Difference between revisions of "F17: Rolling Thunder"

Proj user2 (talk | contribs) (→Steps for triggering and distance calculation for Maxbotix sensors:) |

Proj user2 (talk | contribs) (→Steps for triggering and distance calculation for Maxbotix sensors:) |

||

| Line 569: | Line 569: | ||

#Get the time at which falling edge interrupt occurs on micro-controller pin connected to PWM. This will be the stop time | #Get the time at which falling edge interrupt occurs on micro-controller pin connected to PWM. This will be the stop time | ||

#Calculate the distance in inches to the obstacle using the formula: | #Calculate the distance in inches to the obstacle using the formula: | ||

| − | Distance = [ (start_time – stop_time) /147] (inches) | + | Distance = [ (start_time – stop_time) /147] (inches) |

#Send the calculated distance to the master controller using CAN Bus. | #Send the calculated distance to the master controller using CAN Bus. | ||

Revision as of 00:07, 16 December 2017

Contents

- 1 Legend

- 2 Team Members & Responsibilities

- 3 Abstract

- 4 Schedule

- 5 Parts List & Cost

- 6 Master Controller

- 7 Sensor Controller

- 8 Motor & I/O Controller

- 9 Geographical Controller

- 10 Communication Controller (Bridge)

- 11 Android Application

- 12 Conclusion

- 13 References

Legend

| Color | Component |

|---|---|

|

Orange |

Master Controller |

|

Red |

Geographical Controller |

|

Indigo |

Communication Controller (Bridge) |

|

Green |

Motor/IO Controller |

|

Blue |

Sensor Controller |

|

Teal |

Android Application |

|

Brown |

QA |

Team Members & Responsibilities

- Master Controller

- Akil Khan

- Jerry John

- Geographical Controller

- Abhilash Tuse

- Vishal Shrivastava

- Communication Controller (Bridge)

- Akinfemi Akin-Aluko

- Motor and I/O Controller

- Saurabh Ravindra Badenkal

- Joshua Skow

- Sona Bhasin

- Sensor Controller

- Sona Bhasin

- Thrishna Palissery

- Android Application

- Johnny Nigh

- QA Team

- Akil Khan

- Saurabh Ravindra Badenkal

Abstract

A self-driving car navigates to a destination while avoiding obstacles. The car is a modified RC (remote control) car. The destination is set using an Android app.

Schedule

| Start Date | End Date | Task | Status | Date of Completion | |

|---|---|---|---|---|---|

| 1 | 09/20/2017 | 09/26/2017 |

|

Completed | 09/26/2017 |

| 2 | 09/27/2017 | 10/03/2017 |

|

Completed | 10/03/2017 |

| 3 | 10/04/2017 | 10/10/2017 |

|

Completed | 10/10/2017 |

| 10/10/2017 | Wiki Schedule | Completed | 10/10/2017 | ||

| 4 | 10/11/2017 | 10/17/2017 |

|

Completed | 10/17/2017 |

| 5 | 10/18/2017 | 10/24/2017 |

|

Completed | 10/24/2017 |

| 10/24/2017 | DBC File | Completed | 10/24/2017 | ||

| 10/24/2017 | DEMO: CAN communication between controllers | Completed | 10/24/2017 | ||

| 6 | 10/25/2017 | 10/31/2017 |

|

Completed | |

| 7 | 11/01/2017 | 11/07/2017 |

|

Completed | 11/07/2017 |

| 11/07/2017 | DEMO: Motors driven by wheel feedback and sensors, Basic obstacle avoidance

