number |

| Humidity | | Humidity | ||

|- | |- | ||

| Line 526: | Line 536: | ||

|- | |- | ||

! scope="row"| 3 | ! scope="row"| 3 | ||

| − | | Pressure | + | | Pressure and node number |

| Air Quality | | Air Quality | ||

|- | |- | ||

| Line 543: | Line 553: | ||

|} | |} | ||

| − | It’s the layout of how the display would look for all the screens. We made use of a lookup table for units tens and hundreds positions to update the sensor value on the led matrix. For the LED matrix control signals, as mentioned above in the hardware part, we are making use of SJOne | + | It’s the layout of how the display would look for all the screens. We made use of a lookup table for units, tens and hundreds positions to update the sensor value on the led matrix. For the LED matrix control signals, as mentioned above in the hardware part, we are making use of 12 of the SJOne board's GPIO pins. |

==== MatrixTask: ==== | ==== MatrixTask: ==== | ||

| − | This task | + | This task will perform functions like initializing these GPIO pins to output. Here we are scanning the led matrix at a rate of about 500Hz. We have a row_selection function that will go through each and every row one by one. The OE(Output Enable) will be set to high to keep the display off while the data is being buffered to the matrix. We have an ev_switch function inside the matrix task that will buffer the data along with different colors for all the different sensors. Also the ev_switch function when displaying the temperature will switch to temp_color task which will choose different colors for various temperature ranges. The data is being buffered with a duty cycle just like the PWM to control the brightness of the matrix. After pushing the data on to a single row we turn the OE low to turn the display ON and then set the LAT(Latch) high to mark the end of data for the row. |

| − | + | ====== Pseudo-code ====== | |

| − | ==== | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

*Initialize GPIO pin as output.<br> | *Initialize GPIO pin as output.<br> | ||

| Line 563: | Line 566: | ||

*Assert the clock pin to high and then set it to low to shift the data in the pixel.<br> | *Assert the clock pin to high and then set it to low to shift the data in the pixel.<br> | ||

*Deassert the clock pin.<br> | *Deassert the clock pin.<br> | ||

| − | * | + | *Do this for 32 pixels and then set the LAT to high to indicate end of row and set OE low to display the data.<br> |

| − | *Introduce some delay which will be proportional to the ON time of | + | *Introduce some delay which will be proportional to the ON time of LED i.e. set the duty cycle.<br> |

for (int j = 0; j < no_of_rows; j++) { | for (int j = 0; j < no_of_rows; j++) { | ||

| Line 577: | Line 580: | ||

lat.setHigh(); | lat.setHigh(); | ||

oe.setLow(); | oe.setLow(); | ||

| − | delay_us( | + | delay_us(ON_time); |

} | } | ||

| − | |||

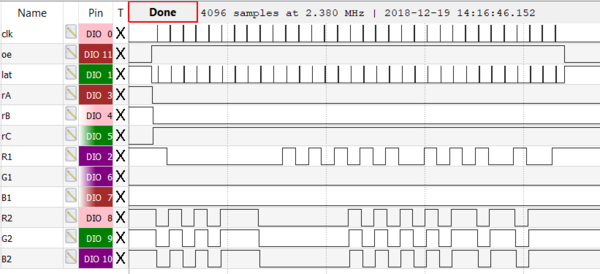

The image below shows a logic analyzer capture of the display of one row of the matrix. | The image below shows a logic analyzer capture of the display of one row of the matrix. | ||

{| | {| | ||

|[[File:Matrix Logic.PNG|600px|thumb|left|Logic Analyzer of LED matrix]] | |[[File:Matrix Logic.PNG|600px|thumb|left|Logic Analyzer of LED matrix]] | ||

| + | |} | ||

| + | ==== SwitcherTask: ==== | ||

| + | Its has a medium priority and it will cycle between four screens for about 2 seconds for each screen thereby blocking this task for 2 seconds. We have 2 pointers top and bottom that will fetch the layout from the lookup table and based on the value of the switcher variable it will update layout that it has to display. If the value of the switcher variable is 1, top and bottom will fetch temperature and humidity layout for the top and the bottom portion of LED Matrix respectively. | ||

| + | |||

| + | ==== Matrix_Value_Update_Task ==== | ||

| + | Here we have a matrix_value_update function that will parse the sensor values received from the nodes using value_extractor function and assign it to a values struct object which has a 0-9 value for the struct members units, tens and hundreds. These values are then passed to a lookup_switch function which will lookup a matrix of 5x3 that matches the 0-9 digit value and assign it to a pointer. The data indicated by the pointer will overwrite the general layout for each sensor value thereby updating the sensor values on the LED Matrix. The same will follow when we update the node number for screen 1 and screen 2. The switching between the nodes has been implemented in this task. We scan the switches and based on which switch is pressed we display the respective sensor values. | ||

| + | |||

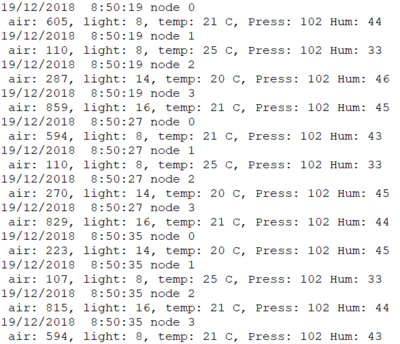

| + | ====Datalogging Task==== | ||

| + | The master module, in addition to displaying the data received from all of the nodes, logs the data to an SD card on the SJ One board. | ||

| + | |||

| + | The data is stored in a structure which holds all sensor values for all nodes. The data for each node is combined into a string using sprintf(), along with the timestamp from rtc_gettime(), and that string is appended to a text file named with today's date. | ||

