Difference between revisions of "S22: Silver Arrow"

Proj user5 (talk | contribs) (→Team Members & Responsibilities) |

Proj user5 (talk | contribs) (→Team Members & Responsibilities) |

||

| Line 30: | Line 30: | ||

* Mechanical/Hardware/circuit/PCB designing | * Mechanical/Hardware/circuit/PCB designing | ||

| − | '''Vilas Dhuri [https://www.linkedin.com/in/vilas-dhuri-b5a9131b5/ LinkedIn]''' | + | '''Vilas Dhuri [https://www.linkedin.com/in/vilas-dhuri-b5a9131b5/ LinkedIn]''' |

* Driver Logic | * Driver Logic | ||

* Car chassis assembly and hardware integration | * Car chassis assembly and hardware integration | ||

Revision as of 22:58, 26 May 2022

Contents

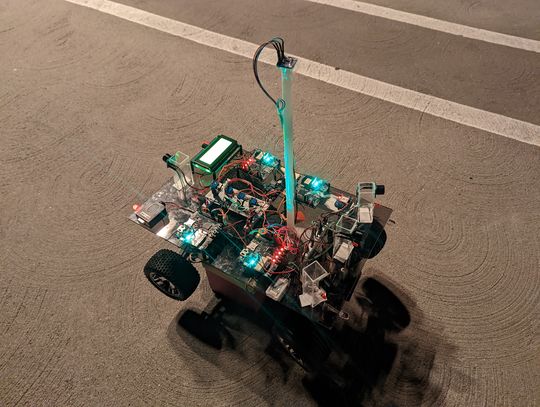

SILVER ARROW

Abstract

Silver Arrow RC is a self-navigating, electric, battery-powered RC car. The goal is to use GPS navigation to get to the location specified in the Android app. To sense its surroundings and avoid obstructions in its route, the car combines input from several sensors and make decisions to navigate itself to the destination location

Introduction

The project was divided into 5 modules:

- Bridge and Sensor Controller

- Motor Controller

- Geographical Controller

- Driver and LCD controller

- Android Application

Team Members & Responsibilities

Pushkar Deodhar LinkedIn

- App development

- Mechanical/Hardware/circuit/PCB designing

Vilas Dhuri LinkedIn

- Driver Logic

- Car chassis assembly and hardware integration

Rishabh Gupta LinkedIn

- Mobile Application

- Wiki page manage

Vivek Tapkir LinkedIn

- Sensor controller

- Communication Bridge Controller

- Hardware Integration

Saharash Shivahre LinkedIn

- Geo controller

- Wiki page manage

Naveena Sura LinkedIn

- Geo controller

- Git repo managment

Daya Modekar LinkedIn

- Motor controller

- Hardware Integration and design

Schedule

| Week# | Start Date | End Date | Task | Status |

|---|---|---|---|---|

| 1 | 03/16/2022 | 03/22/2022 |

|

|

| 2 |

03/23/2022

|

03/29/2022

|

|

|

| 3 |

03/30/2022

|

03/04/2022

|

|

|

| 4 |

04/05/2022

|

04/11/2022

|

|

|

| 5 |

04/12/2022

|

04/18/2022

|

|

|

| 6 |

04/19/2022

|

04/25/2022

|

|

|

| 7 |

04/26/2022

|

05/2/2022

|

|

|

| 8 |

05/3/2022

|

05/09/2022

|

|

|

| 9 |

05/10/2022

|

05/16/2022

|

|

|

| 10 |

05/17/2022

|

05/23/2022

|

|

|

| 11 |

05/25/2022

|

05/25/2022

|

|

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | RC Car | Traxxas | 1 | $250.00 |

| 2 | CAN Transceivers MCP2551-I/P | Microchip [1] | 8 | Free Samples |

Printed Circuit Board

<Picture and information, including links to your PCB>

CAN Communication

<Talk about your message IDs or communication strategy, such as periodic transmission, MIA management etc.>

Hardware Design

<Show your CAN bus hardware design>

DBC File

<Gitlab link to your DBC file> <You can optionally use an inline image>

Sensor ECU

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Motor ECU

Hardware Design

Motor Controller Node includes the operational control of the DC motor, Servo motor, Electronic speed control (ESC), and the wheel encoder(RPM Sensor). The job of the motor controller is to control the steering of front wheels at appropriate angles and to spin the rear wheels at speeds commanded by the driver node in order to traverse the RC car to the destination location.The DC motor, servo motor, and ESC(Traxxas ESC XL-05) were provided with the Traxxas RC car. The wheel encoder and the trigger magnet were purchased separately from Traxxas's website.