Final Wiki Schedule |

Completed | 11/07/2017 | ||

| 8 | 11/08/2017 | 11/14/2017 |

|

Completed | 11/14/2017 |

| 9 | 11/15/2017 | 11/21/2017 |

|

Completed | 11/21/2017 |

| 11/21/2017 | DEMO: GPS driving | Completed | 11/21/2017 | ||

| 10 | 11/22/2017 | 11/28/2017 |

|

Completed | |

| 11 | 11/29/2017 | 12/19/2017 |

|

In Progress | |

| 12/20/2017 | DEMO: Final Project

SUBMISSION: Final Project Wiki |

||||

Parts List & Cost

| Item # | Description | Distributor | Qty | Cost |

|---|---|---|---|---|

| 1 | SJOne Board | Provided by Preet | 5 | $400 |

| 2 | RC Car - Traxxas 1/10 Slash 2WD | Amazon | 1 | $189.95 |

| 3 | Bluetooth Bee BLE 4.0 Module | ebay | 1 | $15 |

| 4 | GPS Module | Amazon | 1 | $28.99 |

| 5 | Compass (CMPS11) | Acroname | 1 | $45.95 |

| 6 | Traxxas 6520 RPM Sensor | Amazon | 1 | $10.82 |

| 7 | Traxxas 2991 LiPo Battery and Charger | Amazon | 1 | $199.95 |

| 8 | Breadboard Jumper Wires | Amazon | 1 | $6.99 |

| 9 | MIFFLIN Acrylic Plexiglass Clear Plastic Sheet | Amazon | 1 | $9.89 |

| 10 | Printed Circuit Board | Amazon | 1 | $16.83 |

| 11 | PCB Mounting Feet Set | Amazon | 1 | $11.99 |

| 12 | Traxxas 6538 Telemetry Trigger Magnet Holder | Amazon | 1 | $4.63 |

| 13 | MB1240 XL-MaxSonar EZ4 Ultrasonic Sensor | Amazon | 2 | $73.90 |

| 14 | Parallax Ping Ultrasonic Range Sensor | Amazon | 2 | $69.98 |

| 15 | CAN Transceiver | Microchip | 10 | Free |

| 16 | 4D systems 32u LCD | 4D Systems | 1 | $85.00 |

| 17 | Miscellaneous Items | 1 | $100.00 |

Total cost: $1,269.87

Master Controller

Design & Implementation

The master controller acts as the brainpower of the car and processes the data from the rest of the nodes to achieve smooth navigation of the car to its destination. Basically, it takes data from the sensor and geo node to ensure obstacle avoidance and navigation.

Hardware Design & Interface

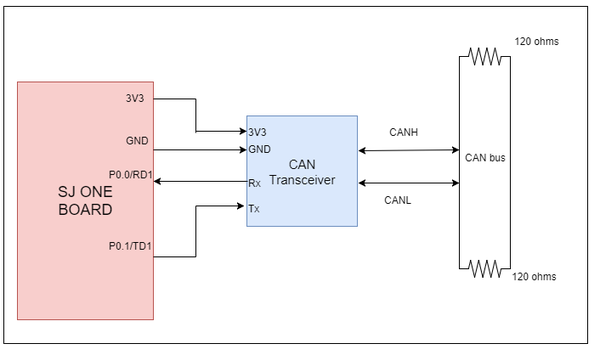

Master controller does not need any other additional hardware to be connected/interfaced to it as it is responsible for implementing the obstacle avoidance and directing the car to the destination. Hence, the hardware design of master controller only consists of the node being connected to the CAN bus via CAN transceiver module. The figure shows the hardware design of the master.

- Below is the pin connection table of the master controller to the CAN bus

| S.R. | CAN Transiever Pins | SJOne Board Pins |

|---|---|---|

| 1 | Vdd | 3.3v |

| 2 | GND | GND |

| 3 | RXD | P0.1 (RXD3) |

| 4 | TXD | P0.0 (TXD3) |

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

<Bug/issue name>

Discuss the issue and resolution.