| + | |||

| + | ===== Storage function ===== | ||

| + | a = rtc_gettime(); | ||

| + | for(int i = 0; i<4; i++) | ||

| + | { | ||

| + | //Create filename | ||

| + | sprintf(fs, "1:SensorData_%i%i%i.txt", a.day, a.month, a.year); | ||

| + | //Create data string | ||

| + | sprintf(ds,"%i/%i/%i %i:%i:%i node %i \n air: %i, light: %i, temp: | ||

| + | %i C, Press: %i Hum: %i\% \n", a.day, a.month, a.year, a.hour, | ||

| + | a.min, a.sec, i, s1[i]._air_q,s1[i]._light, | ||

| + | s1[i]._temp,s1[i]._psi,s1[i]._hum); | ||

| + | //Append data to log file | ||

| + | Storage::append(fs,ds,strlen(ds), 0); | ||

| + | } | ||

| + | This storage function is inside of a logging task, which waits for a binary semaphore to be sent from the matrix task, signaling that it the screen is changing values, and it is okay to store the data. The reason for this is that writing the data to the SD card is slow, and if it was allowed to happen anytime, it would cause a flicker in the screen. Like this, the delay happens when the screen is already changing, therefore the small off time is not noticeable. | ||

| + | |||

| + | A sample of the logged data is below: | ||

| + | |||

| + | {| | ||

| + | |[[File:DataLogging_sample.PNG|400px|thumb|left|Logged data]]<br> | ||

|} | |} | ||

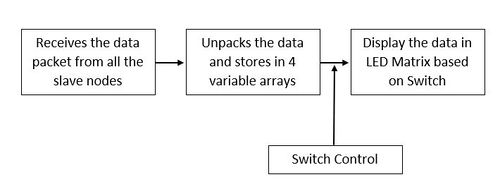

====Wireless Rx Implementation==== | ====Wireless Rx Implementation==== | ||

| − | [[File:Master_wireless_flow.jpeg|500px|thumb|center|Wireless receiver flow]] | + | {| |

| + | |[[File:Master_wireless_flow.jpeg|500px|thumb|center|Wireless receiver flow]] | ||

| + | |} | ||

| − | Nordic Wireless Rx and Tx implementation is done using Preet's Low Powered Mesh Network stack.Each packet is sent via an existing route, and if route has changed, a new route is automatically discovered using a special retry packet.However for our application, all the slaves nodes directly transmit data to the master node so there won't be any other nodes in the path. The minimum payload is 9 bytes, of which, 8 bytes will be the mesh header overhead which contains the network source and destination information, along with packet type and hop count information. | + | Nordic Wireless Rx and Tx implementation is done using Preet's Low Powered Mesh Network stack. Each packet is sent via an existing route, and if route has changed, a new route is automatically discovered using a special retry packet. However for our application, all the slaves nodes directly transmit data to the master node so there won't be any other nodes in the path. The minimum payload is 9 bytes, of which, 8 bytes will be the mesh header overhead which contains the network source and destination information, along with packet type and hop count information. |

| − | For example, if the payload size is 32 bytes, then 8 bytes are used by the network header and 24 bytes are free to be used for transmitting the data.The mesh_packet_t is a structure that is used to transmit the data to understand the data of the wireless packet. It has 4 | + | For example, if the payload size is 32 bytes, then 8 bytes are used by the network header and 24 bytes are free to be used for transmitting the data. The mesh_packet_t is a structure that is used to transmit the data to understand the data of the wireless packet. It has 4 variables. |

*nwk : Packet network address | *nwk : Packet network address | ||

*mac : packet physical address | *mac : packet physical address | ||

| − | *info:Packet header | + | *info: Packet header |

| − | *Data:Type of data to be sent which is 24 bytes. | + | *Data: Type of data to be sent which is 24 bytes. |

| + | |||

| + | In wireless rx, we create an array of structure objects which contains fields defining five sensor data. The data received from all the nodes can be stored in these struct objects. | ||

| + | |||

| + | struct sensor_data{ | ||

| + | int air_quality, | ||

| + | light, | ||

| + | temperature, | ||

| + | pressure, | ||

| + | humidity; | ||

| + | }; | ||

| + | sensor_data sensor[4] = {0}; | ||

| + | |||

| + | We send the command to the nodes whose data needs to be read using '''wireless_send()'''. It is described in Wireless Tx implementation in upcoming section. | ||

| + | Once the command is sent, we check whether any pack is received using the below function. | ||

| + | |||

| + | wireless_get_rx_pkt(&rcvPkt, timeout_ms) | ||

| + | |||

| + | This function is periodically called to get a queued packet. It takes variable of type mesh_packet_t to store the received packet and queue wait time. It returns true if a packet is dequeued or false if there is no packet. Once the packet is received, the data from the sensor nodes can be extracted using the function wireless_deform_packet() as defined below. This data is then stored in the struct object and later the data is displayed in the LED Matrix based on the switch input. | ||

| + | |||

| + | if (wireless_get_rx_pkt(&rx, 1000)) | ||

| + | wireless_deform_pkt(&rx, 5, &s1[i], sizeof(s1[0])); | ||

| + | |||

| + | The above statement deforms the packet only when it receives the packet within 1000ms. First parameter of wireless_deform_packet() is the received packet, followed by the size of the packet. Third parameter is the buffer variable(for our case, it is an array of struct object) in which we need to store the received packet data into, followed by the size of the buffer variable. | ||

=== Slave Node (Sensor reading) === | === Slave Node (Sensor reading) === | ||

| Line 604: | Line 663: | ||

|} | |} | ||

| − | This section includes implementation and calculations for all sensors(Temperature,Pressure,Humidity,Air Quality | + | This section includes implementation and calculations for all sensors (i.e. Temperature, Pressure, Humidity, Air Quality and Light) implemented during software design in the slave node. These sensors reads the data and sends the data to SJOne board which processes the data and performs the desired calibrations. These calibrations are required to convert the raw values to a standard readable value. These sensor readings are then combined together to form a single packet and transmitted wirelessly to master node using Nordic nRF24L01+ chip. |

