Difference between revisions of "S18: XY-Plotter"

Proj user12 (talk | contribs) (→Parser Task) |

Proj user12 (talk | contribs) (→Parser Task) |

||

| Line 351: | Line 351: | ||

float s; // pen up or down | float s; // pen up or down | ||

} command; | } command; | ||

| + | |||

| + | </syntaxhighlight> | ||

| + | |||

| + | Code snippet for parsing the G-code file for G1, G2 and M300 for extracting the desired movement in a direction and distance is as shown below: | ||

| + | |||

| + | <syntaxhighlight lang="c"> | ||

| + | |||

| + | if (4 == sscanf(line.c_str(), "%s X%f Y%f F%f", motion.beg, &motion.x, &motion.y, &motion.feedrate)) | ||

| + | { | ||

| + | printf("motion is %s\n and x y f value is %f %f %f\n",motion.beg, motion.x,motion.y, motion.feedrate); | ||

| + | } | ||

| + | else if(2==sscanf(line.c_str(), "%s S%f", motion.beg, &motion.s)) | ||

| + | { | ||

| + | printf("motion is %s\n and S value is %f\n",motion.beg,motion.s); | ||

| + | } | ||

| + | else if(2==sscanf(line.c_str(), "%s P%f", motion.beg, &motion.p)) | ||

| + | { | ||

| + | printf("motion is %s\n and P value is %f\n",motion.beg,motion.p); | ||

| + | } | ||

</syntaxhighlight> | </syntaxhighlight> | ||

Revision as of 18:57, 23 May 2018

Contents

- 1 Grading Criteria

- 2 Project Title

- 3 Abstract

- 4 Objectives & Introduction

- 5 Schedule

- 6 Parts List & Cost

- 7 Design & Implementation

- 8 Testing and Technical Challenges

- 9 Conclusion

- 10 References

Grading Criteria

- How well is Software & Hardware Design described?

- How well can this report be used to reproduce this project?

- Code Quality

- Overall Report Quality:

- Software Block Diagrams

- Hardware Block Diagrams

- Schematic Quality

- Quality of technical challenges and solutions adopted.

Project Title

XY-Plotter

Abstract

We live in an epoch where the world is driven by technology. In recent decades, there have been so many advances in the field of technology. With this advancement for human upliftment, automation has become a paramount factor. This project aims at building an automatic 2D XY-plotter which can efficiently draw 2D figures. The plotter machine is assembled based on a mechanism similar to H-bot where the two stepper motors are on the main chassis connected to the single belt. Both the motors account for the movement of the chassis in X and Y axis. A servo motor is used to control the pen height which is connected to the main chassis. Gcode interpreter is developed in order to make the SJ one board decode the G-code and control the motors accordingly. Sd-card is used to provide the Gcode to the SJ one board.

Objectives & Introduction

Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands. These machines find their use in any process that can be described as a series of movements and operations. These include 2D printing, laser cutting, welding, hole-punching etc.

