Difference between revisions of "S14: Smart Weather Clock"

Proj user1 (talk | contribs) (→Testing & Technical Challenges) |

Proj user1 (talk | contribs) (→Testing & Technical Challenges) |

||

| Line 567: | Line 567: | ||

One possible solution: Use on-board led’s. Turn ON led’s instead of using printfs. This will not waste time. | One possible solution: Use on-board led’s. Turn ON led’s instead of using printfs. This will not waste time. | ||

For your reference, you can see the data pattern from the sensor. It is captured using a Logic Analyzer. | For your reference, you can see the data pattern from the sensor. It is captured using a Logic Analyzer. | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

Revision as of 13:07, 22 May 2014

Contents

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

Abstract

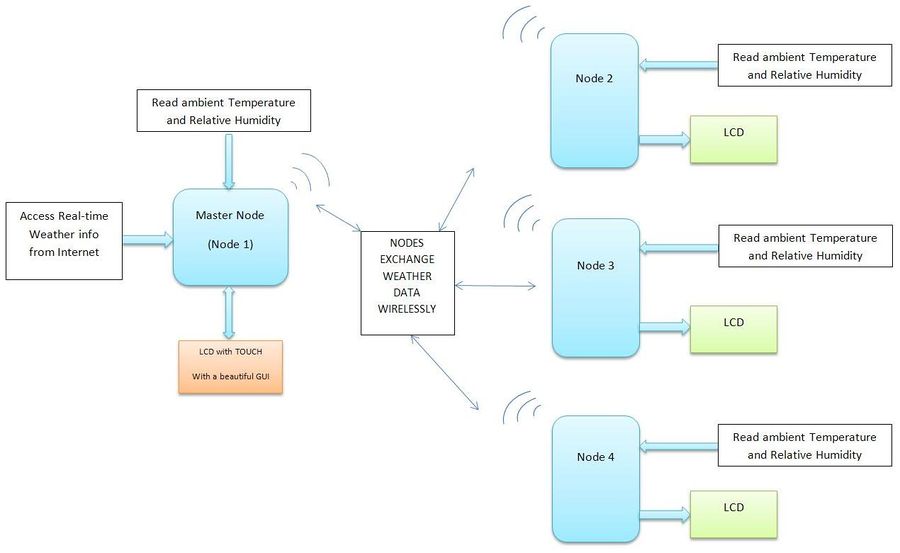

We plan to make four nodes of Weather Clocks that can communicate with each other as well as access the real-time weather from the Internet. The clocks also measure the indoor Temperature and the Humidity. All this information is displayed on a user-interactive graphic LCD with touchscreen. Each node can access the information of every other node as requested by the user. And of course, they also display the time.

Objectives & Introduction

- The main objective is developing a custom wireless protocol using the Nordic Wireless Mesh Network that can be used for communication of the four nodes.

- We also plan to access the real time weather information from the internet. The user can input the location of the city, and our clock will fetch the data from the internet and display it. To implement this, we have decided to use the "Electric IMP". We are giving our clocks the IoT (Internet Of Things) functionality so we can access our clocks virtually from anywhere.

- To make the clocks interactive, we would be using a Graphic LCD with touchscreen(uLCD-32PTU from 4D systems) and design a beautiful GUI. The user can select what information he wishes to see by clicking the icons. The user can also access the information from the other three nodes. The LCD would be interfaced on UART.

- To measure the indoor temperature and humidity, we would be using the DHT-22 sensor which can measure both. It's a One-wire sensor which sends out the data in pulses when requested. Measuring the length or time period of these pulses tells us if the data is logic '1' or '0'.

- All weather information will be logged in the Flash memory and will also be displayed on the graphic LCD as a graph of the parameter v/s time when requested by the user.