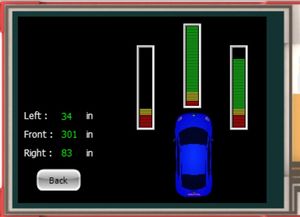

Sensor Controller

Design & Implementation

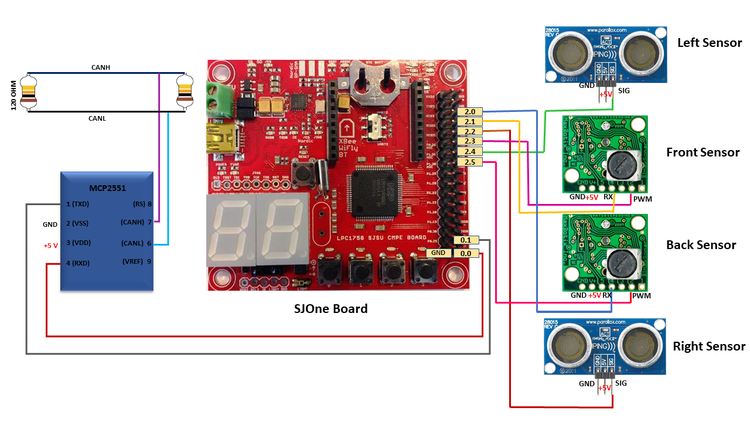

The sensor controller oversees the functioning of ultrasonic sensors for the purpose of obstacle avoidance. The sensor controller comprises of four ultrasonic sensors interfaced to an SJOne board. XL-Maxbotix-ez4 sensors are installed on the front and back of the car respectively and Parallax ping sensors are placed to guard the sides of the car from obstacles. Based on the beam angle of each sensor, they have been mounted to protect the front and rear of the car from hitting obstacles.

XL-Maxbotix-ez4

The XL-Maxbotix-ez4 sensor can detect obstacles up to 7.65 meters and works between a supply voltage range of 3.3 V to 5.5 V. The sensor operates at 42 KHz and is equipped with inbuilt acoustic and electrical noise filtering.

Parallax ping

The Parallax ping sensor requires a supply voltage of 5 V. It can measure the distance of obstacles within a range of 3 cm to 3 m. An LED indicator on the sensor shows that the measurement is in progress. A single General-purpose input/output(GPIO) pin is used to trigger the sensor (to send an ultrasonic burst) as well as to listen for the echo pulse that is returned.

Hardware Design

The sensors are interfaced to the SJOne board on port 2 pins. The ultrasonic sensor triggering and ranging is implemented with the help of GPIO and external interrupts.