| SJ2 Board Pin | Description |

|---|---|

| 5V | Input power |

| 3.3V | CAN transceiver power |

| PWM2 P2.1 | DC Motor Speed Control |

| PWM5 P2.4 | Servo Motor Angle Control |

| CAP0 P2.6 | RPM Sensor\Wheel Encoder |

| CAN1 TX | CAN Transceiver Tx |

| CAN1 RX | CAN Transceiver Rx |

| GND | Grounding |

DC Motor and ESC

The DC motor is controlled by the ESC using PWM signals which were provided by the motor controller board for forward, neutral, and reverse movements.The DC motor and ESC were provided with RC car.The ESC is powered ON using a 7.4 LiPo battery.The ESC converts this 7.4V to 6V and provides input to DC Motor.

| ESC wires | Description | Wire Color |

|---|---|---|

| Vout | Output Power (6V) | RED |

| GND | Ground | BLACK |

| PWM | PWM input from SJ2-Board (P2.1) | WHITE |

The car can be operated at 100Hz in the following 3 modes :

Sport Mode (100% Forward, 100% Brakes, 100% Reverse)

Racing Mode (100% Forward, 100% Brakes, No Reverse)

Training Mode (50% Forward, 100% Brakes, 50% Reverse)

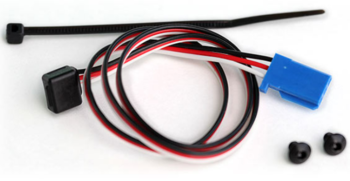

Servo Motor

The servo motor responds to PWM pulses. It has three pins namely Vcc, PWM Input Signal, and GND. The servo is powered using 6V from the car battery. Based on the PWM signal supplied from the SJTwo board the front wheels are turned.

| Servo Wires | Description | Wire Color |

|---|---|---|

| Vin | Input Voltage (6V) | RED |

| GND | Ground | BLACK |

| PWM | PWM input from SJ2-Board (P2.4) | WHITE |

The PWM frequency for our Traxxas Servo motor also needed to be 100Hz. An idle (wheel's pointing forward) duty cycle is 15%. The full duty cycle range is [10%, 20%], where [10%, 15%) is the steer left range, and (15%, 20%] is the steer right.

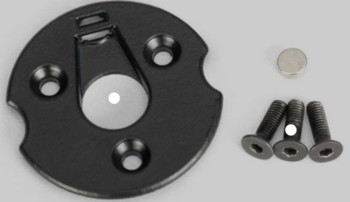

Wheel Encoder

For speed sensing we purchased a Traxxas RPM sensor as it mounted nicely in the gearbox. The RPM sensor works by mounting a magnet to the spur gear and a hall effect sensor fixed to the gearbox. To get the revolutions per second we used Timer2 as an input capture.

| RPM Sensor Wires | Description | Wire Color |

|---|---|---|

| Vin | Input Voltage (6V) | RED |

| GND | Ground | BLACK |

| Sensor Output | Input Capture to SJ2-Board (P2.6) | WHITE |

Software Design

The motor controller code modules consisted of 3 main parts, which are: 1. PWM drivers and motor logic, 2. RPM/speed sensor, 3. PID controller.

Technical Challenges

- First and foremost, the Traxxas motor ESC and other Traxxas components are Traxxas Hobby Parts, and they are not designed for development. As a result, no technical specification documentation or program/development guidelines are accessible. The motor ESC must be tested by supplying PWM duty cycles in different sequences at different duty cycle percentages. We utilized the remote control to recreate certain circumstances in which the ESC acted strangely.

- If a Lipo battery is used, the ESC setup switches to the Lipo battery state. When the NiMH battery is replaced, the ESC begins flashing the led in a green-red pattern, and the ESC power button stops working. In this case, the handbook contains a calibration procedure that can rescue your boat and restore regular ESC operation.

- Another challenge with the motor node program development is that you cannot rely on unit testing. Whoever works on the motor node, should make sure that the sequence of the duty cycles being fed to the ESC produces the expected results on the motor as well. The forward-reverse transitioning and the speed controlling both can be a bit tricky. Also, the hard brake logic can take a while to get working properly.