Team Members & Responsibilities

- Dhaval Parikh

- (Hardware design, sensor and Graphic Touch Screen LCD interface)

- Akshar Ranka

- (Electric Imp and 16x2 LCD interface)

- Huzefa Siyamwala

- (Wireless Communication (Server) and software integration)

- Raashid Kheruwala

- (Wireless Communication (Client) and LCD Interface)

Schedule

| Sr. No | Start Date | Projected End Date | Actual End Date | Task | Status |

|---|---|---|---|---|---|

| 1 | 3/1 | 3/7 | 3/7 | Finalise Component listing and Order Placement | Order Placed |

| 2 | 3/8 | 3/15 | 3/18 | Study of nordic wireless, Graphics LCD, electric Imp | Components Received. Testing begins! |

| 3 | 3/16 | 3/21 | 4/17 | Unit Testing for Graphics LCD, Algorithm and interface of Temp and RH Sensor | Made basic GUI on graphic LCD. Can send and receive data from LCD. Facing problems with Sensor! Working on it. |

| 4 | 3/22 | 3/28 | 4/3 | Getting Data from internet using Electric Imp | Data successfully received from Electric Imp using Openweather.org API's. Real-time weather info now available! |

| 5 | 3/29 | 4/4 | 4/17 | Integrating peripherals with SJ-One, Establishing communication between 4 nodes | Delay in integrating peripherals as sensor not working as desired. Will be done soon. Protocol defined and wireless communication established successfully between 2 nodes. |

| 6 | 4/9 | 4/15 | First phase of Testing / Happy path Testing | Integrated graphic LCD with the Electric Imp. Now displaying real-timer weather on the graphic LCD. Now working on the GUI. Problem with sensor found. Running behind by a week. | |

| 7 | 4/16 | 4/ 21 | Bugs Resolving | Issue with sensor resolved. Observed the data pattern on oscilloscope. Now working on reading data. Also working on communication between 4 nodes. | |

| 8 | 4/22 | 4/30 | Integrating the modules. | Sensor working perfectly. Electric Imp can access weather info from different cities. Now working on Hardware design, integration of all modules and bugs resolving. Back on track! | |

| 9 | 5/1 | 5/6 | Final Testing | Open | |

| 10 | 5/7 | 5/15 | Open |

Parts List & Cost

| Qty | Description | Manufacturer | Part Number | Total Cost |

|---|---|---|---|---|

| 1 | Serial TFT LCD - 3.2" w/ Touch | 4D Systems | uLCD-32PTU-GFX | $84.00 |

| 1 | Electric Imp Breakout board | Electric Imp | BOB-11400 | $20.00 |

| 4 | Humidity and Temperature Sensor- RHT03 | Sparkfun | SEN-10167 | $44.00 |

| 1 | SJOne Board | SJSU | - | $80.00 |

| 1 | Electric Imp card | Electric Imp | - | $30.00 |

| Total Cost | increasing! |

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

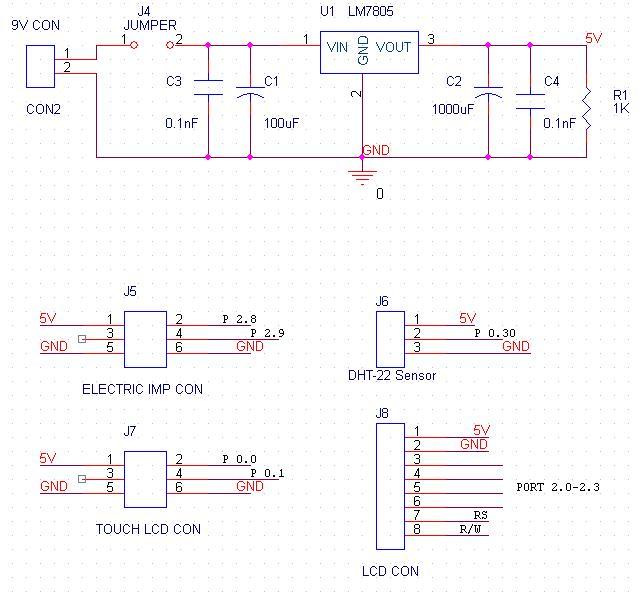

Discuss your hardware design here. Show detailed schematics, and the interface here.