Maxbotix Ultrasonic Sensor

| Position | Maxbotix Sensor Pins | SJOne Board Pins |

|---|---|---|

| Front | RX - Trigger | 2.1 |

| PWM - Echo | 2.3 | |

| Back | RX - Trigger | 2.0 |

| PWM - Echo | 2.5 |

Parallax Ping Ultrasonic Sensor

| Position | Parallax Sensor Pins | SJOne Board Pins |

|---|---|---|

| Left | SIG | 2.4 |

| Right | SIG | 2.2 |

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

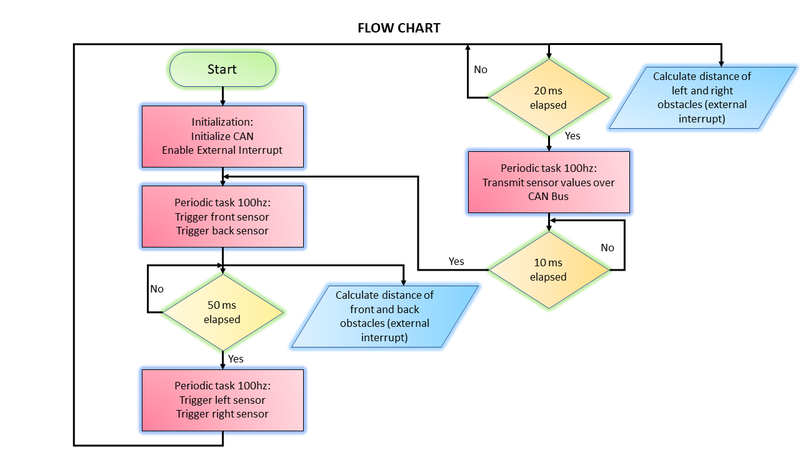

Software Design

The front and the back sensors (Maxbotix sensors) are triggered first by driving their respective Rx pin (Pin 4 of the sensors) high for around 25 microseconds. The PW (Pin 2 of the sensors) pin is set high after the Rx pin is triggered and will be set to low if an object is detected. The PW pin will be held high for 44.4 milliseconds(ms) in case if no obstacle is detected. The front and back sensors are triggered at 10 ms,100ms,200ms, 300ms… and so on. The left and right sensors (parallax ping sensors) are triggered after 50ms is elapsed from the time the Maxbotix sensors are triggered. This is to minimize the effect of reflected waves from the maxbotix interfere with parallax ping which results in erroneous values. The SIG pin of the parallax ping sensors is set high for around 5us to send the trigger pulse. The sensor emits a short 40 kHz (ultrasonic) burst. The same pin is used for listening the echo pulse that is returned from obstacle in parallax ping. The SIG pin is set high after the trigger pulse is sent from the host microcontroller and will be set low if an obstacle is detected. The PW pin will be held high for 18 milliseconds(ms) approximately in case if no obstacle is detected. The left and right sensors are triggered at 60ms, 160ms, 260ms, 360ms… and so on. All the four sensor values will be available at every 90ms and will be transmitted over the CAN bus at 90ms, 190ms, 290ms, 390ms and so on… The triggering as well as the transmitting the sensor values over the CAN bus is handled in 100Hz task with proper elapsed time count check.

Implementation

Steps for triggering and distance calculation for Maxbotix sensors:

- Configure the micro-controller pin which is connected to the RX pin of the sensor as output

- Configure the micro-controller pin which is connected to the PWM pin of the sensor as input

- Enable external interrupts for rising and falling edge for the pin connected to PWM pin of sensor

- Trigger the RX pin by sending a clean high pulse through host micro-controller

- Set GPIO pin connected to RX as low (for a clean high pulse)

- Give delay of ~2us

- Set GPIO pin connected to RX as high

- Give delay of ~25us

- Set GPIO pin connected to RX as low

- Get the time at which rising edge interrupt occurs on micro-controller pin connected to PWM. This will be the start time

- Get the time at which falling edge interrupt occurs on micro-controller pin connected to PWM. This will be the stop time

- Calculate the distance in inches to the obstacle using the formula:

Distance = [ (start_time – stop_time) /147] (inches)

- Send the calculated distance to the master controller using CAN Bus.

Testing & Technical Challenges

Interference between sensors

Due to the placement of front, left and right sensors in close proximity to each other, we observed that there were inconsistencies in sensor readings on the detection of an obstacle. This was checked by monitoring sensor messages on BusMaster.

We were able to reduce the impact of interference by avoiding overlap of ranging time of sensors. To achieve this, the sensors with non-overlapping ranging areas are being triggered at a time and enough time is provided for the sensors to complete their ranging before the next set of sensors are triggered.

Blind spots to the front of the car

On putting the permanent sensor mounts in place and after subsequent testing, it was observed that there were blind spots at the front end of the car such that obstacles falling in some areas weren't being detected effectively.

To overcome the issue, we isolated the sensing area of each sensor based on their respective beam angles and adjusted the sensor positions. As a result, we were able to minimize the blind spots towards the front of the car with least interference. The tradeoff that we had to make was leaving the extreme left and right sides of the car vulnerable to collision with obstacles.

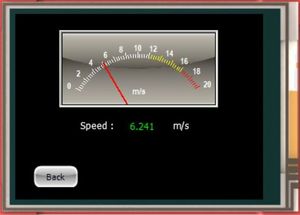

Motor & I/O Controller

Design & Implementation

The Traxxas Slash is a 2 wheel drive car makes use of two motors.

Titan 12-turn 550 Modified Motor

This motor is responsible for driving the rear wheels. This motor takes in a 100Hz duty cycle - 10-15% drives the motor in reverse, 15-20% drives the motor forward.