- We somehow destroyed the ESC and wanted to replace it. We spent both time and money on this. Make sure you don't short the ESC by mistake!

Geographical Controller

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

Communication Bridge Controller & LCD

<Picture and link to Gitlab>

Hardware Design

Software Design

<List the code modules that are being called periodically.>

Technical Challenges

< List of problems and their detailed resolutions>

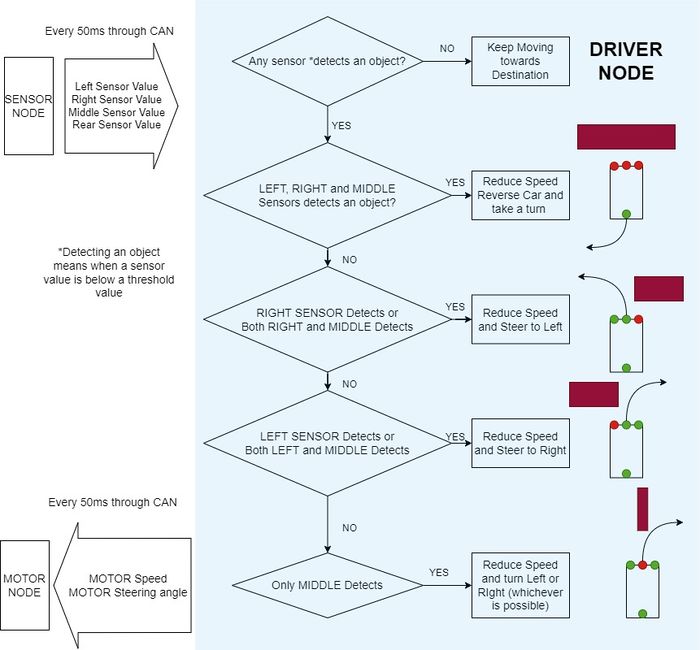

Master Module

<Picture and link to Gitlab>

Hardware Design

Software Design

Object Detection Logic

Technical Challenges

Mobile Application

https://gitlab.com/naveena.sura/silver-arrow/-/merge_requests/8

Hardware Design

Google Pixel 6 mobile was used to run the application and HC-05 Bluetooth Module was used to establish communication between the application and Bridge Controller

Software Design

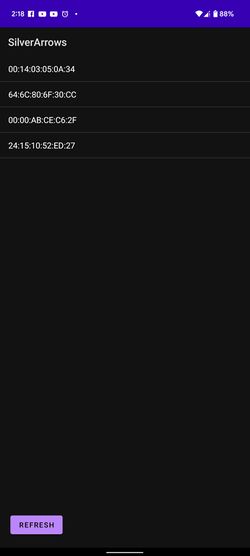

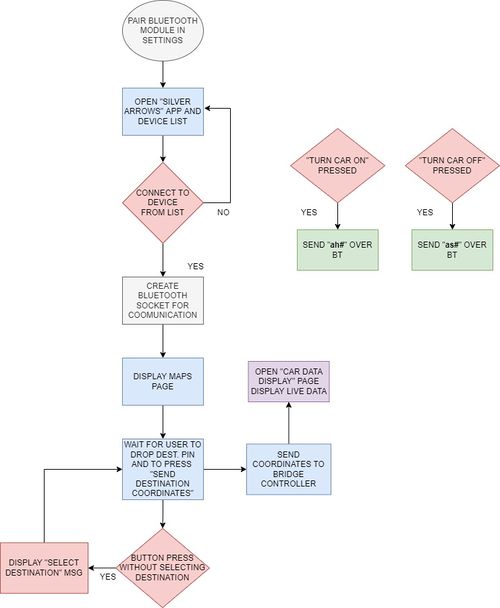

The software's main front-end code was written in Kotlin. We used Bluetooth communication for transferring and receiving data over the application. Before we open the application, we first need to pair the HC-05 Bluetooth module with the mobile. This is done by going to the mobile’s Bluetooth Setting and pairing the module. The application has 3 “activities”. Activity 1: Bluetooth Connection Screen When the app first opens the Bluetooth socket that is created is checked if it is NULL, which it should be with a start-up. If this occurs the Bluetooth connection screen will be brought up, and the user will need to tap a device to attempt a connection. If the connection fails, the screen will again be brought up. Once the connection is successfully established, we move on to the next “Activity 2: Maps Activity”