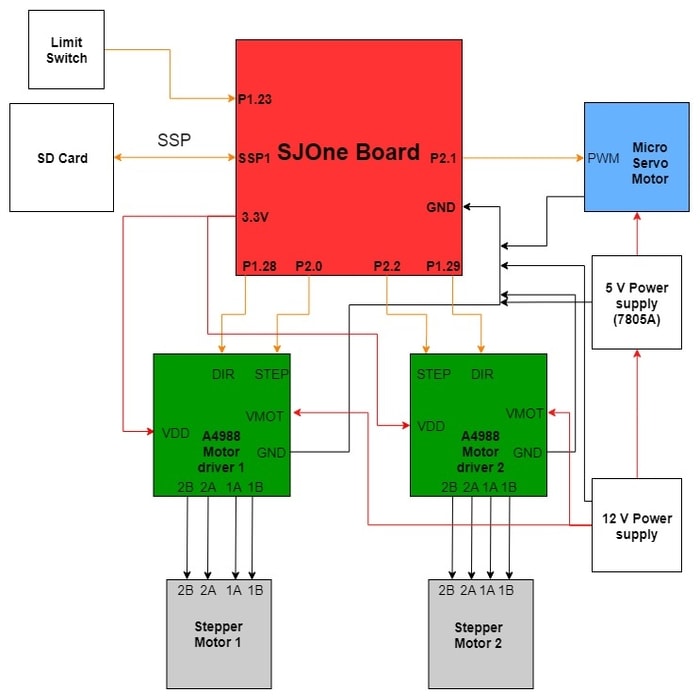

XY plotter is a CNC(Computer Numerical Control) based drawing robot capable of drawing 2D figures. It uses LPC1758 ARM Cortex M3 based microcontroller(SJOne) as a brain of the robot. The SJOne board is interfaced to the motor shield PCB which connects two stepper and one servo motors. SD-card is selected to provide the 2D figures to the SJ one controller in the form of G-codes instructions. A G-code interpreter then decodes the instructions and generate the required movements for the stepper motor and servo motor. The home position for the plotter is specified using the limit switch.

The objectives of the project are:

- To learn FreeRTOS multitasking and demonstrate it.

- To acquire knowledge about intertask communication using queues.

- To become competent in implementing device drivers like GPIO, SPI, PWM.

- To make use of GPIO external interrupts and timer interrupt to connect with the limit switch.

- To understand software watchdogs and apply the same to the project.

- To learn mechanical aspects of rotating a motor through belts and pulleys.

Team Members & Responsibilities

- Akshay Kurli

- Gaurav Yadav

- Pritam Gholap

- Tanmay Kishore Jambhekar

Schedule

| Week# | Date | Task | Actual | Problem Encountered |

|---|---|---|---|---|

| 1 | 03/27 |

|

Completed on 03/31 | |

| 2 | 04/03 |

|

Completed on 04/08 | |

| 3 | 04/10 |

|

| |

| 4 | 04/17 |

|

| |

| 5 | 04/24 |

|

| |

| 6 | 05/01 |

|

| |

| 7 | 05/08 |

|

| |

| 8 | 05/15 |

|

| |

| 9 | 05/22 |

|

|

Parts List & Cost

| Item# | Part Desciption | Vendor | Qty | Cost |

|---|---|---|---|---|

| 1 | SJOne Boards | From Preet | 1 | $80.00 |

| 2 | Nema-17 Stepper Motor | Amazon | 2 | $28.00 |

| 3 | Micro Servo Motor 9G | Amazon | 1 | $2.6 |

| 4 | GT2 Timing Belt and Pulley wheel | Amazon | 1 | $14.99 |

| 5 | Allegro’s A4988 DMOS Microstepping Driver | Amazon | 2 | $9 |

| 6 | Limit Switch | Amazon | 2 | $1 |

| 7 | XY-plotter chassis | Amazon | 1 | $200 |

| 8 | Male and female pin connectors | Excess solutions | 4 (20 X 1) each | $4 |

| 8 | IC 7805A Mouser Electronics | Excess solutions | 1 | $0.58 |

Design & Implementation

Following sections provide the implementation of hardware and its design. The software provides the infrastructure to manage and control the hardware.

System Overview and Mechanism

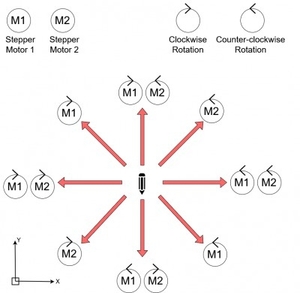

The XY plotter machine is based on a mechanism similar to H-bot where the two motors responsible for XY movements are on the main chassis, which keeps the center of gravity closer to the chassis for a better stability. Graphic animation of the mechanism used in the project is shown in figure 2 where linear motions of the violet slider along X and Y axes are controlled by orange and green driving pulleys depicting two stepper motors. The violet slider has a pen connected at the front. The movement of pen based on the motor rotation is shown in figure 3. Based on the front view, M1 and M2 represent two stepper motors on the left and right of the machine. For example to move the pen in the left direction on the X-axis, both the stepper motor should rotate in a clockwise direction with the same speed. The movement of pen based on the motor rotation is shown in figure 3. Based on the front view in figure 1, M1 and M2 represent two stepper motors on the left and right of the machine and the direction arrows shows the direction of the pen. For example to move the pen in the left direction on the X-axis, both the stepper motor should rotate in a clockwise direction with the same speed.