Traxxas 2075 Waterproof Servo Motor

This motor is responsible for turning the two front wheels left and right. The servo operates on the same duty cycle as the driver motor; 10-15% duty cycle turns the wheels left, 15-20% duty cycle turns the wheels right.

Hardware Design

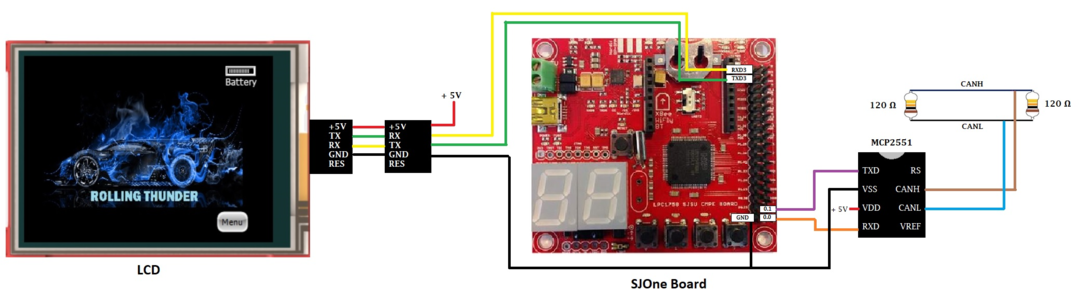

The schematic of the motor controller is:

The Traxxas Slash receiver box contains 3 pin connectors for signal, input voltage (VCC) and ground. There are 4 3 pin connectors that come on the Traxxas Slash receiver - 3 of which are used for the car (Servo motor, Driver motor, and RPM sensor). The VCC of each connector is shorted together, and tied to the car battery. The grounds are all shorted as well and connected to the PCB of everything on the car.

The RPM sensor is connected physically to the gearbox, with a small magnet attached to the largest gear. There is a small hall sensor mounted next to this large gear, and every time the gear makes a revolution the hall sensor provides a high pulse indicating the a rotation. The RPM sensor signal is tied to a GPIO on the SJOne board.

Hardware Interface

The motor controller contains the following interfaces to the SJOne:

- PWM to the Driver motor

- PWM to the Servo motor

- GPIO to the RPM sensor

- GPIO to the ADC for battery voltage monitoring

I/O Module

Software Design

The motor is abstracted as a C++ class. The motor class is able to set the Driver motor and the Servo motor.

The motor class is also responsible for taking in a desired speed, and making sure the car is driving at that speed. The motor class interprets the RPM sensor output, determines the current car speed compared to the desired car speed, and drives the motor to make the current car speed as close to the desired speed as possible.

The motor used a PID (proportional, integral, derivative) based control algorithm to keep the actual motor speed as close as possible to the desired speed. The tuning was done with the car mounted on a platform. The PID was tuned with the following method:

1. Select a proportional coefficient and change it until the motor feedback has a minimal oscillation. 2. Increase the derivative coefficient until there are no more oscillations. 3. Increase the integral coefficient until the speed increases fast enough and there is no oscillations.

I/O Module

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

I/O Module

LCD Screens

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

<Bug/issue name>

Problems faced by motor:

- Measure the motor speed accurately (measure for # of pulses vs. time between pulses)

- How to know when the car is stopped

- How to make the car be the desired speed (steps vs PID)

- Tuning the PID loop

Geographical Controller

Group Members

- Abhilash Tuse

- Vishal Shrivastava

Design & Implementation

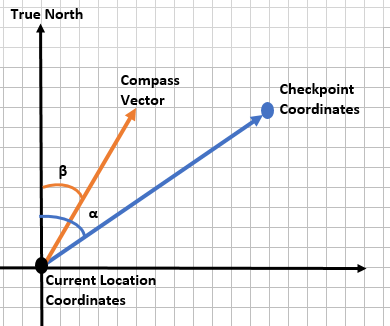

The Geographical Controller is in place for navigation purpose. It has two essential parts, namely GPS and compass. It provides direction to the car, by calculating the heading angle and the distance between the coordinates, based on GPS and compass readings. To calculate heading angle, we need a compass bearing angle and angle between the line joining the two coordinates and the true north (bearing angle for GPS).