Hardware Interface

In this section, you can describe how your hardware communicates, such as which Buses used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

Our hardware module consists of following components:

1. Electric Imp

- Its a device that we are using in our project to connect to the internet. Electric imp is equipped with inbuilt SPI, I2C and UART ports. We are using UART port to communicate with the SJ-one board in this project. There are three UART configuration in the hardware that can be used in software, UART12, UART57 and UART1289. UART12 and UART57 are used for regular Rx and Tx communication. Pins 1 and 5 are used for transmission whereas pins 2 and 7 in the respective configurations are used for reception. UART1289 configuration is used for transmission and reception with flow control signals RTS and CTS.

- We have used UART57 mode for our project. Thus to interface and achieve communication between electric imp and SJ-one board, we have to connect Tx of imp with Rx of SJ-one and Tx of imp with Rx of SJ-one. By interfacing in this fashion, we make sure that data that is transferred by either imp or SJ-one will be received at the receiving end.

2. Graphics Touch Screen LCD

3. Temperature and Humidity Sensor(DHT-22)

Software Design

Server:

The main task of server is to provide communication link with all client nodes and periodically update itself with data from client node. It also need to refresh itself with real time data available from internet (openWeather API's) using electric imp.

Pseudo Code:

Server Code

int32_t main(){

/// initialize all input/output devices

gLCD_Imp_init()

while(1){

recieveDataFromClient();

updateDatatoLCD();

delay();

}

}

Initialize Graphics LCD(UART3) / Electric Imp(UART2) ports

int32_t gLCD_Imp_init(){

/// Power up

LPC_SC->PCONP |= power_on_uartx;

/// For enabling clock to UARTx

LPC_SC->PCLKSEL1 &= ~(3 << 16);

LPC_SC->PCLKSEL1 |= (1 << 16);

/// Selecting UARTx TX/RX pin from Multiplexed port pins

LPC_PINCON->PINSEL4 &= ~(0xF << 16);

LPC_PINCON->PINSEL4 |= (0xA << 16);

/// Enable DLAB for setting Baud Rate

LPC_UARTx->LCR = enb_DLAB;

LPC_UARTx->DLM = 1; //1;

LPC_UARTx->DLL = (clock) / (16 * 9600);

LPC_UARTx->LCR = 3;

/// Enable fifo mode

LPC_UARTx->FCR = ((1 << 0) | (1 << 6));

/// Enable RDA interrupt

LPC_UARTx->IER = 1;

/// Hooking up Interrupt Handler

NVIC_EnableIRQ(UARTx_IRQn);

}

Receive data from Client Nodes

int32_t receiveDataFromNodes(){

Loop until response from all Nodes are received

For node i,

wireless_send_packet(Client_Address,mesh_pkt_ack_app,FLAGS);

wait for response, until predefined time

if(wireless_get_ack_packet()){

wireless_deform_packet(buffer);

update sensor array data

}

iterate through other node

}

Recieve live realtime data from internet

typedef struct electric_imp_buffer{

char city[16];

char description[20];

char temperature[10];

char humidity[5];

char datetime[20];

}electric_imp_buffer;

electric_imp_buffer buffer;

int32_t UART3_IRQHandler(){

/// We have configured Electric imp to send size of data

/// as first two bytes of payload

/// And each field of payload is separated by '#'

char ch;

if(counter<2){

electic_imp_buffer=electric_imp_buffer<<8;

electric_imp_buffer|= LPC_UART3->RBR;

}else{

while((ch=LPC_UART3->RBR)!='#'){

buffer.city[counter++]=LPC_UART3->RBR;