==== Pseudo-code ==== | ==== Pseudo-code ==== | ||

| Line 615: | Line 674: | ||

*Initialize wireless parameters | *Initialize wireless parameters | ||

*Initialize Air quality sensor variables | *Initialize Air quality sensor variables | ||

| − | *Start while | + | *Start the while loop and calibrate ADC readings according to atmosphere CO2 value |

| − | |||

*Calculation:<br> | *Calculation:<br> | ||

MQ_135 = adc0_get_reading(3); | MQ_135 = adc0_get_reading(3); | ||

| Line 622: | Line 680: | ||

temp = __resistance/33; | temp = __resistance/33; | ||

air_quality = (PARA*pow(temp,-PARB)); | air_quality = (PARA*pow(temp,-PARB)); | ||

| − | *Get temperature data in form of float from the sensor by reading 0xFA through 0xFC and | + | *Get temperature data in form of float from the sensor by reading registers 0xFA through 0xFC and use it to calculate raw temperature data.<br> |

| − | *Raw data is converted into degree | + | *Raw data is converted into degree °C using some mathematical calculation as shown below<br> |

temp = (temp * 5 + 128) >> 8; | temp = (temp * 5 + 128) >> 8; | ||

tempf = (float)temp; | tempf = (float)temp; | ||

return (tempf/100.0f); | return (tempf/100.0f); | ||

| − | *Get pressure data in form of float from the sensor by reading 0xF7 through 0xF9 and combining it to get raw pressure data.<br> | + | *Get pressure data in form of float from the sensor by reading registers 0xF7 through 0xF9 and combining it to get raw pressure data.<br> |

*This raw pressure data is converted into actual pressure data in form of kPa.<br> | *This raw pressure data is converted into actual pressure data in form of kPa.<br> | ||

press = (((1048576 - press_raw) - (var2 >> 12))) * 3125; | press = (((1048576 - press_raw) - (var2 >> 12))) * 3125; | ||

| Line 636: | Line 694: | ||

return (pressf/1000.0f); | return (pressf/1000.0f); | ||

| − | *Get humidity data in form of float from the sensor by reading 0xFD through 0xFF and combining it to get raw humidity data.<br> | + | *Get humidity data in form of float from the sensor by reading registers 0xFD through 0xFF and combining it to get raw humidity data.<br> |

| − | *This raw humidity data is converted into real value | + | *This raw humidity data is converted into real value to represent a precent.<br> |

v_x1 = (v_x1 > 419430400 ? 419430400 : v_x1); | v_x1 = (v_x1 > 419430400 ? 419430400 : v_x1); | ||

humf = (float)(v_x1 >> 12); | humf = (float)(v_x1 >> 12); | ||

| Line 643: | Line 701: | ||

====Wireless Tx Implementation==== | ====Wireless Tx Implementation==== | ||

| − | The calibrated sensor values are stored into a single int array of size 5 to store all 5 sensor readings. The following function "wireless_send()" is responsible to send the packet wherein the address of the destination node, type of mesh protocol used, pointer to the data to send, length of the data to send and number of hops is passed as a parameter. It returns true if packet is sent successfully. For our application, we are passing the below parameters to the wireless send() | + | The calibrated sensor values are stored into a single int array of size 5 to store all 5 sensor readings. The following function "wireless_send()" is responsible to send the packet wherein the address of the destination node, type of mesh protocol used, pointer to the data to send, length of the data to send and number of hops is passed as a parameter. It returns true if the packet is sent successfully. For our application, we are passing the below parameters to the wireless send() |

*Our Master LED Matrix node address is selected as 5 | *Our Master LED Matrix node address is selected as 5 | ||

*The mesh protocol used is mesh no-acknowledgement | *The mesh protocol used is mesh no-acknowledgement | ||

*We will send the int sensor array along with the size. | *We will send the int sensor array along with the size. | ||

| − | *For our application, since all the slave nodes directly send data to master node, there shall be no intermediate node, hence the max_hops is | + | *For our application, since all the slave nodes directly send data to master node, there shall be no intermediate node, hence the max_hops is kept 0 in our implementation. |

Below is the function: <br> | Below is the function: <br> | ||

| Line 662: | Line 720: | ||

=== Sensors === | === Sensors === | ||

===== Air quality sensor calibration ===== | ===== Air quality sensor calibration ===== | ||

| − | To get accurate and stable data, we | + | To get accurate and stable data, we needed to keep MQ135 constantly plugged to the power source for 12 to 24 hours and only then we were able to calibrate the sensor reading to accurate values. Also, every time we removed power supply we needed to reset the calibration factor. |

=== LED Matrix === | === LED Matrix === | ||

| Line 668: | Line 726: | ||

*Header breakout did not help, investigating possibility of an issue with the matrix itself. | *Header breakout did not help, investigating possibility of an issue with the matrix itself. | ||

*Issue resolved. The breakout board did end up fixing the connection issue, but an erroneous line of code which set the latch too early was the main problem. | *Issue resolved. The breakout board did end up fixing the connection issue, but an erroneous line of code which set the latch too early was the main problem. | ||

| − | Synchronizing all the task after integrating the wireless part was | + | Synchronizing all the task after integrating the wireless part was a challenge. |

| − | *We were able synchronize the tasks pretty well by changing the | + | *We were able synchronize the tasks pretty well by changing the priorities and eliminating certain delays. |

| − | The data logger task gave a blackout while the sensor data was being displayed | + | The data logger task gave a blackout while the sensor data was being displayed on the LED Matrix. |

| − | * | + | *Solved the issue by synchronizing this task and taking the log of the data when the LED Matrix switches to next screen. |