GPS Bearing angle calculation

With the reference to the figure, the bearing angle for GPS is the angle between the line joining the two coordinates and the true north. To calculate it graphically, draw a vector pointing towards the destination coordinates from the start point coordinate and measure the angle between the vector and the true north. Use the below formula to calculate the angle mathematically.

Bearing angle(α) = atan2(sin Δλ ⋅ cos φ2 , cos φ1 ⋅ sin φ2 − sin φ1 ⋅ cos φ2 ⋅ cos Δλ)

where,

φ1 = Latitude of 1st Coordinate

φ2 = Latitude of 2nd Coordinate

λ1 = Longitude of 1st Coordinate

λ2 = Longitude of 2nd Coordinate

Δλ = λ2 - λ1

Heading angle calculation

The heading angle is the angle between the compass vector and the vector drawn for calculating GPS bearing angle.

Heading angle(γ) = α – β

where,

α = Angle between the line joining the two coordinates and the true north

β = Angle between compass vector and the true north (Compass bearing angle)

If heading angle is positive the car turns right or else turns left.

Distance between the two coordinates calculation

The distance between the two coordinates can be calculated using the Haversine formula.

a = sin²(Δφ/2) + cos φ1 ⋅ cos φ2 ⋅ sin²(Δλ/2)

c = 2 ⋅ atan2(√a, √(1−a))

d = R ⋅ c

where,

φ1 = Latitude of 1st Coordinate

φ2 = Latitude of 2nd Coordinate

λ1 = Longitude of 1st Coordinate

λ2 = Longitude of 2nd Coordinate

Δφ = φ2 - φ1

Δλ = λ2 - λ1

d = distance between the two coordinates

R = earth’s radius (mean radius = 6,371km)

Note: All the angles should be in radians.

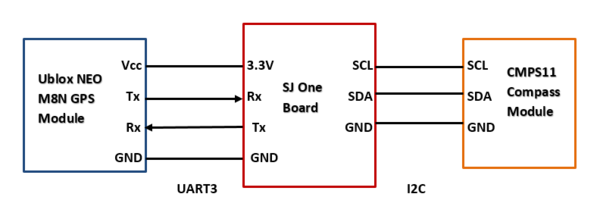

Hardware Design

The diagram below shows the h/w interfacing of SJ One board with GPS module and Compass module. The GPS module and the Compass module is communicating over UART3 and I2C respectively with SJ One board.

Pin mapping of GPS module with SJ One board:

| GPS Module Pins | SJ One Board Pins |

|---|---|

| Vin | 3.3v |

| GND | GND |

| TX | RXD3 |

| RX | TXD3 |

Pin mapping of Compass module with SJ One board:

| Compass Module Pins | SJ One Board Pins |

|---|---|

| GND | GND |

| SDA | SDA |

| SCL | SCL |

Compass module requires an external power supply of 5V.

Hardware Interface

GPS Module

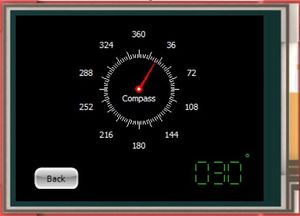

Gps is communication over UART with SJ One board. The data from the GPS is updated at a 5Hz frequency. The most important part is GPS configuration. It is configured using FTDI cable and Ublox software kit. We are using settings for GPS configuration in Ublox as shown below:

Compass Module

Compass is communicating over I2C with SJ One board. The register 2 and 3 of the compass provide the compass bearing angle (0- 360 range). Calibrating the compass is an important part. We are calibrating it on ‘horizontal calibration mode’, it works for us because the compass has tilt calibration.