}

counter=0;

while((ch=LPC_UART3->RBR)!='#'){

buffer.description[counter++]=LPC_UART3->RBR;

}

counter=0;

while((ch=LPC_UART3->RBR)!='#'){

buffer.temperature[counter++]=LPC_UART3->RBR;

}

counter=0;

while((ch=LPC_UART3->RBR)!='#'){

buffer.humidity[counter++]=LPC_UART3->RBR;

}

counter=0;

while((ch=LPC_UART3->RBR)!='#'){

buffer.datetime[counter++]=LPC_UART3->RBR;

}

}

}

Update data to LCD

int32_t updateGLCD(){

/// Writing commands to graphics LCD in specified format

write_obj_to_display(WRITE_OBJ, GENIE_OBJ_METER, 0, 0,

(a[NO_OF_NODES - 1][1] / 10));

write_obj_to_display(WRITE_OBJ, GENIE_OBJ_THERMOMETER, 0, 0,

(a[NO_OF_NODES - 1][0] / 10));

write_obj_to_display(WRITE_OBJ, GENIE_OBJ_LED_DIGITS, 1, 0,

(a[NO_OF_NODES - 1][0] / 10));

write_obj_to_display(WRITE_OBJ, GENIE_OBJ_LED_DIGITS, 2, 0,

(a[NO_OF_NODES - 1][1] / 10));

}

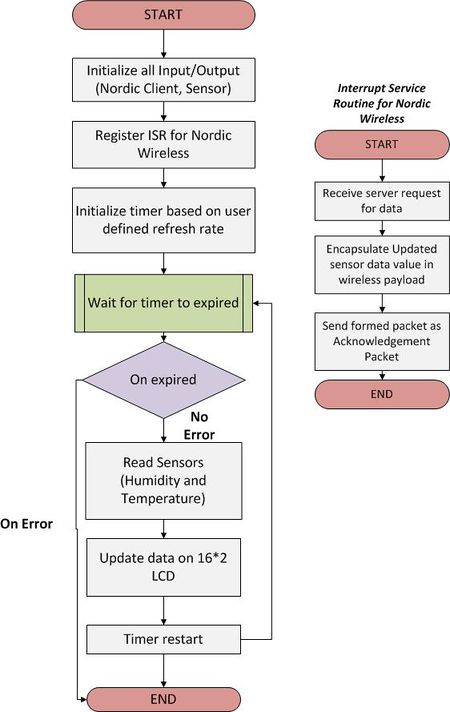

Client Node:

Pseudo Code:

Client Code

int32_t main(){

/// initialize all input/output devices

Sensor_LCD_init();

while(1){

writeDatatoLCD();

delay();

}

}

Setting Node Address

int32_t setNodeAddress(uint32_t address){

return (int32_t) mesh_set_node_address(address);

}

ISR For Nordic Wireless receiving Server Request

void NORDIC_UartHandler(){

if (wireless_get_rx_pkt(&pkt, 100)) {

/// Check if we were asked for an application ACK

if (wireless_is_ack_required(&pkt)) {

uint8_t tempOpcode=0;

uint8_t humidityOpcode=1;

wireless_form_pkt(&pkt, pkt.nwk.src, mesh_pkt_ack_rsp, 1,

4,&tempOpcode,sizeof(tempOpcode),

&temp_data,sizeof(temp_data),

&humidityOpcode,sizeof(humidityOpcode),

&rh_data,sizeof(rh_data); );

}

}

wireless_send_formed_pkt(&pkt);

}

Implementation

1. Electric Imp

Electric Imp Bringup:

It’s an easy to use device using which we can connect our LPC micro-controller to the internet. By connect I mean we can fetch the data from web pages in real time. This data can then be used for processing such as controlling the sensors, motors, LED’s etc. So, using this data we can build and control systems without being present in the same area or any part of the world. Think of an air-conditioner, music player or entire home automation system which can be monitored and controlled from any part of the world via mobile phone or web browser. It has grown on the power of Internet of Things which has picked momentum in the recent time and combined the networking and embedded worlds.