=== RTC === | === RTC === | ||

| − | Time just kept resetting on board reset, even after setting the time. We figured out | + | Time just kept resetting on board reset, even after setting the time. We figured out we had to store some value in "day of year" register to satisfy the if condition that goes to default if DOY register isn't within the acceptable range. Additionally, the terminal task did not support entering a DOY parameter, therefore the time command handler had to be updated to accept the input. |

== Conclusion == | == Conclusion == | ||

| − | + | We successfully implemented Wireless Sensor Network which can sense different environmental variables. It gave us hands on working experience on FreeRTOS and how to write drivers. This project gave us a good experience of working with a team to manage the time and tasks assigned to each one of us. We faced many difficulties in the getting LED Matrix to work, I2C communication, RTC and synchronizing different task, but were eventually able to fulfill the objective of this project through coordinated efforts of all the members. There was a steep learning curve and we all gained lots of experience by developing this project. | |

| − | |||

=== Project Video === | === Project Video === | ||

[https://youtu.be/VuM8LY8q-X0 Demo] | [https://youtu.be/VuM8LY8q-X0 Demo] | ||

=== Project Source Code === | === Project Source Code === | ||

| − | * [https:// | + | * [https://github.com/reldnach/Wireless-Sensor-Network-CMPE-244 GitHub Code Link] |

== References == | == References == | ||

| Line 695: | Line 752: | ||

*Low Powered Mesh Network Stack: http://socialledge.com/sjsu/index.php/SJ_One_Board#Wireless<br> | *Low Powered Mesh Network Stack: http://socialledge.com/sjsu/index.php/SJ_One_Board#Wireless<br> | ||

*Nordic nRFL2401+ tutorial: http://paulfjujo.free.fr/_NRF2401_Transceiver/datas/nrf24l01_tutorial_0.pdf<br> | *Nordic nRFL2401+ tutorial: http://paulfjujo.free.fr/_NRF2401_Transceiver/datas/nrf24l01_tutorial_0.pdf<br> | ||

| − | *MQ-135: https://blog.robberg.net/mq-135-arduino/<br> | + | *Building a Wireless Sensor Network with the nRF24L01+(Part 1-6): https://www.youtube.com/watch?v=RrmpN1_Py_4&list=PLufvMUgRha2bHfX1_LReVowCrEeAblzAP<br> |

| − | + | *MQ-135: | |

| − | + | **https://blog.robberg.net/mq-135-arduino/<br> | |

| + | **https://hackaday.io/project/3475-sniffing-trinket/log/12363-mq135-arduino-library<br> | ||

| + | **https://www.engineeringtoolbox.com/co2-comfort-level-d_1024.html<br> | ||

Latest revision as of 05:21, 20 December 2018

Contents

- 1 Wireless Sensor Network

- 2 Abstract

- 3 Objectives & Introduction

- 4 Team Members & Responsibilities

- 5 Schedule

- 6 Parts List & Cost

- 7 Design & Implementation

- 8 Hardware Interface

- 9 Software Design

- 10 Testing & Technical Challenges

- 11 Conclusion

- 12 References

Wireless Sensor Network

Wireless Sensor Network project displays data received from various nodes on a 16*32 LED Matrix which is connected with the Master node (SJOne Board).

Each node measures various environmental parameters from its surrounding and send those data to master in form of packets.

Abstract

A wireless sensor network (WSN) consists of collection of sensor nodes. Each individual node consists of MCU with on-board sensors and Nordic wireless for communication, which are distributed to monitor physical or environmental conditions, such as temperature, ambient light, humidity, air pressure and air quality. The SJ-One board contains an onboard light intensity sensor, and a custom PCB for the project has a combined Temperature, Pressure, and Humidity sensor and an air quality sensor. These sensor data are transmitted to a network coordinator which controls the wireless network. The coordinator board collates the data from all nodes, and displays it on a 16x32 LED matrix.

Objectives & Introduction

This project was a culmination of a semester of learning about FreeRTOS and embedded software. Our objectives were to apply what we had learned, while also using our critical thinking and problem solving to figure out how to implement parts of our project that we didn't yet know how to do, such as interfacing with an LED Matrix display and wireless communication. In this project we have created wireless network which includes one master node(SJ-One board), 4 slave nodes(SJ-One board) and LED matrix on which we will display data. Purpose of these network is to measure pressure, temperature, humidity and air quality of surrounding atmosphere. We are using MQ135 for air quality sensor and BME280 sensor for pressure, temperature, humidity. These network will work as follow.

- 4 slave nodes have sensors on them which will sense atmospheric parameters and do some process on them to convert them into human readable data.

- Slave will send these data to master node.

- master node will transfer these data to LED matrix.

- LED matrix will show us data one of the slave node which we have selected from master node.(Select node using on board switches on master node)

Team Members & Responsibilities

- Halak Vyas

- Temperature, Pressure and Humidity Sensor Driver (BME280), RTC Config (primary), Wireless driver (secondary), .