Calibration process: First of all, you need to enter the calibration mode by sending a 3-byte sequence of 0xF0,0xF5 and then 0xF7 to the command register, these MUST be sent in 3 separate I2C frames. There MUST be a minimum of 20ms between each I2C frame.

The LED will then extinguish and the CMPS11 should now be rotated in all directions on a horizontal plane, if a new maximum for any of the sensors is detected then the LED will flash, when you cannot get any further LED flashes in any direction then exit the calibration mode with a command of 0xF8.

Note: Please make sure that the CMPS11 is not located near to ferrous objects as this will distort the magnetic field and induce errors in the reading. While calibrating rotate the compass slowly. Only the X and Y magnetometer axis is calibrated in this mode.

We are sending 3-byte sequence command of 0xF0,0xF5 and then 0xF7 on 4th switch press and 0xF8 command on 2nd switch press of the SJ One board. You can always restore factory calibration mode by sending the 3-byte sequence command of 0x20,0x2A,0x60. We are using switch 3 to restore factory calibration.

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show pseudocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

GPS doesn’t retain configuration settings

Every time the GPS is powered down it forgets the configuration settings after 4-5 hours and it has to be configured again. It could retain the configuration for some time (after powering down) because of a super capacitor. We replaced the super capacitor with a 3.3v battery and now it retains the configuration after it is powered down

Compass frequently losing calibration

Compass was losing calibration because of the magnetic interference from the motors. We wrapped the acrylic sheet (on which our compass was placed) with aluminum foil that acts as a magnetic shield for the compass. To ease the calibration process, we came up with an idea to do it on a switch press.

Unable to send complete GPS coordinates on CAN bus (with 6 decimal digits)

GPS coordinates require double data type and current python script doesn't handle it. So we had to make changes to Python script. Reference: F16: Titans Team

Communication Controller (Bridge)

Group Members

- Akinfemi Akin-Aluko

Design & Implementation

The design section can go over your hardware and software design. Organize this section using sub-sections that go over your design and implementation.

Hardware Design

Hardware Components:

|

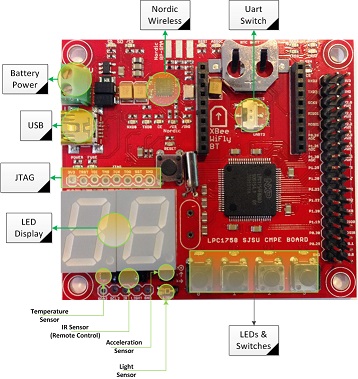

SJ-One Board Features Summary :

|

|

XBee Bluetooth.

|

Hardware Interface

In this section, you can describe how your hardware communicates, such as which BUSes used. You can discuss your driver implementation here, such that the Software Design section is isolated to talk about high level workings rather than inner working of your project.

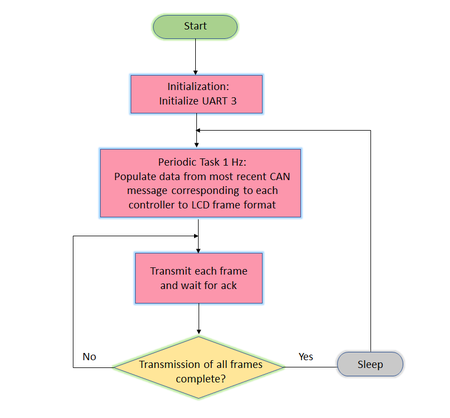

Software Design

Show your software design. For example, if you are designing an MP3 Player, show the tasks that you are using, and what they are doing at a high level. Do not show the details of the code. For example, do not show exact code, but you may show psuedocode and fragments of code. Keep in mind that you are showing DESIGN of your software, not the inner workings of it.

Implementation

This section includes implementation, but again, not the details, just the high level. For example, you can list the steps it takes to communicate over a sensor, or the steps needed to write a page of memory onto SPI Flash. You can include sub-sections for each of your component implementation.

Testing & Technical Challenges

Describe the challenges of your project. What advise would you give yourself or someone else if your project can be started from scratch again? Make a smooth transition to testing section and described what it took to test your project.