The following steps are to be followed when you first start working with the Electric Imp:

Step 1: Create an Electric Imp Account on www.electricimp.com

The first thing we need to do is create an Electric Imp account. Your Electric Imp account will be used to communicate with your imp, as well as provide access to the online Electric Imp development environment (IDE). No dedicated IDE on local machine is required for writing control programs for imp. The online IDE on imp website, its documentation about the API’s and knowledge of Squirrel scripting language are enough to use imp.

Step 2: BlinkUp Your Device

BlinkUp is the process used to transmit your wireless network's SSID (name) and encryption key (password) to your imp so that it can get online. BlinkUp transmits the information to the imp optically (by blinking the phone's screen). BlinkUp can be accomplished through Electric Imp's official iPhone or Android app.

Make sure the power jumper on your April board is populated, and set to USB

Let's make sure your imp is getting power:

1. Insert your imp into the SD slot.

2. Plug your USB mini cable into the imp, and your computer.

3. Your imp should begin blinking an internal orange LED.

4. Remove the imp from the SD socket (blinkup will only work during the first minute the imp has power - we're going to reinsert the imp right before we click BlinkUp in the mobile app).

Enter your credentials in the mobile app:

1. Open the mobile application on your iPhone or Android device.

2. Enter your account information and click login.

3. Select the wifi network you would like to connect your imp to.

4. If your wifi network has a password, enter the wifi password.

BlinkUp: 1. Reinsert the imp into the SD socket, and make sure the imp's internal LED is blinking.

2. Press the "Send BlinkUp" button in the mobile application.

3. Hold the screen of your phone flush against the end of the imp - Try to block out as much ambient light as possible. We recommend covering the exposed bit of the imp with a thumb while blinking up.

Your imp should now be online. It can now interact with the imp IDE hosted on www.electricimp.com website. If everything was successful the internal LED should be blinking green.

Step 3: Building out Circuit

Let us take the example of blinking an LED by controlling it from the browser: Electric imp card consist of an ARM processor embedded into it. Thus, it is like any other fully functional controller with communication protocols such as UART, SPI, I2C present for onboard communication with other controllers. The impee also consists of a 12-bit ADC and fixed frequency DAC.

In this example a Led connected on pin9. This led will be set or reset by hitting a link in the browser. Every electric imp device has a dedicated agent link. This link is to be used to control any activity on the imp by using any parameter to set or reset in the browser query. The link looks as follows:

https://agent.electricimp.com/SRwUO3A-ty4c

Step 4: Getting our IDE setup

Once your imp is BlinkedUp it should be online and associated with your account. When you open Electric Imp's web based development environment (IDE) it should be listed under new devices.

To edit code for your new device: 1. Click on "New Devices" to view your un-configured device.

2. Hover over your new device, and click the gear icon next to it.

3. Enter a name for the device (the board the imp is plugged into).

4. Enter a name for the model (the block of code that will execute).

5. Click Save Changes.

At this point, you should see 3 windows:

1.The Agent window is where you write code that you want to run in the Electric Imp cloud.

2. The Device window is where you write code that you want to run on the local device.

3. The Log window is where you can view system information (device on/off, connect/disconnect, as well as anything logged with server.log).

Step 5: Writing the Code

Code is written in agent as well as the device section to make the electric imp work. The agent gets the data from the internet by accessing different links that is specified in the agent code. The agent can access the data from the link itself. Suppose in the above LED blinking example we are required to control the led blinking using an android application consisting of two buttons, one for led on and off each. In the background we can design the app to access the agent link with state value padded at the end as follows, https://agent.electricimp.com/SRwUO3A-ty4c?state=0 For this link when state=0 is appended then LED may be turned off and vice versa with state=1.