|

|

|

Printed Circuit Board (PCB)

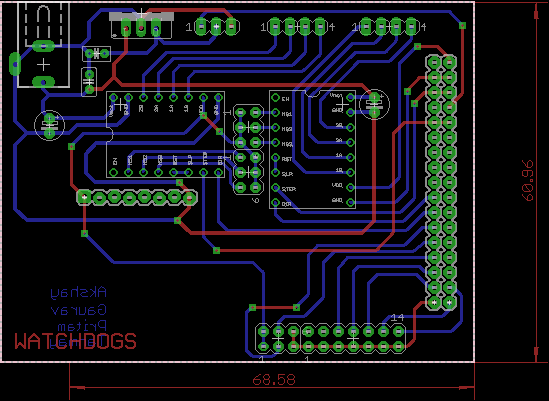

Schematic and PCB Layout

PCB design is used to reduce the hardware complexity and complicated one-to-one wire connections. For this project, PCB designing was done using Autodesk's EAGLE 7.6.0. In this schematic of the board is done in which all the components are selected and general connections are done. After completing the schematics, it is converted to board file in which actual placement of components on board and routing of the signals is done. EAGLE provides features like auto routing, multilayer signal routing, converting the file specs in Gerber format for PCB printing and so on. In this project, the board was designed for interfacing two motor drivers and one servo motor with SJOne board. Before concluding the design, all the components were placed on a breadboard and tested to check their functionality separately and then all together. After checking the hardware requirement and its availability, the board design was finalized. The designed board consists of:

- Board size is 60.96 mm X 80.01 mm

- Voltage regulator to supply 5V to the servo motor and 3 pin connector for the same

- 12V power supply for stepper motor

- Two motor drivers interfacing SJOne

- one 17 X 2, one 10 X 2 and one 8 X 1 pin connector for GPIO, 3.3V and GND from SJOne board

Track width for the signal is 0.016 mm and for the power signal, it is 0.024 mm. Package library of the A4988 driver was imported from the Sparkfun. The PCB design is then sent to PCB manufacturer with Gerber file.

Hardware Design

Hardware Interface

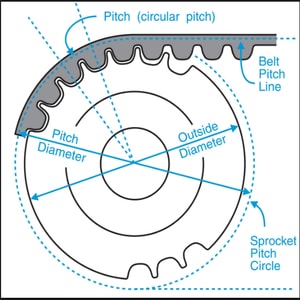

GT2 Timing Belt and Pulley

A 2mm pitch and 6mm wide GT2 timing belt and pulley are used to transfer rotational motion (from a stepper motor) into linear motion (along with a rail). Figure 6 shows Timing Belt and Pulley alignment. With the H-bot mechanism described above, the two stepper motors on the main chassis are connected together with one GT2 belt with the help of two same-sized pulleys as shown in Figure 7.

- Calculation:

Specification of the pulley used in this project is:

Number of teeth= 16;

Pitch = 2mm.

Therefore,as per the Figure 4 ,Circumference = pitch * number of teeth = 2 * 16 = 32mm.

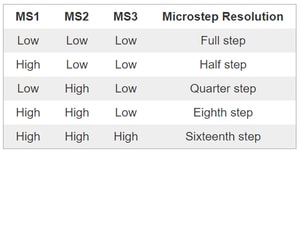

A4988 Stepper Motor driver

A4988 stepper motor driver is DMOS microstepping driver with translator and overcurrent protection. This motor driver can supply up to 2A current per coil of the bipolar stepper motor. This driver requires the supply voltage of 3 - 5.5V. The motor supply voltage ranges from 8V to 35V depending upon the motors. These supplies should have appropriate decoupling capacitors close to the board, and they should be capable of delivering the expected currents.