Include sub-sections that list out a problem and solution, such as:

<Bug/issue name>

Discuss the issue and resolution.

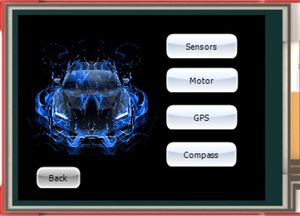

Android Application

Design & Implementation

The app was designed for Android 8.0 (Oreo; API level 26) and requires Android 4.4 (KitKat; API level 19) or higher. Google Play Services 11.0.0 or higher is required to use the Google Maps portion of the app (to select the destination).

The app plays a crucial role in the project since it provides the checkpoints for the car's route.

Software Design (GUI)

The GUI uses a fragment instead of activities to make it easier to add more features such as a wireless CAN bus monitor (which we did not have time to complete).

activity_main.xml

This layout is displayed after the app is launched. The parent layout uses RelativeLayout and it contains a FrameLayout for loading fragments.

fragment_main.xml

This is the only fragment in the app. This layout uses a RelativeLayout with a child layout that uses ConstraintLayout and a child MapView.

The ConstraintLayout contains an ImageView, TextView, and Button. The ImageView and TextView are for displaying the Bluetooth connection status on the top left-hand side of the screen. Both of these components change based on the following conditions:

- Bluetooth is disabled.

- The app is connected to the Bluetooth module on the communication controller (the bridge).

- The app is not connected to the Bluetooth module.

- The app is trying to connect to the Bluetooth module.

To the right of the Bluetooth status is a Button used to set the destination and put the vehicle in self-driving mode (if the user has already tapped on a location on the map) or to stop the car manually (if the vehicle is in self-driving mode).

The rest of the screen is the MapView. The map shows the location of the vehicle using a green marker and a red marker is used to show the destination (if applicable).

Implementation

build.gradle (app)

This particular Gradle build file (which is different than the Gradle build file for the project) has the Play Services version requirement, the target SDK version (Android API level 26), minimum SDK version (Android API level 19), and the key information for generating the .apk file.

AndroidManifest.xml

The manifest file contains the permission to access the device's Bluetooth and the key for using the Google Maps Android API (this is required to display the Google Map within the MapView component of the fragment_main.xml layout).

strings.xml

This file stores all of the strings used in the app.

MainActivity.java

This is the only activity in the app and it is first loaded when the app is started. It loads the activity_main.xml layout which holds a FrameLayout. The FrameLayout is used for loading fragments.

MainFragment.java

This is the only fragment in the app and contains the ImageView and TextView objects for the Bluetooth connection status, the button for setting the destination and stopping the vehicle, and the (Google) MapView.

locationPoint.java

This is a user-defined class for each location that is used in the app (each of the checkpoints, the vehicle, and the destination). The class contains a String and double field for the latitude and corresponding fields for the longitude (there are also byte array fields for both of these coordinates).

The method processLatLong() processes the latitude and longitude so that each coordinate has six decimal places. This method also calculates the byte array versions of the latitude and longitude.

The String and double coordinates are assigned using the setLatLong(double latitude, double longitude) method, which also calls processLatLong() to get the byte array versions.

The methods getMessageNumberOfBytesLatitude() and getMessageNumberOfBytesLongitude() return the number of bytes for the coordinate in the byte array format.

Testing & Technical Challenges

Conclusion

By completing this project we all learned how to use a very important and necessary tool in development-Git (if we did not have experience with it previously). Git allowed us to keep track of changes to the master branch as well as branches for each of the controllers and the app.

We also got hands-on experience with the CAN bus protocol which is useful for any embedded system in the automotive industry. This includes learning how to use the DBC format and the BusMaster CAN tracing tool.

We were required to complete unit testing for each of the controllers. Learning TDD (Test-Driven-Development) was a challenge but overall it was a great experience for us because developing this way reduces time spent on debugging.