Difference between revisions of "S23: Meh-sla Automotive"

(→Motor ECU) |

(→Motor ECU) |

||

| Line 499: | Line 499: | ||

== Motor ECU == | == Motor ECU == | ||

| − | [[File:traxxasRemotePWM.jpeg|300px|center|thumb|Traxxas Antenna PWM Connections] || [File:TraxxasAntennaDevice.jpg|300px|center|thumb|Traxxas | + | {| |

| + | |[[File:traxxasRemotePWM.jpeg|300px|center|thumb|Traxxas Antenna PWM Connections]] || [[File:TraxxasAntennaDevice.jpg|300px|center|thumb|Traxxas TQ Top Qualifier Module]] | ||

| + | | | ||

| + | |} | ||

* [https://gitlab.com/karthigaiamutha.ezhilarasu/meh-sla-automotive/-/tree/motor_board?ref_type=heads Motor Controller Gitlab link] | * [https://gitlab.com/karthigaiamutha.ezhilarasu/meh-sla-automotive/-/tree/motor_board?ref_type=heads Motor Controller Gitlab link] | ||

Revision as of 23:12, 20 May 2023

Contents

Project Title

<Team Name>

Abstract

<2-3 sentence abstract>

Introduction

The project was divided into 5 modules:

- Sensor

- Motor

- Geological

- Driver

- Android

Team Members & Responsibilities

<Team Picture>

Gitlab Project Link - [1]

<Provide ECU names and members responsible> <One member may participate in more than one ECU>

- Tony Zunino

- Team Lead

- Motor Board

- Sindhuja Ravi

- Geo Board

- Android App

- Stephen Oneto

- Driver and LCD Board

- Karthigai Amutha Ezhilarasu

- Sensor Board

- Geo Board

- Phil Bloxom

- Hardware Setup

- Software Testing

Schedule

| Week # | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 2/12/2023 | 2/18/2023 |