- Jay Parsana

- Display driver (primary), Sensor drivers

- Prashant Gandhi

- PCB Assembly, PCB Design (review), Sensor drivers

- Tristan French

- Team lead, PCB Design (primary), PCB Assembly (secondary), Display driver (secondary)

- Vatsal Makani

- Wireless driver (Primary), PCB design (secondary), Wiki lead

Schedule

| Week# | Date | Task | Actual |

|---|---|---|---|

| 1 | 10/9 | Tristan

Everyone

|

Tristan

Everyone

|

| 2 | 10/16 | Everyone

|

Everyone

Unforeseen issues

|

| 3 | 10/23 | Vatsal

|

Vatsal

|

| 4 | 10/30 | Halak

Tristan

|

Halak

Tristan

|

| 5 | 11/6 | Halak

Jay

Prashant

Tristan

Vatsal

|

Halak

Jay

Prashant

Tristan

Vatsal

|

| 6 | 11/13 | Halak

Jay

Prashant

Tristan

Vatsal

|

Halak

Jay

Prashant

Tristan

Vatsal

|

| 7 | 11/20 | Halak

Jay

Prashant

Tristan

Vatsal

|

Halak

Jay

Prashant

Tristan

Vatsal

|

| 8 | 11/27 | Halak

Jay

Prashant

Tristan

Vatsal

|

Halak

Jay

Prashant

Tristan

Vatsal

|

| 9 | 12/4 | Halak

Jay

Prashant

Tristan

Vatsal

Everyone

|

Halak

Jay

Prashant

Tristan

Vatsal

Everyone

|

| 10 | 12/11 | Everyone

|

Everyone

|

| 11 | 12/19 | Everyone

|

Everyone

|

Parts List & Cost

Top level BoM

| Item# | Part | Source | Quantity | Unit

Cost($) |

Total

Cost($) |

|---|---|---|---|---|---|

| 1 | SJ One Board | Preet | 5 | 80.00 | 400.00 |

| 2 | Adafruit RGB LED Matrix | LED Matrix | 1 | 24.95 | 24.95 |

| 3 | LED matrix Connector board | LED Matrix | 1 | 1.00 | 1.00 |

| 4 | Led Matrix Power Adapter | N/A (Stock) | 1 | N/A | 0.00 |

| 5 | Air Quality Sensor | Willwin | 4 | 4.50 | 18.00 |

| 6 | Custom Sensor PCB Assembly | In House | 4 | 14.72 | 58.87 |

| 7 | CR1225 RTC Battries | Amazon | 10 | 0.7 | 6.99 |

Total (minus SJ One cost): $109.82

Custom PCB BoM

| Item# | Part | Source | Quantity | Unit

Cost($) |

Total

Cost($) |

|---|---|---|---|---|---|

| 1 | Custom Sensor PCB | JLCPCB | 4 | 0.20 | 0.80 |

| 2 | SMD P, T, H sensor | Digikey | 1 | 6.628 | 6.628 |

| 3 | USB mini-B SMD receptacle | Digikey | 1 | 0.87 | 0.87 |

| 4 | 2-position screw terminal, .1in pitch | Digikey | 1 | 0.595 | 0.595 |

| 5 | 2-pin male header, .1in pitch | Digikey | 2 | 0.099 | 0.198 |

| 6 | 4-pin female header, .1in pitch | Digikey | 1 | 0.45 | 0.45 |

| 7 | 17-pin female header w/ long pins, .1in pitch | Digikey | 2 | 1.719 | 3.438 |

| 8 | Red SMD LED, 0603 | Digikey | 2 | N/A | 0.00 |

| 9 | 100 Ohm SMD resistor, 0603 | Digikey | 1 | 0.30 | 0.30 |

| 10 | 300 Ohm SMD resistor, 0603 | Digikey | 1 | 0.066 | 0.066 |

| 11 | 2.2 kOhm SMD resistor, 0603 | Digikey | 2 | 0.024 | 0.048 |

| 12 | 3.3 kOhm SMD resistor, 0603 | Digikey | 2 | 0.024 | 0.048 |

| 13 | 4.7 kOhm SMD resistor, 0603 | Digikey | 4 | 0.30 | 1.20 |

| 14 | 0.1uF ceramic capacitor, 0603 | Digikey | 2 | 0.038 | 0.076 |

| 15 | SMD Air Quality sensor | Digikey | 1 (optional) | 12.88 | 0.00 |

| 16 | 2-pin jumper, .1in pitch | Digikey | 1 (optional) | 0.45 | 0.00 |

Total: $14.72

Design & Implementation

Hardware Design

The project is based around the SJ one board, which uses an LPC1758 Arm Cortex M3 microcontroller. The system design consists of two main devices: a wireless master with a display and a wireless sensor node (of which there are several).

Wireless Master

The master board's role is to drive the LED matrix, and receive and log the sensor data. The majority of the functionality of the master can be handled with the default hardware on the SJ One board. The only addition necessary was an antenna for the wireless chip, and a custom connector board.

The custom connector board mounts to the 17x2 header on the SJ One board, and the pins were routed to the appropriate pins of a 2x8 pin header, which the matrix plugged into.

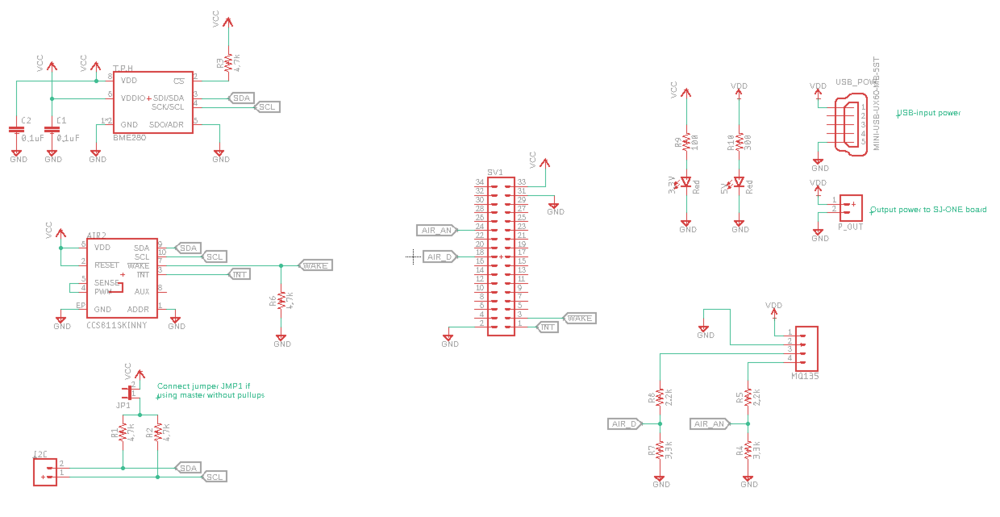

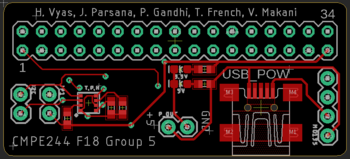

Wireless Slave Node

Each slave node has to interface with each of its sensors and send the data wirelessly. The sensors were interfaced using a custom PCB shown below.