Activity 2: Maps Activity: The Google Map SDK is so large and has so many capabilities, we created an account on Google Cloud Console, enabled the API, and then utilized the API key in the Android App's Manifest file. In this activity, we have set up 3 “OnClickListners” viz. My Location, North Align, Send Destination Coordinates. If the user clicks on to “My Location” icon and if the Mobile’s location is “On”, then the map will transport itself to the current location of the mobile. The user can zoom in and out like any other GoogleMaps application and click anywhere on the map to drop a pin. If the user again taps onto the pin, then it will show the coordinates of the selected dropped pin. When the user clicks on “Send Destination Coordinates” the coordinates of the dropped pin are sent over Bluetooth to the Bridge Controller, and the app goes to the final activity “Activity 3: CarDataDisplaActivity”. Advice for future students: Enable "Satellite View" in your Maps Activity so that it easier for you to add your destination location.

Activity 3: CarDataDisplayActivity: This is a very simple activity. All this activity does that it shows the various data that are sent over the CAN bus on the car and displays it live on the app. The application receives the data over the HC-05 Bluetooth module in a long comma (,) separated string format and then segregates the data into the respective fields. Few of the data that are displayed on the application include all the sensor values, current car speed, distance remaining towards the destination, etc. Lastly, this activity has two buttons to start and stop the car.

Technical Challenges

One of the major technical challenges was getting acquainted with the Android Studio Environment. One mistake that we made was that instead of implementing with a relatively well-known JavaScript language, we used Kotlin language which was difficult to get the hang of. Luckily, the android developer’s website provides a lot of useful information for newbie application developers for getting started with the basic building blocks.

Secondly, with security and privacy being an essential paradigm for any app development, setting up and granting permissions for the app to use location and Bluetooth was tricky. Googling stuff and diving deep into the developer’s website helps us overcome these issues. When using Google Maps, you’ll need to create an account and use a key to connect to the app. In Android Studio, that key is located in the "googlemapsapi" file and is ignored by default in git.

In order to display different types of car data, such as sensor data, car speed, current, and destination heading, the bridge controller is appending all the necessary data, that it received over the CAN bus, and sends it in a string format and comma (,) separated. This was decoded in the form of an array of range values and then displayed on the mobile app screen. The range for each value and the message format and structure early was pre-decided. For e.g., sensor values will only range from 0 – 99, whereas the distance from the destination will range from 0-999. If you decide to go by our method, we highly suggest that you carefully decide on the message format and structure. Our implementation is as follows:

Decoding the String message of car data to display on the app

val startOfHashIndex: Int = recDataString.indexOf("#")

if (startOfHashIndex != -1) {

recDataString = recDataString.substring(startOfHashIndex, recDataString.length)

val endOfLineIndex: Int = recDataString.indexOf("~") // determine the end-of-line

if (endOfLineIndex > 0)

{ // make sure there data before ~

var dataInPrint: String = recDataString.substring(0, endOfLineIndex) // extract string

txtString!!.setText("Data Received = $dataInPrint")

val dataLength = dataInPrint.length //get length of data received

txtStringLength!!.setText("String Length = $dataLength")

if (recDataString[0] === '#') //if it starts with # we know it is what we are looking for

{

val sensor0: String = recDataString.substring(1,3) //get sensor value from string between indices 1-5

val sensor1: String = recDataString.substring(5, 7) //same again...

val sensor2: String = recDataString.substring(9, 11)

val sensor3: String = recDataString.substring(13, 15)

val distance_remain: String = recDataString.substring(17, 20)

val compass_direction: String = recDataString.substring(22, 25)

val compass_direction2: String = recDataString.substring(27, 30)

car_speed!!.setText("Current car Speed: " + sensor0 + " km/hr") //update the textviews with sensor values

sensorView1!!.setText("Right Sensor: " + sensor1 + " inches")

sensorView2!!.setText("Left Sensor: " + sensor2 + " inches")

sensorView3!!.setText("Middle Sensor: " + sensor3 + " inches")

rem_dist!!.setText("Distance from Destination: " + distance_remain + " meters")

heading_direction!!.setText("Current Heading: " + compass_direction + " '")

heading_direction2!!.setText("Destination Heading: " + compass_direction2 + " '")

}

}

Conclusion

<Organized summary of the project>

<What did you learn?>

Project Video

Project Source Code

Advise for Future Students

<Bullet points and discussion>