Some of the key features of this driver are:

- Simple step and direction control interface

- Five different step resolutions: full-step, half-step, quarter-step, eighth-step, and sixteenth-step

- Adjustable current control to achieve higher step rates

- Over-temperature thermal shutdown, under voltage lockout and crossover current protection

- Short-to-ground and shorted-load protection

The motor movement is generally controlled by two pins, i.e, STEP and DIR. These both pins are not pulled to any voltages internally and so both pins shouldn't be left floating. PWM signals are applied to STEP input in order to run the motors with selected step size. Now the selection of step size is also important which is done using MS1, MS2 and MS3 pins. Microstepping is important in order to achieve smoother and precise plotting. But it also draws more current than it takes in full step mode. The reference voltage (VREF) is measured in order to keep the current supplied to coils within bound. VREF = 8 ⋅ IMAX ⋅ RCS where, IMAX is current limit and RCS is current sense resistance (0.068 Ω).

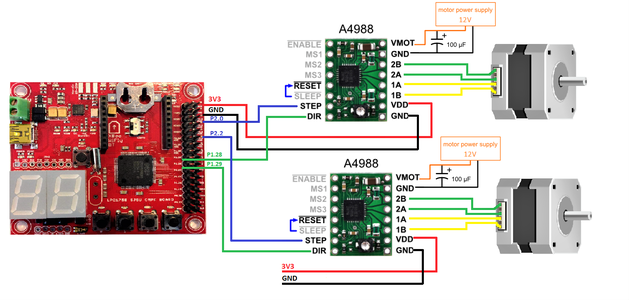

NEMA 17 Stepper Motor

A stepper motor is one kind of electric motor used in the robotics industry, it converts electronic signals into mechanical movement each time an incoming pulse is applied to the motor. Two NEMA 17 Stepper Motors are used to move the pen with the help of GT2 belt ad pulley discussed earlier. Each pulse moves the shaft in fixed increments. Stepper motor used in the project has a 1.8° step resolution, and in order for the shaft to rotate one complete revolution, in full step operation, the stepper motor would need to receive 200 pulses, 360° ÷ 1.8 = 200. Interfacing of the stepper motor to the SJone board is shown in figure 9. GPIO pins P2.0 and P2.2 are used to generate the pulses for the stepper motor at frequency 1Khz.

- Calculation of steps:

The belt moves along the circumference of the pulley connected with the stepper motor shaft. As per the figure 1 calculation, for one complete rotation of the stepper motor, the belt will move at a distance equivalent to 32mm. i.e. 360° rotation = 32mm linear movement. Therefore, one step which is equal to 1.8° will move the plotter by a distance of (32/360°)*1.8°= 0.16mm. Now, as an example, 100mm linear movement along X or Y axis would require 100/0.16 steps which are equal to 625 steps or pulses.

To achieve even fine resolution and smoother motion of the motors, half, quarter, eight, sixteenth step operation can be used with NEMA 17 stepper motors. Micro-stepping increases number of steps per revolution by a factor of 2^n (where n is the micro-stepping factor).

For example half step n = 1/2, a single step will now become 1.8° * 2^(1/2) = 0.9, this doubles the number of required pulses.So a 100 mm line along X or Y axis will now require 1250 pulses.

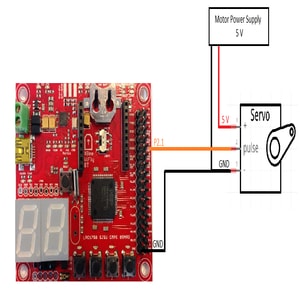

Servo motor

Figure 10 and 11 shows the servo motor and interfacing it with the SJone board.

|

|

|

The bracket holding the pen in place can be moved up and down vertically using a servo motor. This mimics picking up the pen during drawing or writing by hand. A SG90 9g digital servo motor is used for this. PWM input for the servo motor is given from pin P2.2 configured as PWM output on the SJ One Board.

For pen down, a PWM pulse of 1.5ms at 50 Hz, servo motor stays at the neutral position or 0°, the pen comes in contact with the surface and the plotter starts drawing.

For pen up, a PWM pulse of 2ms at 50Hz is input, servo motor rotates right.

Limit Switch

Figure 12 shows the 250V 5A SPDT 1NO 1NC limit switch used in the project for defining the plotter home position. The plotter after finishing the drawing moves towards the home position till it encounters the limit switch placed at the starting position. It then generates an interrupt to the SJone board which disables the motion.