The PCB accomplishes the following:

- Accept USB mini power

- Provide 5V output to power SJ One

- Robust and compact mounting to SJ One board

- Provide I2C connection for BME280

- Mounting header for MQ-135

- Voltage divider to convert 5V analog output from MQ-135 to 3.3V

- Leave unused SJ One pins available for other uses (accessible through extra long header pins)

The PCB design was completed in Eagle

Hardware Interface

The system utilizes several different interfaces to achieve its purpose. Specifically, it uses a 2.4GHz Nordic Wireless protocol, I2C to read sensors, an ADC to read sensors, and SPI to log data on an SD card.

LED Matrix

The LED matrix is controlled through a 12-pin header consisting of the following pins:

- An output enable (oe) which turns the LEDs on when pulled low

- Latch pin (lat) which prevents data being shifted into the shift registers when set high

- Clock pin (clk) which triggers a shift on the shift registers

- Three Address pins (rA, rB, and rC) to select the row

- Three RGB pins for the top half (R1, G1, and B1)

- Three RGB pins for the bottom half (R2, G2, and B2)

Nordic Wireless

The Nordic nRF24L01+ wireless sensor is a highly integrated, ultra low power (ULP) 2Mbps RF transceiver IC for the 2.4GHz ISM (Industrial, Scientific and Medical) band. The nRF24L01+ is designed for operation in the frequency band of 2.400 - 2.483GHz. The high air data rate combined with two power saving modes make the nRF24L01+ very suitable for ultra-low power designs. This chip is interfaced with LPC1758 microcontroller of SJOne Board using SPI pins (MOSI, MISO, CLK, CS). It is an on-board chip on the SJOne Board, so no breakout board connections are required for this project. We had to attach an RP-SMA Adapter as well as antenna to communicate between the multiple nodes and the master board.

Sensors

Light Sensor

Light Sensor is an on-board sensor in SJOne Board which interfaces with LPC1758 microcontroller at Port 0, pin 25 analog signal. This sensor shall give the raw value to the controller which will be processed by 12-bit microcontroller ADC. The output of the sensor is shown in a form of 'bulb' indication in LED Matrix

Temperature, Pressure and Humidity (BME280)

BME280 supports both SPI and I2C bus communication. In our wireless project we have used I2C bus over SPI as it can read and write registers very easily compared to SPI. Here we are using BME280 sensor of Bosch which has a facility to measure Temperature, Pressure and Humidity using a single sensor. It only uses 3.6μA of current at 1Hz and requires 3.3V which is provided by SJOne board.

Operating Range : Temperature (-40°C to +85°C), Pressure (300hPa to 1100hPa), Humidity (0% to 100%) with a tolerance of ±1%.

The sensor facilitates the user with various modes of operation which can be selected as per preferred environmental conditions. There are basically 3 modes for which range of IIR filter is varied. These modes are:

- Indoor Navigation

- Weather Monitoring

- Gaming Mode

We can switch between any of these modes depending on our requirement. But for our project we are making use of the Indoor mode as our project will be tried and tested in confined spaces.

Air Quality Sensor

MQ135 is used for measuring air quality index in this project. MQ135 is a low cost semiconductor sensor which can detect carbon-dioxide(CO2), benzene, smoke, ammonia(NH3), mono-nitrogen oxide. Sno2 is used for sensing gases as it's conductivity is low in clean air. As the concentration to these gases increases, sensor conductivity also increases. This module can give both analog and digital outputs. For this project we are using analog output. Analog output can go upto 5V, but our SJ-One board can support a max value of 3.3V as input, so we need voltage divider circuit which can convert 5V output from module to 3.3V. As we are using analog pin output from module we will configure ADC driver of SJ-One board to read that ADC value and calculate the air quality index in ppm for CO2. Note that in this project we will calibrate our value such that we will get CO2 in ppm.

Software Design

Master node with LED Matrix

General Layout for displaying Data on LED Matrix

We basically made a bit pattern on the matrix for the 4 screens and each of them displays:

| Screen# | Row (0:7) | Row (8:15) |

|---|---|---|

| 1 | Temperature and Node number | Humidity |

| 2 | Temperature(Sun) | Temperature(Sun) |

| 3 | Pressure and node number | Air Quality |

| 4 | Light bulb with bars | Light bulb with bars |

| | |

It’s the layout of how the display would look for all the screens. We made use of a lookup table for units, tens and hundreds positions to update the sensor value on the led matrix. For the LED matrix control signals, as mentioned above in the hardware part, we are making use of 12 of the SJOne board's GPIO pins.

MatrixTask:

This task will perform functions like initializing these GPIO pins to output. Here we are scanning the led matrix at a rate of about 500Hz. We have a row_selection function that will go through each and every row one by one. The OE(Output Enable) will be set to high to keep the display off while the data is being buffered to the matrix. We have an ev_switch function inside the matrix task that will buffer the data along with different colors for all the different sensors. Also the ev_switch function when displaying the temperature will switch to temp_color task which will choose different colors for various temperature ranges. The data is being buffered with a duty cycle just like the PWM to control the brightness of the matrix. After pushing the data on to a single row we turn the OE low to turn the display ON and then set the LAT(Latch) high to mark the end of data for the row.