This is just a help-get-start Project. By learning squirrel and reading the API documentation provided by electric imp programmers can use other exciting functions according to the need and relevance in their project.

2. Graphics LCD

We have used the uLCD-32PTU from 4D Systems. It’s a graphic LCD with a resolution of 240x320 which is very simple to use. The LCD can be used for making quick GUI’s.

We need the IDE which is available on the website to program the LCD.

We can program the LCD using three methods:

1) ViSi Genie: This is a drag and drop mode. There are objects available in the menu which can be drag-dropped on the screen. These objects include switches, text boxes, gauges, thermometers, angular meters, etc. This mode doesn’t require any programming. Just like the name, it’s a genie. We use the object which we want and the IDE automatically generates the code required for it. We have used this mode for programming the LCD.

2) ViSi : This mode is a combination of the 4DGL programming language assisted with drag-drop of objects. Since we had a deadline to meet, we didn’t learn the 4DGL programming language. But this can be done if you have enough time.

3) Designer: This mode is pure 4DGL programming language. Each object needs to added using the programming language. The only benefit of using this code is we can make use of the peripherals and busses available on the Touchscreen. The uLCD-32PTU has on-board I2C and UART ports and also has buzzer and ADC. We can make use of these functionalities by using the 4DGL programming language. These peripherals can also be used in the ViSi mode. Once you’ve made up your mind with the environment you wish to use (mostly you would go with the ViSi Genie environment), we will show you how to use the IDE and the LCD from scratch. 4D systems has very well documented app notes which can be found on this link: http:/www.4dsystems.com.au/appnotes/ Refer the app notes in the ViSi-Genie category.

• First you need the uUSB-PA5 : microUSB Programming Adaptor OR the Programming Cable : USB to Serial UART Bridge Converter Cable. IMPORTANT NOTE: Without either of these you cannot program the LCD. VERY IMPORTANT NOTE: DO NOT USE THE STANDARD USB TO 232 CONVERTER! THIS WOULD INSTANTLY DAMAGE THE LCD. YOU NEED THE USB TO TTL CONVERTER AND NOT 232.

• Once you have interfaced the LCD using the USB to SERIAL cable now comes the fun part of making beautiful GUI on the LCD.

• After selecting the appropriate model of the LCD (uLCD-32PTU in our case) , select the ViSi – Genie environment.

• You will see the screen on the left. This screen is for our reference and it gives us an idea how our GUI would look on the LCD without actually programming it.

• The way it works is that we can make FORMS on the LCD. Forms are like different pages which are used for displaying information or taking inputs from user.

• We will start with the first and default form. You can see the different tabs on the top in the IDE. These tabs contain objects such as buttons, angular meters, etc. We leave the exploration of the different objects on you.

• To start with select the “Fancy Button” under the buttons tab. Draw the button of your desired size anywhere on the screen. On the right side, you can see the “object inspector” of the button. You can change the name of the button (under “captions” field), the background and foreground color, the font size and style. It is very flexible.

• Important thing to note is the name which would “Winbutton0”, since it’s the first button. The ‘0’ here is the index which acts as a reference to address the button.

• Now add an “angular gauge” to the screen. Resize it, change the color, the digits size, color, the span of the arc, the range in the “object inspector” section. We leave the exploration on you. Note the name of the meter and more important the number at the end of the name – the index. (e.g. angularmeter0). We will give more light on the index field later on.

• Your first Form is now ready. Let’s add one more form from the “system/media” tab. This form is named as form1. Now we will link the button created on the first form to the Form1 such that by pressing the button, Form1 will be displayed.

• Goto the Form0. Select the button. In the object inspector, select the “Events” tab. Each press on the screen creates an event and we can configure the event whether to goto a new form when pressed or report a message to the host controller.

• On clicking on the handler, we can see the various options available. Select the “Form1 activate”. This means that the Form1 would be activated when the button is pressed. Your basic GUI is now complete! It’s simple isn’t it?

Steps to program the LCD:

• Once the LCD is properly interfaced (you need to cross the Rx and Tx lines), goto “COMMS” tab and select the proper COM port and you should see the name of the LCD on the top left corner of the IDE. There would be a green symbol which means the IDE has detected the LCD.

• Press the “Copy/Build” button. NOTE: You would need a microSD card. The IDE stores the user images on the microSD. Even though we are not using any images, we still need a microSD card. The microSD should be formatted in FAT file format only.

• Just follow the steps on the dialogues popped in the IDE and you should be just fine.

• After the process is finished, the LCD won’t show our GUI unless we insert the SD card. It would keep flashing an error message.

• After inserting the SD card, our GUI would be up and running! Voila! Press the button, you can goto the next screen.

Now we show you how to interface this LCD with a host processor (the SJ – One board in our case).

• Interfacing LCD with the processor is simple. We have used the UART port which was initially used for programming the LCD.

• Again you need to cross connect the Rx and Tx pins of SJ-One board and the LCD.

• But to send the data on the LCD and specifically to objects like thermometers and gauges, we need to follow the specific frame format for the LCD.

• Remember the index which we talked about previously? We need to use those index numbers to address the object.

• We would recommend you to go through the ViSi-Genie Reference manual available on the app notes section of the website to understand the frame format in detail. Here’s the link: http://www.4dsystems.com.au/downloads/Software/4D-Workshop4-IDE/Docs/ViSi-Genie/ViSi-Genie-Reference-Manual-REV1.pdf

• You can Write objects ( e.g. sending some data for the angular meter), or Write Strings or Read Objects.

• Just to give you a basic idea of the UART frame format required: We will give you an example on how to write objects (angular meter in our case).

1) Byte 1: CMD (0x01) which is the write object command.

2) Byte 2: OBJ-ID. This is the ID that tells the LCD that we are addressing the Angular meter and the Thermometer or anything else. The list of ID’s can be found on page 7 of the “Writing to Genie Objects from Arduino” file in the app notes section. Here’s the link of the PDF: http://www.4dsystems.com.au/downloads/Application-Notes/4D-AN-P4018_R_1_0.pdf . The ID for angular meter is 0x07.

3) Byte 3: OBJ-INDEX. This is the index number previously mentioned. The index is ‘0’ in our case. So this field would be 0x00.

4) Byte 4: The Most Significant Byte of the value to be sent.

5) Byte 5: The Least Significant Byte of the value to be sent. (e.g. to send a value 360 (0x168) to the meter, MSB : 0x01 and LSB : 0x68 )

6) Byte 6: CHECKSUM. The checksum byte is used for verification of the frame. Calculating the checksum is fairly simple. Just XOR (using the ^ operator) all the bytes from byte 1 to byte 5.

• So our UART frame would be: 0x01, 0x07, 0x00, 0x01, 0x68, 0x6F

• When we send this frame, the LCD will automatically move the needle of the meter to the value 360.

• Another thing to note is, that if the LCD receives the frame without any errors, it will send one byte of ACK (0x06) back to us. If there is data corruption or invalid frame format sent by us, it sends a NACK byte (0x15). This can be used as a trigger to resend the data to the LCD or give some warnings!

This covers the basics of making a GUI on the uLCD-32 PTU. Using this as a guide, we encourage you to try more stuff on your own.

3. DHT-22 - Temperature and Humidity Sensor

The DHT – 22 Sensor also known as the RHT03 sensor is a 1-wire temperature and humidity (relative humidity) sensor. The best part is that it requires only one pin from the GPIO port and it can used long transmission distances up to 100m.

There isn’t any good documentation on the internet for this sensor. The references available online is one datasheet from MaxDetect and the Arduino libraries. We will try to cover the sensor’s working in detail.

VERY IMPORTANT NOTE: Before we start, one thing to note is that although the operating voltage range of the sensor is mentioned as 3.3V – 5V on the datasheet we found that the sensor does NOT work at 3.3V. So we recommend you to use a 5V supply and have a common ground with SJ-ONE board’s ground.

The data pin of the sensor (Pin 2) is an open collector I/O pin, which means the pin can only pull itself low (0 V) and it cannot drive itself High (5V) . The documentation found on the internet says we need an external pull-up resistor of 4K7 Ohm connected to Vcc. However, if you measure the resistance between the Vcc pin (pin 1) and the data pin (pin 2) there is already a pull-up inside the sensor. Thus, you don’t need an external pull-up resistor. Although, it’s always advisable to check if there is a resistor inside. The 1-wire protocol is actually simple to understand but a little tricky to implement. The protocol works as follows:

Unlike the usual sensors, the DHT-22 sensor being a 1-wire sensor sends out data only on a single pin. Instead of pulling low for sending a ‘0’ and pulling high for sending a ‘1’, the sensor sends out ‘pulses’ of different time periods for bits 1 and 0.

For sending a bit ‘0’, the sensor sends out a pulse of 28us ON time and for bit data ‘1’, it sends out a pulse of 70us ON time.So the tricky part is detecting the 1’s and 0’s on the line.

According to the protocol,

1) First, we need to configure the GPP pin of our SJ-ONE board as output. Then we need to send a ‘START’ pulse to sensor. This is sent by pulling low the line for a minimum time period of 1ms. Then the line should be pulled high for a time of 20-40us. On detecting this pattern, the sensor will automatically pull-low the data pin for 80us followed by pulling it high again for 80us. This is like an ACK signal.

2) After this, the sensor sends 40 bits of data one after the other continuously.

16 bits of RH data + 16 bits of Temperature data + 8 bits of checksum.

Checksum can verified by OR-ring the RH and temperature data 8 bits at a time.

(8bitsRH + 8BitsRH + 8bitsTemp + 8bitsTemp).

3) To detect the bits we can use a do-while() loop which keeps polling the data line periodically say every 2us and breaks if the time exceeds because of an error. Another option is to use hardware timer interrupt and external interrupt.

How we implemented the protocol: We start by configuring the data pin as output. The start signal is sent by using the delay_ms(). We make the pin low, then call the delay_ms(1). Next we configure the pin as external interrupt to detect the rising edge. Thus each time the sensor sends the pulse (each pulse has a rising edge), the external interrupt occurs. In the external interrupt ISR we start a hardware timer configured to produce interrupt every 70us. Inside the timer interrupt ISR, we check whether the pin is high or low. If the pin is still high, the data sent by sensor is data ‘1’ if pin is low that means the data sent is ‘0’. On detection of the data bit, we left shift the data into a variable, reset and stop the timer, and clear the timer interrupt. You might have noticed that in sending the start signal we are NOT pulling high the data pin for 80us after pulling it low for 1ms. This is a quick fix, once we pull up the data line after 1ms, the sensor does everything else! It automatically sends the ACK signal followed by 40 bits of data i.e. the sensor pulls down and pulls up the data pin on its own, and our external interrupt and Timer ISR does the rest.

One Critical Point to take care of: If you are trying to interface the sensor without the hardware timers and external interrupt. You can do that by referring the Arduino libraries. But, the point to take care of is it is hard to debug the logic when you use do_while() loops and delay_us() functions. You might use printf() to see your program flow, but this would actually make your logic to NOT work. Since the sensor sends precisely timed pulses, using printf() would introduce even more delays in your code and you won’t be able to read actual data. One possible solution: Use on-board led’s. Turn ON led’s instead of using printfs. This will not waste time. For your reference, you can see the data pattern from the sensor. It is captured using a Logic Analyzer.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

My Issue #1

Discuss the issue and resolution.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

Send me your zipped source code and I will upload this to SourceForge and link it for you.

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

List any references used in project.

Appendix

You can list the references you used.