Figure 13 shows the interface of the limit switch used with the normally open mode.

Software Design

This section shows the software modules implemented to control the hardware interfaced with the SJone board. FreeRtos is used to handle the operations. Below are the three task developed.

- Parser Task: This task handles the parsing of the G-code instructions line by line and extracts the desired information.

- Motor Task: This task is used to control the stepper motor and servo motor according to the G-code instruction.

- Watchdog Task: This task monitors the above task for completion of Gcode. In case of inactivity of the above tasks, watchdog task force the plotter to in a direction towards the home position.

Parser Task

This task is created at low priority and is developed to parse and decode the G-code instructions. The desired values are stored in a struct command and are sent to the motor task.

typedef struct

{

char motion[8]; //motion type stored in a charcter array;

float x; // x axis coordinate value

float y; // y axis coordinate value

float feedrate; // feed rate value

float p; // wait ime

float s; // pen up or down

} command;Code snippet for parsing the G-code file for G1, G2 and M300 for extracting the desired movement in a direction and distance is as shown below:

if (4 == sscanf(line.c_str(), "%s X%f Y%f F%f", motion.beg, &motion.x, &motion.y, &motion.feedrate))

{

printf("motion is %s\n and x y f value is %f %f %f\n",motion.beg, motion.x,motion.y, motion.feedrate);

}

else if(2==sscanf(line.c_str(), "%s S%f", motion.beg, &motion.s))

{

printf("motion is %s\n and S value is %f\n",motion.beg,motion.s);

}

else if(2==sscanf(line.c_str(), "%s P%f", motion.beg, &motion.p))

{

printf("motion is %s\n and P value is %f\n",motion.beg,motion.p);

}

Below is the flow of the parser task

Motor Task

Watchdog Task

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing and Technical Challenges

Current calculation of motor

- Stepper motor requires a minimum amount of current to run at a required frequency.

- High current is required for the stepper motor coils to rotate at a higher frequency say 1Khz.

- Vref=8*Imax*Rsc from the driver datasheet is used to find out the limiting current which is provided to the motor coils. The voltage Vref across the potentiometer was adjusted to ensure that the current is within the current limits of the motor as per the Nema-17 datasheet.

- For a full step configuration, Vref was adjusted to 0.7V.

Erroneous movement of stepper motor using PWM

- Stepper motors were initially interfaced with the PWM outputs. However, there was no accuracy of the number of steps taken by the stepper since it requires a precise timing control to stop it at a given step or position.

- Also, since all the PWM channels have the same frequency at a given time, therefore we had an issue providing different frequencies to the two stepper motors.

- In order to resolve aforementioned issues, GPIO was used to provide the accurate steps to the stepper motor.

Task synchronization issue

- Parser task was sending the next Gcode instruction on queue when the motor task was still performing the previous Gcode instruction due to the delay used in the motor task for running the stepper motor with GPIO.

- vTasksuspend was used to suspend the parser task when the queue item was received by the motor task. And was resumed after the motor task has completed the desired output from the instruction received.

Different task for two Stepper Motor

- Making an arc requires both the stepper motor to run on changing frequencies with steps.

- Therefore, two task was created initially for two different motors which could take the queue item from the parser task and run at their desired frequency accordingly.

- Above mechanism created a problem of jerking movement of the belt every time a task switch happens which resulted in wearing off the belt.

- A single task was created which could take the queue struct item from the parser task and run both the stepper motors.

Issue with drawing arcs

- The algorithm used for drawing the arc in the project resulted in an incorrect movement of the pen.

- Drawing arcs with the plotter require a perfect algorithm.

- Therefore, one possible solution is to use an algorithm like Bresenham algorithm for circle and line.

Conclusion

Conclude your project here. You can recap your testing and problems. You should address the "so what" part here to indicate what you ultimately learnt from this project. How has this project increased your knowledge?

Project Video

Upload a video of your project and post the link here.

Project Source Code

References

Acknowledgement

Any acknowledgement that you may wish to provide can be included here.

References Used

- JRC 7805 datasheet

- A4988 DMOS microstepping driver

- SG90 Micro servo

- Wiki page for G code interpretation

Appendix

You can list the references you used.