Pseudo-code

- Initialize GPIO pin as output.

- Set OE(Output Enable) to high and LAT(Latch) to low.

- Select row to which the data will be shifted.

- Enter the RBG data for a single pixel.

- Assert the clock pin to high and then set it to low to shift the data in the pixel.

- Deassert the clock pin.

- Do this for 32 pixels and then set the LAT to high to indicate end of row and set OE low to display the data.

- Introduce some delay which will be proportional to the ON time of LED i.e. set the duty cycle.

for (int j = 0; j < no_of_rows; j++) {

lat.setLow();

oe.setHigh();

row_selection(i);

for (int j = 0; j < no_of_pixel_on_each_row; j++) {

input_data(i, j);

clk.setHigh();

clk.setLow();

}

lat.setHigh();

oe.setLow();

delay_us(ON_time);

}

The image below shows a logic analyzer capture of the display of one row of the matrix.

SwitcherTask:

Its has a medium priority and it will cycle between four screens for about 2 seconds for each screen thereby blocking this task for 2 seconds. We have 2 pointers top and bottom that will fetch the layout from the lookup table and based on the value of the switcher variable it will update layout that it has to display. If the value of the switcher variable is 1, top and bottom will fetch temperature and humidity layout for the top and the bottom portion of LED Matrix respectively.

Matrix_Value_Update_Task

Here we have a matrix_value_update function that will parse the sensor values received from the nodes using value_extractor function and assign it to a values struct object which has a 0-9 value for the struct members units, tens and hundreds. These values are then passed to a lookup_switch function which will lookup a matrix of 5x3 that matches the 0-9 digit value and assign it to a pointer. The data indicated by the pointer will overwrite the general layout for each sensor value thereby updating the sensor values on the LED Matrix. The same will follow when we update the node number for screen 1 and screen 2. The switching between the nodes has been implemented in this task. We scan the switches and based on which switch is pressed we display the respective sensor values.

Datalogging Task

The master module, in addition to displaying the data received from all of the nodes, logs the data to an SD card on the SJ One board.

The data is stored in a structure which holds all sensor values for all nodes. The data for each node is combined into a string using sprintf(), along with the timestamp from rtc_gettime(), and that string is appended to a text file named with today's date.

Storage function

a = rtc_gettime();

for(int i = 0; i<4; i++)

{

//Create filename

sprintf(fs, "1:SensorData_%i%i%i.txt", a.day, a.month, a.year);

//Create data string

sprintf(ds,"%i/%i/%i %i:%i:%i node %i \n air: %i, light: %i, temp:

%i C, Press: %i Hum: %i\% \n", a.day, a.month, a.year, a.hour,

a.min, a.sec, i, s1[i]._air_q,s1[i]._light,

s1[i]._temp,s1[i]._psi,s1[i]._hum);

//Append data to log file

Storage::append(fs,ds,strlen(ds), 0);

}

This storage function is inside of a logging task, which waits for a binary semaphore to be sent from the matrix task, signaling that it the screen is changing values, and it is okay to store the data. The reason for this is that writing the data to the SD card is slow, and if it was allowed to happen anytime, it would cause a flicker in the screen. Like this, the delay happens when the screen is already changing, therefore the small off time is not noticeable.

A sample of the logged data is below:

Wireless Rx Implementation

Nordic Wireless Rx and Tx implementation is done using Preet's Low Powered Mesh Network stack. Each packet is sent via an existing route, and if route has changed, a new route is automatically discovered using a special retry packet. However for our application, all the slaves nodes directly transmit data to the master node so there won't be any other nodes in the path. The minimum payload is 9 bytes, of which, 8 bytes will be the mesh header overhead which contains the network source and destination information, along with packet type and hop count information.

For example, if the payload size is 32 bytes, then 8 bytes are used by the network header and 24 bytes are free to be used for transmitting the data. The mesh_packet_t is a structure that is used to transmit the data to understand the data of the wireless packet. It has 4 variables.

- nwk : Packet network address

- mac : packet physical address

- info: Packet header

- Data: Type of data to be sent which is 24 bytes.

In wireless rx, we create an array of structure objects which contains fields defining five sensor data. The data received from all the nodes can be stored in these struct objects.

struct sensor_data{

int air_quality,

light,

temperature,

pressure,

humidity;

};

sensor_data sensor[4] = {0};

We send the command to the nodes whose data needs to be read using wireless_send(). It is described in Wireless Tx implementation in upcoming section. Once the command is sent, we check whether any pack is received using the below function.

wireless_get_rx_pkt(&rcvPkt, timeout_ms)

This function is periodically called to get a queued packet. It takes variable of type mesh_packet_t to store the received packet and queue wait time. It returns true if a packet is dequeued or false if there is no packet. Once the packet is received, the data from the sensor nodes can be extracted using the function wireless_deform_packet() as defined below. This data is then stored in the struct object and later the data is displayed in the LED Matrix based on the switch input.

if (wireless_get_rx_pkt(&rx, 1000))

wireless_deform_pkt(&rx, 5, &s1[i], sizeof(s1[0]));

The above statement deforms the packet only when it receives the packet within 1000ms. First parameter of wireless_deform_packet() is the received packet, followed by the size of the packet. Third parameter is the buffer variable(for our case, it is an array of struct object) in which we need to store the received packet data into, followed by the size of the buffer variable.