|

|

| 2 | 2/19/2023 | 2/25/2023 |

|

|

| 3 | 26/2/2023 | 3/4/2023 |

|

|

| 4 | 3/5/2023 | 3/11/2023 |

|

|

| 5 | 3/12/2023 | 3/18/2023 |

|

|

| 6 | 3/19/2023 | 3/25/2023 |

|

|

| 7 | 3/26/2023 | 4/1/2023 |

|

|

| 8 | 4/2/2023 | 4/8/2023 |

|

|

| 9 | 4/9/2023 | 4/15/2023 |

|

|

| 10 | 4/16/2023 | 4/22/2023 |

|

|

| 11 | 4/23/2023 | 4/29/2023 |

|

|

| 12 | 4/30/2023 | 5/6/2023 |

|

|

| 13 | 5/7/2023 | 5/13/2023 |

|

|

| 14 | 5/14/2023 | 5/19/2023 |

|

|

| 15 | 5/20/2023 | 5/26/2023 |

|

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Traxxas | 1 | $250.00 |

| 2 | CAN Transceivers MCP2551-I/P | Microchip [2] | 8 | Free Samples |

Printed Circuit Board

<Picture and information, including links to your PCB>

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management etc.>

Hardware Design

<Show your CAN bus hardware design>

DBC File

VERSION "" NS_ : BA_ BA_DEF_ BA_DEF_DEF_ BA_DEF_DEF_REL_ BA_DEF_REL_ BA_DEF_SGTYPE_ BA_REL_ BA_SGTYPE_ BO_TX_BU_ BU_BO_REL_ BU_EV_REL_ BU_SG_REL_ CAT_ CAT_DEF_ CM_ ENVVAR_DATA_ EV_DATA_ FILTER NS_DESC_ SGTYPE_ SGTYPE_VAL_ SG_MUL_VAL_ SIGTYPE_VALTYPE_ SIG_GROUP_ SIG_TYPE_REF_ SIG_VALTYPE_ VAL_ VAL_TABLE_ BS_: BU_: DBG DRIVER MOTOR SENSOR GEO BO_ 100 DRIVER_HEARTBEAT: 1 DRIVER SG_ DRIVER_HEARTBEAT_cmd : 0|8@1+ (1,0) [0|0] "" SENSOR,MOTOR BO_ 101 MOTOR_SPEED: 1 DRIVER SG_ DC_MOTOR_DRIVE_SPEED_sig : 0|8@1+ (0.1,-10) [-10|10] "kph" MOTOR BO_ 102 MOTOR_ANGLE: 1 DRIVER SG_ SERVO_STEER_ANGLE_sig : 0|8@1+ (1,-45) [-45|45] "degrees" MOTOR BO_ 200 SENSOR_SONARS: 4 SENSOR SG_ SENSOR_SONARS_left : 0|8@1+ (1,0) [0|158] "inch" DRIVER SG_ SENSOR_SONARS_right : 8|8@1+ (1,0) [0|158] "inch" DRIVER SG_ SENSOR_SONARS_front : 16|8@1+ (1,0) [0|158] "inch" DRIVER SG_ SENSOR_SONARS_rear : 24|8@1+ (1,0) [0|158] "inch" DRIVER BO_ 202 GPS_DESTINATION_LOCATION: 8 SENSOR SG_ GPS_DEST_LAT_SCALED_1000000 : 0|32@1- (1,0) [0|0] "Degrees" GEO SG_ GPS_DEST_LONG_SCALED_1000000 : 32|32@1- (1,0) [0|0] "Degrees" GEO BO_ 203 GEO_STATUS: 8 GEO SG_ GEO_STATUS_COMPASS_HEADING : 0|12@1+ (0.1,0) [0|359.9] "Degrees" DRIVER,SENSOR SG_ GEO_STATUS_COMPASS_BEARING: 12|12@1+ (0.1,0) [0|359.9] "Degrees" DRIVER,SENSOR SG_ GEO_STATUS_DISTANCE_TO_DESTINATION : 24|16@1+ (0.01,0) [0|0] "Meters" DRIVER,SENSOR BO_ 204 GPS_CURRENT_INFO: 8 GEO SG_ GPS_CURRENT_LAT_SCALED_1000000 : 0|32@1- (1,0) [0|0] "degrees" DRIVER,SENSOR,MOTOR SG_ GPS_CURRENT_LONG_SCALED_1000000 : 32|32@1- (1,0) [0|0] "degrees" DRIVER,SENSOR,MOTOR BO_ 205 GPS_CURRENT_DESTINATIONS_DATA: 8 GEO SG_ CURRENT_DEST_LAT_SCALED_1000000 : 0|32@1- (1,0) [0|0] "Degrees" DRIVER SG_ CURRENT_DEST_LONG_SCALED_1000000 : 32|32@1- (1,0) [0|0] "Degrees" DRIVER BO_ 206 BRIDGE_APP_COMMANDS: 1 SENSOR SG_ APP_COMMAND : 0|2@1+ (1,0) [0|0] "" GEO,DRIVER BO_ 300 MOTOR_STATUS: 3 MOTOR SG_ MOTOR_STATUS_wheel_error : 0|1@1+ (1,0) [0|0] "" DRIVER,IO SG_ MOTOR_STATUS_speed_kph : 8|16@1+ (0.001,0) [0|0] "kph" DRIVER,IO BO_ 401 MOTOR_DEBUG: 1 MOTOR SG_ IO_DEBUG_test_unsigned : 0|8@1+ (1,0) [0|256] "sec" DBG CM_ BU_ DBG "The debugging node for testing dbc with the car"; CM_ BU_ DRIVER "The driver controller driving the car"; CM_ BU_ MOTOR "The motor controller of the car"; CM_ BU_ SENSOR "The sensor controller of the car"; CM_ BU_ GEO "The geological Controller of the car"; CM_ BO_ 100 "Sync message used to synchronize the controllers"; CM_ SG_ 100 DRIVER_HEARTBEAT_cmd "Heartbeat command from the driver"; CM_ SG_ 101 DC_MOTOR_DRIVE_SPEED_sig "The speed in kph to set the motor speed. TODO: choose kph/mph"; CM_ SG_ 102 SERVO_STEER_ANGLE_sig "The direction in degrees to set the RC car servo direction."; BA_DEF_ "BusType" STRING ; BA_DEF_ BO_ "GenMsgCycleTime" INT 0 0; BA_DEF_ SG_ "FieldType" STRING ; BA_DEF_DEF_ "BusType" "CAN"; BA_DEF_DEF_ "FieldType" ""; BA_DEF_DEF_ "GenMsgCycleTime" 0; BA_ "GenMsgCycleTime" BO_ 100 1000; BA_ "GenMsgCycleTime" BO_ 200 50; BA_ "FieldType" SG_ 100 DRIVER_HEARTBEAT_cmd "DRIVER_HEARTBEAT_cmd"; VAL_ 100 DRIVER_HEARTBEAT_cmd 2 "DRIVER_HEARTBEAT_cmd_REBOOT" 1 "DRIVER_HEARTBEAT_cmd_SYNC" 0 "DRIVER_HEARTBEAT_cmd_NOOP" ;

Sensor and Bridge Controller

Hardware Design

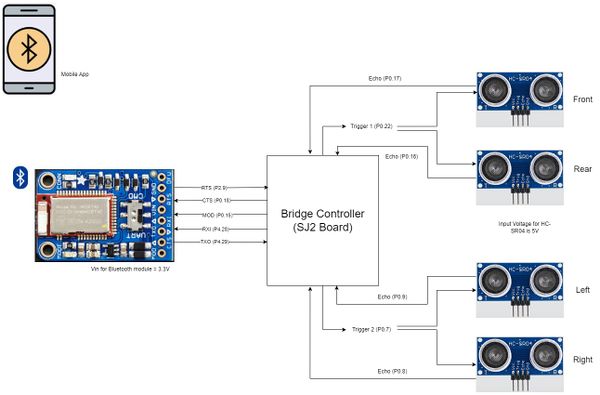

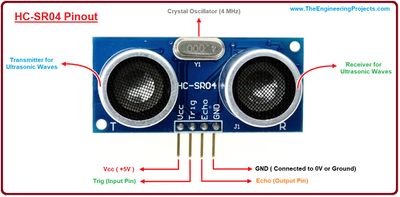

Ultrasonic Sensors

We used HC-SR04 ultrasonic sensors for obstacle detection. It could provide a range from 2 cm to 400 cm non-contact measurement. The ranging accuracy is approximately 3mm and the effectual angle is less than 15°. It needs to be powered by a 5V power supply. We are using 4 HC-SR04 sensors in the RC car(front, rear, left, and right).

HC-SR04 specifications

- Operating voltage: +5V

- Theoretical Measuring Distance: 2cm to 450cm

- Practical Measuring Distance: 2cm to 80cm

- Accuracy: 3mm

- Measuring angle covered: <15°

- Operating Current: <15mA

- Operating Frequency: 40Hz

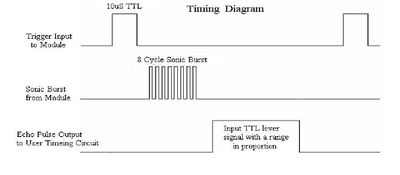

The pinout and the timing diagram of the HC-SR04 sensor are shown in the following figures. The module includes an ultrasonic transmitter, a receiver, and a control circuit. The basic principle of work: When the trigger pin is set HIGH for at least 10us, the module automatically sends a 40 kHz ultrasonic wave from the Ultrasonic transmitter. This wave travels in the air and when it gets obstructed by any material it gets reflected back toward the sensor. This reflected wave is observed by the Ultrasonic receiver module. Once the wave is returned the Echo pin goes high for a particular amount of time which will be equal to the time taken for the wave to return back to the sensor. The amount of time during which the Echo pin stays high is measured by the SJ2 board as it gives the information about the time taken for the wave to return back to the Sensor. Using this information the distance is measured as explained in the above heading. From that duration, the distance at which the object is present can be measured using the formula, Distance = Speed × Time.

Bluetooth Module

For the communication between the mobile and the RC Car, we are using Adafruit Bluefruit LE UART Friend - BLE module. This module communicates with the SJ2 board through UART at a baud rate of 9600. It also has the capability of working in two modes (data mode and command mode). We can toggle between the two modes using the MOD pin through a GPIO signal or manually using the onboard switch. It supports AT command set, which can be used to control the device's behavior. In data mode, the data written to the UART in the form of a string will be sent through Bluetooth.

Adafruit Bluefruit specifications

- ARM Cortex M0 core running at 16MHz

- 256KB flash memory

- 32KB SRAM

- Transport: UART @ 9600 baud with HW flow control (CTS+RTS required)

- 5V-safe inputs

- On-board 3.3V voltage regulation

- Bootloader with support for safe OTA firmware updates

- Easy AT command set to get up and running quickly

Software Design

We read about the signal interference of adjacent sensors from many of the past projects. So we decided to avoid that interference by triggering two non-adjacent sensors at a time. The FRONT_REAR sensor pair is triggered first. Once both of the sensors compute the distance from the obstacle, then the next pair, RIGHT_LEFT is triggered. For the ultrasonic sensors, we used a separate task instead of the periodic callbacks since this task sleeps on a semaphore which might affect the other functions in the periodic callback function.

Ultrasonic Sensors

SONAR task

void sonar_task(void *p) {

sonar__init();

front_rear_echo_received = xSemaphoreCreateBinary();

left_right_echo_received = xSemaphoreCreateBinary();

lpc_peripheral__enable_interrupt(LPC_PERIPHERAL__GPIO, sonar__interrupt_dispatcher, "sonar_timing_handler");

NVIC_EnableIRQ(GPIO_IRQn);

while (1) {

sonar__send_trigger_for_10us(FRONT_REAR);

if (xSemaphoreTake(front_rear_echo_received, 1000)) {

sonar_pair_info[0].distance_from_obstacle_sonar1 = sonar__compute_obstacle_distance_single_sensor(FRONT_SONAR);

sonar_pair_info[0].distance_from_obstacle_sonar2 = sonar__compute_obstacle_distance_single_sensor(REAR_SONAR);

}

sonar__send_trigger_for_10us(LEFT_RIGHT);

if (xSemaphoreTake(left_right_echo_received, 1000)) {

sonar_pair_info[1].distance_from_obstacle_sonar1 = sonar__compute_obstacle_distance_single_sensor(LEFT_SONAR);

sonar_pair_info[1].distance_from_obstacle_sonar2 = sonar__compute_obstacle_distance_single_sensor(RIGHT_SONAR);

}

sonar__averaging_sensor_values();

vTaskDelay(10);

}

}

Technical Challenges

< List of problems and their detailed resolutions>

Motor ECU

Hardware Design

Software Design

<List the code modules that are being called periodically.>

RPM Module

Tony will write about how the RPM module was implemented using triggers.

void sonar_task(void *p) {

Test

}

Motor Module

Tony will write about the motor and how forward/reverse works

static float test_task(float lol) {

Just wanted to see if this is cool;

}

Steering Module

Tony will write about the motor and how forward/reverse works

static float test_task(float lol) {

Preet is cool;

if(Phil_is_reading) Phil is cooler;

else Tony is the coolest

}

Technical Challenges

< List of problems and their detailed resolutions>

Geographical Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Mobile Application

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

Advise for Future Students

<Bullet points and discussion>

Acknowledgement

=== References ===