Slave Node (Sensor reading)

This section includes implementation and calculations for all sensors (i.e. Temperature, Pressure, Humidity, Air Quality and Light) implemented during software design in the slave node. These sensors reads the data and sends the data to SJOne board which processes the data and performs the desired calibrations. These calibrations are required to convert the raw values to a standard readable value. These sensor readings are then combined together to form a single packet and transmitted wirelessly to master node using Nordic nRF24L01+ chip.

Pseudo-code

- Initialize ADC

- Initialize BME280:

- Create wireless transmit task

- Start task scheduler

- Start wireless transmit task

- Initialize wireless parameters

- Initialize Air quality sensor variables

- Start the while loop and calibrate ADC readings according to atmosphere CO2 value

- Calculation:

MQ_135 = adc0_get_reading(3); __resistance=((4095./(float)MQ_135) - 1.); temp = __resistance/33; air_quality = (PARA*pow(temp,-PARB));

- Get temperature data in form of float from the sensor by reading registers 0xFA through 0xFC and use it to calculate raw temperature data.

- Raw data is converted into degree °C using some mathematical calculation as shown below

temp = (temp * 5 + 128) >> 8; tempf = (float)temp; return (tempf/100.0f);

- Get pressure data in form of float from the sensor by reading registers 0xF7 through 0xF9 and combining it to get raw pressure data.

- This raw pressure data is converted into actual pressure data in form of kPa.

press = (((1048576 - press_raw) - (var2 >> 12))) * 3125; var1 = ((int32_t)dig_P9 * ((int32_t)(((press >> 3) * (press >> 3)) >> 13))) >> 12; var2 = (((int32_t)(press >> 2)) * (int32_t)dig_P8) >> 13; press = (press + ((var1 + var2 + dig_P7) >> 4)); return (pressf/1000.0f);

- Get humidity data in form of float from the sensor by reading registers 0xFD through 0xFF and combining it to get raw humidity data.

- This raw humidity data is converted into real value to represent a precent.

v_x1 = (v_x1 > 419430400 ? 419430400 : v_x1); humf = (float)(v_x1 >> 12); return (humf/1024.0f);

Wireless Tx Implementation

The calibrated sensor values are stored into a single int array of size 5 to store all 5 sensor readings. The following function "wireless_send()" is responsible to send the packet wherein the address of the destination node, type of mesh protocol used, pointer to the data to send, length of the data to send and number of hops is passed as a parameter. It returns true if the packet is sent successfully. For our application, we are passing the below parameters to the wireless send()

- Our Master LED Matrix node address is selected as 5

- The mesh protocol used is mesh no-acknowledgement

- We will send the int sensor array along with the size.

- For our application, since all the slave nodes directly send data to master node, there shall be no intermediate node, hence the max_hops is kept 0 in our implementation.

Below is the function:

wireless_send(addr, mesh_pkt_nack, &sensor_data, sizeof(sensor_data), max_hops);

Testing & Technical Challenges

Nordic Wireless

Merging the sensor data into a single packet and transmitting the packet at Tx section. Incorrect values received at the Rx section with significant delay. Ensuring the receipt of packets from the correct node without data corruption.

Sensors

Air quality sensor calibration

To get accurate and stable data, we needed to keep MQ135 constantly plugged to the power source for 12 to 24 hours and only then we were able to calibrate the sensor reading to accurate values. Also, every time we removed power supply we needed to reset the calibration factor.

LED Matrix

Unstable/inconsistent display on LED matrix. Suspect it is due to high frequency and poor connections with jumper cables, planning to make simple header breakout for more robust connection.

- Header breakout did not help, investigating possibility of an issue with the matrix itself.

- Issue resolved. The breakout board did end up fixing the connection issue, but an erroneous line of code which set the latch too early was the main problem.

Synchronizing all the task after integrating the wireless part was a challenge.

- We were able synchronize the tasks pretty well by changing the priorities and eliminating certain delays.

The data logger task gave a blackout while the sensor data was being displayed on the LED Matrix.

- Solved the issue by synchronizing this task and taking the log of the data when the LED Matrix switches to next screen.

RTC

Time just kept resetting on board reset, even after setting the time. We figured out we had to store some value in "day of year" register to satisfy the if condition that goes to default if DOY register isn't within the acceptable range. Additionally, the terminal task did not support entering a DOY parameter, therefore the time command handler had to be updated to accept the input.

Conclusion

We successfully implemented Wireless Sensor Network which can sense different environmental variables. It gave us hands on working experience on FreeRTOS and how to write drivers. This project gave us a good experience of working with a team to manage the time and tasks assigned to each one of us. We faced many difficulties in the getting LED Matrix to work, I2C communication, RTC and synchronizing different task, but were eventually able to fulfill the objective of this project through coordinated efforts of all the members. There was a steep learning curve and we all gained lots of experience by developing this project.

Project Video

Project Source Code

References

Acknowledgement

We would like to thank Prof. Preetpal Kang for teaching us this course because of which we became familiar with driver development, the knowledge of which helped us in developing this project. We would also like to thank him for motivating and supporting us during the whole journey. We would also like to thank our classmates and ISA team who helped us to solve few bugs.

References Used

- LED Matrix: https://learn.adafruit.com/32x16-32x32-rgb-led-matrix?view=all

- BME-280 : https://www.bosch-sensortec.com/bst/products/all_products/bme280

- Low Powered Mesh Network Stack: http://socialledge.com/sjsu/index.php/SJ_One_Board#Wireless

- Nordic nRFL2401+ tutorial: http://paulfjujo.free.fr/_NRF2401_Transceiver/datas/nrf24l01_tutorial_0.pdf

- Building a Wireless Sensor Network with the nRF24L01+(Part 1-6): https://www.youtube.com/watch?v=RrmpN1_Py_4&list=PLufvMUgRha2bHfX1_LReVowCrEeAblzAP

- MQ-135: